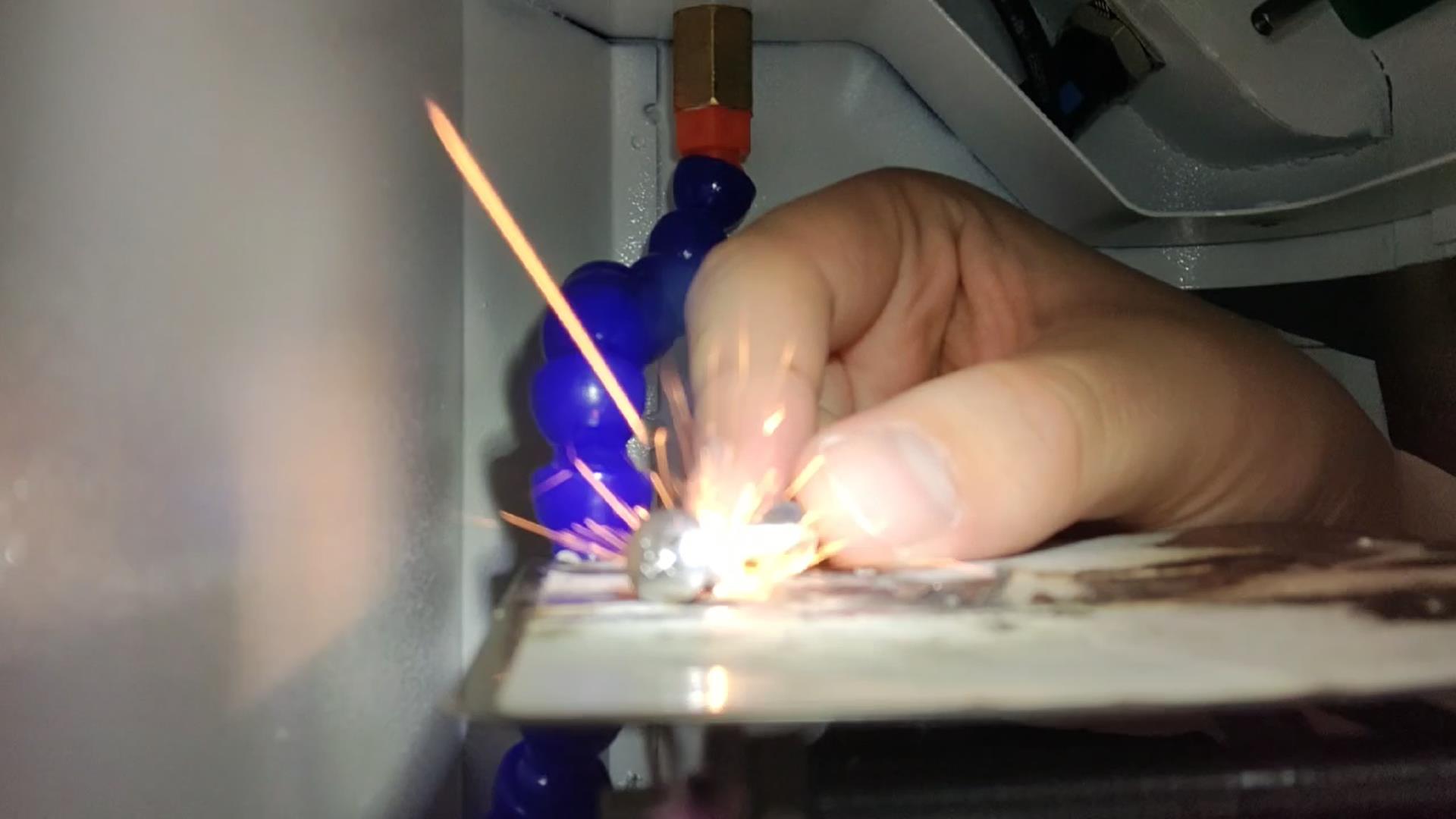

Mabenyane a khauta le silevera a bohlokoa haholo bophelong ba batho, empa ho sa tsotellehe hore na a theko e boima hakae, a boetse a hloka hore batho ba lokisetsoe ka hloko ho bontša 'mala oa bona o nepahetseng. Leha ho le joalo, ho na le taba e batlang e le boima mosebetsing oa ho lokisa mabenyane, ke hore,laser tjheseletsa. E-ba hlokolosi haholo ha u etsa soldering, 'me u hloka ho bona hantle haholo.

Mochini oa ho roala mabenyane a laser lethebae sebelisoa haholo-holo bakeng sa ho lokisa masoba le mahlaseli a ho cheselletsa matheba a mabenyane a khauta le silevera. Laser spot welding ke e 'ngoe ea lintlha tsa bohlokoa tsa ts'ebeliso ea theknoloji ea laser material process. Mocheso o kenella ka hare ka ho tsamaisa mocheso, 'me ka ho laola litekanyetso tse kang bophara, matla, matla a tlhōrō le ho pheta-pheta maqhubu a laser pulse, workpiece e qhibiliha ho etsa letamo le khethehileng le qhibilihisitsoeng. Ka lebaka la melemo ea eona e ikhethang, e sebelisitsoe ka katleho ho sebetsa mabenyane a khauta le silevera le welding ea likarolo tse nyane le tse nyane.

Mochini oa welding oa laserhaholo-holo e entsoe ka laser, phepelo ea motlakase le taolo, mochini o pholisang, tataiso ea leseli le tsepamiso, le pono ea li-binocular stereomicroscopic. E na le sebopeho sa compact le molumo o monyenyane. Matla a Laser, maqhubu a pulse le bophara ba pulse a ka hlophisoa esale pele mme a fetoloa ka phanele ea taolo. Motlakase o nka mohaho oa li-drawer, oo ho leng bonolo ho o tlosa, kahoo thepa e bonolo ho sebetsa le ho e hlokomela. Ha ho na tlhoko ea ho tlatsa solder, lebelo le phahameng la welding, puisano e tšepahalang, deformation e nyane ea workpiece, sebopeho se setle.

Likarolo tsa mochini oa welding laser spot welding:

● Matla, pulse width, frequency, spot size, joalo-joalo e ka fetoloa ka mefuta e mengata ho finyella liphello tse sa tšoaneng tsa welding. Li-parameter li lokisoa ke li-levers ka kamoreng e koetsoeng, e bonolo ebile e sebetsa hantle.

● Ho sebelisa ceramic concentrator cavity e tsoang linaheng tse ling ho tsoa UK, e hanyetsanang le kutu, mocheso o phahameng, le katleho e phahameng ea ho fetola photoelectric.

● Ho sebelisa mokhoa o tsoetseng pele oa lefats'e oa shading ho felisa ho halefa ha mahlo nakong ea lihora tsa mosebetsi.

● Ka bokhoni ba ho sebetsa bo tsoelang pele ba lihora tse 24, mochine oohle o na le ts'ebetso e tsitsitseng ea ho sebetsa 'me ha o na tlhokomelo nakong ea lihora tse 10,000.

● Moralo oa batho, o lumellanang le ergonomics, o sebetsa nako e telele ntle le mokhathala.

Ha mabenyane a khauta le silevera 'marakeng a ntse a fokotseha le ho feta, mathata a kang ho robeha le ho senya hangata a etsahala nakong ea tlhahiso kapa ho apara. Thetokiso ya mabenyanehangata e hloka theknoloji ea welding laser.Mechini ea ho roala mabenyane a laserba phethile karolo ea bohlokoa 'marakeng oa indasteri ena. Ka lebaka la mabenyane a mangata a bonolo a tšepe, mekhoa e mengata e phethoa ke theknoloji ea boemo bo holimo ea laser welding.

Joale ke hobane'ng ha mabenyane a sebelisa mechine ea welding ea laser? E fapane joang le mesebetsi ea matsoho ea setso?

Mokhoa o tloaelehileng oa tlhahiso ea mabenyane ke ho qhibilihisa tšepe ka mocheso o phahameng, ebe oa e cheselletsa le ho e sebetsa. Ts'ebetso ena ea welding hangata e etsa hore ho chesoa ha mabenyane a mabenyane, a ke keng a tlosoa ka ho feletseng esita le ka mor'a ho hloekisa hamorao, 'me ka linako tse ling a baka mabenyane a pele ka boeona. Gloss e fokotseha, e amang ka botebo botle ba mabenyane. Bakeng sa mathata a kopanang le tshebetso ya ho roala mabenyane a kapa ho lokisa laser tjheseletsa, themochini oa ho roala mabenyane oa lasere ka rarolla bothata habonolo le ka potlako. Ke ho lokisa sebaka se khanyang sebakeng sa tjheseletsa ea mabenyane a kang khauta le silevera, ho holisa sebaka sa welding ka lesoba la ho shebella, le ho etsa ts'ebetso sebakeng se lokelang ho sebetsoa.

Melemo ea ho sebelisa theknoloji ea welding ea laser ho sebetsa le ho lokisa mabenyane ke efe?

Ha e le hantle, ho tjheseletsa laser letheba ke mofuta oa conductivity ea mocheso, e nang le tšusumetso e nyenyane ea mocheso holim'a mabenyane, manonyeletso a manyenyane a solder, 'me a ke ke a silafatsa likarolo tse ling.Molemo ona o boetse o sebelisoa haholo ho tjheseletsa likarolo tse nepahetseng tse nepahetseng. Ho phaella moo, theknoloji ena e tla boela e sebelisane le tsamaiso ea tsamaiso ho ntlafatsa ts'ebetso e tsitsitseng ea mochine le lisebelisoa. E ka laola khafetsa le matla a lebone ho netefatsa phello ea welding ea meaho e rarahaneng kapa lintlha, ho ntlafatsa ho nepahala ha mosebetsi oa ho cheselletsa, le ho qoba ho cheseha ho tloaelehileng 'meleng oa motho. tshenyo ya mahlo.

Haeba u batla ho ithuta ho eketsehileng ka mochine oa welding oa laser, kapa u batla ho u rekela mochine o motle ka ho fetisisa oa welding oa laser, ka kopo siea molaetsa ho websaeteng ea rona mme u re romelle imeile ka ho toba!

Nako ea poso: Nov-26-2022