Xa kufikwa koomatshini bokuwelda i-laser, kukho iindidi ezininzi kwimarike. Phakathi kwazo, iinketho ezimbini ezithandwayo ziimatshini zokuwelda ze-laser ezipholile ngamanzi kunye ne-air-cooled handheld laser welding machine. Oomatshini ababini abahlukanga kuphela kwiindlela zabo zokupholisa, kodwa nakwezinye iindlela ezininzi. Kweli nqaku, siza kuphonononga umahluko phakathi kwezi ntlobo zimbini zoomatshini bokuwelda, ukuba bapholiswe njani, kunye nolwahlulo oluhambelanayo loqwalaselo.

Makhe siqale sihlolisise iindlela zokupholisa ezisetyenziswa ngaba matshini. Oomatshini bokuwelda belaser abapholiswe ngamanzi, njengoko igama libonisa, baxhotyiswe ngetanki yamanzi ngeenjongo zokupholisa. Kwelinye icala,ukuwelda i-laser ephethwe ngomoya epholileyooomatshini abafuni itanki yamanzi. Endaweni yoko, isebenzisa ifeni ukuqondisa umoya kwintloko ye-welding ukutshabalalisa ubushushu. Lo mahluko kwiindlela zokupholisa kubangela ukungafani okuphawulekayo kwimiba efana nokubonakala kunye nomthamo.

Omnye umahluko ophawulekayo bubukhulu kunye nobunzima baba matshini. Kuba ingekho itanki yamanzi, oomatshini bokuwelda belaser abapholiswe ngomoya bancinci kwaye bakhaphukhaphu kunesandla esibanjwe ngamanzi.oomatshini bokuwelda laser. Abasebenzisi abaninzi bafumana oku kunenzuzo kuba kunokusebenza ngokulula ngezandla zombini. Ubungakanani be-compact yenza ukuba intshukumo ibe lula kakhulu, ngakumbi kwiimeko ze-welding apho ukunyakaza rhoqo kwezixhobo kuyadingeka. Oomatshini bokuwelda belaser abapholiswe ngamanzi, kwelinye icala, nangona bebakhulu kwaye benzima, bahlala benamavili ajikelezayo ezantsi. Olu phawu lwenza kube lula ukusebenza kunye nokuthutha ukusuka kwindawo ukuya kwenye.

Enye inkalo ebalulekileyo ekufuneka iqwalaselwe yinkqubo yofakelo. Ekubeni oomatshini bokuwelda belaser abapholiswe ngamanzi badinga itanki yamanzi, ukufakwa kwabo kuyinkimbinkimbi kunomoya opholileyo. Itanki yamanzi kufuneka idibaniswe kwaye idibaniswe ngokufanelekileyo kwinkqubo yonke, eyongeza inyathelo elongezelelweyo kwinkqubo yokufakela. Ngokwahlukileyo, i-air-cooledoomatshini bokuwelda belaser ngesandlaayifuni ukufakwa kwetanki yamanzi, ukwenza lula inkqubo yokumisela. Oku kwenza ukuba oomatshini abapholileyo bomoya babe yindlela efanelekileyo ngakumbi kubasebenzisi ababeka phambili ukukhululeka kunye nokusebenza kakuhle kwenkqubo ye-welding.

Ukugcinwa ngomnye umahluko phakathi kwezi ntlobo zimbini ze-welders. Oomatshini bokuwelda belaser abapholiswe ngamanzi badinga ukubekwa esweni rhoqo kunye nokugcinwa kwetanki yamanzi. Oku kubandakanya ukucoca rhoqo kunye nokutshintsha kwamanzi ukuqinisekisa ukusebenza kakuhle. Okuchasene,umoya-opholileyo laser welder ngesandlaakukho mfuneko yokugcinwa kwamanzi. Ekuphela kwento efunekayo kukugcina ifeni kunye nemibhobho yomoya icocekile ukuqinisekisa ukupholisa okufanelekileyo. Oku kulula ukugcinwa kwenza oomatshini abapholileyo emoyeni babe yinto ekhangayo ngakumbi kwabo bakhetha umatshini ongenaxhala.

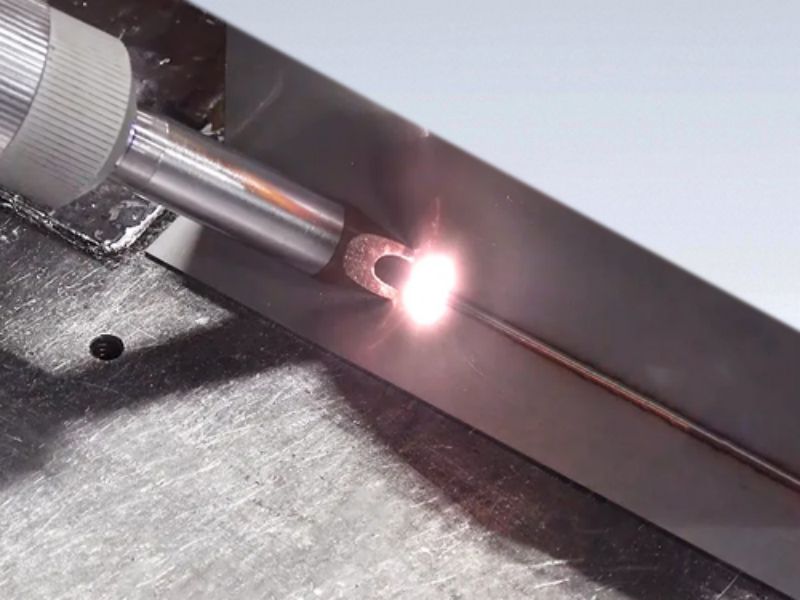

Into ephambili engenakuhoywa kukusebenza kwendlela yokupholisa. Amanzi apholileumatshini welding laser weldingiza netanki yamanzi enika ukupholisa okusebenzayo nokusebenzayo. Amanzi anomthamo ophezulu wobushushu obukhethekileyo, nto leyo ethetha ukuba anokufunxa ubushushu obukhulu phambi kokuba ubushushu bawo bunyuke kakhulu. Oku kuvumela umatshini ukuba asebenze ngokuqhubekayo ngaphandle kokutshisa. Kwelinye icala, oomatshini bokuwelda bezandla be-laser baxhomekeke kuphela kubalandeli ngokutshabalalisa ubushushu. Nangona kusebenza, ukupholisa okunikezelwa yifeni kusenokungasebenzi njengesixhobo sokupholisa amanzi. Oku kunokubangela imida encinci efana nokunciphisa ixesha eliqhubekayo lokusebenza ngenxa yokushisa okunokwenzeka.

Ukushwankathela, umahluko phakathi koomatshini ababini abancinci be-laser welding kunye neendlela ezahlukeneyo zokupholisa zilele kumahluko kwinkqubo yokupholisa ngokwayo kunye noqwalaselo oluhambelanayo. Oomatshini bokuwelda belaser abapholiswe ngamanzi badinga itanki lamanzi lokupholisa, ngelixa iintlobo ezipholileyo zomoya zisebenzisa iifeni. Lo mahluko usisiseko uchaphazela imiba emininzi, kubandakanywa ubungakanani, ubunzima, inkqubo yokufakela, iimfuno zokugcina kunye nokusebenza kakuhle kokupholisa. Ngokuqonda lo mahluko, abasebenzisi banokwenza izigqibo ezinolwazi ngokusekelwe kwiimfuno zabo ze-welding kunye nezinto eziphambili.

Ixesha lokuposa: Oct-09-2023