Njengoba sonke sazi, i-laser inezici "ze-monochromaticity enhle, isiqondiso esiphezulu, ukuhambisana okuphezulu nokukhanya okuphezulu".I-laser weldingfuthi kuyinqubo lapho kusetshenziswa khona ukukhanya okukhishwa nge-laser. Ngemuva kokucutshungulwa kwe-optical, i-laser beam igxile ekukhiqizeni i-beam yamandla amakhulu, ekhishwa nge-radiated engxenyeni ye-welding yezinto ezoshiswa futhi zincibilike ukuze zakhe uxhumano oluhlala njalo.

Kodwa futhi kukhona abantu abaningi abazohlangana nemibuzo ehlukahlukene ngesikhathi sokusetshenziswa, okulandelayo isifinyezo sethu sale mibuzo.

1. Umshini wokushisela obanjwe ngesandla welding slag splashKanjani to wenzeni?

Ngohlelo lwelaser welding, into encibilikisiwe isakazeka yonke indawo futhi inamathele ebusweni bento, okwenza izinhlayiya zensimbi zivele phezulu futhi zithinte ukubukeka komkhiqizo.

Imbangela yenkinga: Ukuchaphaza kungase kubangelwe amandla amaningi aholela ekuncibilikeni okusheshayo, noma ngenxa yokuthi ingaphezulu lempahla ayihlanzekile, noma igesi inamandla kakhulu.

Indlela yenkululeko: 1. Lungisa amandla ngendlela efanele;

2. Naka ukuhlanzeka kwendawo ebonakalayo;

3. Yehlisa umfutho wegesi

2. Okufanele ukwenze uma umthungo we-welding womshini wokushisela ophethwe ngesandla mkhulu kakhulu?

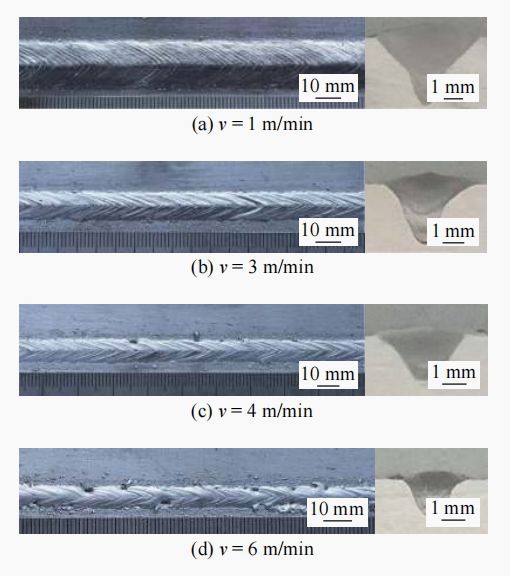

Phakathiukushisela, kuzotholakala ukuthi i-weld seam iphakeme kakhulu kunezinga elivamile, okuholela ekutheni i-weld seam ikhuliswe futhi ibukeke ingabonakali kakhulu.

Isizathu senkinga: ijubane lokuphakela ucingo lishesha kakhulu, noma isivinini sokushisela sihamba kancane

Isixazululo: 1. Yehlisa isivinini sokuphakela ucingo ohlelweni lokulawula;

2. Khulisa isivinini sokushisela.

3. Okufanele ukwenze lapho isikhundla se-offset somshini wokushisela ophethwe ngesandla sishiselwe?

Lapho i-welding, ayiqinisiwe ekuhlanganyeleni kwesakhiwo, futhi ukubekwa akukona okunembile, okuzoholela ekuhlulekeni okuphelele kwe-welding.

Isizathu senkinga: ukuma akunembile ngesikhathi sokushisela; indawo yokuphakela ucingo kanye ne-laser irradiation ayihambisani.

Isixazululo: 1. Lungisa i-laser offset kanye ne-swing angle ebhodini;

2. Hlola ukuthi ingabe kukhona ukuchezuka ekuxhumekeni phakathi kwesiphakeli socingo nekhanda le-laser.

4. Kungani umbala we-weld seam ube mnyama kakhulu uma ushisela ngomshini wokushisela obanjwe ngesandla?

Uma welding insimbi engagqwali, i-aluminium alloy nezinye izinto, umbala we-weld umnyama kakhulu, okuzokwenza umehluko oqinile phakathi kwe-weld kanye nobuso bezinto ezibonakalayo, okuzothinta kakhulu ukubukeka.

Imbangela yenkinga: Amandla e-laser mancane kakhulu, okuholela ekushiseni okunganele, noma isivinini sokushisela sishesha kakhulu.

Isixazululo: 1. Lungisa amandla e-laser;

2. Lungisa isivinini sokushisela

5. Iyini isizathu sokungalingani kwe-fillet weld ngesikhathi sokushisela?

Lapho ushisela amakhona angaphakathi nangaphandle, ijubane noma ukuma akulungisiwe emakhoneni, okuzoholela kalula ekushiseni okungalingani emakhoneni, okungathinti kuphela amandla okushisela, kodwa futhi kuthinta ubuhle be-weld.

Imbangela yenkinga: Ukuma kwe-welding kuyaphazamisa.

Isixazululo: Lungisa i-focus offset ohlelweni lokulawula i-laser, ukuze ikhanda le-laser elibanjwe ngesandla likwazi ukwenza imisebenzi yokushisela eceleni.

6. Yini okufanele uyenze uma i-weld seam ishona ngesikhathi sokushisela?

Ukucindezeleka ekuhlanganyeleni okushiselwe kuzoholela ekuqineni okunganele kwe-welding kanye nemikhiqizo engafaneleki.

Imbangela yenkinga: Amandla e-laser makhulu kakhulu, noma ukugxilwa kwe-laser kusethwa ngokungalungile, okubangela ukuthi ichibi elincibilikisiwe lijule kakhulu futhi impahla incibilike ngokweqile, okubuye kubangele ukuthi i-weld icwile.

Isixazululo: 1. Lungisa amandla e-laser;

2. Lungisa ukugxila kwe-laser

7. Okufanele ukwenze uma ubukhulu be-weld seam bungalingani ngesikhathi sokushisela?

I-weld ngezinye izikhathi inkulu kakhulu, ngezinye izikhathi incane kakhulu, noma ngezinye izikhathi ivamile.

Imbangela yenkinga: ayikho inkinga ngokuphuma kokukhanya noma ukuphakelwa ngocingo

Isixazululo: Hlola ukuqina kwe-laser kanye ne-wire feeder, okuhlanganisa amandla kagesi kagesi, isistimu yokupholisa, isistimu yokulawula, izintambo eziphansi, njll.

8. Iyini i-undercut?

I-Undercut ibhekisela ekuhlanganiseni okungalungile kwe-weld kanye nempahla, kanye nokuvela kwama-grooves nezinye izimo, ngaleyo ndlela kuthinte ikhwalithi yokushisela.

Imbangela yenkinga: Ijubane lokushisela lishesha kakhulu, ukuze ichibi elincibilikisiwe lingasatshalaliswa ngokulinganayo ezinhlangothini zombili zezinto ezibonakalayo, noma igebe lempahla likhulu futhi izinto zokugcwalisa azanele.

Isixazululo: 1. Lungisa amandla e-laser nesivinini ngokuya ngamandla wento kanye nobukhulu be-weld;

2. Yenza umsebenzi wokugcwalisa noma wokulungisa esikhathini esizayo.

Isikhathi sokuthumela: Dec-12-2022