Ho phahama ha mebuso e meholo ea lefats'e ho qala ka ho haha likepe le ho pholletsa le leoatle. E le letšoao la bohlokoa la boemo ba indasteri ea naha,indasteri ea kaho ea likepe, e le "moqhaka oa liindasteri tse pharaletseng", o na le tekanyo e phahameng ea katoloso ea liindasteri le koloi e matla ea indasteri. Ho tloha halofo ea pele ea selemo sena, khaello ea bokhoni ba ho tsamaisa thepa lefatšeng ka bophara e lebisitse ho phahama ha litheko tsa likepe, 'me ho hōla ha tlhokahalo ea likepe ho entse hore ho be le keketseho ea litaelo tse ncha tsa likepe tsa machaba, ho tsoala "sebaka se atlehileng se sa kang sa bonoa lilemong tse leshome" indastering ea lefats'e ea kaho ea likepe. e ntle.

Leha boemo bo le botle, indasteri ea kaho ea likepe e ntse e hloka ho tobana le mathata a mangata a ntlafatso ea indasteri tlasa khatello e phahameng ea ts'ireletso ea tikoloho. Lilemong tsa morao tjena, Mokhatlo oa Machaba oa Maritime (IMO) o potlakisitse molao oa oona oa ts'ireletso ea tikoloho butle-butle, 'me matšoao a sebetsang hantle a matla le matla a khabone a thehile nako ea ho kena tšebetsong.

Ka nako e ts'oanang, sepheo sa "carbon peak le carbon neutral" se boetse se hlahisitsoe bakeng sa nts'etsopele e tala ea indasteri ea kaho ea likepe. Ka litlhoko tse ncha, "decarbonization" ke ea bohlokoa, 'me ts'ebeliso e tebileng ea matla a macha, lisebelisoa tse ncha le theknoloji e tala le e bohlale e fetohile tataiso ea bohlokoa ea indasteri ea kaho ea likepe le ho lokisa le ho tsamaisa likepe nakong e tlang.

Ka tloaelo, ho theola sekepe ke karolo ea bohlokoa ea ho lokisa le ho lokisa likepe. Nakong e fetileng, e ne e etsoa haholo-holo ka hamore ea kharafu ea matsoho kapa ho phatloha ha moea. Leha ho le joalo, hona joale likhoebong tse kholo tsa kaho ea likepe, ho hloekisoa ka laser ho ntseng ho eketseha ho sebelisoa ho hloekisa likepe. Ho hloekisa, ke hobane'ng ha ho na le phetoho e joalo? Kapa melemo eamechine ea ho hloekisa laserha li bapisoa le mekhoa ea khale ea ho hloekisa?

Mokhoa o tloaelehileng oa ho hloekisa ka ho haha le ho lokisa likepe

Kahong ea likepe le ho lokisoa, ho na le palo e kholo ea likhokahano tsa ho hloekisa, haholo-holo ho kenyeletsoa pretreatment ea tšepe ea tšepe (pele ho tjheseletsa le ka mora ho tjheseletsa) le segmental pretreatment (pele ho penta) ea likepe tse ncha, hammoho le ho tlosoa ha mafome le ho tlosoa ka kakaretso ho lokisoeng le ho hlokomeloa ha likepe tsa khale. Pente le tlhokomelo ea pente ea bobeli.

Mekhoa e tloaelehileng ea ho hloekisa le ho tlosa pente haholo-holo e kenyelletsa ho sila ka letsoho, ho qhomisa lehlabathe, ho phatloha ha lithunya, ho hlatsoa metsi ka khatello e phahameng le ho hloekisa lik'hemik'hale. Mekhoa ena ea setso ea ho hloekisa e ka finyella litlhoko tsa ho hloekisa li-hull mabapi le katleho le boleng ba ho tlosa mafome, empa e ke ke ea hlokomolohuoa. E, ka kakaretso ke mosebetsi o boima, tšebeliso e phahameng ea metsi le motlakase, haholo-holo sandblasting e hlahisa mosi o mongata le lerōle, e bakang tšilafalo e tebileng ho tikoloho, hammoho le ho sebelisoa ha metsi a litšila ka mor'a ho hlatsoa metsi ka khatello e phahameng, 'me mesebetsi e meng e nang le litlhoko tse phahameng tsa bohloeki e ke ke ea phethoa joalo-joalo.

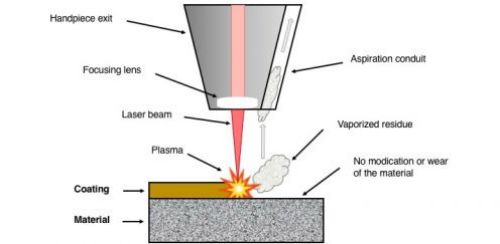

Theknoloji ea ho hloekisa lasere na le melemo e mengata joalo kaha ho na tšenyo ho substrate, taolo e nepahetseng boemong ba micron, ho boloka matla le ts'ireletso ea tikoloho, kahoo e fetohile sebaka sa lipatlisiso kahong ea likepe.

1. Ho tlosoa ha mafome ka letsoho

Lisebelisoa tsa ho tlosa mafome ka letsoho li kenyelletsa lihamore, likharafu, lithipa tsa tšepe, borashe ba terata, joalo-joalo. Matla a phahameng a mosebetsi le katleho e tlase ea ho tlosa mafome.

2. Ho tlosoa ha mafome a mechine

(1) Ho tlosa mafome a manyenyane a moea kapa a motlakase; (2) Ho ntša mafome a thunyang (lehlabathe);

(3) Ho senyeha ha metsi ka khatello e phahameng; (4) Ho senya ka ho thunya.

3. Ho tlosoa ha mafome a lik'hemik'hale

Haholo-holo ke mokhoa oa ho tlosa mafome o sebelisang lik'hemik'hale tsa lik'hemik'hale pakeng tsa asiti le li-oxide tsa tšepe ho tlosa mafome holim'a tšepe ea tšepe, ke hore, seo ho thoeng ke pickling le ho tlosoa ha mafome, se ka sebetsoang feela ka har'a workshop. Ho tlosa mafome a lik'hemik'hale ho na le kotsi e kholo, tšilafalo e tebileng ea tikoloho, 'me e thibetsoe ho sebelisoa.

4. Ho tlosoa ha mafome a laser

Ho tlosoa ha mafome a laser ke theknoloji e ncha e tala, e nang le tikoloho, e sebetsang hantle le e sireletsehileng, e tla tloha e nkela mekhoa e ka holimo sebaka 'me e sebelisoe haholo. Haholo-holo ho hlobolisa pente, ho tlosa oli, ho hloekisa le ho tlosa mafome, le ho tlosoa ha oxide layer, ho hloekisa laser ho tla bapala karolo e ke keng ea nkeloa sebaka.

Ho ipapisitsoe le 'nete e boletsoeng ka holimo, tlas'a litlhoko tsa litekanyetso tse ncha tsa EIA, likhoebo tsa indasteri ea kaho ea likepe li tlameha ho batla mekhoa le mekhoa e mecha ea ho hloekisa, e sebetsang hantle le e hloekileng ho rarolla mathata a indasteri.

Ho hloekisa ka laser ho etsa hore ho hloekisa sekepe e be khetho ea bohlokoa

Lilemong tsa morao tjena, tlas'a bobuelli ba ts'ebetso e phahameng, ho boloka matla le ts'ireletso ea tikoloho ho ntšetsa pele nts'etsopele ea indasteri, theknoloji ea ho hloekisa ka laser e hlahile butle-butle lits'ebetsong tse phahameng tse kang likoloi tse ncha tsa matla, sefofane le lisebelisoa tsa elektronike tse nepahetseng, 'me e boetse e bontšitse bokhoni bo eketsehileng ba ho sebetsa indastering ea kaho ea likepe.

Theknoloji ea ho hloekisa laser e na le melemo e mengata e kang ho se senyehe ho substrate, taolo e nepahetseng boemong ba micron, ho boloka matla le ts'ireletso ea tikoloho, joalo-joalo, 'me e ka finyella ka botlalo litlhoko tsa ho tlosoa ha mafome a profiles tsohle tsa tšepe le pretreatment pele le ka mor'a welding.

Mabapi le tlhokomelo ea likepe, ho hloekisa ka laser, e le theknoloji ea "high-precision" ea ho hloekisa, e loketse ho pebola ha mafome le pente holim'a li-cabins, litanka tsa ballast, litanka tsa mafura, joalo-joalo, hammoho le ho hloekisa li-deposit tsa carbon tse kang li-cylinder valves tsa marine diesel.

Haeba u batla ho ithuta ho eketsehileng ka ho hloekisa ka laser, kapa u batla ho u rekela mochine o molemo ka ho fetisisa oa ho hloekisa ka laser, ka kopo siea molaetsa ho websaeteng ea rona 'me u re romelle imeile ka ho toba!

Nako ea poso: Oct-12-2022