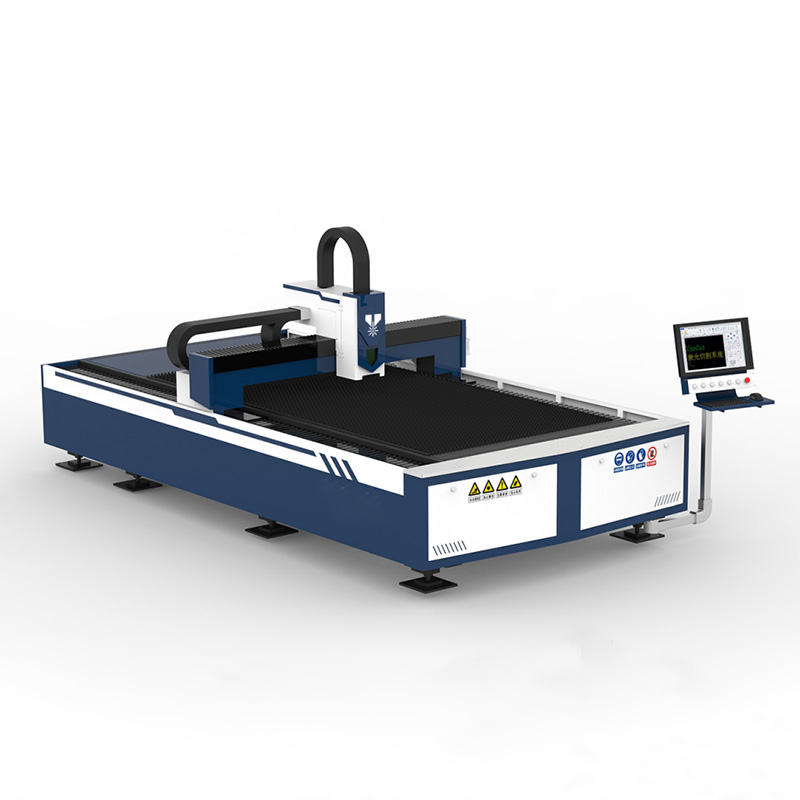

Ékonomi Metal Serat Laser Mesin motong

Ékonomi Metal Serat Laser Mesin motong

Karakter Mesin motong laser logam

●Servo dual struktur gantry drive:Mesin laser struktur gantry sasak, rak rail drive, ngagunakeun alat lubrication terpusat, sarta éta gampang pikeun pangropéa;

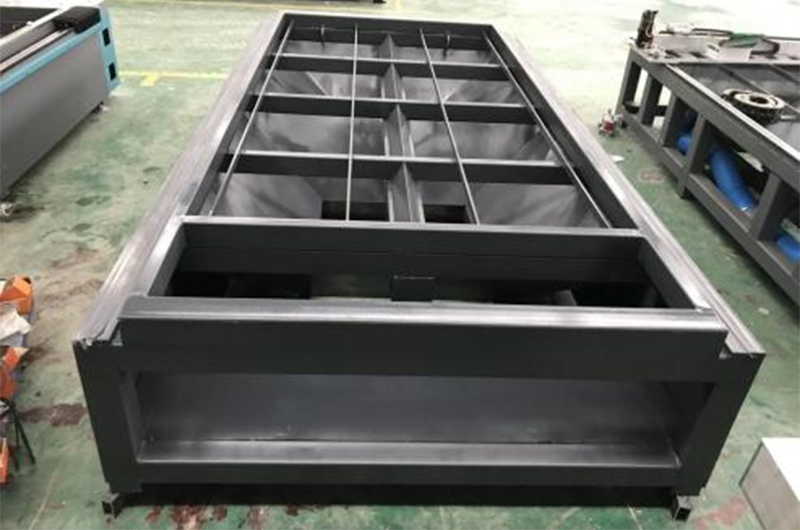

●Prasional jeung Stabil: ranjang mesin las bertulang, suhu luhur tempering perlakuan Geter pikeun ngaleungitkeun setrés. The deformasi alat mesin bisa dikawasa dina ± 0.02mm;

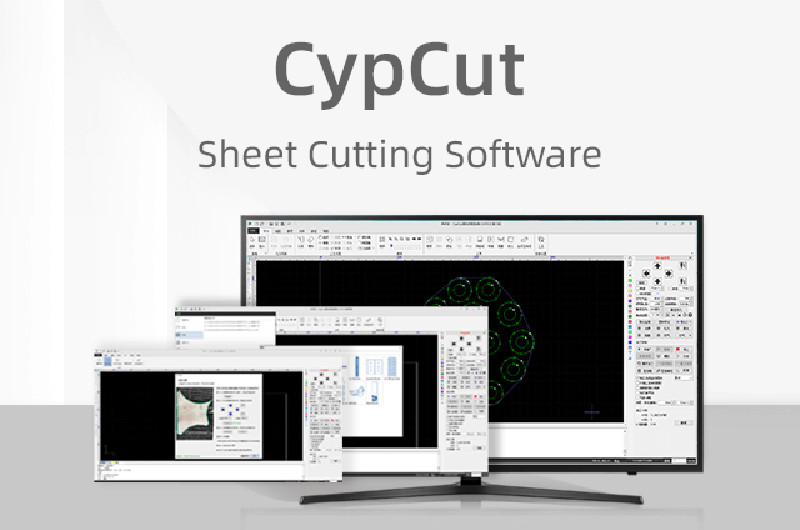

●Operasina basajan: Langkung ti 23000 pangguna nganggo sistem motong CNC profésional ieu. Sistim operasi ieu boga fungsi adjustment kakuatan laser pikeun mastikeun kualitas motong;

●Desain éstétika industri: Standar ékspor di Éropa jeung Amérika, penampilan desain éstétika ngajadikeun eta tampi di pasar global;

●Pamotongan kualitas luhur:The-precision High anti tabrakan profésional motong laser sirah ensures pangaruh motong pangalusna pikeun potongan karya anjeun sarta proyék;

●bahan efisien:Dipaké dina spésifikasi standar motong lambar logam, ngahemat waktos sareng biaya;

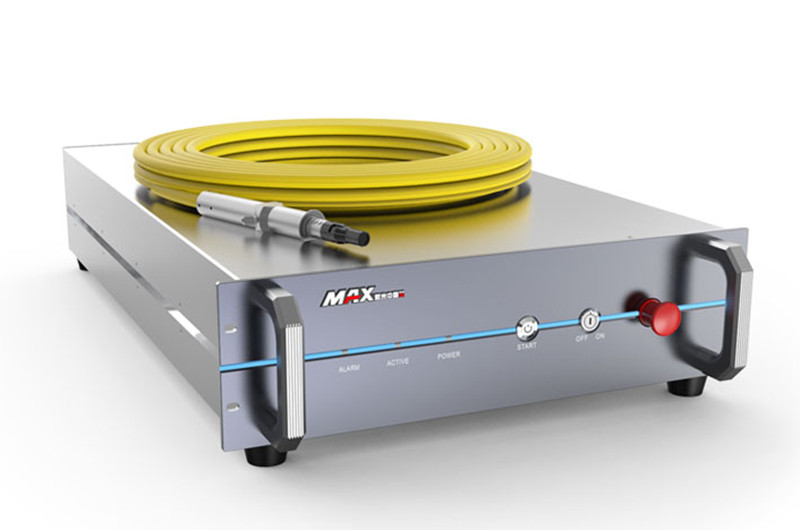

●Serat laser: Anggo sumber laser serat Maxphotonics (Laser merek sanésna opsional), kakuatan stabil sareng dipercaya, kinerja dijamin;

| Konfigurasi mesin | |

| Modél | Serat laser motong Mesin FL-S Series |

| Wewengkon Gawé | 3000mm * 1500mm |

| Sumber laser | 1000w Max |

| Sistim motong CNC | Sistem operasi Cypcut 1000 |

| sirah laser | Fokus Manual OSPRI |

| Ranjang mesin | Pakaya Laser |

| X / Y sumbu gear rak | Pakaya Laser |

| Panungtun linier precision | ROSÉ |

| Motor Girang | Motor Servo Yaskawa Jepang (X750W/Y750W/Z400W) |

| komponén éléktronik | Perancis Schneider |

| Sistim réduksi | PHILANDE |

| komponén pneumatic | SMC Jepang |

| Asesoris ranjang mesin | Pakaya Laser |

| Chiller cai | Hanli |

| Parabot daur ulang runtah | Pakaya Laser |

Catetan: Konfigurasi mesin ieu ngan pikeun rujukan anjeun, loba merek sejen pikeun tiap bagian tina mesin anu pilihan dumasar kana sarat anjeun sarta anggaran Anjeun. Mangga ngarasa Luncat ngahubungan kami pikeun leuwih rinci.

Parameter mesin

| Modél | FL-S2015 | FL-S3015 | FL-S4020 | FL-S6020 |

| Wewengkon Gawé (L*W) | 2000 * 1500mm | 3000 * 1500mm | 4000 * 2000mm | 6000 * 2000mm |

| X / Y Axis Posisi Akurasi | ± 0,03mm / 1000mm | ± 0,03mm / 1000mm | ± 0,03mm / 1000mm | ± 0,03mm / 1000mm |

| X / Y Axis Ulang Posisi Akurasi | ± 0,02 mm | ± 0,02 mm | ± 0,02 mm | ± 0,02 mm |

| Max Pindah Speed | 80000mm / mnt | 80000mm / mnt | 80000mm / mnt | 80000mm / mnt |

| Akselerasi Max | 1,2g | 1,2g | 1,2g | 1,2g |

| Max Loading Beurat | 600 kg | 800 kg | 1200 kg | 1500 kg |

| Sasayogian tanaga | AC380V / 50Hz | AC380V / 50Hz | AC380V / 50Hz | AC380V / 50Hz |

| Daya Sumber Laser (Opsional) | 1kW/1.5kW/2kW/2.5kW/3kW/4kW/6kW/8kW/10kW/12kW/15kW/20kW | |||

Aplikasi

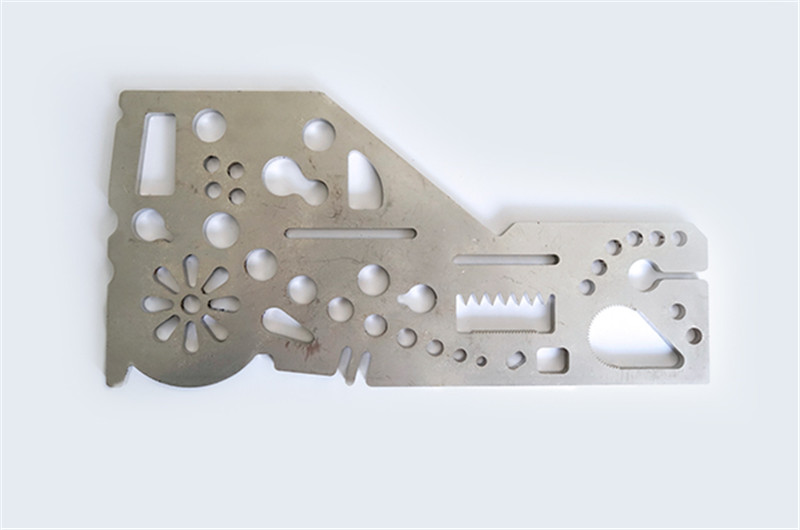

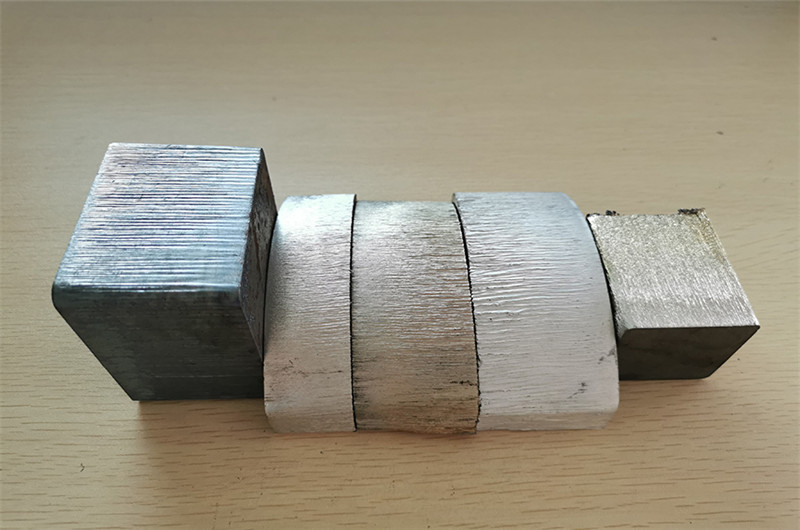

Cocog pikeun ngolah lambaran logam sapertos stainless steel, baja karbon, baja alloy, baja silikon, pelat baja galvanis, alloy nikel-titanium, inconel, alloy titanium, jsb.

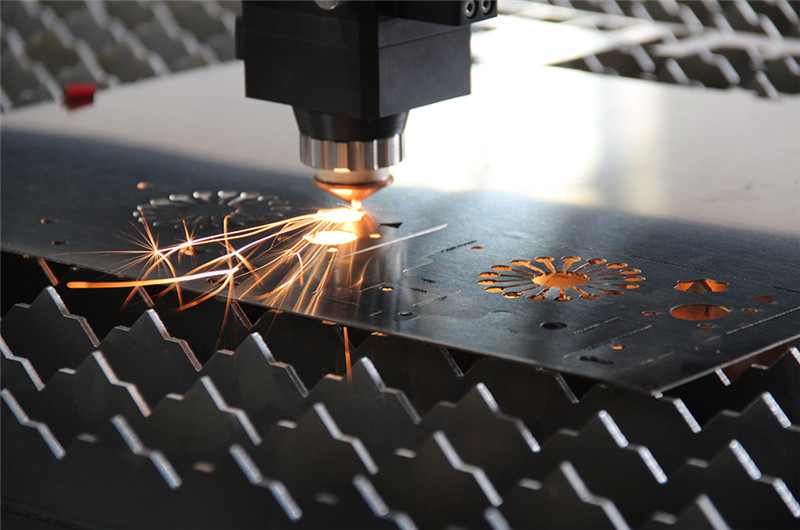

Témbongkeun Sampel

Max Laser Sumber Motong Parameter Prosés

| Catetan 1: Diaméter inti tina 1000W ~ 1500W serat kaluaran laser dina data motong nyaéta 50 microns; diaméter inti serat kaluaran 2000 ~ 4000W nyaéta 100 microns; | |||||||||

| Catetan 2: data motong ieu adopts Raytools motong sirah, collimation / fokus panjang fokus lénsa: 100mm / 125mm; | |||||||||

| Catetan 3: Alatan béda dina konfigurasi pakakas sarta prosés motong (alat mesin, cooling cai, lingkungan, motong nozzle sarta tekanan gas) diadopsi ku konsumén béda, data ieu keur rujukan wungkul; | |||||||||

| Matérial | Ketebalan (mm) | Gsalaku Tipe | 1000W | 1500W | 2000W | 2500W | 3000W | 4000W | 6000W |

| laju(m / mnt) | laju(m / mnt) | laju(m/min) | laju(m / mnt) | laju(m / mnt) | laju(m / mnt) | laju(m / mnt) | |||

| Beusi sténless | 1 | N2 | 20~24 | 28~32 | 38 | 30 | 50 | 42~43 | 70~75 |

| 2 | N2 | 5.4 | 7.5 | 12 | 10 | 13 | 19~20 | 25~30 | |

| 3 | N2 | 2.2 | 4 | 7 | 6 | 8 | 11~12 | 12~15 | |

| 4 | N2 | 1.2 | 2 | 4 | 4 | 5 | 6.5~7.5 | 7.5-9 | |

| 5 | N2 |

| 1.1 | 2 | 2.5 | 2.5 | 4~5 | 6~7.5 | |

| 6 | N2 |

| 0.8 | 1.5 | 1.5 | 1.5 | 2~3 | 5~6.5 | |

| 8 | N2 |

|

| 0.8 | 0.7 | 1 | 1.5~2 | 3.5~4.5 | |

| 10 | N2 |

|

| 0.5 | 0.5 | 0.8 | 1 | 2.1 | |

| 12 | N2 |

|

|

|

| 0.5 | 0.8 | 1.1 | |

| 14 | N2 |

|

|

|

|

|

| 0.9 | |

| Matérial | Ketebalan (mm) | Gsalaku Tipe | 1000W | 1500W | 2000W | 2500W | 3000W | 4000W | 6000W |

| laju(m / mnt) | laju(m / mnt) | laju(m/min) | laju(m / mnt) | laju(m / mnt) | laju(m / mnt) | laju(m / mnt) |

| Baja Karbon | 1 | hawa | 9~12 | 27~30 | 27~30 | 30 | 50 | 43 | 70~75 |

| 2 | hawa | 6~8 | 8~10 | 10~12 | 12 | 13 | 20 | 25~30 | |

| 3 | O2 | 3 | 3 | 3 | 4 | 4.5 | 4.5 | 4.5 | |

| 4 | O2 | 2 | 2.5 | 3.1 | 3.3 | 3.5 | 3.8 | 3.8 | |

| 5 | O2 | 1.6 | 2 | 2.5~3 | 2.5 | 3 | 3.5 | 3.7 | |

| 6 | O2 | 1.4 | 1.8 | 2.2 | 2.3 | 2.5 | 2.8 | 3.3 | |

| 8 | O2 | 1.1 | 1.3 | 1.5 | 1.5 | 2 | 2.3 | 2.8 | |

| 10 | O2 | 0.9 | 1.1 | 1 | 1.2 | 1.4 | 1.8 | 2.1 | |

| 12 | O2 | 0.7 | 0.9 | 0.8 | 1 | 1.1 | 1.5 | 1.6 | |

| 14 | O2 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 0.95 | ||

| 16 | O2 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 0.85 | ||

| 18 | O2 | 0.5 | 0.6 | 0.7 | 0.8 | 0.75 | |||

| 20 | O2 | 0.4 | 0.5 | 0.6 | 0.7 | 0.65 | |||

| 22 | O2 | 0.4 | 0.5 | 0.5 | 0.5 | ||||

| alumunium | 1 | hawa | 12~13 | 15 | 17~18 | 29 | 45 | 35~37 | 70~75 |

| 2 | hawa | 4~4.5 | 6 | 7.5 | 8.5 | 11 | 15 | 25~30 | |

| 3 | hawa | 1~1.5 | 3 | 5 | 5 | 7 | 8~9 | 15 | |

| 4 | hawa | 0.8~1 | 2 | 3 | 4 | 6 | 10 | ||

| 5 | hawa | 1 | 1.5 | 3 | 8 | ||||

| 6 | hawa | 0.6 | 1 | 2 | 5.5 | ||||

| 8 | hawa | 0.5 | 1 | 2.5 | |||||

| 10 | hawa | 0.5 | 1.3 | ||||||

| 12 | hawa | 0.9 | |||||||

| Kuningan | 1 | hawa | 10 | 12 | 15 | 24 | 40 | 30~33 | 65-70 |

| 2 | hawa | 3 | 5 | 6 | 7.5 | 10 | 13 | 20~25 | |

| 3 | hawa | 0.5 | 2 | 3 | 4 | 4 | 7 | 5 | |

| 4 | hawa | 0.5 | 1.5 | 2 | 3 | 5 | 4 | ||

| 5 | hawa | 0.5 | 1 | 1.5 | 2 | 3 | |||

| 6 | hawa | 0.5 | 0.8 | 1.5 | 2 | ||||

| 8 | hawa |

| 0.8 | 1.2 | |||||

| 10 | hawa |

|

| 0.5 |

Syarat Lingkungan Gawé

1. syarat kalembaban anu 40% -80%, euweuh kondensasi.

2. Sarat grid kakuatan: 380V; 50Hz/60A.

3. fluctuations grid catu daya: 5%, kawat taneuh grid meets sarat internasional.

4. Motong jeung gas bantu: Bersih, hawa dikomprés garing jeung oksigén purity tinggi (O2) jeung nitrogén (N2), purity teu kurang ti 99,9% purity.

5. Teu kudu aya gangguan éléktromagnétik kuat deukeut parabot instalasi.

6. Hindarkeun pamancar radio atawa stasiun relay sabudeureun situs instalasi.

7. Daya lalawanan grounding: ≤ 4 ohm. Amplitudo taneuh: kirang ti 50um; akselerasi Geter: kirang ti 0,05g.

8. Hindarkeun sajumlah ageung pakakas mesin sapertos stamping di sakurilingna.

9. tekanan hawa: 86-106kpa.

10. Sarat spasi Equipment dijamin bébas haseup jeung lebu-gratis, Ngahindarkeun lingkungan kerja berdebu kayaning polishing logam jeung grinding.

11. Hiji lantai anti statik kudu dipasang jeung kabel shielded disambungkeun.

12. Kualitas cai tina cai sirkulasi cooling digawé mastikeun diperlukeun, sarta cai murni, cai deionized atawa cai sulingan kudu dipaké.