Insimbi engagqwali isetshenziswa kabanzi ezimbonini ezehlukene ngenxa yezakhiwo zayo ezihlukile ezifana nokumelana nokugqwala nokwakheka. Ngokuthuthuka kobuchwepheshe, i-laser welding isiyindlela entsha yokushisela, enezinzuzo eziningi uma iqhathaniswa nezindlela zendabuko zokushisela. Nokho, enye yezinselelo zelaser weldingukuguqulwa kwensimbi engagqwali. Kulesi sihloko, sizoxoxa ngendlela yokugwema i-stainless steel laser welding deformation futhi sihlole izici ezisondelene nayo.

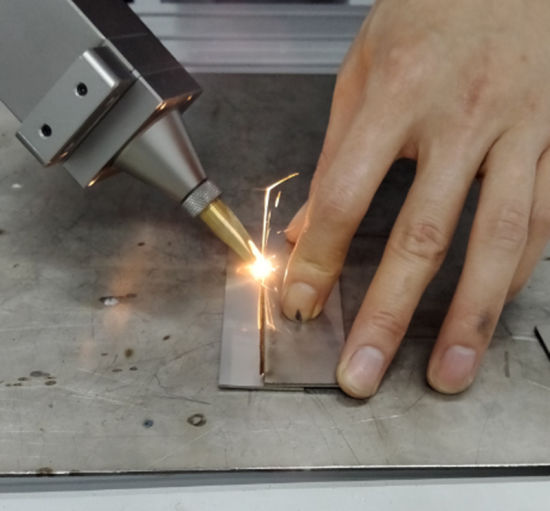

Okokuqala, kuyadingeka ukuqonda ukuthi kungani i-laser welding ibangela ukuwohloka kwensimbi engagqwali. Ukushisela nge-laser kuhilela ukusebenzisa i-laser enamandla amakhulu ukuncibilikisa nokuhlanganisa izindawo ezimbili zensimbi ndawonye. Phakathi nale nqubo, ukushisa okusheshayo nokupholisa kubangela ukuphazamiseka okushisayo, okubangela ukuguqulwa kwendawo ehlanganisiwe. Nakuba lokhu kubonakala kungenakugwema, kunezinyathelo ezimbalwa ezingathathwa ukuze kuncishiswe noma kuqedwe ngisho nokuhlanekezela.

Esinye sezinyathelo zokuqala zokugwemalaser weldingukuhlanekezela ukukhethwa ngokucophelela kwemingcele ye-laser welding efanele. Izinto ezinjengamandla e-laser, isivinini sokushisela, nokugxila kwe-beam kufanele kuthuthukiswe ukuze kuzuzwe ikhwalithi yokushisela oyifunayo. Ngokulungisa la mapharamitha, okokufaka ukushisa kungalawulwa futhi ukuwohloka kokushisa okubangela ukuhlanekezela kungancishiswa. Ukwengeza, ukusebenzisa imodi ye-pulsed kunemodi yegagasi eqhubekayo kusiza ukunciphisa indawo ethinteke ukushisa kanye nokonakala okulandelayo.

Okunye okucatshangelwayo okubalulekile ukuklama kwesixhumi ngokwaso. Ukuma, usayizi kanye nokucushwa kwesihlanganisi kungathinta kakhulu inani lokuguqulwa okwenzeka ngesikhathilaser welding. Ukuze unciphise ukuhlanekezela, kunconywa ukusebenzisa ama-welds abanzi futhi ugweme amakhona abukhali noma abukhali. Lokhu kusabalalisa ukushisa ngokulinganayo futhi kunciphisa ukugxila kokucindezeleka okushisayo. Ukwengeza, ukusetshenziswa kwe-fillet welds (ama-welds ane-concave noma i-convex curve shapes) nakho kusiza ukunciphisa ukuhlanekezela.

Ngaphezu kwamapharamitha wokushisela kanye nokwakheka okuhlanganyelwe, ukukhetha kokuqina kwempahla nakho kudlala indima ebalulekile ekugwemeni ukuhlanekezela. Amashidi ensimbi engagqwali ashubile athambekele kakhulu ekuwohlokeni ngenxa ye-thermal conductivity ephezulu. Ukuze unciphise lokhu, kunconywa ukusebenzisa amashidi ensimbi angagqwali azacile noma usebenzise isinki sokushisa noma isistimu yokupholisa phakathi nenqubo yokuhlanganisa. Lezi zindlela zokupholisa zisiza ukuqeda ukushisa okweqile futhi zinciphise ama-thermal gradients, zinciphise ukuhlanekezela.

Ukwengeza, ukusebenzisa amasu okulungisa nokubopha ngendlela efanele kungasiza kakhulu ekugwemeni ukuhlanekezelwa kwe-laser welding. I-fixture ibhekisela ekumisweni nasekulungiseni i-workpiece ngesikhathi senqubo yokushisela. Kubalulekile ukuqinisekisa ukuthi i-workpiece isekelwa ngokwanele futhi iqondaniswe ukuze kuvinjelwe noma yikuphi ukunyakaza noma ukungqubuzana ngesikhathi sokushisela. Ukugoqa, ngakolunye uhlangothi, kuhlanganisa ukubamba ucezu lokusebenza endaweni usebenzisa amajigi aklanywe ngokukhethekile. Ukubamba ngendlela efanele kusiza ukugcina izinga elifiswayo lokuqondanisa futhi kunciphisa ithuba lokungqubuzana.

Okokugcina, ukwelashwa kokushisa kwe-post-weld kungasetshenziswa ukukhulula ukucindezeleka okusele nokunciphisa ukuhlanekezela. I-annealing, eqeda ingcindezi, kanye nezinqubo zokupholisa umoya ezilula zisiza ukuzinzisa izakhiwo ezishiselwe futhi zinciphise ukuhlanekezela. Ukusetshenziswa kwemishini ekhethekile yokwelapha ukushisa kanye namasu kunganikeza ukuhamba ngebhayisikili okushisayo okudingekayo ukuze kuqinisekiswe insimbi engagqwali eshiselwe ihlala izinzile futhi ingaguquki.

Ngokufigqiwe,laser weldinginikeza izinzuzo eziningi kunezindlela zendabuko zokushisela ngokuya ngesivinini, ukunemba kanye nekhwalithi. Kodwa-ke, ukuwohloka kwensimbi engagqwali kubangela izinselelo enqubweni yokushisela i-laser. Ukuhlanekezelwa kwe-laser yensimbi engagqwali kungasingathwa ngokuphumelelayo ngokukhethwa ngokucophelela kanye nokwenza kahle kwemingcele yokushisela, ukuklanywa kokulungiswa okuhlanganyelwe okufanele, ukucabangela ukushuba kwempahla, ukuqaliswa kokulungiswa okufanele kanye namasu okubamba, kanye nokusetshenziswa kokwelashwa kokushisa kwangemva kokushisela. Lezi zinyathelo, ezihlanganiswe nezakhiwo ezingokwemvelo zensimbi engagqwali, zifaka isandla ekushiseleni kwekhwalithi ephezulu nokuhlanekezela okuncane.

Uma ufuna ukufunda okwengeziwe mayelana ne-laser welding, noma ufuna ukukuthengela umshini we-laser welding ongcono kakhulu, sicela ushiye umlayezo kuwebhusayithi yethu futhi usithumele i-imeyili ngokuqondile!

Isikhathi sokuthumela: Jul-18-2023