Izacholo zegolide nezesilivere zibalulekile kubomi babantu, kodwa kungakhathaliseki ukuba zibiza kangakanani na, zikwafuna ukwenziwa ngocoselelo ngabantu ukubonisa umbala wazo ofanelekileyo. Nangona kunjalo, kukho umbandela onzima kakhulu ekusebenzeni kwezacholo, oko kukuthi,welding laser. Lumka kakhulu xa uthengisa, kwaye ufuna ukubona kakuhle kakhulu.

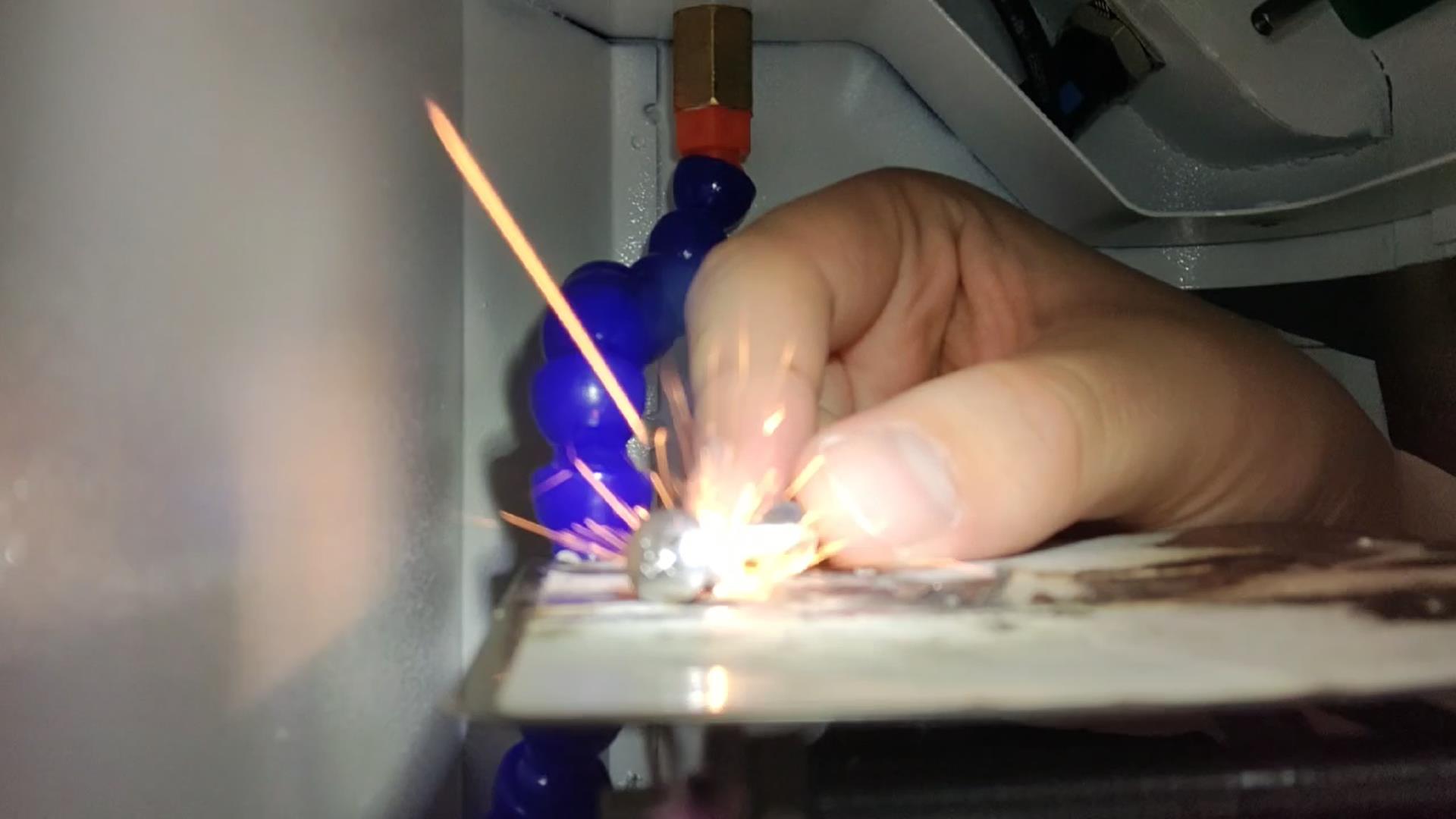

Jewelry laser spot welding machineisetyenziswa ikakhulu ukulungisa imingxunya kunye namadyunguza e-welding yegolide kunye nezacholo zesilivere. Ukuwelda indawo yeLaser yenye yezinto ezibalulekileyo ekusetyenzisweni kobuchwepheshe bokusetyenzwa kwe-laser. Ubushushu busasazeka ngaphakathi ngaphakathi ngokuqhutywa kwe-thermal, kwaye ngokulawula iiparamitha ezinje ngobubanzi, amandla, amandla aphezulu kunye nokuphindaphinda ukuphindaphinda kwe-laser pulse, i-workpiece iyanyibilika ukwenza ichibi elithile elityhidiweyo. Ngenxa yeenzuzo zayo ezizodwa, isetyenziswe ngempumelelo kwigolide kunye nesilivere yobucwebe bokucutshungulwa kunye ne-welding ye-micro and small parts.

Umatshini wokuwelda indawo laserikakhulu yenziwe ngelaser, unikezelo lwamandla kunye nolawulo, umatshini wokupholisa, isikhokelo sokukhanya kunye nokugxila, kunye ne-binocular stereomicroscopic observation. Inokwakheka okudibeneyo kunye nomthamo omncinci. Amandla e-Laser, i-pulse frequency kunye nobubanzi be-pulse inokubekwa kwangaphambili kwaye itshintshwe ngephaneli yokulawula. Umbane wamandla wamkela isakhiwo se-drawer, ekulula ukusisusa, ngoko ke izixhobo zilula ukusebenza nokugcina. Akukho mfuneko yokuzalisa i-solder, isantya esiphezulu se-welding, uqhagamshelwano oluthembekileyo, i-deformation encinci ye-workpiece, ukubunjwa okuhle.

Iimpawu zomatshini we-laser welding jewelry:

● Amandla, ububanzi be-pulse, frequency, ubukhulu bendawo, njl. Iiparameters zihlengahlengiswa ngama-levers kwigumbi elivaliweyo, elilula kwaye lisebenza kakuhle.

● Ukusebenzisa i-ceramic concentrator cavity evela e-UK, ekwazi ukumelana nokubola, ubushushu obuphezulu, kunye nokusebenza kakuhle kokuguqulwa kweefoto zombane.

● Ukusebenzisa inkqubo ye-shading ye-automatic ehamba phambili yehlabathi ukuphelisa ukucaphuka kwamehlo ngexesha leeyure zokusebenza.

● Nge-24-iyure eqhubekayo yokukwazi ukusebenza, umatshini wonke unomsebenzi ozinzile kwaye awugcini ukugcinwa kwiiyure ze-10,000.

● Uyilo olwenziwe ngabantu, ngokuhambelana ne-ergonomics, ixesha elide lisebenza ngaphandle kokudinwa.

Njengoko ubucwebe begolide kunye nesilivere emarikeni busiya busiba buthathaka kwaye bubuthathaka, iingxaki ezinjengokwaphuka kunye nokuqhekeka zihlala zisenzeka ngexesha lemveliso okanye inkqubo yokunxiba. Iukulungiswa kwezacholoihlala ifuna iteknoloji ye-laser welding.oomatshini bokuwelda i-laser yobucwebebaye badlala indima ebalulekileyo kwimarike yolu shishino. Ngenxa yobuninzi bezacholo zetsimbi ezithambileyo, iinkqubo ezininzi zigqitywe ngobuchwepheshe obuphezulu be-laser welding.

Ke kutheni na ubucwebe usebenzisa oomatshini bokuwelda laser? Yahluke njani kubugcisa bemveli?

Inkqubo yokuvelisa ubucwebe bemveli kukunyibilikisa isinyithi kwiqondo lobushushu eliphezulu, emva koko udibanise kwaye uyiqhube. Le nkqubo ye-welding idla ngokubangela ukutshisa umnyama kwizinto zokugqoka, ezingenakususwa ngokupheleleyo nangemva kokucoca kamva, kwaye ngamanye amaxesha kubangela ubucwebe bokuqala ngokwabo. I-gloss iyancipha, echaphazela kakhulu i-aesthetics yobucwebe. Kwiingxaki ezijongene nokucubungula ubucwebe okanye ukulungiswa kwe-laser welding, ijewelry laser welding machineinokusombulula ingxaki ngokulula nangokukhawuleza. Kukulungisa indawo yokukhanya kwindawo yokuwelda ubucwebe obufana negolide nesilivere, ukwandisa indawo yokuwelda ngomngxuma wokujonga, kwaye uqhubele phambili ukusetyenzwa kwindawo ekufuneka kusetyenzwe ngayo ukuwelda indawo.

Ziziphi iingenelo zokusebenzisa itekhnoloji ye-laser ye-welding kwiprosesa yezacholo kunye nokulungiswa?

Ngokusisiseko, i-laser spot welding luhlobo lwe-thermal conductivity, enempembelelo encinci ye-thermal kwi-jewelry, i-solder encinci ye-solder, kwaye ayiyi kungcolisa ezinye iindawo. Ukongeza, le teknoloji iya kusebenzisana nolawulo lwenkqubo yokuphucula ukusebenza okuzinzileyo komatshini kunye nezixhobo. Iyakwazi ukulawula ukuphindaphinda kunye nokuqina kokukhanya ukuqinisekisa impembelelo ye-welding yezakhiwo eziyinkimbinkimbi okanye iinkcukacha, ukuphucula ukuchaneka komsebenzi we-welding, kwaye ugweme i-welding yendabuko emzimbeni womntu. umonakalo wamehlo.

Ukuba ufuna ukufunda ngakumbi malunga nomatshini we-laser welding, okanye ufuna ukukuthengela umatshini we-laser welding, nceda ushiye umyalezo kwiwebhusayithi yethu kwaye usithumelele i-imeyile ngqo!

Ixesha lokuposa: Nov-26-2022