Fortune Laser Mini 1000W/1500W/2000W 3 KwiFiber Handheld Laser Welding Machine

Fortune Laser Mini 1000W/1500W/2000W 3 KwiFiber Handheld Laser Welding Machine

Kwangaxeshanye, lo matshini omncinci we-laser welding wesandla uxhasa ukusika kunye ne-welding ngaxeshanye kunye nomatshini oqhelekileyo wokusabalalisa ucingo, onokunciphisa iimfuno zokuhlanjululwa kwamacandelo kunye nokuphucula ngakumbi umgangatho we-welding. Isenokusetyenziswa ngokubambisana nerobhothi ehlangeneyo ukulungisa itotshi ye-welding kwi-robot yentsebenziswano, ukunciphisa ubuninzi bomsebenzi wabasebenzi kunye nokuphucula umgangatho we-welding weld.

1000W 1500w 2000w 3000W Mini Laser Welding Machine Advantage

Uyilo lwe-chassis yonke-in-one lufanelekile

I-Fortunelaser ebambe ngesandla i-fiber laser welding machine ithatha uyilo lwekhabhathi edibeneyo, edibanisa i-laser, i-chiller, ulawulo lwesoftware, njl.

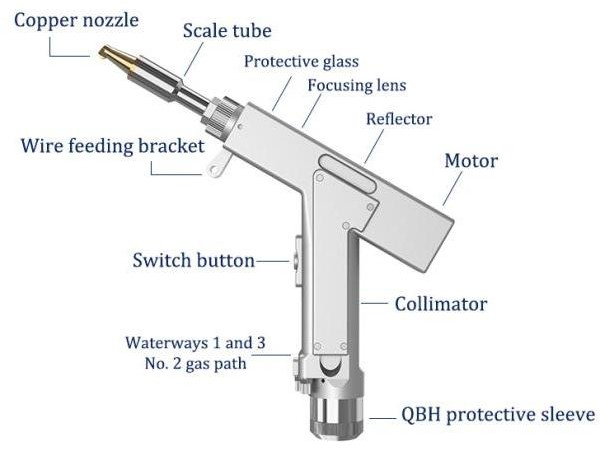

Endaweni yokuba "indlela ye-optical esisigxina", umsebenzi ulungele ngakumbi.

Ngoku i-welding ebanjwe ngesandla, usebenzisa i-welding gun ebanjwe ngesandla ukuze ithathe indawo yendlela ehleliweyo ye-optical, ukusebenza kulula ngakumbi, ukuphula imida ye-workbench, ukuhlangabezana ne-welding yee-angles ezahlukeneyo kunye nezikhundla. Ukongeza, indawo ye-infrared isetyenziselwa ukubeka indawo echanekileyo kunye nokulinganisa indawo ye-welding ukuze kuqinisekiswe i-welds ezintle ngakumbi.

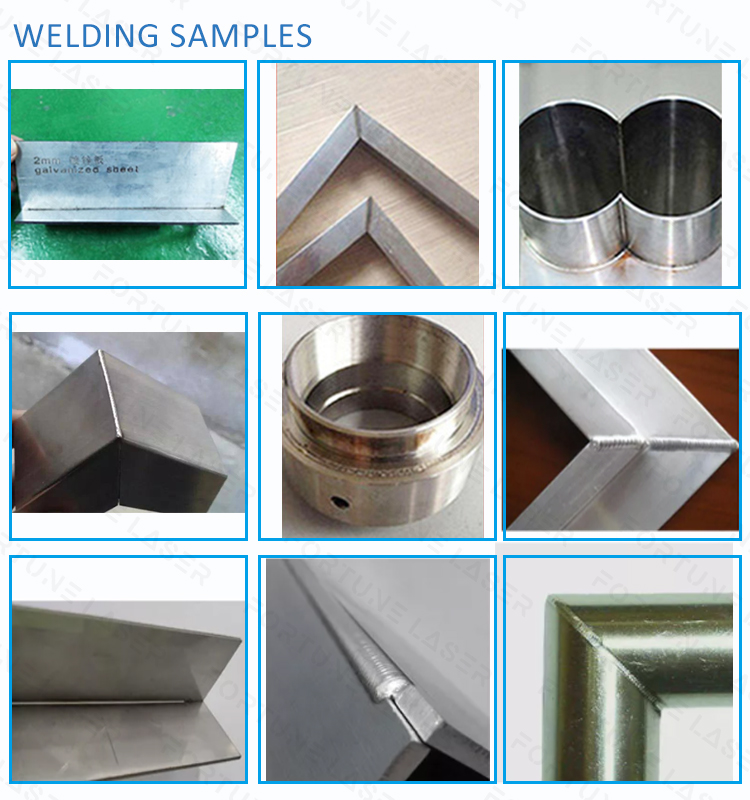

I-deformation encinci ye-thermal, i-weld egudileyo kunye nenhle

Siyabona ukuba i-welding seam yomshini we-laser welding we-fiber optical igudileyo kwaye intle, i-welding workpiece ayinayo i-deformation, ayikho i-welding scar, kwaye i-welding iqinile, inciphisa inkqubo yokusila elandelayo, ukonga ixesha kunye neendleko. I-welding Traditional inzima ukufezekisa ubuhle be-welding ye-workpieces enzima, ngelixa i-welding ebanjwe ngesandla inokufikelela kwii-engile ezifanelekileyo, iikona ezijikelezileyo kunye neendlela ezininzi ze-welding, ukwenza i-welding ibe lula.

Ubunzulu be-welding bukhulu kwaye i-welding iqinile

Umatshini we-fiber laser welding obambe ngesandla usetyenziswa ikakhulu kwi-laser welding yomgama omde kunye nezixhobo zokusebenza ezinkulu. Ummandla ochaphazelekayo ngubushushu ngexesha le-welding lincinci, elingayi kubangela ukuguqulwa komsebenzi, ubumnyama, kunye nomkhondo kumqolo. Ubunzulu be-welding bukhulu, i-welding iqinile, kwaye ukunyibilika kwanele.

Umatshini omnye uxhasa imisebenzi emithathu yokuwelda, ukusika nokucoca

Ukuguqulwa kwemisebenzi emi-3 kunokuqondwa kuphela ngentloko ye-laser.

Fortune Laser Mini Laser Welding Machine Technical Parameters

| Umzekelo | FL-HW1000M | FL-HW1500M | FL-HW2000M |

| Amandla eLaser | 1000W | 1500W | 2000W |

| Indlela yokupholisa | Ukupholisa Amanzi | Ukupholisa Amanzi | Ukupholisa Amanzi |

| ILaserWubude | 1080nm | 1080nm | 1080nm |

| Way Yokusebenza | Cokuqhubekayo/ Ukuguquguqula | ||

| Ubude beFayibha | Umgangatho we-10m, ubude obude obulungiselelweyo yi-15m | ||

| Ubungakanani | 100*68*45cm | ||

| WSibhozo | 165kg | ||

| Iinketho | Ephathekayo | ||

| Uluhlu lwesantya se-welder | 0-120mm/s | ||

| Ubushushu | 15-35℃ | ||

| I-Voltage yokusebenza | AV 220V | ||

| Ububanzi beNdawo ekuJoliswe kuyo | 0.5mm | ||

| Ubungqingqwa be-welding | 0.5-5mm | ||

Iimbonakalo

l Iimpawu ezisisiseko: i-self-developed self-in-one control system, i-flexible switching of welding, ukucoca, kunye nokusika, ii-alamu ezininzi zokhuseleko, ukusebenza okulula kunye nokuguquguqukayo.

l Ukuzinza ngakumbi: Zonke iiparameters ziyabonakala, ukujonga kwangexesha lokwenene isimo somatshini wonke, ukuphepha iingxaki kwangaphambili, ukuququzelela iingxaki kunye nokusombulula iingxaki, kunye nokuqinisekisa ukusebenza okuzinzile kwenkqubo.

l Inkqubo: Iiparamitha zenkqubo zinokusetwa, kwaye iziphumo ezahlukeneyo zenkqubo zinokuzanywa ngokuguquguqukayo.

l Iiparamitha ezizinzile kunye nokuphindaphinda okuphezulu: Uxinzelelo lomoya we-nozzle kunye ne-lens state, nje ngokuba amandla e-laser azinzile, iiparitha zenkqubo kufuneka ziphindwe, eziphucula kakhulu ukusebenza kakuhle.

| Umbane wobonelelo (V) | 220V±10% AC 50/60Hz |

| Beka okusingqongileyo | Umcaba, akukho ngcangcazelo kunye nokothuka |

| Iqondo lobushushu elisebenzayo (℃) | 10-40 |

| Ukufuma kwendawo yokusebenza(%) | <70 |

| Indlela yokupholisa | Ukupholisa amanzi |

| Ukudityaniswa | D20*5/F60 |

| Ugxininiso (imowudi yewelding ephathwayo) | D20*4.5/F150 |

| Ukugxila (imo yokucoca) | D20*4.5/F400 |

| Ukucamngca | 30*14 T2 |

| Iimpawu zelensi ezikhuselayo | 18*2 |

| Uxinzelelo lomoya oluphezulu oluxhaswayo | 10Ibha |

| Gxininisa uluhlu lohlengahlengiso oluthe nkqo | ±10mm |

| Uluhlu lohlengahlengiso lwamabala (imowudi yesandla) | 0 ~6mm |

| Uluhlu lohlengahlengiso lwamabala (indlela yokucoca) | 0 ~ 50mm |