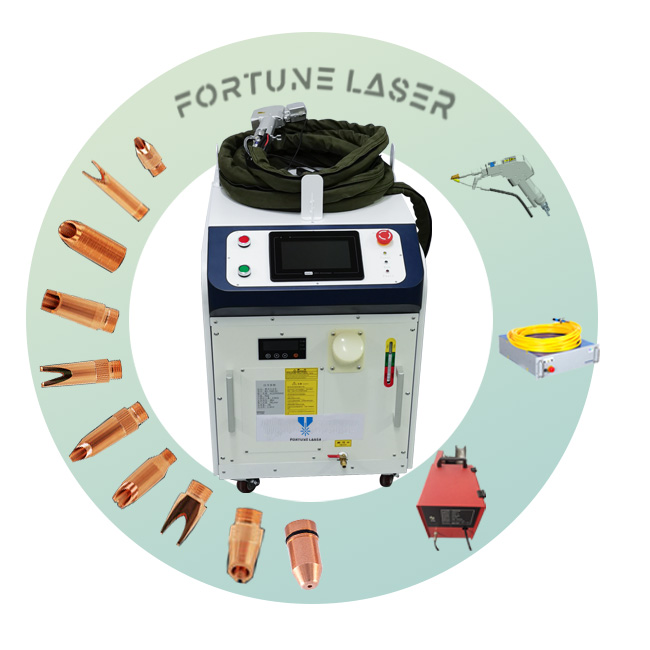

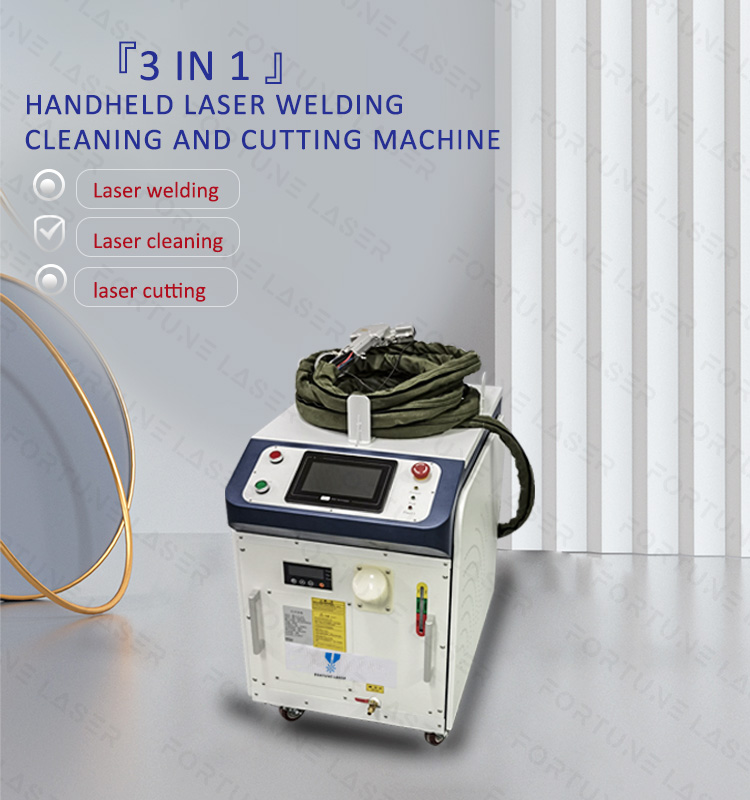

I-Handheld 3 kwi-1 i-Laser Welding Cleaning Cutting Machine

I-Handheld 3 kwi-1 i-Laser Welding Cleaning Cutting Machine

3 Kwi-1 Handheld Laser Cutting, Welding, Cleaning Machine Features

1. Njengoko aisicoci laser, yindlela yokucoca "eluhlaza". Akufuneki ukusebenzisa nayiphi na i-ejenti yeekhemikhali kunye nesisombululo sokucoca. Inkunkuma ecociweyo ngumgubo oqinileyo. Incinci, kulula ukuyigcina kwaye inokuphinda isetyenziswe. Iyakwazi ukusombulula ngokulula ingxaki yongcoliseko lwendalo olubangelwa kukucocwa kweekhemikhali.

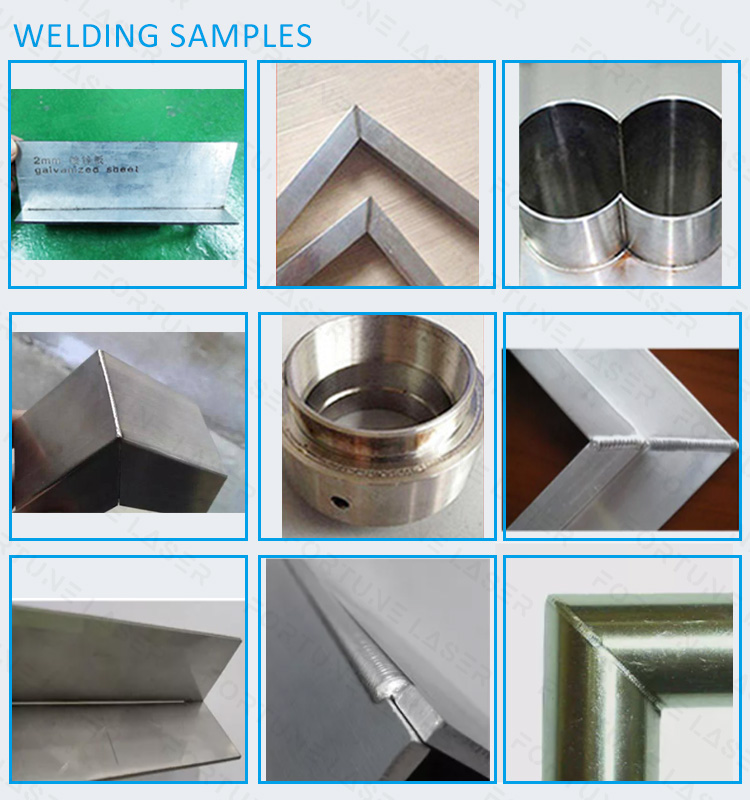

2. Njengoko alaser welder, i-welding seam igudile kwaye intle, akukho mfuneko yokupolisha, akukho deformation okanye i-welding scar, i-welding eqinile yenxalenye. Gcina ixesha kwaye uphucule ukusebenza kakuhle.

3. Njengoko aumsiki laser, kulula kakhulu ukusebenza ukusika zonke iintlobo zesinyithi.

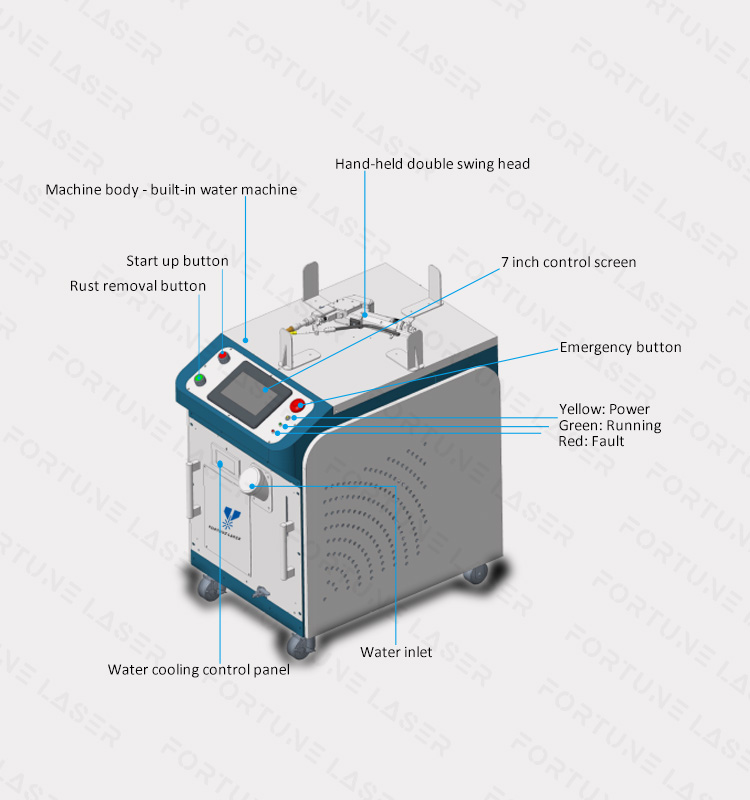

I-4.I-laser gun ephathekayo inesakhiwo esilula esiphathwayo kwaye kulula ukuyiphatha. Ixhotyiswe ngesikrini sokuchukumisa, esilungele ukutshintsha iiparitha ngexesha lomsebenzi kunye nokwenza lula ukusebenza. Ubunzima buyi-0.8kg, elula ukuyisebenzisa ngaphandle kokudinwa.

I-5.Yamkela umthombo we-fiber laser oqeqeshiweyo kunye nesantya esisezantsi sempazamo, ukusetyenziswa kwamandla aphantsi, ukugcinwa simahla, kwaye kulula ukudibanisa.

6.Industrial rhoqo lobushushu amanzi okupholisa chiller iyilwe ngokukodwa. I-chiller yamanzi ixhotyiswe ngesihluzo, esinomsebenzi okhuselekileyo, ozinzileyo, kunye nozinzile kunye nobomi obude benkonzo. Inkqubo yokupholisa amanzi eyomeleleyo kwaye ezinzileyo iya kuqinisekisa ukuba umthombo wefiber laser usebenze ngokugqibeleleyo.

7. Uyilo oluphathekayo: I-Compact, uyilo lwe-ergonomic, kunye namavili okuhamba ngokukhululekileyo.

| Fortune Laser Portable 3 in 1 Laser Welding Cleaning Cutting Machine | |||

| Amandla eLaser | 1000W | 1500W | 2000W |

| Umthombo weLaser | GW 25um core idayamitha ifayibha laser(Raycus/JPT/MAX/IPG ngokuzithandela) | ||

| Ubude bamaza (nm) | 1064 - 1080 | ||

| Indlela yeLaser | Laser Welding / Laser Cutting / Laser Ukucoca | ||

| Ubude beFayibha | 10M(inokwenziwa ngokwezifiso) | ||

| Indlela yokusebenza | Ukuqhubekeka / Ukumodareyitha | ||

| Intloko yeLaser | I-Dual Axis | ||

| Ujongano | QBH | ||

| Ububanzi beWelding | 0.2-0.5mm(iyalungiseka) | ||

| Laser Preview | Umboniso odityanisiweyo wokuKhanya okuBomvu | ||

| Iimfuno ze-welding gap | ≤1.2mm | ||

| Ubukhulu be-welding | 0.5-3mm | ||

| Isantya seWelding | 0-120mm/s (iyalungiseka) | ||

| Ubude bokujongwa okuhlanganisiweyo | 75mm | ||

| Ukugxila/Coca Ubude bokuJonga | F150mm/F500mm | ||

| Uluhlu lojingi | 0.1—5mm | ||

| Ujingi rhoqo | 0-300Hz | ||

| Ukupholisa | I-Integrated Water Chiller | ||

| Ulwimi | IsiTshayina / isiNgesi / isiRashiya / isiKorea / kunye nezinye iilwimi njengoko kufuneka. | ||

| Ukunikezwa Amandla | I-AC 220V, 50Hz/60Hz | I-AC 380V, 50Hz/60Hz | |

| Ukumisela iParameter | Iphaneli yokuchukumisa | ||

| Izinto zokuwelda | Intsimbi yeCarbon, iStainless Steel, iAluminiyam, iBrass, iAlloy njl. | ||

| Ubushushu obugciniwe | 10–40°C | ||

| Ukuthobeka kokusingqongileyo | <70% Ngaphandle kokuNxibelelana | ||

| I-LASER WEDING PARAMETERS | ||

| Izinto eziphathekayo | Amandla eLaser (watt) | Ukungena okuphezulu (mm) |

| Yenziwe ngentsimbi eshayinayo | 1000 | 0.5-3 |

| Yenziwe ngentsimbi eshayinayo | 1500 | 0.5-4 |

| Intsimbi yeCarbon | 1000 | 0.5-2.5 |

| Intsimbi yeCarbon | 1500 | 0.5-3.5 |

| Ingxubevange yeAluminiyam | 1000 | 0.5-2.5 |

| Ingxubevange yeAluminiyam | 1500 | 0.5-3 |

| Iphepha eliGalvanized | 1000 | 0.5-1.2 |

| Iphepha eliGalvanized | 1500 | 0.5-1.8 |

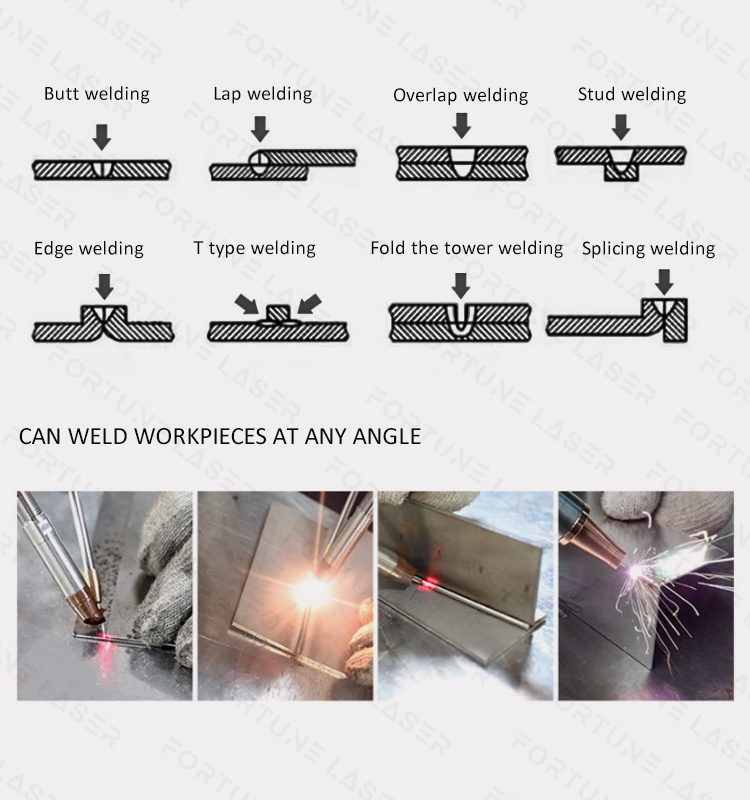

Umpu we-laser ophethwe ngesandla unokwenza i-welding, ukucoca, kunye nokusika kunye nomlawuli ohlakaniphile, kulula ukuyisebenzisa kumatshini oguquguqukayo, ophathwayo kunye nobukhulu obuncinci, ixabiso eliphantsi ngaphandle kokusetyenziswa. Abasebenzisi banokuseta iiparamitha ngesikrini sokuchukumisa kwisibhamu se-laser, esilungele kakhulu kwaye kulula ukuyisebenzisa.

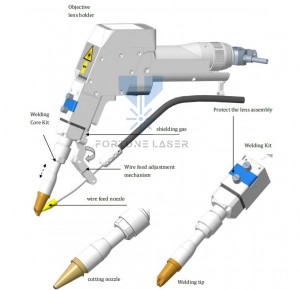

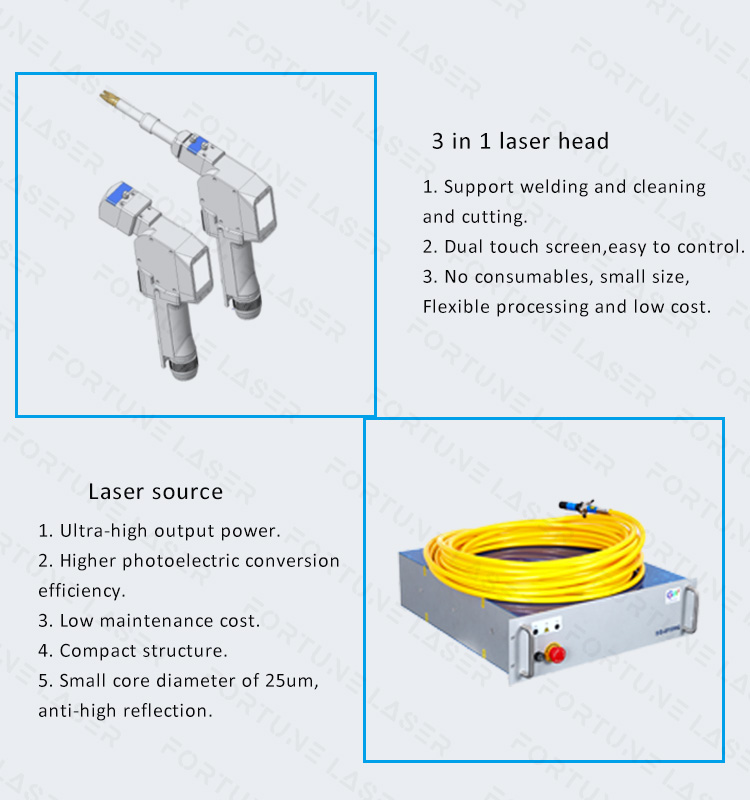

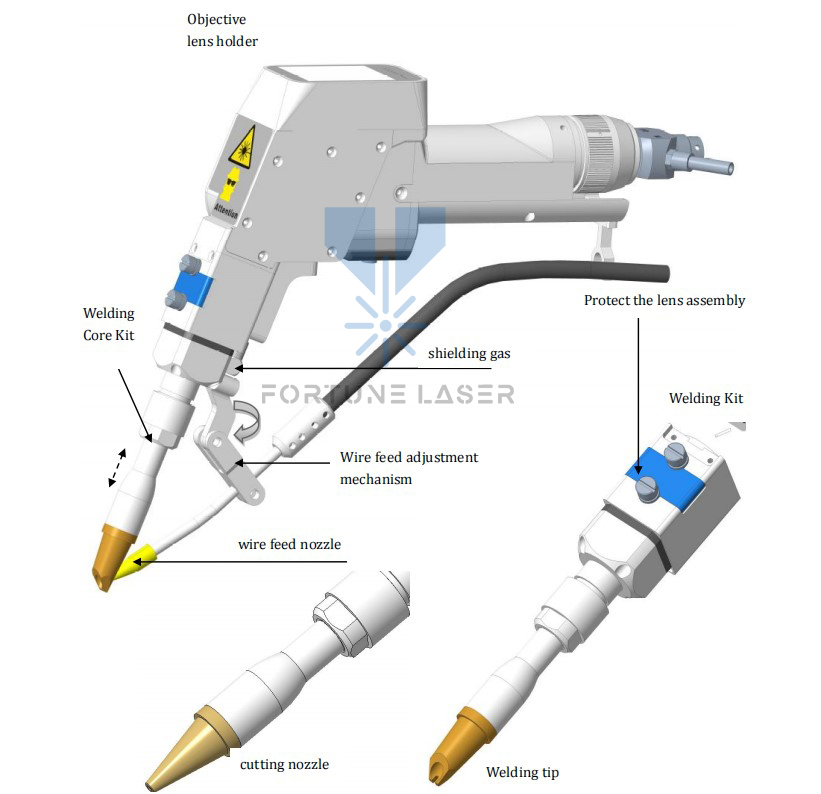

Intloko ye-welding ye-pendulum ephindwe kabini Iimpawu zentloko:

A. Le ntloko ye-welding ineenzuzo ezinamandla kwinsimbi engenasici, i-aluminium alloy welding, kunye nezicelo ze-welding ezincinci kunye neziphakathi zamandla. Yintloko ye-welding engabizi kakhulu.

B.Intloko ye-welding ithatha i-motor-driven X, i-Y-axis vibrating lens, eneendlela ezininzi zokujingi, kunye ne-swing welding ivumela i-workpiece ukuba ibe ne-welding engaqhelekanga, izithuba ezinkulu kunye nezinye iiparitha zokucubungula, ezinokuphucula kakhulu umgangatho we-welding.

C.Isakhiwo sangaphakathi sentloko ye-welding ivalwe ngokupheleleyo, enokuthintela inxalenye ye-optical ukuba ingcoliswe ngothuli.

I-D.Optional welding / cuting kits kunye neekiti zokucoca zinokufezekisa ngokwenene imisebenzi emithathu ye-welding, ukusika kunye nokucoca.

E.I-lens yokukhusela ithatha isakhiwo sedrowa, ekulula ukuyibuyisela.

F.Ingakwazi ukuxhotyiswa ngee-lasers ezahlukeneyo kunye nezihlanganisi ze-QBH.

G. Ubungakanani obuncinci, inkangeleko entle kunye nokuziva.

I-HA touch screen inokuzikhethela kwintloko ye-welding, enokuthi idibaniswe nesikrini seqonga ukuze ufumane amava angcono okulawula umatshini.

IFayibha Laser Generator

I-GW (i-JPT, i-Raycus, i-MAX, i-RECI kunye ne-IPG i-generator ye-laser iyakhethwa) kunye ne-photoelectric ephezulu yokuguqulwa kwe-photoelectric, izinga eliphantsi lephutha, ukusetyenziswa kwamandla aphantsi, ukugcinwa kwamahhala, kunye nesakhiwo esincinci.

Uyilo olwakhiweyo lweChiller lwaManzi

Iyakwazi ukunqanda amakhamandela eengcingo ukuziqhelanisa neendawo ezininzi, kwaye ibe neziphumo ezilungileyo zokungangenwa luthuli kunye nezokuchasana ne-condensation. Iphaneli yoLawulo lwe-Smart eyakhelwe-ngaphakathi uluhlu lohlengahlengiso lweeparamitha likhulu, kwaye isiqalo sesitshixo esisodwa silula kwaye kulula ukuyisebenzisa.

I-3 kwi-1 ye-Handheld Laser yokucoca, i-Welding, i-Cutting Machine Applications

Umatshini we-laser wemisebenzi emininzi usetyenziselwa ukwenza, iimoto, ikhitshi, iishelufa, izinyusi, iibhokisi zokuhambisa, ii-oveni, ifenitshala yentsimbi, izixhobo zombane, unxibelelwano lwamehlo, isivamvo, izixhobo zemoto, amazinyo eporcelain, iiglasi, amandla elanga, kunye nokwenziwa kwezinto ezichanekileyo.

1. Nge-laser welding gun, i-laser welder ephathekayo ukuwelda i-aluminium, insimbi engenasici, i-titanium, igolide, isilivere, ubhedu, i-nickel, i-chromium, kunye nezinye isinyithi okanye i-alloys, inokusetyenziswa kwiindidi ze-welds phakathi kweentsimbi ezahlukeneyo, ezifana ne-titanium-igolide, i-copper-bracos-brass, i-nickel-copper kunye ne-nickel-copper kunye ne-nickel.

I-2.Ngompu wokucoca i-laser, i-laser yokucoca i-laser ephathekayo ukususa i-rust, i-resin, i-coating, i-oyile, i-stain, i-peint, i-intract for treatment surface kunye ne-hobbyists kunye ne-industrial production, inokunciphisa ngokufanelekileyo iindleko zokugcinwa komatshini kunye nokuphucula umphumo wokucoca i-industrial.

I-3.Ngompu wokusika i-laser, yinto enye ephathekayo ephathekayo ye-laser cutter kuzo zonke iintlobo zokusika isinyithi.

(Ifanele ipleyiti yentsimbi ecekethekileyo kuphela.)

Ezintathu kwi-One Handheld Laser welding ukucoca inkqubo yokusika umatshini ulwazi ukupakisha

Ubungcalifiber laser welding ukucoca umatshini wokusikaumenzi weshishini lenkonzo yemveliso yesinyithi. I-laser welder, isicoci selaser kunye nelaser cutter zithengiswa eAlgeria, eArmenia, eArgentina, eOstriya, eOstreliya, eAzerbaijan, eBangladesh, eBelgium, eBulgaria, eBolivia, eBrazil, eBelarus, eCanada, eChile, eChina, eKholombiya, eCzech, eCyprus, eJamani, eDenmark, e-Ecuador, e-Estonia, e-Egypt, eSpain, eFinland, eFransi, eGeorgia, eGrisi, eHungary, e-Indonesia, e-Ireland, e-Ireland, e-Ireland, e-Ireland, eHungary, e-Ireland, e-Ireland Lebanon, Latvia, Morocco, Malta, Mexico, Malaysia, Netherlands, Norway, New Zealand, Oman, Peru, Philippines, Poland, Portugal, Paraguay, Qatar, Romania, Russia, Saudi Arabia, Switzerland, Sweden, Singapore, Slovenia, Slovakia, Swaziland, South Africa, Thailand, Tunisia, Turkey, United Kingdom, UAE, USA, Uruguay, Venezuela, Uzbeet

I-laser welders ephathekayo kunye nezicoci ze-laser zithandwa ngakumbi. Ingaba ukhangele umatshini we-welding okanye isixhobo sokucoca ukusetyenziswa, okanye uceba ukuqala ishishini lenkonzo ye-welding kunye nokucoca, le 3 kwi-1 umatshini we-laser lukhetho oluhle kakhulu. Nceda uqhagamshelane nathi namhlanje ngeenkcukacha ezithe vetshe.