I-Wobble Head 3 ku-1 Handheld Laser Welder Cleaner Cutter

I-Wobble Head 3 ku-1 Handheld Laser Welder Cleaner Cutter

Izici ze-3 IN 1 Laser Machine

I-1.Ububanzi be-welding ebanzi: ikhanda le-welding elibanjwe ngesandla lifakwe i-fiber optical yasekuqaleni engu-10M, enqoba ukulinganiselwa kwesikhala sebhentshi lokusebenzela futhi ingasetshenziselwa ukushisela ngaphandle kanye nokushisela ibanga elide;

2. Ukusetshenziswa okulula nokuguquguqukayo:I-laser welding ebanjwa ngesandlaifakwe ama-pulleys anyakazayo, ekhululekile ukubamba futhi ingalungisa isiteshi nganoma yisiphi isikhathi ngaphandle kweziteshi ezinamaphoyinti angashintshi. Imahhala futhi iyavumelana nezimo, futhi ifanele izimo ezihlukahlukene zendawo yokusebenza.

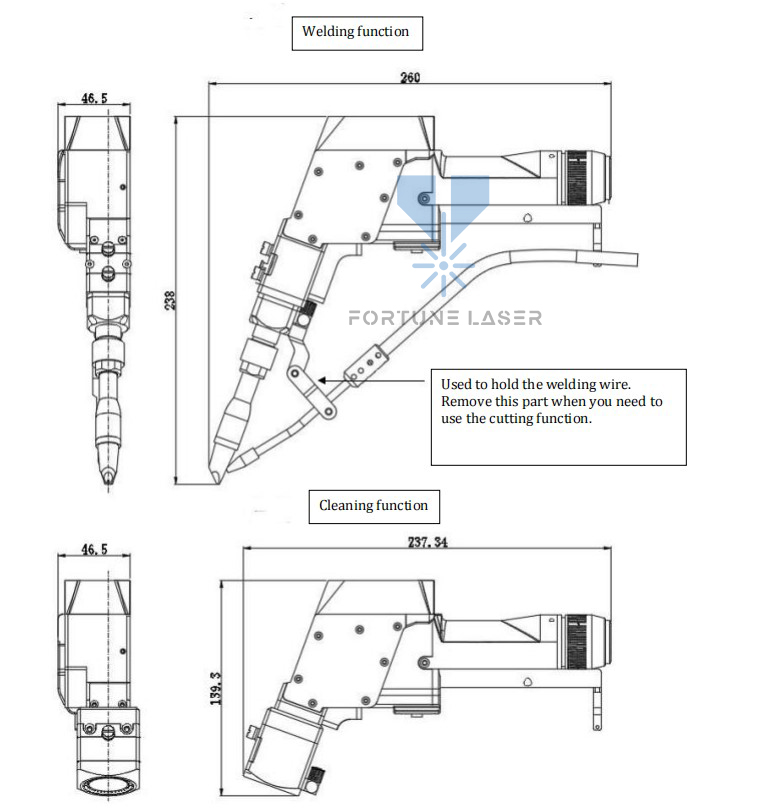

I-3.Izindlela ezihlukahlukene zokuthungatha: i-welding kunoma iyiphi i-engeli ingabonakala: i-lap welding, i-butt welding, i-welding eqondile, i-flat fillet welding, i-fillet yangaphakathi ye-welding, i-fillet yangaphandle ye-welding, njll. Bona ukushisela kunoma iyiphi i-engeli. Ngaphezu kwalokho, ingakwazi futhi ukuqedela ukusika, i-welding kanye nokusika kungashintshwa ngokukhululekile, vele uguqule i-nozzle ye-welding yethusi ku-nozzle yethusi yokusika, elula kakhulu.

4.Ukusika, ukushisela, nokuhlanza kuvame ukuxhunyaniswa eduze nezinqubo eziphezulu neziphansi ekusebenzeni kwensimbi. Indlela yokusebenza evamile ivamise ukudinga izinto zokusebenza ezintathu ezihlukene ukwenza izinqubo ezintathu. Ukuphendula le nkinga, sinikeza amakhasimende isisombululo esididiyelwe futhi sethula umshini wokusika ophathwa ngesandla we-laser kanye nokushisela konke-in-one! Lena idivayisi enemisebenzi emithathu ye-laser welding, yokuhlanza nokusika.

5. Ngokushesha futhi kalula isusa amafutha, ukugqwala kanye nama-coatings ngaphambi kokushisela, futhi isusa imfucumfucu nokushintsha umbala ngemva kokushisela, kuyilapho yenza izinqubo zokusika ezinhlobonhlobo zamapuleti. Ingasiza amakhasimende ngendlela efanele nangempumelelo ukuthi afinyelele ukusebenza kahle kakhulu futhi ahlangabezane nezimo eziningi zomsebenzi. Ububanzi be-welding swing buphakeme njengo-5mm, futhi ubude be-swing yokuhlanza bufika ku-100mm. Ingakwazi ukusika amapuleti ensimbi engagqwali ngaphansi kuka-6mm. Inkomba yenqubo inamandla, ikakhulukazi inkomba yokuhlanza cishe ayifaniswe!

I-Fortune Laser Mini Laser Welding Machine Imingcele Eyisisekelo Yezobuchwepheshe

Amapharamitha okungena okushisela (I-Material & Thickness Welding Range) ukuze kusetshenziswe ireferensi

| Okubalulekile | Amandla okukhipha (W) | Ukungena okuphezulu (mm) |

| Insimbi engagqwali | 1000 | 0.5-3 |

| Insimbi engagqwali | 1500 | 0.5-4 |

| Insimbi engagqwali | 2000 | 0.5-5 |

| Insimbi ye-carbon | 1000 | 0.5-2.5 |

| Insimbi ye-carbon | 1500 | 0.5-3.5 |

| Insimbi ye-carbon | 2000 | 0.5-4.5 |

| Ingxube ye-aluminium | 1000 | 0.5-2.5 |

| Ingxube ye-aluminium | 1500 | 0.5-3 |

| Ingxube ye-aluminium | 2000 | 0.5-4 |

| Ishidi elinothayela | 1000 | 0.5-1.2 |

| Ishidi elinothayela | 1500 | 0.5-1.8 |

| Ishidi elinothayela | 2000 | 0.5-2.5 |

[Owolintshi/Omnyama Nomhlophe/Oluhlaza okwesibhakabhaka ngemibala emibili yomshini (bonisa njengasesithombeni) ingeyenketho.]

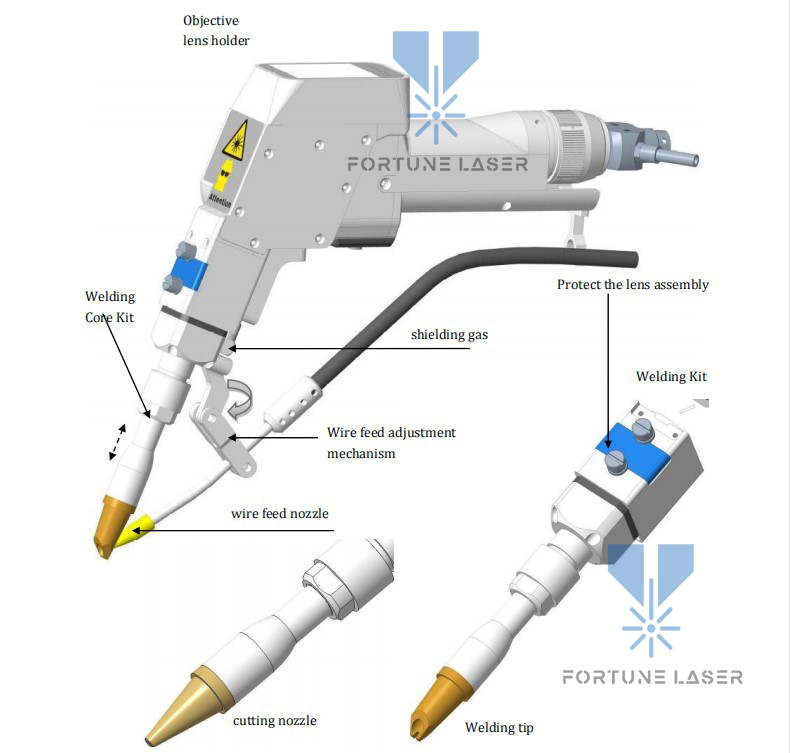

1. Le nhloko yokushisela inezinzuzo eziqinile ensimbi engagqwali, i-aluminium alloy welding, kanye nezicelo zokushisela amandla amancane naphakathi. Ikhanda le-welding elibizayo.

2. Ikhanda lokushisela lamukela i-X eqhutshwa yi-motor-driven, i-Y-axis vibrating lens, ene-swing modes eminingi, futhi i-swing welding ivumela i-workpiece ukuba ibe ne-welding engavamile, izikhala ezinkulu kanye neminye imingcele yokucubungula, engathuthukisa kakhulu izinga lokushisela.

3. Isakhiwo sangaphakathi sekhanda le-welding sivalwe ngokuphelele, esingavimbela ingxenye ye-optical ukuthi ingangcoliswa uthuli.

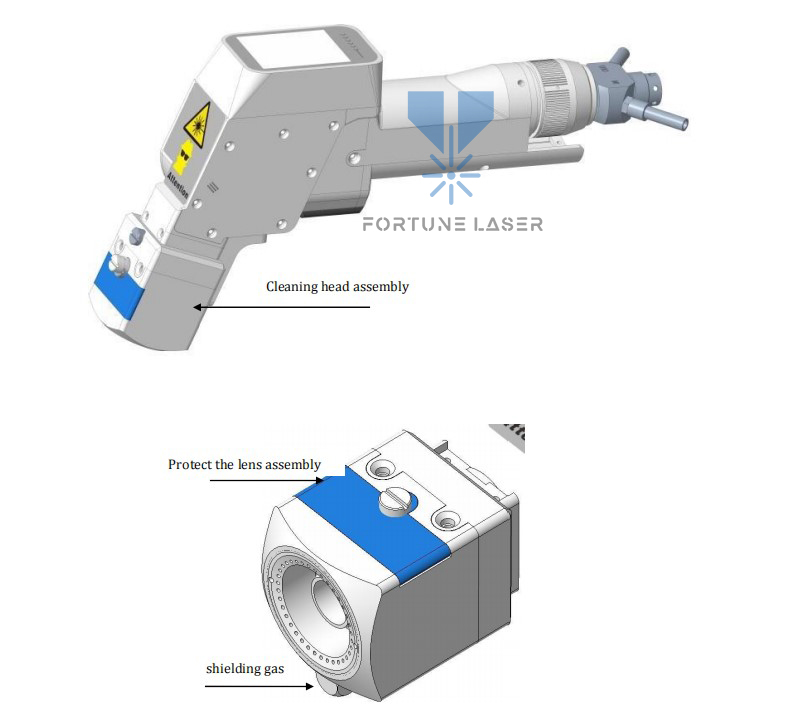

4. Amakhithi okushisela/ukusika ongazikhethela nawo kanye nezinto zokuhlanza kungafeza ngempela imisebenzi emithathu yokushisela, ukusika nokuhlanza.Siphinde sibe nomshini wokuhlanza omncane onomsebenzi wokuhlanza ohlukile)

5. I-lens yokuzivikela yamukela isakhiwo se-drawer, okulula ukusishintsha.

6. Ingafakwa amalaser ahlukahlukene anezixhumi ze-QBH.

7. Usayizi omncane, ukubukeka okuhle nokuzizwa.

8. Isikrini sokuthinta singakhethwa ekhanda lokushisela, elingaxhunywa nesikrini seplathifomu ukuze uthole ulwazi olungcono lokulawula umshini womuntu

| I-voltage yokuhlinzeka (V) | 220V±10% AC 50/60Hz |

| Amandla alinganiselwe | 1500W |

| Ubude bokugxila obuhlanganisiwe | 75 mm |

| Umswakama wendawo yokusebenza(%) | <70 |

| Gxila/Hlanza Ubude bokugxila | F150mm/F500mm |

| Ibanga le-swing | 0.1-5mm |

| Indlela yokupholisa | Isibandisi samanzi |

| Imvamisa ye-Swing | 0-300Hz |

| Isisindo | 0.8kg |

| Ongakukhetha | Ikhanda Lokuhlanza / Isiphakeli Socingo / Ithiphu Yokusika / Ikhithi Yokushisela |

| Usayizi wesikrini | Isikrini esikhulu esijwayelekile + isikrini esincane esingamayintshi angu-2 |

| Gxila kububanzi bokulungisa obuqondile | ±10mm |

| Ibanga lokulungiswa kwendawo (imodi yokubamba ngesandla) | 0~6mm |

| Ibanga lokulungiswa kwendawo (imodi yokuhlanza) | 0~50mm |

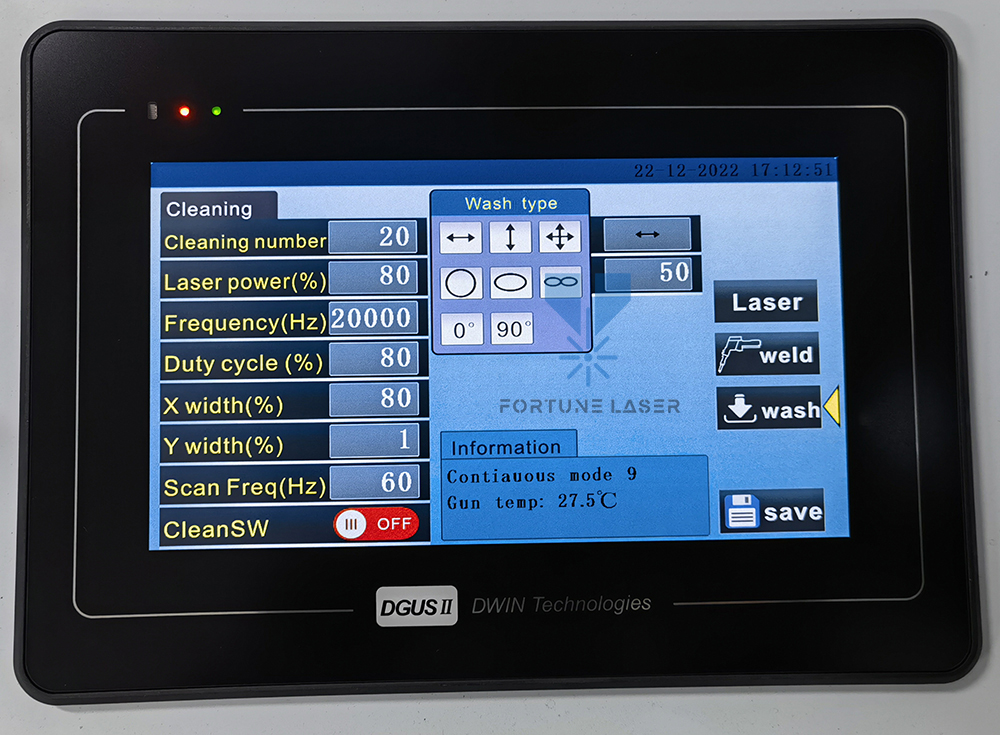

Zonke izindlela zokusebenza zemishini yethu zilula futhi ziqondakala kalula. Khetha amapharamitha ofuna ukuwashintsha ngesikrini esithintwayo bese uwagcina. Imisebenzi yokuhlanza nokushisela kulula ukuyishintsha. Vele ukhethe izinketho emshinini futhi izoshintsha imodi oyifunayo.

Futhi abangani abaningi abangazange bayisebenzise bazophinde bazibuze ukuthi balungise kanjani imingcele. Sizosetha amapharamitha afanele wena lapho sithumela umkhiqizo. Lapho uyisebenzisa, udinga kuphela ukushintsha amandla ukuze uyisebenzise. Uma usazizwa ungakhululekile, siphinde sibe nesethi yocwaningo. Ithebula lepharamitha elifanele ukushiselwa kwezinto ezihlukahlukene liyireferensi yamakhasimende ethu.

Indlela yokubona, isistimu, ihadiwe, njll. konke kuthuthukiswe ngokuzimela. I-interface yokusebenza inembile futhi ilula, futhi ukusebenza kulula. Amahora okuqeqeshwa angakwenza uzizwe njengomshiseli onekhono. Yehlisa izindleko zabasebenzi ngenkathi uthuthukisa ikhwalithi, ukungaguquguquki, kanye nokukhiqiza.

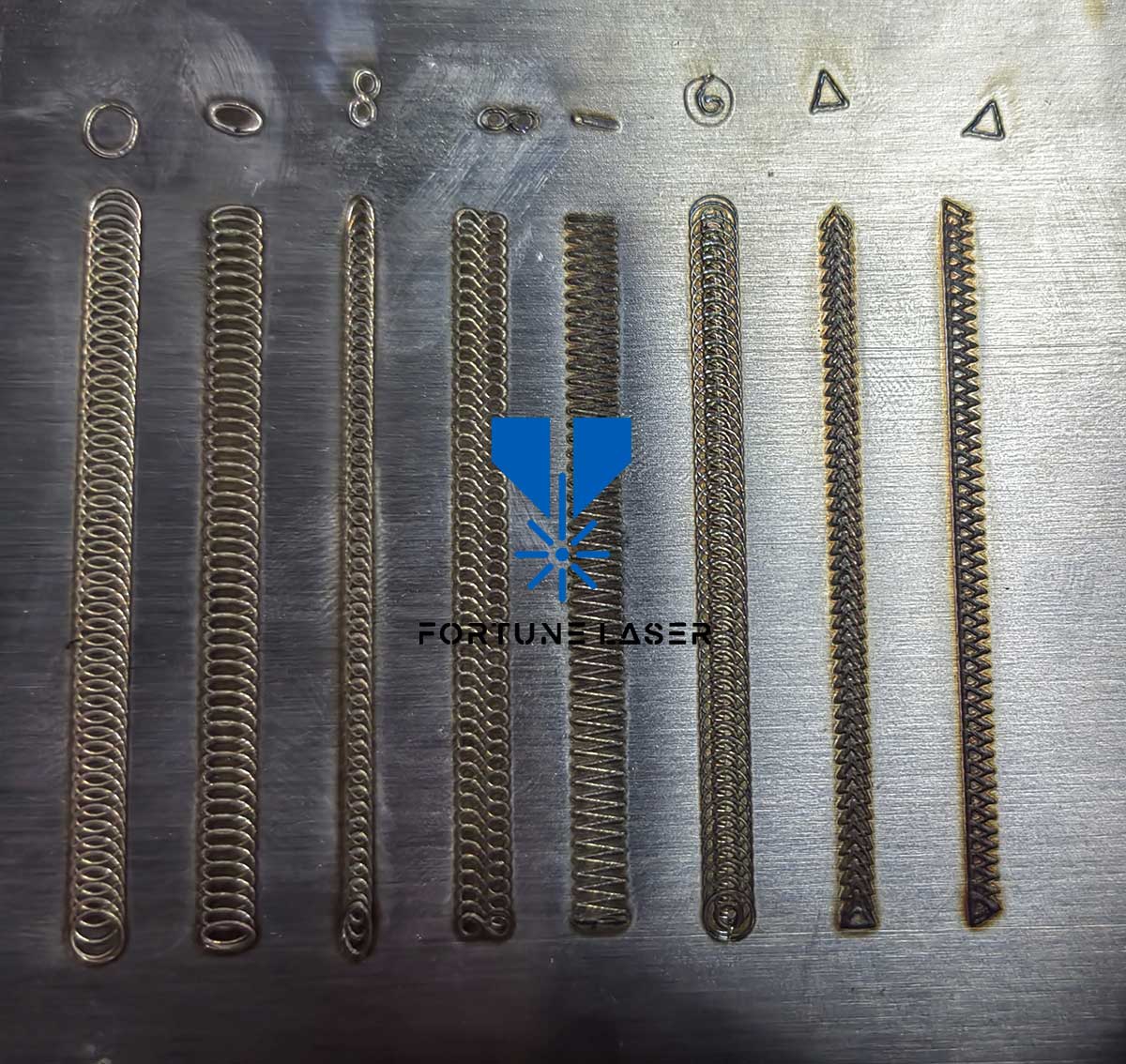

Ngokwesisekelo sika-3 no-1, umshini wethu ungaphinda uguqule izinhlobo ezahlukene zamachashazi njengoba kubonisiwe esithombeni esingezansi.

Amaphethini ashiselwe ngomumo wogongolo ngamunye ahlukile. Izimo zethu zemishayo zihlanganisa umugqa oqondile, indilinga, unxantathu, umdwebo 8, i-ellipse, 90° kanye nezinye izimo ezivamile.

1.Le nhloko ye-laser iwumkhiqizo wethu okhethekile owenziwe ngezifiso, cishe awekho ofana nawo emakethe;

2.Sinezinkundla eziningi zokuthenga ze-B2B, ezingaqinisekisa ukuphepha kokuthenga kwakho;

3.Sizinikezele ukwesekwa kwezobuchwepheshe kanye nesevisi yamahora angu-24 ngemva kokuthengisa ukuze sithuthukise ulwazi lwamakhasimende;

4.Yonke imishini yethu inewaranti yonyaka ongu-1.

5.Sigxila ekuthuthukiseni imikhiqizo yethu ngobuciko futhi sinikeze imigomo yokuncintisana.

6.Sineqembu elinekhono nelithembekile emsebenzini wakho, elizibophezele ekunikezeni isevisi yamakhasimende yomuntu siqu kuwo wonke amakhasimende ethu.