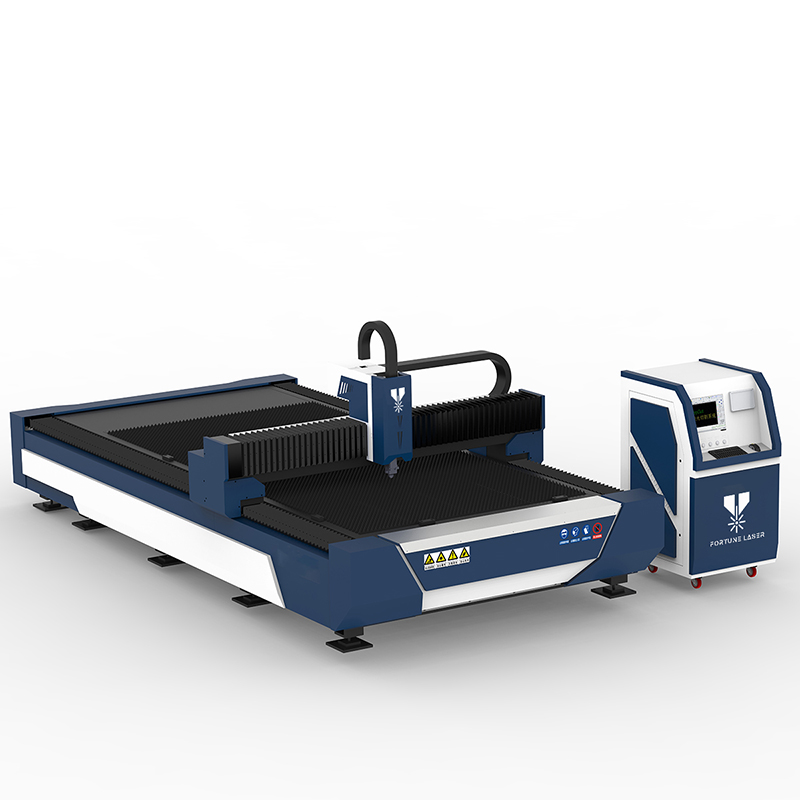

Top Quality Laser Welding Machine Jewelry - Fortune Laser Automatic 300W Yag Laser Mold Welding Machine – Fortune

Top Quality Laser Welding Machine Jewelry - Fortune Laser Automatic 300W Yag Laser Mold Welding Machine – Fortune

Top Quality Laser Welding Machine Jewelry - Fortune Laser Automatic 300W Yag Laser Mold Welding Machine – Fortune Detail:

Basic Principles of Laser Machine

Four-axis linkage laser welding machine adopts advanced single-lamp ceramic reflector cavity, powerful power, programmable laser pulse and intelligent system management. The Z-axis of the worktable can be moved up and down to focus, controlled by an industrial PC. Equipped with a standard separated X/Y/Z axis three-dimensional automatic moving table, equipped with an external cooling system. Another optional rotating fixture (80mm or 125mm models are optional). The monitoring system adopts microscope and CCD

300w Automatic Laser Welding Machine Characteristic

1. Using high-quality dual-lamp ceramic condenser cavity, long life (8-10 years), corrosion resistance and high temperature resistance.

2. The production efficiency is high, the welding speed is fast, and the assembly line can be automated for mass production.

3. The laser welding head, the whole optical path part can be rotated 360 degrees, and can be moved back and forth.

4. Electric adjustment of light spot size.

5. The worktable can be moved three-dimensionally electrically.

Fortune Laser Automatic Laser Welding Machine Technical Parameters

|

Model |

FL-Y300 |

|

Laser Power |

300W |

|

Cooling Way |

Water Cooling |

|

Laser Wavelength |

1064nm |

|

Laser Working Medium Nd 3+ |

YAG Ceramic Conde |

|

Spot Diameter |

φ0.10-3.0mm adjustable |

|

Pulse Width |

0.1ms-20ms adjustable |

|

Welding Depth |

≤10mm |

|

Machine Power |

10KW |

|

Control System |

PLC |

|

Aiming and Positioning |

Microscope |

|

Worktable Stroke |

200×300mm (Z-axis electric lift) |

|

Power Demand |

Customized |

Accessories

1. Laser source

2. Fiber Laser cable

3. YAG laser welding head

4. 1.5P chiller

5. PC and welding system

6. 125×100×300mm Linear Rail Servo Electric Translation Stage

7. four-axis control system

8. CCD camera system

9. Mainframe cabine

What Application Can This Machine Be Used For?

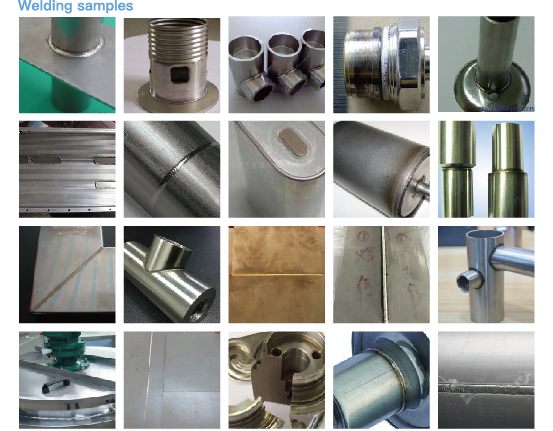

Mold laser welding machine adopts ceramic concentrating cavity imported from the UK, which is corrosion-resistant and high-temperature resistant; the laser head rotates 360 degrees, suitable for various mold repairs; the laser welding machine can be intelligently controlled by remote control. It is widely used in mobile phones/digital products/ In the mold manufacturing and molding industries such as automobiles and motorcycles, the substrates that can be repaired include: various mold steels/stainless steel/beryllium copper/precious metals and extremely hard materials (~HRC60), etc.

Advantages Of Automatic Laser Welding Technology

The mold laser welding machine adopts a large-screen LCD interface display, which makes it easier for the operator to learn and operate. The equipment also uses the font programming function to realize multi-mode work, which is suitable for mold repair of most materials.

Not only the heat-affected area is small, the oxidation rate is low, and there will be no blisters, pores, etc. After the mold is repaired, the effect will be that there will be no unevenness at the joint, and it will not cause mold deformation.

Laser welding can realize spot welding, butt welding, stitch welding, sealing welding, etc. on thin-walled materials and precision parts.

The laser power is high, the weld seam has a high aspect ratio, the heat-affected zone is small, the deformation is small, and the welding speed is fast.

The quality of the weld is high, flat and beautiful, without pores, and the toughness of the welded material is at least equivalent to that of the parent material.

Humanized design, LCD screen display, and centralized button operation are easier.

The four-dimensional ball screw workbench adopts imported servo control system and optional rotary workbench, which can realize automatic welding such as spot welding, linear welding and circumferential welding, with wide application range, high precision and fast speed.

8. The current waveform can be adjusted arbitrarily, and different waveforms can be set according to different welding materials to match the welding parameters and welding requirements to achieve the best welding effect.

What after-sales service can we provide?

1. The equipment is guaranteed for one year free of charge, and the laser source is guaranteed for 2 years, excluding consumables (consumables include: protective lenses, copper nozzles, etc. (except for human failures, non-equipment quality reasons and natural disasters).

2. Free technical consultation, software upgrade and other services;

3. Rapid customer service response speed;

4. Provide technical support services for life.

What Is The Difference Between YAG Laser Welding And Continuous Laser Welding?

Continuous Laser Welding Machine:

A fiber laser is an optical waveguide laser that uses an optical fiber doped with rare earth elements (Nd, Yb or Er) as the working material and a diode laser as the pump source. It can work continuously in pulses, and its light guiding principle is the total internal reflection mechanism of light. Under the action of the pump light, it is easy to form a high power density in the optical fiber, so that the laser energy level of the laser working substance is “filled with an inversion”. When a positive feedback loop is properly added (forming a resonant cavity), the laser oscillation output can be formed.

YAG Laser Welding:

The YAG laser source uses garnet crystals doped with neodymium or yttrium metal ions as the laser active medium, and emits laser light mainly through optical pumping. A YAG laser source with a flash lamp typically emits light at a wavelength of 1064 nm. The optical design of its laser is relatively simple. Its heart is the power supply that drives and controls the voltage of the flash lamp and allows the use of internal optical feedback to precisely control peak power and pulse width during laser pulses.

Application:

The continuous laser welding machine is suitable for welding materials above 0.5mm, it emits light continuously and has a fast welding speed. YAG welding machine is suitable for welding thin materials of 0.1mm-0.5mm, but it is usually used for spot welding.

Beam Quality:

There is an internal temperature gradient in the working process of the YAG welding machine, which limits the further improvement of the average laser power and beam quality. In addition, since the refractive index change rate of continuous laser welding is much smaller than that of semiconductors, the continuous beam quality is better.

Smart and maintenance cost:

Since there is no optical lens in the resonant cavity of the fiber laser, it has the advantages of no adjustment, no maintenance, and high stability, which is unmatched by traditional YAG laser sources.

Power Consumption and Operating Efficiency

Service Life:

Continuous laser source life: more than 100,000 hours.

YAG laser source life: about 15,000 hours.

Video

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can guarantee our combined price competiveness and quality advantageous at the same time for Top Quality Laser Welding Machine Jewelry - Fortune Laser Automatic 300W Yag Laser Mold Welding Machine – Fortune , The product will supply to all over the world, such as: Botswana, Chile, Cannes, We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!