Insimbi engenasici isetyenziswa ngokubanzi kumashishini ahlukeneyo ngenxa yeempawu zayo ezizodwa ezifana nokuxhathisa ukubola kunye nokubumba. Ngokuhambela phambili kwetekhnoloji, ukuwelda kwelaser kuye kwaba yindlela entsha yokuwelda, enezibonelelo ezininzi xa kuthelekiswa nobugcisa bemveli bokuwelda. Nangona kunjalo, omnye wemingeni yewelding laserkukuguqulwa kwentsimbi engenasici. Kweli nqaku, siza kuxubusha indlela yokuphepha intsimbi ye-laser welding deformation kwaye sijonge kwizinto ezinxulumene nayo.

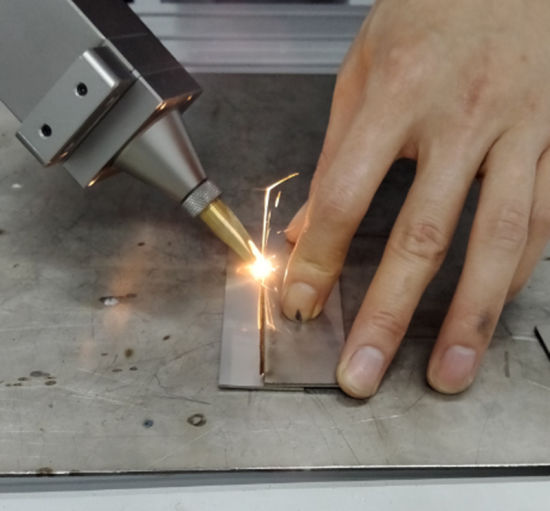

Okokuqala, kuyimfuneko ukuqonda ukuba kutheni i-laser welding ibangela ukuguqulwa kwentsimbi engenasici. Ukuwelda kweLaser kubandakanya ukusebenzisa umqadi welaser one-eneji ephezulu ukunyibilika kunye nokuxubha imiphezulu yamaqhekeza amabini esinyithi kunye. Ngethuba le nkqubo, ukufudumeza ngokukhawuleza kunye nokupholisa kubangela ukuphazamiseka kwe-thermal, okubangela ukuguqulwa kwendawo edibeneyo. Nangona oku kubonakala kungenakuphepheka, kukho intaphane yamanyathelo anokuthathwa ukuze kuncitshiswe okanye kupheliswe ukugqwetheka.

Elinye lamanyathelo okuqala ekuphepheniwelding laserukugqwetheka kukukhetha ngononophelo iiparamitha ezifanelekileyo ze-laser welding. Izinto ezinje ngamandla e-laser, isantya se-welding, kunye nokugxilwa komqadi kufuneka kuphuculwe ukufezekisa umgangatho ofunekayo we-weld. Ngokulungelelanisa ezi parameters, igalelo lobushushu linokulawulwa kwaye i-thermal deformation ebangela ukuphazamiseka kunokunciphisa. Ukongeza, ukusebenzisa imowudi ye-pulsed kunemowudi yamaza eqhubekayo kunceda ukunciphisa indawo echaphazelekayo yobushushu kunye nokuguqulwa okulandelayo.

Olunye uqwalaselo olubalulekileyo luyilo lwekhonkco ngokwayo. Ubume, ubungakanani kunye nokucwangciswa kokubambisana kunokuchaphazela kakhulu inani le-deformation eyenzeka ngexeshawelding laser. Ukunciphisa ukuphazamiseka, kucetyiswa ukuba usebenzise i-welds ebanzi kwaye ugweme iikona ezibukhali okanye ezibukhali. Oku kusasaza ubushushu ngokulinganayo kwaye kunciphisa uxinzelelo lwe-thermal. Ukongezelela, ukusetyenziswa kwee-welds ze-fillet (i-welds ezine-concave okanye i-convex curve shapes) nazo zinceda ukunciphisa ukuphazamiseka.

Ukongeza kwiiparamitha ze-welding kunye noyilo oludibeneyo, ukhetho lobunzima bezinto eziphathekayo lukwadlala indima ebalulekileyo ekuthinteleni ukugqwetheka. Amashiti entsimbi etyebileyo atyekele ngakumbi kwi-deformation ngenxa ye-conductivity ephezulu ye-thermal. Ukunciphisa oku, kucetyiswa ukuba usebenzise amacwecwe amancinci angenasici okanye usebenzise i-heat sink okanye inkqubo yokupholisa ngexesha lenkqubo ye-soldering. Ezi ndlela zokupholisa zinceda ukukhupha ubushushu obugqithisileyo kunye nokunciphisa i-gradients ezishisayo, ukunciphisa ukuphazamiseka.

Ukongeza, ukusebenzisa iindlela ezifanelekileyo zokulungiswa kunye nokubambelela kunokunceda kakhulu ukunqanda ukuphazamiseka kwe-laser welding. I-fixture ibhekisela ekumiseni nasekulungiseni i-workpiece ngexesha lenkqubo ye-welding. Kubalulekile ukuqinisekisa ukuba i-workpiece ixhaswa ngokwaneleyo kwaye ihambelana nokuthintela nayiphi na intshukumo okanye i-warping ngexesha le-welding. Ukubamba, kwelinye icala, kubandakanya ukubamba i-workpiece endaweni usebenzisa i-jigs okanye izixhobo ezenziwe ngokukodwa. I-clamping efanelekileyo inceda ukugcina inqanaba elifunekayo lokulungelelaniswa kunye nokunciphisa ithuba lokulwa.

Ekugqibeleni, unyango lwe-post-weld heat lungasetyenziselwa ukukhulula uxinzelelo olushiyekileyo kunye nokunciphisa ukuphazamiseka. I-Anealing, ukunciphisa uxinzelelo, kunye neenkqubo ezilula zokupholisa umoya zinceda ukuzinzisa izakhiwo ezidityanisiweyo kunye nokunciphisa ukugqwetheka. Ukusetyenziswa kwezixhobo ezikhethekileyo zonyango lobushushu kunye nobuchule kunokubonelela ngebhayisikile ye-thermal efunekayo ukuqinisekisa ukuba insimbi engenasici edibeneyo ihlala izinzile kwaye ikhululekile kwi-deformation.

Isishwankathelo,welding laserinika iingenelo ezininzi kwiindlela zokuwelda zemveli ngokwesantya, ukuchaneka kunye nomgangatho. Nangona kunjalo, ukuguqulwa kwensimbi engenasici kubangela imingeni kwinkqubo ye-laser welding. I-stainless steel laser welding distorations inokusingathwa ngokufanelekileyo ngokukhethwa ngokucokisekileyo kunye nokulungiswa kweeparameters ze-welding, uyilo lolungelelwaniso olufanelekileyo oludibeneyo, ukuqwalaselwa kobunzima bezinto eziphathekayo, ukuphunyezwa kokulungiswa okufanelekileyo kunye nobuchule bokubamba, kunye nokusetyenziswa kwonyango lokushisa emva kwe-weld. Le milinganiselo, idibaniswe neempawu zendalo zensimbi engenasici, igalelo kwii-welds ezikumgangatho ophezulu kunye nokuphazamiseka okuncinci.

Ukuba ufuna ukufunda ngakumbi malunga ne-laser welding, okanye ufuna ukukuthengela umatshini we-laser welding, nceda ushiye umyalezo kwiwebhusayithi yethu kwaye usithumelele i-imeyile ngqo!

Ixesha lokuposa: Jul-18-2023