Fortune Laser Handheld Fiber Laser Welding Machine

Fortune Laser Handheld Fiber Laser Welding Machine

Fortune Laser Handheld Laser Welder Technical Parameters

| Umzekelo | FL-HW1000 | FL-HW1500 | FL-HW2000 |

| Uhlobo lweLaser | 1070nm iFayibha Laser | ||

| Amandla eLaser yeNominal | 1000W | 1500W | 2000W |

| Inkqubo yokupholisa | Ukupholisa Amanzi | ||

| Indlela yokusebenza | Ukuqhubekeka / Ukumodareyitha | ||

| Uluhlu lwesantya se-welder | 0~120 mm/s | ||

| Ububanzi beNdawo ekuJoliswe kuyo | 0.5mm | ||

| Uluhlu lobushushu be-Ambient | 15 ~ 35 ℃ | ||

| Uluhlu lokufuma kokusingqongileyo | <70% ngaphandle kwe-condensation | ||

| Ubukhulu be-welding | 0.5-1.5mm | 0.5-2mm | 0.5-3mm |

| Iimfuno ze-welding gap | ≤1.2mm | ||

| I-Voltage yokusebenza | I-AC 220V/50HZ 60HZ/ 380V±5V 50HZ 60HZ 60A | ||

| Ubungakanani beKhabhinethi | 120*60*120cm | ||

| Ubungakanani bePhakeji yoMthi | 154*79*137cm | ||

| Ubunzima | 285KG | ||

| Ubude beFayibha | I-10M eqhelekileyo, ubude obude obulungiselelweyo yi-15M | ||

| Isicelo | I-Welding kunye nokulungiswa kwensimbi engenasici, i-carbon steel, i-aluminium alloy. | ||

Ephathwayo Handheld Laser Welder for Metals

| Izinto eziphathekayo | Amandla emveliso (W) | Ukungena okuphezulu (mm) |

| Yenziwe ngentsimbi eshayinayo | 1000 | 0.5-3 |

| Yenziwe ngentsimbi eshayinayo | 1500 | 0.5-4 |

| Yenziwe ngentsimbi eshayinayo | 2000 | 0.5-5 |

| Intsimbi yekhabhoni | 1000 | 0.5-2.5 |

| Intsimbi yekhabhoni | 1500 | 0.5-3.5 |

| Intsimbi yekhabhoni | 2000 | 0.5-4.5 |

| Aluminiyam ingxubevange | 1000 | 0.5-2.5 |

| Aluminiyam ingxubevange | 1500 | 0.5-3 |

| Aluminiyam ingxubevange | 2000 | 0.5-4 |

| Iphepha elenziwe ngegalvanized | 1000 | 0.5-1.2 |

| Iphepha elenziwe ngegalvanized | 1500 | 0.5-1.8 |

| Iphepha elenziwe ngegalvanized | 2000 | 0.5-2.5 |

Imibala emithathu yoKhetho lwakho

Izinto eziluncedo kwi-Handheld Laser Welding Machine

1. Uluhlu olubanzi lwe-welding:

Intloko ye-welding ye-handheld ixhotyiswe nge-10M ye-fiber optical yasekuqaleni (ubude obude obulungiselelweyo yi-15M), eyoyisa imida yendawo yokusebenza, kwaye inokudityaniswa ngaphandle kunye ne-welding emide;

2. Kulula kwaye kulula ukuyisebenzisa:

I-laser welding ebanjwe ngesandla ixhotyiswe ngeepulleys ezihambayo, ekhululekile ukubamba, kwaye inokulungelelanisa isikhululo nangaliphi na ixesha, ngaphandle kwesikhululo esisisigxina, esikhululekile kwaye siguquguqukayo, kwaye sifanelekile kwiimeko ezahlukeneyo zokusebenza.

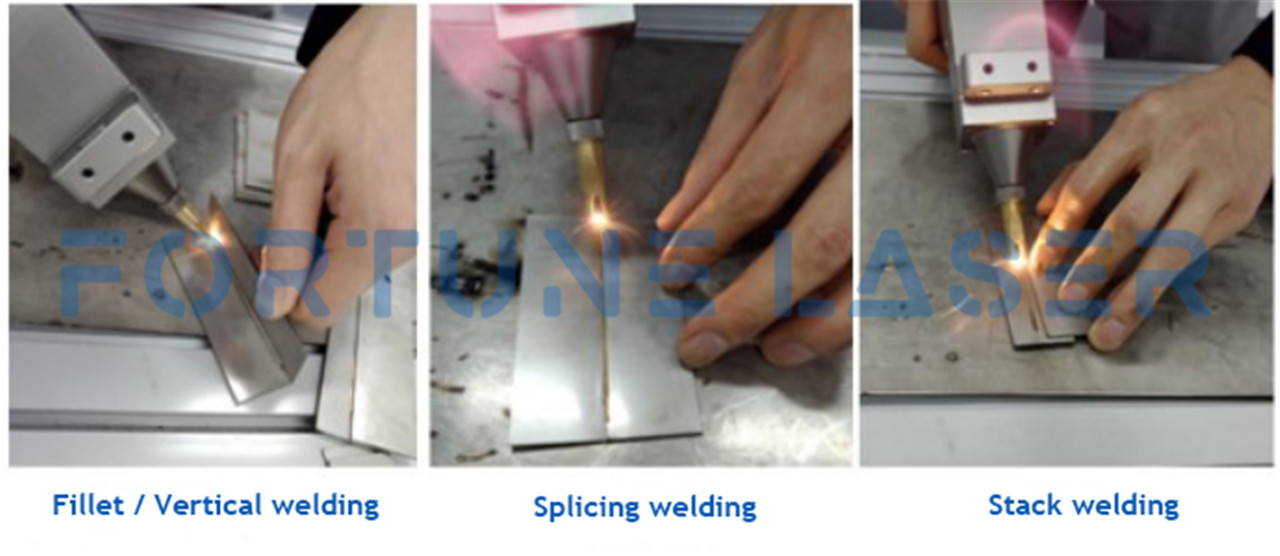

3. Iindlela ezininzi ze-welding:

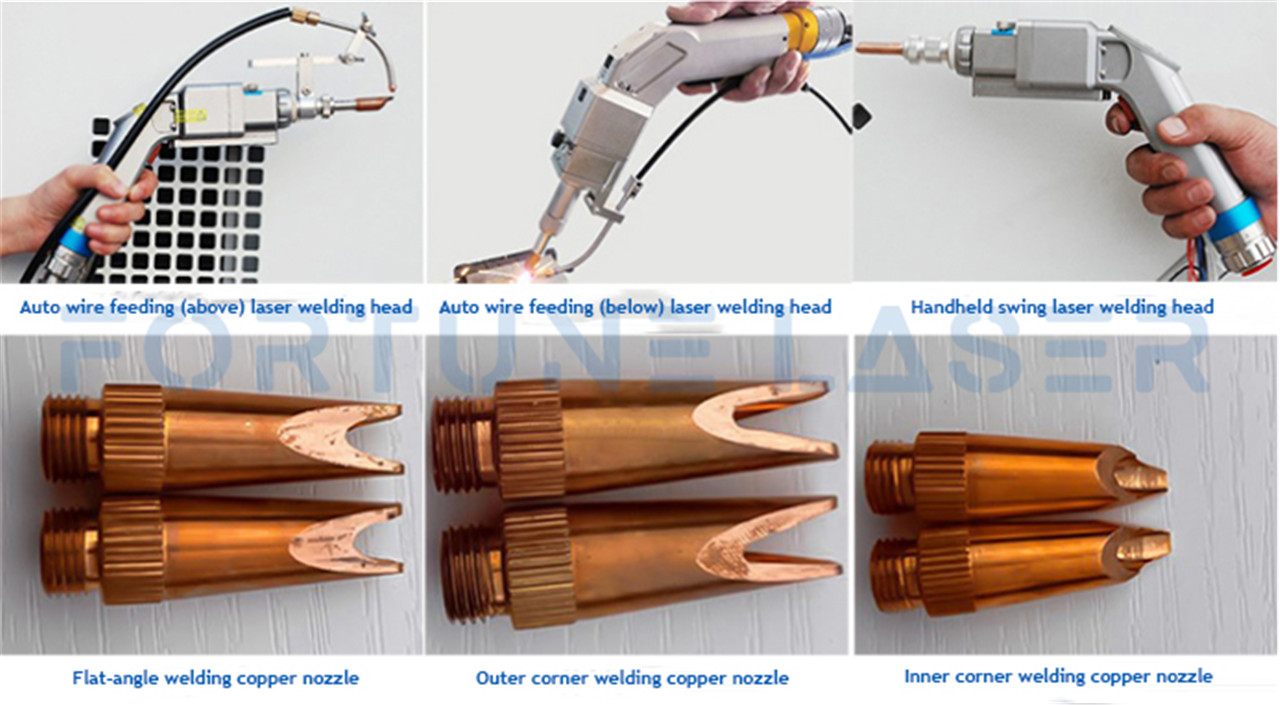

I-Welding kuyo nayiphi na i-engile inokuphunyezwa: ukuwelda kwe-welding, i-welding ye-butt, i-welding ethe nkqo, i-flat fillet welding, i-fillet ye-welding yangaphakathi, i-fillet ye-welding yangaphandle, njl. Qonda i-welding kuyo nayiphi na i-engile. Ukongeza, inokuphinda igqibe ukusika, i-welding kunye nokusika kunokutshintshwa ngokukhululekileyo, tshintsha nje umbhobho wobhedu we-welding kwi-nozzle yobhedu yokusika, efanelekileyo kakhulu.

4. Isiphumo esihle se-welding:

I-laser ebanjwe ngesandla yi-thermal fusion welding. Xa kuthelekiswa ne-welding yemveli, i-laser welding ine-energy ephezulu kwaye inokufikelela kwiziphumo ezingcono ze-welding. Indawo ye-welding inempembelelo encinci ye-thermal, ayilula ukukhubaza, imnyama, kwaye inemizila emqolo. Ubunzulu be-welding bukhulu, ukunyibilika kwanele, kwaye kuqinile kwaye kunokwethenjelwa, kwaye amandla e-weld afikelela okanye adlula isiseko sesinyithi ngokwawo, esingenakuqinisekiswa ngoomatshini abaqhelekileyo be-welding.

5. Umthungo we-Welding awufuni ukuba uphuculwe.

Emva kwe-welding yendabuko, indawo ye-welding kufuneka iphuculwe ukuqinisekisa ukuba igudileyo kwaye ayikho rhabaxa. I-laser ye-laser ebanjwe ngesandla ibonisa ngokuchanekileyo inzuzo engaphezulu kwi-process effect: i-welding eqhubekayo, i-welding egudileyo kwaye ingabikho izikali zeentlanzi, ezintle kwaye azikho iziva, kunye neenkqubo ezimbalwa zokupholisha.

6. Welding ngei-wire feeder ezenzekelayo.

Kwingcinga yabantu abaninzi, ukusebenza kwewelding "yi-left hand goggles, right hand clamp welding wire". Kodwa ngomatshini we-laser welding welding, ukuwelda kunokugqitywa ngokulula, okunciphisa iindleko zezinto ezibonakalayo kwimveliso kunye nokucubungula.

7. Ikhuselekile ngakumbiumqhubi.

Ngama-alamu amaninzi okhuseleko, i-tip ye-welding isebenza kuphela xa utshintshi luchukumisa xa luchukumisa isinyithi, kwaye ukukhanya kuvaliwe ngokuzenzekelayo emva kokuba umsebenzi owenziweyo ususwe, kwaye umtshini wokuchukumisa unokuqonda ukushisa komzimba. Ukhuseleko luphezulu ukuqinisekisa ukhuseleko lomsebenzisi ngexesha lomsebenzi.

8. Yonga iindleko zabasebenzi.

Xa kuthelekiswa ne-arc welding, iindleko zokucubungula zingancitshiswa malunga ne-30%. Utyando lulula, kulula ukulufunda, kwaye luyakhawuleza ukuqalisa. Umda wobugcisa wabaqhubi awukho phezulu. Abasebenzi abaqhelekileyo banokuthatha izithuba zabo emva koqeqesho olufutshane, olunokufikelela ngokulula kwiziphumo eziphezulu ze-welding.

9. Kulula ukutshintshela kwiindlela zemveli ze-welding ukuya kwi-fiber laser welding.

Unokufunda indlela yokusebenzisa umatshini we-Fortune Laser fiber laser welding phakathi kweeyure ezimbalwa, kwaye akukho ntloko yokukhangela iingcali zokuwelda, ungakhathazeki malunga neshedyuli yokuhanjiswa eqinile. Ngaphezu koko, ngale teknoloji intsha kunye notyalo-mali, uya kuba phambili kwimarike kwaye wamkele imida yenzuzo eyandisiweyo kuneendlela zokuwelda zemveli.

Iinkalo zeSicelo ze-Handheld Laser Welding Machine

I-laser welder ephathwayo yenzelwe ubukhulu kunye nobukhulu obuphakathi bentsimbi, iikhabhathi, i-chassis, i-aluminium alloy door kunye nefreyimu yefestile, izitya zokuhlambela zensimbi ezingenasici kunye nezinye izinto ezinkulu zokusebenza, ezifana ne-angle yangaphakathi yasekunene, i-angle yangaphandle yasekunene, i-weld welding, indawo encinci echaphazelekayo ukushisa ngexesha le-welding, i-deformation encinci, kunye nobunzulu be-welding.

I-Fortune Laser ephathwayo koomatshini bokuwelda i-laser isetyenziswa ngokubanzi kwiinkqubo zokuwelda ezintsonkothileyo kunye nezingaqhelekanga zeshishini lekhitshi kunye negumbi lokuhlambela, ishishini lezixhobo zekhaya, ishishini lentengiso, ishishini lokungunda, ishishini lemveliso yentsimbi, ishishini lobunjineli bentsimbi, iingcango kunye noshishino lwefestile, ishishini lezandla, ishishini lempahla yasekhaya, ishishini lefenitshala, ishishini lamalungu emoto, njl.

Ukuthelekiswa kwe-Handheld Laser Welding Machine kunye neArgon Arc Welding

1. Ukuthelekisa ukusetyenziswa kwamandla:Xa kuthelekiswa ne-arc welding yendabuko, umatshini we-laser welding welding ugcina malunga ne-80% ukuya kwi-90% yamandla ombane, kwaye iindleko zokucubungula zingancitshiswa malunga ne-30%.

2. Uthelekiso lwesiphumo se-Welding:i-laser yokubamba ngesandla i-welding inokugqiba intsimbi engafaniyo kunye ne-welding yentsimbi eyahlukileyo. Isantya sikhawuleza, i-deformation incinci, kwaye indawo echaphazelekayo yokushisa incinci. Umthungo we-weld mhle, ugudile, akukho porosity encinci, kwaye akukho ngcoliseko. Umatshini we-laser welding we-handheld ungasetyenziselwa iindawo ezincinci ezivulekileyo kunye ne-welding echanekileyo.

3. Ukuthelekisa inkqubo yokulandelela:igalelo lobushushu obuphantsi ngexesha le-laser ebanjwe ngesandla, i-deformation encinci ye-workpiece, i-welding surface enhle inokufumaneka, akukho okanye unyango olulula kuphela (kuxhomekeke kwiimfuno ze-welding surface effect). Umatshini wokuwelda we-laser ophathwa ngesandla unokunciphisa kakhulu iindleko zabasebenzi zenkqubo enkulu yokupolisha kunye nenqanaba.

| Uhlobo | Argon arc welding | UKUwelda kwe-YAG | Ukubanjwa ngesandlaILaserukuwelda | |

| Umgangatho wokuwelda | Igalelo lobushushu | Enkulu | Incinci | Incinci |

|

| Ukuguqulwa kweworkpiece / undercut | Enkulu | Incinci | Incinci |

|

| Ukwenza i-weld | Ipateni yokulinganisa intlanzi | Ipateni yokulinganisa intlanzi | Mhle |

|

| Ukuqhubekeka okulandelayo | Polish | Polish | Akukho nanye |

| Sebenzisa ukusebenza | Isantya sokuwelda | Cotha | Phakathi | Ukukhawuleza |

|

| Ubunzima bokusebenza | Kunzima | Kulula | Kulula |

| Ukhuseleko lokusingqongileyo kunye nokhuseleko | Ungcoliseko lokusingqongileyo | Enkulu | Incinci | Incinci |

|

| Ukwenzakala emzimbeni | Enkulu | Incinci | Incinci |

| Iindleko zokuwelder | Izinto ezisetyenziswayo | Intonga ye-welding | Ikristale yeLaser, isibane sexenon | Akukho mfuneko |

|

| Ukusetyenziswa kwamandla | Incinci | Enkulu | Incinci |

| Indawo yomgangatho wezixhobo | Incinci | Enkulu | Incinci | |