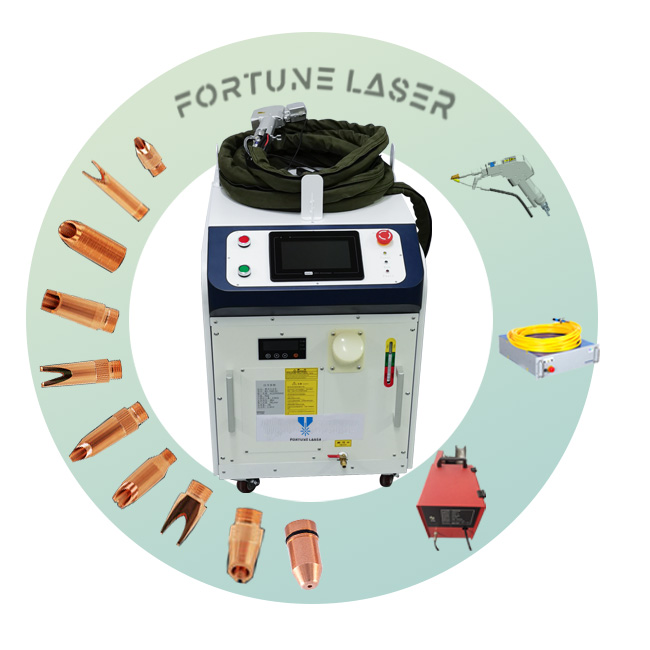

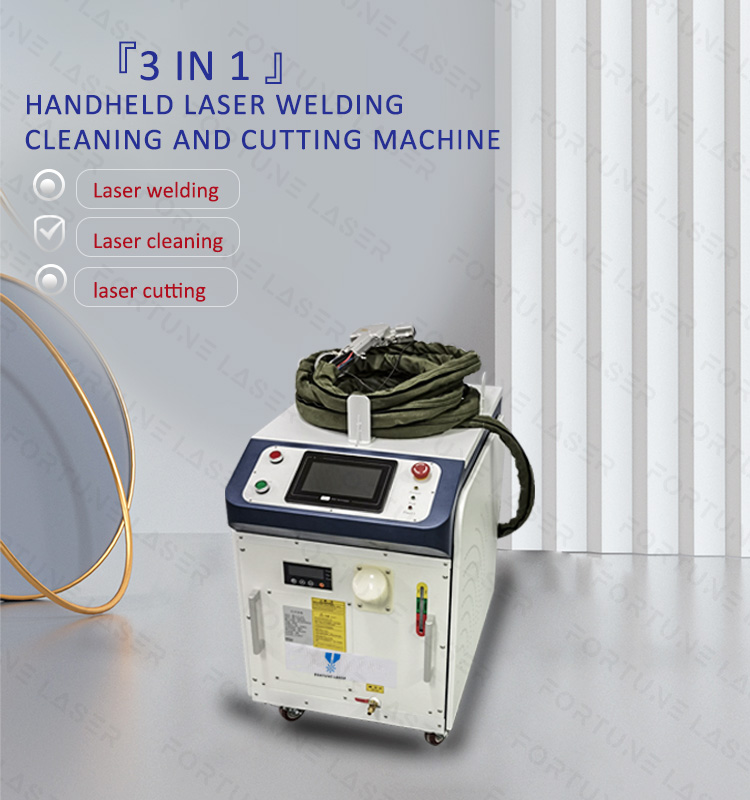

Ephathwayo 3 ku-1 Laser Welding Cleaning Machine Cutting

Ephathwayo 3 ku-1 Laser Welding Cleaning Machine Cutting

3 Ku-1 Handheld Laser Cutting, Welding, Cleaning Machine Izici

1.Njengei-laser cleaner, kuyindlela yokuhlanza "eluhlaza". Akudingi ukusebenzisa noma iyiphi i-ejenti yamakhemikhali nesisombululo sokuhlanza. Imfucuza ehlanziwe ngokuyisisekelo iyimpushana eqinile. Incane, kulula ukuyigcina futhi igaywa kabusha. Ingakwazi ukuxazulula kalula inkinga yokungcoliswa kwemvelo okubangelwa ukuhlanzwa kwamakhemikhali.

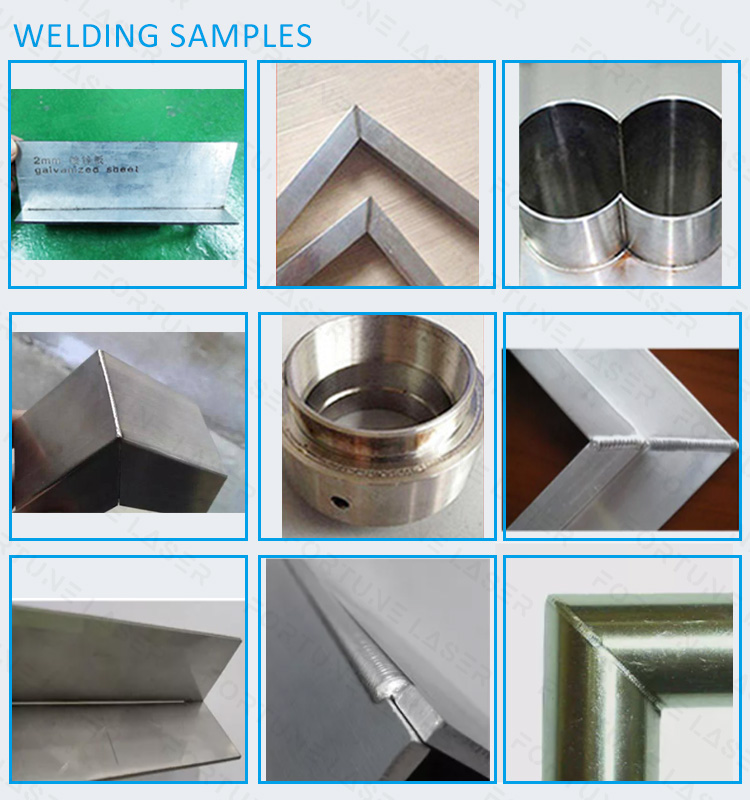

2.Njengoba alaser welder, umthungo wokushisela uyashelela futhi muhle, asikho isidingo sokupholisha, akukho deformation noma isibazi sokushisela, ukushisela okuqinile kwengxenye. Yonga isikhathi futhi uthuthukise ukusebenza kahle.

3.Njengoba aumsiki we-laser, kulula kakhulu ukusebenza ukusika zonke izinhlobo zezinsimbi.

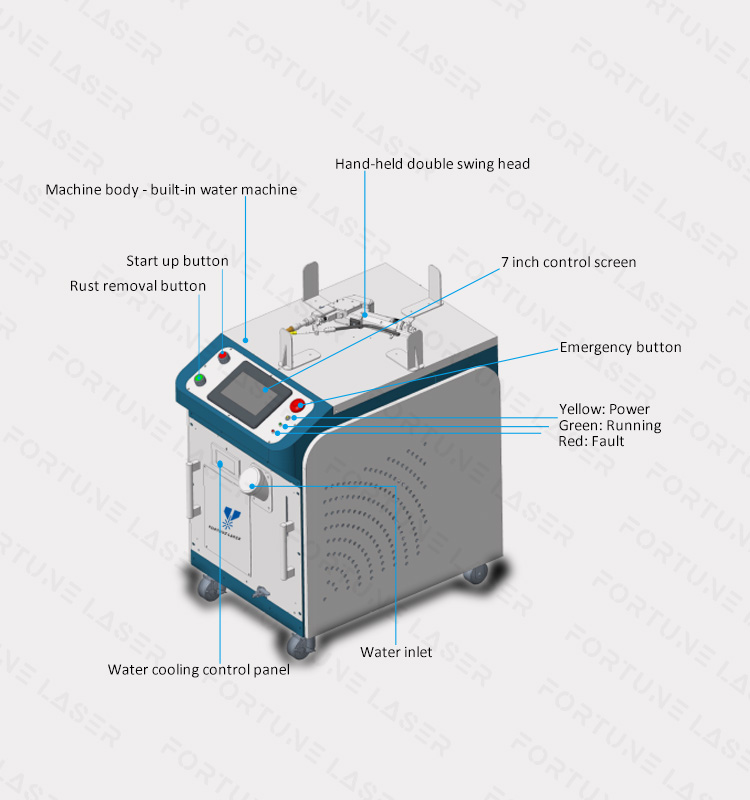

I-4.Isibhamu se-laser esiphathwayo sinesakhiwo esiphathwayo esilula futhi kulula ukusiphatha. Ifakwe isikrini sokuthinta, esilungele ukushintsha amapharamitha ngesikhathi somsebenzi nokwenza kube lula ukusebenza. Isisindo singu-0.8kg, okulula ukusisebenzisa ngaphandle kokukhathala.

I-5.Yamukela umthombo we-fiber laser ochwepheshe onezinga eliphansi lamaphutha, ukusetshenziswa kwamandla okuphansi, ukugcinwa mahhala, futhi kulula ukuhlanganisa.

6.Industrial engaguquki izinga lokushisa amanzi ukupholisa chiller iklanywe ngokukhethekile. I-water chiller ifakwe isihlungi, esinokusebenza okuphephile, okuhlala isikhathi eside, nokuzinzile nempilo ende yesevisi. Uhlelo lokupholisa amanzi oluqinile futhi oluzinzile luzoqinisekisa ukuthi umthombo we-fiber laser usebenza kahle.

7. Idizayini ephathekayo: Idizayini ehlangene, e-ergonomic, enamasondo ukuhamba ngokukhululeka.

| Fortune Laser Portable 3 in 1 Laser Welding Cleaning Cutting Machine | |||

| Laser Amandla | 1000W | 1500W | 2000W |

| Umthombo we-Laser | I-GW 25um core diameter fiber laser(Raycus/JPT/MAX/IPG ngokuzikhethela) | ||

| I-Wavelength (nm) | 1064 - 1080 | ||

| Imodi ye-Laser | I-Laser Welding / Laser Cutting / Laser Cleaning | ||

| Ubude be-Fiber | 10M(kungenziwa ngokwezifiso) | ||

| Indlela Yokusebenza | Okuqhubekayo / Ukuguquguquka | ||

| Ikhanda le-laser | I-Dual Axis | ||

| Isixhumi esibonakalayo | QBH | ||

| Ububanzi be-Welding | 0.2-0.5mm(iyalungiseka) | ||

| Ukubuka kuqala kwe-Laser | Ukubuka kuqala Kokukhanya Okubomvu Okuhlanganisiwe | ||

| Izidingo zegebe lokushisela | ≤1.2mm | ||

| Welding ukujiya | 0.5-3mm | ||

| Isivinini sokushisela | 0-120mm/s (iyalungiseka) | ||

| Ubude bokugxila obuhlanganisiwe | 75 mm | ||

| Gxila/Hlanza Ubude bokugxila | F150mm/F500mm | ||

| Ibanga le-swing | 0.1—5mm | ||

| Imvamisa ye-Swing | 0-300Hz | ||

| Ukupholisa | I-Integrated Water Chiller | ||

| Ulimi | IsiShayina/isiNgisi/isiRashiya/isiKorea/Nezinye izilimi njengoba kudingeka. | ||

| Ukunikezwa kwamandla kagesi | I-AC 220V, 50Hz/60Hz | I-AC 380V, 50Hz/60Hz | |

| Ukusetha Ipharamitha | Iphaneli yokuthinta | ||

| Izinto zokushisela | I-Carbon Steel, Insimbi Engagqwali, I-Aluminium, Ithusi, Ingxubevange njll. | ||

| I-Ambient Temperature | 10–40°C | ||

| Ukuthobeka Kwemvelo | <70% Ngaphandle Kokujiya | ||

| I-LASER WELDED PARAMETERS | ||

| Okubalulekile | Amandla e-Laser (watt) | Ukungena Okukhulu (mm) |

| Insimbi engagqwali | 1000 | 0.5-3 |

| Insimbi engagqwali | 1500 | 0.5-4 |

| Insimbi Yekhabhoni | 1000 | 0.5-2.5 |

| Insimbi Yekhabhoni | 1500 | 0.5-3.5 |

| I-aluminium Alloy | 1000 | 0.5-2.5 |

| I-aluminium Alloy | 1500 | 0.5-3 |

| Ishidi Elinothayela | 1000 | 0.5-1.2 |

| Ishidi Elinothayela | 1500 | 0.5-1.8 |

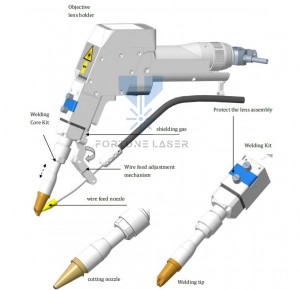

Isibhamu se-laser esiphathwa ngesandla singenza ukushisela, ukuhlanza, nokusika ngesilawuli esihlakaniphile, kulula ukusebenzisela umshini oguquguqukayo, ophathwayo ngosayizi omncane, izindleko eziphansi ngaphandle kwezinto ezisetshenziswayo. Abasebenzisi bangabeka amapharamitha ngesikrini sokuthinta kusibhamu se-laser, esilula kakhulu futhi esisebenziseka kalula.

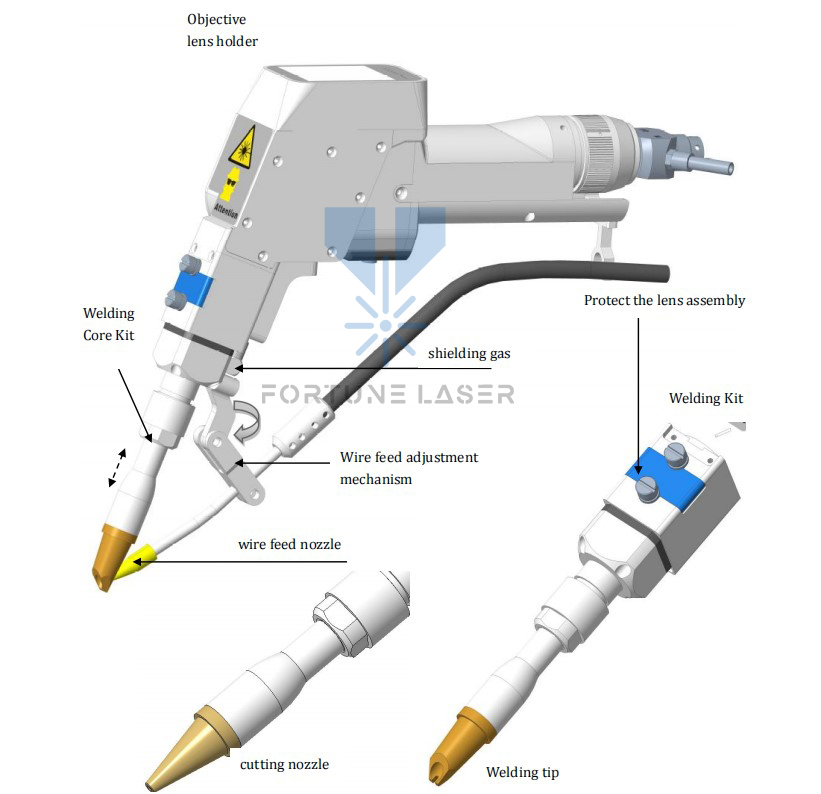

I-Double pendulum handheld welding head Izici:

A.Le nhloko yokushisela inezinzuzo eziqinile ensimbini engagqwali, i-aluminium alloy welding, kanye nezicelo zokushisela amandla amancane naphakathi. Ikhanda lokushisela elingabizi kakhulu.

B.Ikhanda lokushisela lamukela i-X eqhutshwa yi-motor, i-Y-axis vibrating lens, enamamodi amaningi wokushwibeka, futhi i-swing welding ivumela i-workpiece ukuba ibe nokushisela okungavamile, izikhala ezinkulu kanye neminye imingcele yokucubungula, engathuthukisa kakhulu izinga lokushisela.

C. Isakhiwo sangaphakathi sekhanda lokushisela sivalwe ngokuphelele, esingavimbela ingxenye ye-optical ukuba ingangcoliswa uthuli.

D.Izikhithi zokushisela/zokusika ezingazikhethela kanye nezinto zokuhlanza zingafeza ngempela imisebenzi emithathu yokushisela, ukusika nokuhlanza.

E.Ilensi yokuzivikela yamukela isakhiwo sekhabethe, okulula ukusishintsha.

F.Ingakwazi ukuhlonyiswa ngamalaser ahlukahlukene anezixhumi ze-QBH.

G. Usayizi omncane, ukubukeka okuhle nokuzwakala.

Isikrini sokuthinta se-HA siyakhetheka ekhanda lokushisela, elingaxhunyaniswa nesikrini seplathifomu ukuze uthole ulwazi olungcono lokulawula umshini womuntu.

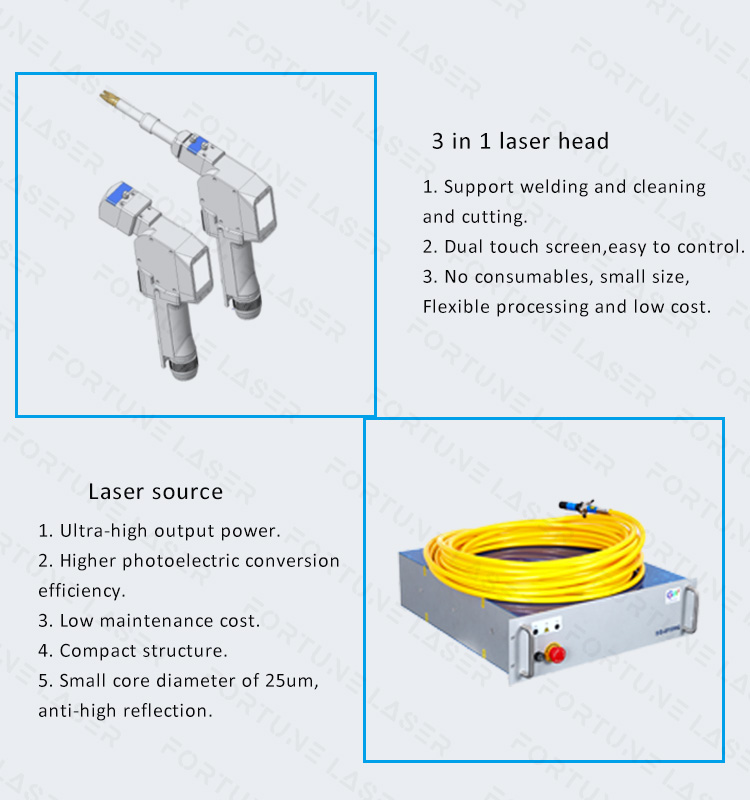

I-Fiber Laser Generator

I-GW (i-JPT, i-Raycus, i-MAX, i-RECI kanye namajeneretha we-laser we-IPG ayakhethwa) enokuguqulwa okuphakeme kwe-photoelectric ukusebenza kahle, izinga lephutha eliphansi, ukusetshenziswa kwamandla okuphansi, ukugcinwa mahhala, kanye nesakhiwo esihlangene.

Idizayini eyakhelwe ngaphakathi ye-Water Chiller

Ingagwema izintambo zezintambo ukuze ivumelane nezindawo eziningi, futhi inemiphumela emihle yokuvikela uthuli kanye ne-anti-condensation. Iphaneli Yokulawula Ehlakaniphile Ibanga lokulungiswa kwamapharamitha eyakhelwe ngaphakathi likhulu, futhi ukuqalisa kokhiye owodwa kulula futhi kulula ukukusebenzisa.

3 Koku-1 Ukuhlanza I-Laser Ephathwayo, Ukushisela, Izicelo Zomshini Wokusika

Umshini we-laser owenziwe ngezinto eziningi usetshenziswa ekukhiqizeni, kwezezimoto, kwezakhishi, emashalofini, kumakheshi, amabhokisi okusabalalisa, ohhavini, ifenisha yensimbi, i-elekthronikhi hardware, ukuxhumana optical, inzwa, izesekeli zezimoto, amazinyo e-porcelain, izibuko, amandla elanga, kanye nokukhiqiza izingxenye ezinembayo.

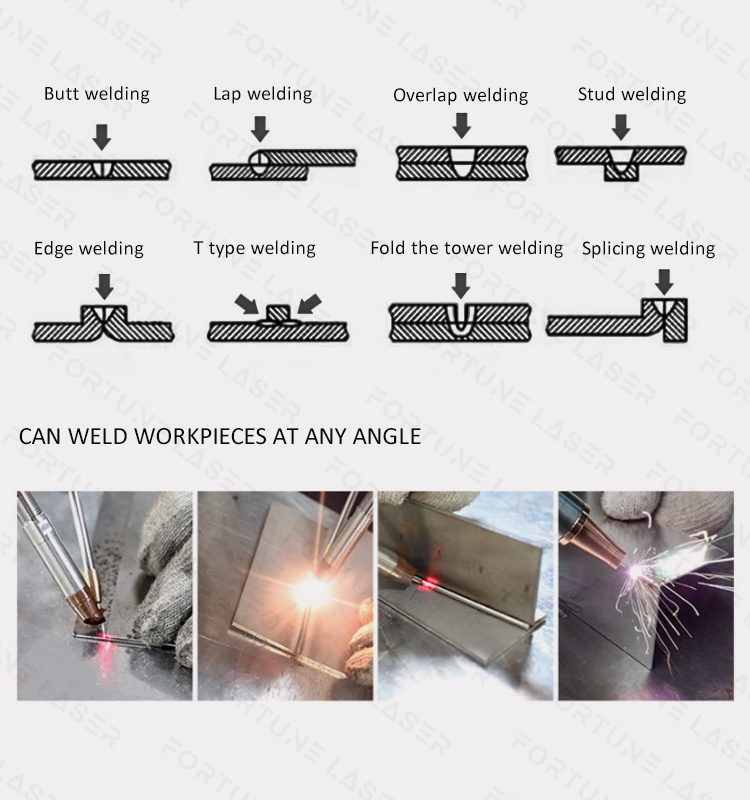

1.Ngesibhamu sokushisela i-laser, iwumshini wokushisela we-laser wokushisela i-aluminium, insimbi engagqwali, i-titanium, igolide, isiliva, ithusi, i-nickel, i-chromium, nezinye izinsimbi noma ama-alloys amaningi, ingasetshenziswa futhi kuma-welds ahlukahlukene phakathi kwezinsimbi ezahlukene, njenge-titanium-igolide, i-copper-brass-copper, i-nickel-copper, i-tickel-copper, i-tickel-copper, i-nickel-copper, i-nickel-copper kanye ne-alloys.

I-2.Ngesibhamu sokuhlanza i-laser, i-laser cleaner ephathekayo yokususa ukugqwala, i-resin, i-coating, uwoyela, amabala, upende, ukungcola kokwelashwa okungaphezulu ngama-hobbyists kanye nokukhiqizwa kwezimboni, inganciphisa ngempumelelo izindleko zokugcinwa komshini futhi ithuthukise umphumela wokuhlanza izimboni.

3.Ngesibhamu sokusika i-laser, iyisisiki esisodwa se-laser esiphathwayo esiphathwayo sazo zonke izinhlobo zokusika izinsimbi.

(Ifanele ipuleti lensimbi elincanyana kuphela.)

Amathathu ku-One Handheld Laser welding yokuhlanza uhlelo lokupakisha ulwazi lomshini wokupakisha

Uchwepheshei-fiber laser welding yokuhlanza umshini wokusikaumkhiqizi webhizinisi lenkonzo yokukhiqiza insimbi. I-laser welder, i-laser cleaner kanye ne-laser cutter ithengiswa e-Algeria, Armenia, Argentina, Austria, Australia, Azerbaijan, Bangladesh, Belgium, Bulgaria, Bolivia, Brazil, Belarus, Canada, Chile, China, Colombia, Czech, Cyprus, Germany, Denmark, , Ecuador, Estonia, Egypt, Spain, Finland, France, Georgia, Greece, Hungary, Indonesia, Ireland, Israel, Ireland, Kuwait, Ireland, Ireland, Hungary, India, Ireland, Jordan, Ireland Lebanon, Latvia, Morocco, Malta, Mexico, Malaysia, Netherlands, Norway, New Zealand, Oman, Peru, Philippines, Poland, Portugal, Paraguay, Qatar, Romania, Russia, Saudi Arabia, Switzerland, Sweden, Singapore, Slovenia, Slovakia, Swaziland, South Africa, Thailand, Tunisia, Turkey, United Kingdom, UAE, USA, Uruguay, Venezuela, Uzbe.

Izishicileli ze-laser eziphathwayo nezihlanzi ze-laser zithandwa kakhulu. Kungakhathaliseki ukuthi ufuna umshini wokushisela noma ithuluzi lokuhlanza ozolisebenzisa, noma uhlele ukuqala ibhizinisi lenkonzo yokushisela nokuhlanza, lo mshini we-laser ongu-3 ku-1 uyisinqumo esihle kakhulu. Sicela usithinte namuhla ukuze uthole imininingwane eyengeziwe.