Enqubweni yokukhiqiza izimoto, ukudweba izinto zokugcoba noma izithambisi zokupholisa kanye namafutha avimbela ukugqwala asetshenziswa angakwazi ukungcolisa izingxenye zezimoto futhi kwehlise kakhulu ikhwalithi yezinqubo zokujoyina noma zokuhlanganisa okunamandla aphezulu. Kuthisinqubo, ama-welds namabhondi ezingxenyeni ze-powertrain kufanele kube amazinga aqinile wekhwalithi ayahlangatshezwana nawo. Ngakho-ke, izindawo ezihlangene kufanele zihlanzwe kahle.

Kungani abantu abaningi ngokwengeziwe kithieukuhlanza nge-laser esikhundleni sokuhlanza okungokwesiko? Uyini umehluko phakathi kokuhlanza nge-laser nokuhlanzwa kwendabuko ezinhlelweni zezimoto?

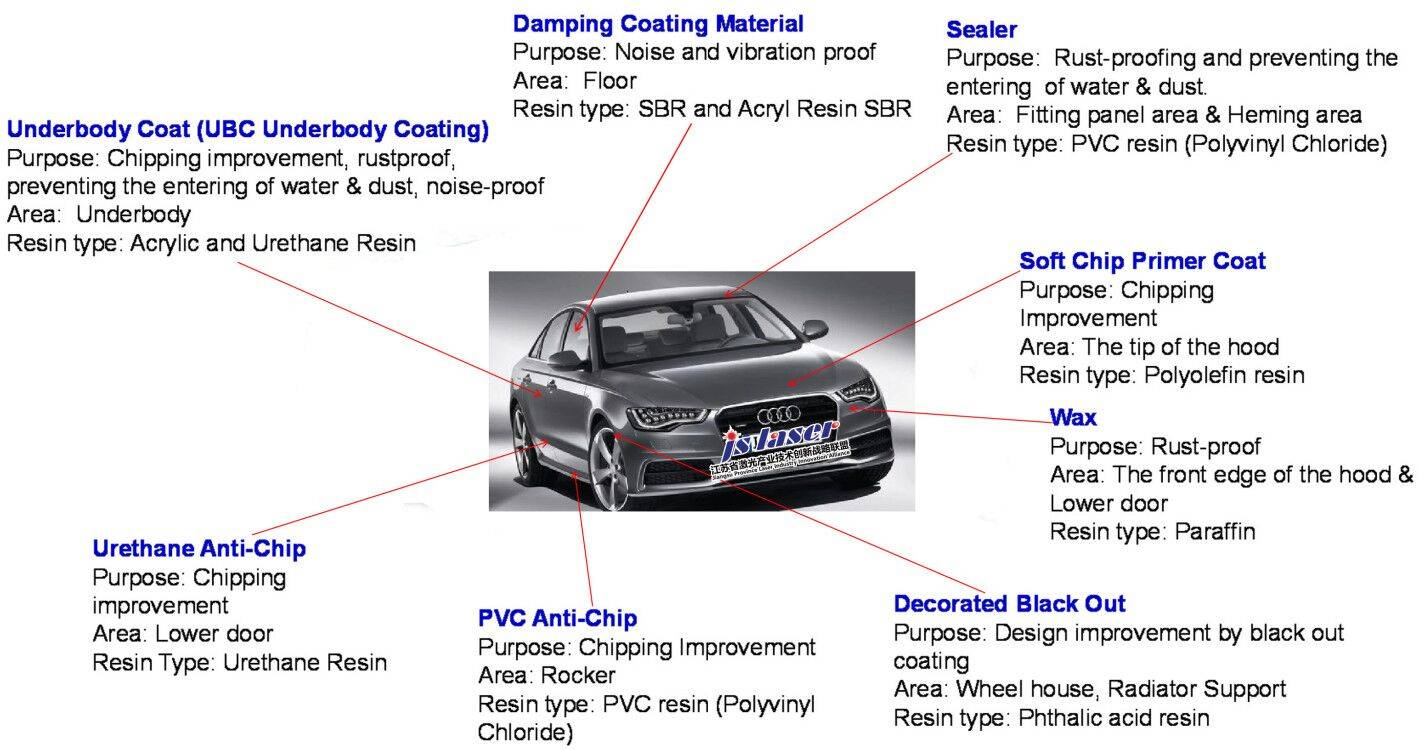

Embonini yezimoto, upende omdala ongaphezulu udinga ukususwa ukuze kufakwe upende omusha ngaphambi kokuba umzimba ulungiswe.

Kunezindlela eziningi zendabuko zokuhlanza upende womzimba wemoto, ikakhulukazi kuhlanganisa izindlela zemishini nezamakhemikhali. Ezindleleni zemishini, kuhlanganisa ukususwa kopende wejethi wamanzi anengcindezi ephezulu, i-sandblasting kanye nokugaya ibhulashi lensimbi. Futhi izindlela zamakhemikhali ngokuyinhloko zibhekisela kuma-reagents amakhemikhali okukhipha upende. Lezi zindlela zineziphambeko ezifana nezindleko eziphezulu, ukusetshenziswa kwamandla aphezulu, ukungcola okulula, nokulimala okulula ebusweni be-substrate, futhi kancane kancane zehlulekile ukuhlangabezana nezidingo eziphezulu zesimanje zokuvikelwa kwemvelo kwezindlela zokuhlanza.

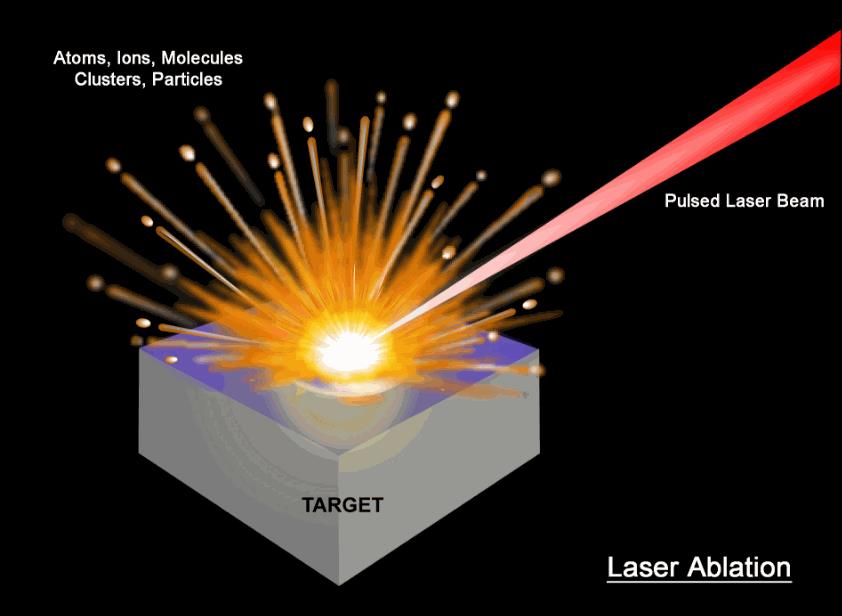

Imvelo esheshayo, ezenzakalelayo yokuhlanza nge-laser ivumela ukuhlanzwa okuphelele kwezinsalela ezingaphezulu, okuholela ekushiseni okuqinile, okungenalutho kanye nama-micro-crack-free namabhondi. Ngaphezu kwalokho, ukuhlanza nge-laser kumnene futhi inqubo ishesha kakhulu kunezinye izindlela, izinzuzo eziye zaqashelwa imboni yezimoto.

Emkhakheni wezimboni, ukuze kuvikelwe insimbi noma ezinye izinto ze-substrate, indawo engaphezulu ivame ukupendwa ukuvimbela ukugqwala, i-oxidation, nokugqwala. Uma ungqimba lukapende luhlutshiwe ngokwengxenye noma indawo engaphezulu idinga ukupendwa kabusha ngenxa yezinye izizathu, ungqimba lukapende lwangempela ludinga ukuhlanzwa ngokuphelele.

Ukuphendula lesi simo, sekuvele ubuchwepheshe obuningi obusha bokuhlanza, futhi ukuhlanza nge-laser, njengenye yezindlela ezibalulekile, kuye kwabonisa kancane kancane ukuphakama kwayo. Ngokuhambisanayo, sizokwethula uhlelo lokuhlanza lweumshini wokuhlanza we-laser embonini yezimoto.

1. Kukhona inqubo ephelele uma kuqhathaniswaekhipha upende ebusweniwezimoto kanye nenqubo yokukhipha i-primer yamapuleti ensimbi. I-laser beam idluliselwa nge-fiber optical futhi iskenwe ngokuqhubekayo ukuze kukhishwe ungqimba lukapende kanye ne-primer ebusweni bepuleti lensimbi, kushiye indawo ehlanzekile ebusweni bepuleti lensimbi, elifanele ukupendwa kabusha noma ukuqhubeka nezinye izinqubo.

Ukusetshenziswa kwalobu buchwepheshe bokuhlanza nge-laser ukuhlanza amabhuleki ezimoto kuyindlela ehlukile yokuhlanza indawo evamile. Inqubo yokuhlanza yendabuko yamabhuleki emoto, njenge-sandblasting, ayilula ukuhlanza iphaneli yangemuva. Ukusetshenziswa kwe-adaptive laser yokuhlanza ubuchwepheshe kungafinyelela indlela ezenzakalelayo yokuhlanza ipuleti elingemuva le-brake pad ukuhlangabezana nenqubo yokumboza elandelayo. Ukususwa okukhethiwe, akukho monakalo we-substrate, namazinga okuhlanza ngokushesha yizici ezibalulekile ezivumela upende wokuhlanza nge-laser.

2. Lapho izimoto zabantu ezindala zidinga ukulungiswa ukuze zibuyisele ubuhle bazo bangempela noma zihlotshiswe kabusha izinto zazo ezindala, ngokwanda kwamandla e-laser,laser yokuhlanza ubuchwephesheizodlala indima enkulu. Ukuhlanza ngelaser kwanamuhla kungahlanza futhi kususe izindawo ezindala ezingafuneki cishe kuzo zonke izingxenye zemoto ezindala. Isibonelo, ngisho nongqimba olungaphezulu lwe-chrome-plated lungasuswa ngokuphelele. Ngokuvamile, i-coat of weathered phezu kwemoto idinga ukususwa ngokuphelele ngaphambi kokuba kufakwe upende omusha. Njengoba izici ezingokomzimba nezamakhemikhali zongqimba olungaphezulu lukapende zihlukile kune-primer, amandla kanye nemvamisa ye-laser ingasethwa ukuze isuse kuphela ungqimba olungaphezulu lwepende.

Amasu okushisela amanoveli noma izinqubo zokujoyina ezamukelwa ekwenziweni okusha okuqhubekayo kobuchwepheshe bezimoto zidinga ukwelashwa okuphelele kwangaphambili kwezindawo ezishiselwe noma ezihlanganisiwe, futhi ngalesi sikhathi ukuhlanza nge-laser kunganikeza ukwelashwa Kokuhlanza okomile, okunembayo nokungahubi, kuyilapho ukuhlanzwa kwamakhemikhali okumanzi noma izindlela zokwelapha zokugaya ngokuvamile kunzima ukuhlangabezana, futhi izingxenye eziningi manje sezihlanzwa nge-laser.

Futhiukuhlanza laser kunezinzuzo eziningiphezu kokuhlanza ngokwesiko:

1. Umugqa wokuhlanganisa ozenzakalelayo: Umshini wokuhlanza we-laser ungahlanganiswa namathuluzi omshini we-CNC noma amarobhothi ukuze kusetshenziswe isilawuli kude nokuhlanza, okungakwazi ukubona ukuzenzekelayo kwemishini, ukwenza imisebenzi yomugqa wokuhlanganisa umkhiqizo, futhi usebenze ngobuhlakani.

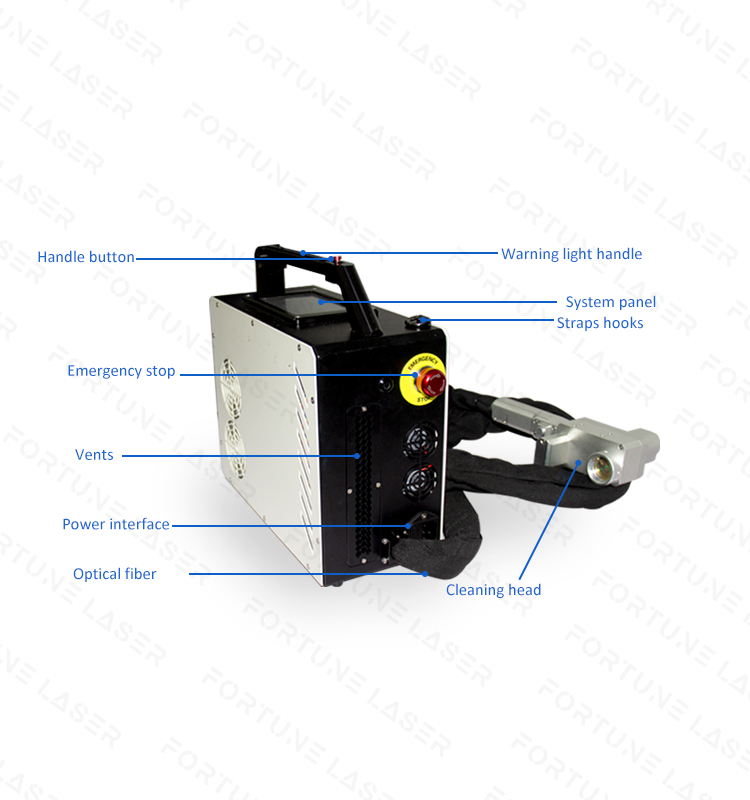

2. Ukuma okunembile: sebenzisa ukudluliswa kwe-fiber optical ukuze uqondise i-laser ukuyenza ibe lula, futhi ulawule indawo yokukhanya ukuze ihambe ngesivinini esiphezulu nge-galvanometer yokuskena eyakhelwe ngaphakathi, elungele izingxenye ezingaxhunywanga okunzima ukufinyelela kuzo njengezingxenye ezinomumo okhethekile, izimbobo, nemisele okunzima ukufinyelela kuyo ngezindlela zokuhlanza ezivamile. ukuhlanza kwe-laser emhlabathini.

I-3.Awukho umonakalo: umthelela wesikhashana ngeke ushise indawo yensimbi, futhi akukho monakalo ku-substrate.

I-4.Ukuzinza okuhle: I-laser pulsed esetshenziswa emshinini wokuhlanza we-laser inokuphila kwenkonzo ende, ngokuvamile kufika emahoreni angu-100,000, ngekhwalithi ezinzile nokuthembeka okuhle.

5. Izindleko zokulungisa eziphansi: azikho izinto ezisetshenziswayo ezisetshenziswayo ngesikhathi kusetshenziswa umshini wokuhlanza we-laser, futhi izindleko zokusebenza ziphansi. Esigabeni sakamuva, i-lens kuphela edinga ukuhlanzwa noma ukushintshwa njalo, futhi izindleko zokuyilungisa ziphansi, eziseduze nokungakhathalelwa.

Okungenhla yizinhlelo zokusebenza zokuhlanza kanye nezinzuzo zemishini yokuhlanza i-laser embonini yezimoto. Ukusetshenziswa kwe-laser polishing, ukuhlanza indawo kanye nokususwa kwe-coating kukhula ngokushesha. Ngokuya ngohlelo lokusebenza, imvamisa yokushaya kwenhliziyo, amandla kanye nobude begagasi be-laser kumele kukhethwe kahle ukuze kuhlanzeke, kupholishwe futhi kucishwe okokusebenza okuqondiwe. Ngesikhathi esifanayo, noma yiluphi uhlobo lokulimala kwezinto eziyisisekelo kufanele lugwenywe.

Uma ufuna ukufunda okwengeziwe mayelana nokuhlanza i-laser, noma ufuna ukukuthengela umshini wokuhlanza we-laser ongcono kakhulu, sicela ushiye umlayezo kuwebhusayithi yethu futhi usithumele i-imeyili ngokuqondile!

Isikhathi sokuthumela: Sep-26-2022