Ukuwelda kweLaserngomnye wemiba ebalulekileyo ekusetyenzisweni kobuchwepheshe bokusetyenzwa kwe-laser. Isetyenziselwa ikakhulu ukuwelda izinto ezibhityileyo ezinodonga kunye nesantya esisezantsi. Inkqubo ye-welding yeyohlobo lokuqhuba ubushushu, oko kukuthi, i-laser radiation itshisa umphezulu we-workpiece, kwaye ubushushu bomhlaba busasazeka ngaphakathi ngokuqhuba ubushushu. Ngokulawula iiparamitha ezinjengobubanzi, amandla, amandla encopho kunye nokuphindaphinda ukuphindaphinda kwe-laser pulse, i-Workpiece iyanyibilika ukwenza ichibi elithile elityhidiweyo. Isetyenziswa kakhulu kwimveliso yoomatshini, i-aerospace, ishishini leemoto, i-powder metallurgy, i-biomedical microelectronics industry kunye namanye amacandelo.

Ngokukhula okugqabhukileyo kwezithuthi zamandla amatsha, ukwanda kwemveliso yebhetri yamandla kuqhube ukukhula kwe-laser welding. Ukusukela kwisiqingatha sesibini sika-2018, i-laser welding ephathwayo iye yafumana ukuthandwa ngokuthe ngcembe, kwaye ibe yindawo eqaqambileyo kwimakethi ye-laser welding kwisiqingatha sokuqala salo nyaka. Ngomgangatho wangoku wobugcisa kunye neemeko zesicelo zeukuwelda ngelaser ngesandla, kunokwenzeka kakhulu ukubuyisela umatshini wokuwelda we-TIG wendabuko (i-argon arc welding) kwimarike.

Kule minyaka yangoku,i-fiber lasersbaye benza inkqubela enkulu, kwaye iingenelo zabo ikakhulu zibandakanya: izinga eliphezulu lokuguqulwa kweefoto zombane, ukutshatyalaliswa kobushushu okukhawulezayo, ukuguquguquka okulungileyo, amandla anamandla okuchasana nokuphazamiseka, ixabiso eliphantsi, ubomi obude, ukulungiswa-free, ukugcinwa-free, uzinzo oluphezulu, ubungakanani obuncinci, Isixhobo sokuwelda i-laser ebanjwe ngesandla usebenzisa i-fiber lasers nayo iphuhliswe ngokuthe ngcembe.

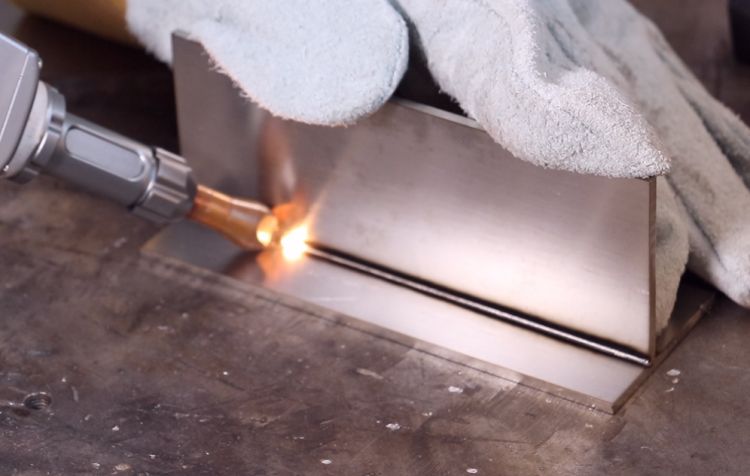

Ukuwelda kweLaserifuna ukuchaneka okuphezulu kwendibano yomsebenzi, kwaye i-weld seam ithande ukuba neziphene. Ukusombulula le ngxaki, umyili ubhekiselele kwisixhobo sokuwelda i-laser yenqwelomoya ekhethekileyo ukuphuhlisa isixhobo sokuwelda i-laser esiphathwayo esinendawo ejingizayo. I-laser ikwimo ye "8" okanye "0" uhlobo lwe-swing inokunciphisa ukuchaneka kwendibano ye-workpiece kunye nokunyusa ukungena kwe-welding. Emva koluhlu lokuphucula kunye nokuphucula, izixhobo ze-laser eziphathwayo eziqhelekileyo zinamandla e-0.5-1.5KW, kwaye ubungakanani kunye nobunzima bezixhobo zilingana noomatshini bokuwelda be-argon, abanokuthi badibanise iipleyiti zetsimbi ze-3mm okanye ngaphantsi. Ukuze kulungiswe iintsilelo zamandla angonelanga we-welding yezakhiwo ze-laser welding, kwiminyaka yakutshanje, abavelisi bezixhobo baye badibanisa izixhobo ezizenzekelayo zokutyisa ucingo ngesiseko se-laser welding, kunye nokuphuhliswa kwezixhobo ze-laser zokuzalisa i-laser eziphathwayo ezinokutya ngokuzenzekelayo iingcingo, ezihlangabezana neemfuno zeepleyiti zentsimbi ezibhityileyo ezingaphantsi kwe-4m. I-welding inokuthi ithathe indawo kwaye idlule i-argon arc welding, iqonde isantya esiphezulu, igalelo lobushushu eliphantsi, i-deformation encinci, i-welding yexabiso eliphantsi lokusingqongileyo, kunye neendleko zokuvelisa zingaphantsi kunezo ze-argon arc welding phantsi kweemeko ezifanayo.

Xa usebenza, intloko ebanjwe ngesandla kumatshini we-welding inobubanzi bokuskena, kwaye indawo yayo yobubanzi incinci, ngoko xa i-welding, ihlola ukusuka kwelinye iphuzu ukuya kwelinye inqaku ngomgca, ngaloo ndlela yenza i-weld bead. Xa kuthelekiswa nomatshini wokuwelda obandayo oqhelekileyo, isantya sokuwelda se-laser esibambe ngesandla siya kukhawuleza, kwaye inkqubo ye-welding ye-shot-shot inquma ukuba ifaneleke ngakumbi kwi-welding mass of seams emide ethe tye.

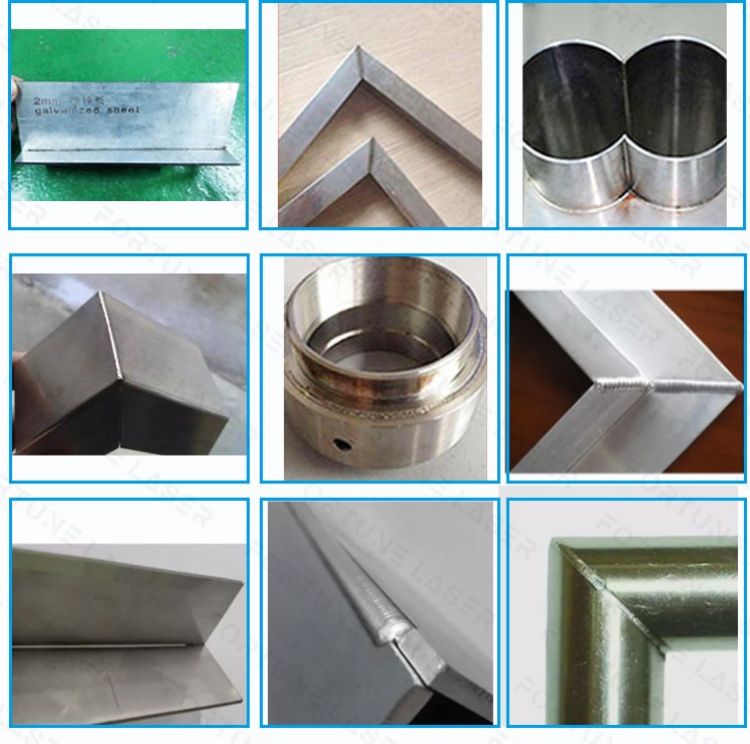

Kwaye umatshini we-laser welding obambe ngesandla uthatha indawo encinci, kwaye ngokuqhelekileyo uxhotyiswe ngeentlobo zeentloko eziphathwa ngesandla. Ngokweemfuno ezahlukeneyo zamacandelo esinyithi afana ne-welding yangaphandle, i-welding yangaphakathi, i-right-angle welding, i-welding edge emxinwa, kunye ne-welding enkulu yamabala, iintloko ze-welding ezahlukeneyo eziphathwayo zingakhethwa. Iimveliso ezinokuthi zifakwe kwi-welded zihlukeneyo, kwaye ubume bemveliso buguquguqukayo. Kwiindibano zocweyo zemveliso ezibandakanyeka ekusetyenzweni komgangatho omncinci kunye ne-welding engeyiyo enkulu, oomatshini bokuwelda bezandla be-laser ngokuqinisekileyo lolona khetho lungcono.

Izixhobo zetsimbi ezahlukeneyo zineendawo ezahlukeneyo zokunyibilika: ukusetwa kweeparamitha ze-welding kwiintlobo ezahlukeneyo zezixhobo ze-welding zinobunzima, kwaye iimpawu ze-thermophysical ze-welding materials ziya kubonisa ukuhluka okuhlukeneyo kunye nokutshintsha kweqondo lokushisa; izinga lokufunxwa kweentlobo ezahlukeneyo zezixhobo ze-laser nazo ziya kwahluka kunye Utshintsho lobushushu lubonisa iiyantlukwano ezahlukeneyo; i-solder joint melting kunye nokuguqulwa kwesakhiwo sendawo echaphazelekayo ukushisa ngexesha lokuqiniswa kwe-weldment; iziphene ezidibeneyo zomshini we-laser welding welding, uxinzelelo lwe-welding inxaxheba kunye ne-thermal deformation, njl.

Ziziphi izinto ezinokuthiumatshini welding laser weldingweld?

1. Intsimbi engatyiwayo

Insimbi engenasici ine-coefficient ephezulu yokwandiswa kwe-thermal, kwaye ijwayele ukutshisa ngexesha le-welding. Xa indawo echaphazeleke bubushushu incinci, iya kubangela iingxaki ezinzulu zokuguqula. Nangona kunjalo, ubushushu obuveliswa ngumatshini we-laser welding we-handheld ngexesha lenkqubo yonke ye-welding iphantsi. Idityaniswe ne-conductivity ephantsi ye-thermal, izinga eliphezulu lokufunxa amandla kunye nempumelelo yokunyibilika kwensimbi engenasici, eyenziwe kakuhle, i-welds egudileyo kunye nenhle inokufumaneka emva kwe-welding.

2. Intsimbi yekhabhoni

Intsimbi yekhabhoni eqhelekileyo inokudityaniswa ngokuthe ngqo nge-laser ephathwayo ngesandla, umphumo unokuthelekiswa nentsimbi yentsimbi, kwaye indawo echatshazelwe bubushushu incinci, kodwa xa ukuwelda okuphakathi kunye nentsimbi yekhabhoni ephezulu, ubushushu obushiyekileyo buphezulu ngokwentelekiso, ngoko ke kusafuneka ukuwelda phambi kokuwelda. Ukushisa kwangaphambili kunye nokugcinwa kobushushu emva kwe-welding ukukhulula uxinzelelo kunye nokuphepha iintanda. Apha singakwazi ukuthetha ngomatshini we-welding obandayo. Intsimbi ephakathi kunye nephezulu yekhabhoni inokudityaniswa okanye ilungiswe ngesantya esicothayo kunye ne-welding ebandayo kunye nentsimbi yokuphosa intsimbi. Ngokubhekiselele kulawulo lobushushu, ulawulo lobushushu, kunye nolawulo lobushushu, umatshini wokuwelda obandayo unokufundisa i-laser welding ebambe ngesandla isebenze ngokufanelekileyo kwintsalela yobushushu emva kwe-welding.

3. Die intsimbi

Kufanelekile ukuwelda iintlobo ezahlukeneyo zentsimbi yokufa, kwaye umphumo we-welding ulungile kakhulu.

4. I-Aluminiyam kunye ne-aluminium ingxubevange

I-aluminium kunye ne-aluminium alloys zizinto ezibonisa kakhulu, kwaye i-porosity inokuvela kwi-pool etyhidiweyo okanye kwiingcambu ngexesha le-welding. Xa kuthelekiswa nezixhobo zetsimbi zangaphambili, i-aluminium kunye ne-aluminium alloys ineemfuno eziphezulu zeeparitha, kodwa nje ukuba iiparamitha ezikhethiweyo ze-welding zifanelekile, i-weld seam eneempawu ezifanayo zokwenza isiseko sesinyithi sinokufumaneka.

5. Ubhedu kunye ne-alloy yobhedu

I-thermal conductivity yobhedu inamandla kakhulu, kwaye kulula ukubangela ukungena okungaphelelanga kunye nokudibanisa inxalenye ngexesha le-welding. Ngokuqhelekileyo, izinto zobhedu zifudumala ngexesha lenkqubo ye-welding ukuncedisa i-welding. Apha sithetha ngezinto zobhedu ezibhityileyo. I-laser ebanjwe ngesandla ingadibanisa ngokuthe ngqo i-Welding, ngenxa yamandla ayo agxininisekile kunye nesantya se-welding ekhawulezayo, ayichatshazelwa kangako yi-thermal conductivity ephezulu yobhedu.

6. Ukuwelda phakathi kwezinto ezingafaniyo

Umatshini we-laser welding welding unokuqhutywa phakathi kweentlobo ezahlukeneyo zetsimbi ezingafaniyo, ezifana ne-copper-nickel, i-nickel-titanium, i-copper-titanium, i-titanium-molybdenum, i-brass-copper, i-carbon steel-copper ephantsi kunye nezinye iintsimbi ezingafaniyo. I-laser welding inokuqhutywa phantsi kwayo nayiphi na imeko (igesi okanye ubushushu).

Umatshini wokuwelda we-laser ophathwa ngesandla okwangoku uyimveliso esetyenziswa kakhulu kwishishini lokuwelda, ikakhulu kuba nangona esi sixhobo sikhangeleka zibiza kakhulu, sinokusindisa iindleko zabasebenzi kakuhle kakhulu. Iindleko zomsebenzi weentsimbi zixabisa kakhulu. Ukusebenzisa oku Imveliso isombulula ingxaki yokuqashwa kwamaxabiso abizayo kwaye anzima. Ngapha koko, umatshini we-laser welding obambe ngesandla uphumelele indumiso evumelanayo kumawakawaka abathengi ngenxa yobomi bayo obude kunye nokusetyenziswa kwamandla aphantsi.

Ukuba ufuna ukufunda ngakumbi malunga nokucoca i-laser, okanye ufuna ukukuthengela umatshini wokucoca i-laser, nceda ushiye umyalezo kwiwebhusayithi yethu kwaye usithumelele i-imeyile ngqo!

Ixesha lokuposa: Dec-03-2022