Theknoloji ea ho hloekisa ka laser ke theknoloji e ncha ea ho hloekisa e tsoetseng pele ka potlako lilemong tse 10 tse fetileng. Butle-butle e nkile sebaka sa mekhoa ea khale ea ho hloekisa masimong a mangata ka melemo ea eona le ho se nkeloe sebaka. Ho hloekisa ka laser ho ka sebelisoa eseng feela ho hloekisa litšila tsa lintho tse phelang, empa hape le ho hloekisa lintho tse sa tloaelehang, ho akarelletsa le mafome a tšepe, likaroloana tsa tšepe, lerōle, joalo-joalo. Likopo tse ling tse sebetsang li hlalositsoe ka tlase. Theknoloji ena e hōlile haholo ebile e sebelisoa haholo.

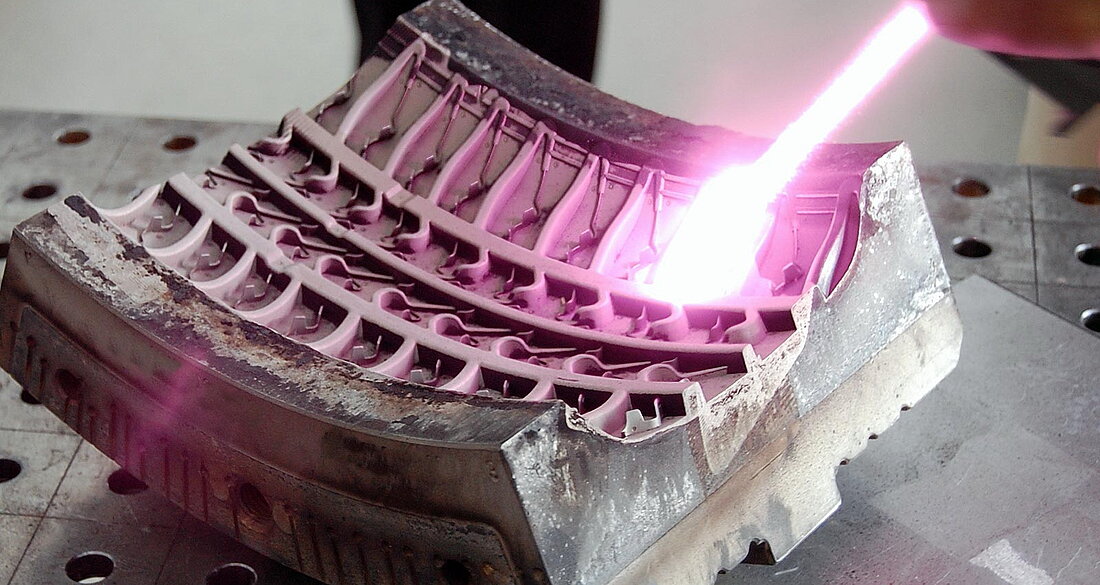

Bahlahisi ba lithaere lefatšeng ka bophara ba etsa lithaere tse limilione tse makholo selemo se seng le se seng, ’me ho hloekisoa ha hlobo ea lithaere nakong ea tlhahiso e tlameha ho etsoa ka potlako le ka botšepehi e le ho boloka nako ea ho theoha. Mekhoa e tloaelehileng ea ho hloekisa e kenyelletsa ho hloekisa lehlabathe, ho hloekisa ka ultrasonic kapa carbon dioxide, joalo-joalo, empa hangata mekhoa ena e lokela ho isoa lisebelisoa tsa ho hloekisa ka mor'a hore hlobo e chesang e chesang e pholile lihora tse 'maloa, e leng nako e telele' me e senya habonolo ho nepahala ha hlobo. , metsoako ea lik'hemik'hale le lerata le tsona li tla baka mathata a kang polokeho le tšireletso ea tikoloho.

Ho sebelisa mokhoa oa ho hloekisa ka laser, hobane laser e ka fetisoa ka fiber optical, e bonolo haholo ha e sebelisoa; hobane mokhoa oa ho hloekisa laser o ka kopanngoa le fiber optical ho tataisa leseli ho ea sekhutlong se shoeleng sa hlobo kapa likarolo tse seng bonolo ho hloekisoa, kahoo ho bonolo ho li sebelisa; Ha ho na gasification, kahoo ha ho na khase e chefo e tla hlahisoa, e tla ama tšireletseho ea tikoloho ea mosebetsi.

Theknoloji ea ho hloekisa hlobo ea lithaere ka laser e sebelisitsoe haholo indastering ea mabili Europe le United States. Le hoja litšenyehelo tsa pele tsa matsete li le holimo, melemo e fumanoang ka ho boloka nako ea ho ema, ho qoba tšenyo ea hlobo, tšireletso ea ho sebetsa le ho boloka thepa e tala e ka fumanoa kapele.

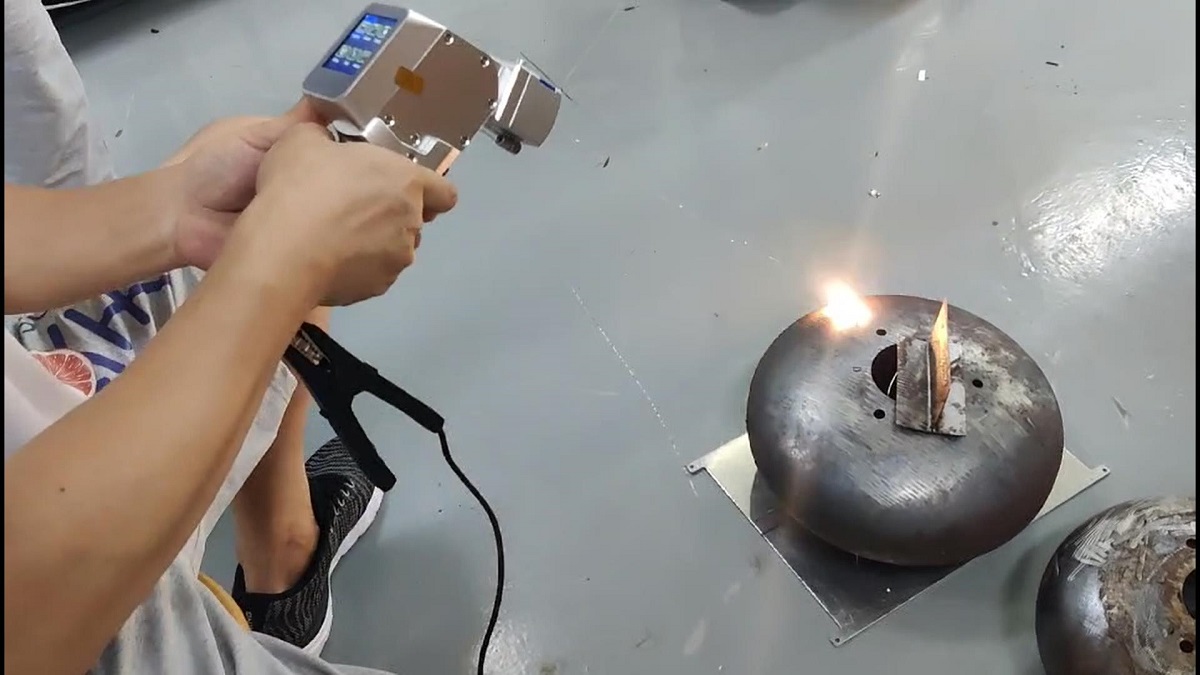

Joalo ka litšepe tse hloekisang, ho ntšoa ka laser bakeng sa lirafshoa ho sebetsa ka ho khantša litšila tse holim'a metsi ka likete tsa maqhubu a laser motsotsoana. Ts'ebetso e bolokehile bakeng sa lera la ceramic la substrate mme e baka litšila tse nyane - tseo hangata li nkuoang ke nozzle e hahelletsoeng ka har'a laser.

Joalo ka ts'ebeliso efe kapa efe ea ho hloekisa ka laser, senotlolo sa katleho ea ho hloekisa ceramic ke tharollo ea laser e lekantsoeng hantle. U batla sisteme ea laser e ka fihlelang moeli o hlokahalang bakeng sa ho hloekisa likarolo tse silafatsang ntle le ho senya lihlahisoa tseo u li hloekisang. Ka hona, ho khetha laser kaboemo bo nepahetseng ba matla, litlhophiso, optics, le tsamaiso ea ho fana ke ea bohlokoa. Ka lehlohonolo,litsebi tsa rona tsa laserba le tsebo ea ho netefatsa hore u lula u e-na le laser e nepahetseng bakeng sa mosebetsi.

3. Ho hloekisa pente ea khale ea lifofane

Sistimi ea ho hloekisa ka laser esale e sebelisoa indastering ea lifofane Europe. Bokaholimo ba sefofane bo hloka ho penta bocha ka mor'a nako e itseng, empa pente ea khale ea khale e hloka ho tlosoa ka ho feletseng pele e penta. Mokhoa o tloaelehileng oa ho tlosa pente ea mechine o bonolo ho baka tšenyo holim'a tšepe ea sefofane, e leng se tlisang likotsi tse patehileng ho fofa ho sireletsehileng. U sebelisa lisebelisoa tse ngata tsa ho hloekisa ka laser, pente e ka tlosoa ka ho feletseng ho Airbus ea A320 nakong ea matsatsi a mabeli ntle le ho senya bokaholimo ba tšepe.

4. Ho hloekisa mohaho oa mabota a ka ntle

Ka tsoelo-pele e potlakileng ea moruo oa naha ea rona, ho se ho hahiloe mehaho e meholohali e ntseng e eketseha, ’me bothata ba ho hloekisa mabota a ka ntle a mehaho bo se bo totile haholo. Sistimi ea ho hloekisa laser e fana ka tharollo e ntle ea ho hloekisa mabota a kantle a meaho ka likhoele tsa optical. E ka khona ho hloekisa ka katleho litšila tse fapaneng holim'a majoe a fapaneng, tšepe le khalase, 'me katleho e phahame ka makhetlo a mangata ho feta ea ho hloekisa ka mokhoa o tloaelehileng. E ka boela ea tlosa matheba a matšo le matheba holim'a thepa e sa tšoaneng ea majoe ea mehaho.

Indasteri ea lisebelisoa tsa elektronike e hloka ho hloekisoa ka mokhoa o nepahetseng haholo, 'me e loketse ka ho khetheha bakeng sa laser deoxidation. Lithako tsa motsoako li tlameha ho hlakoloa ka botlalo pele li soasoa ho etsa bonnete ba hore ho na le khokahano e nepahetseng ea motlakase ntle le ho senya lithakhisa nakong ea ts'ebetso ea ho tlosa litšila. Ho hloekisa ka laser ho ka finyella litlhoko tsa ts'ebeliso, 'me katleho e phahame haholo,' me ke pin e le 'ngoe feela e hlokang ho khabisoa ka laser.

6. Ho hloekisoa ka mokhoa o nepahetseng ho hloekisa indasteri ea lisebelisoa tse nepahetseng

Indasteri ea mechini e nepahetseng hangata e hloka ho tlosa li-ester le oli ea liminerale tse sebelisetsoang ho tlotsa le ho thibela kutu likarolong, hangata ka lik'hemik'hale, 'me ho hloekisa lik'hemik'hale hangata ho siea masalla. Laser deesterification e ka tlosa li-ester le oli ea diminerale ka botlalo ntle le ho senya bokaholimo ba likarolo. Ho tlosoa ha litšila ho finyelloa ke maqhubu a ts'oaetso, a entsoeng ke ho phatloha ha gasification ea lesela le tšesaane la oxide holim'a likarolo, e leng se etsang hore ho tlosoe litšila ho e-na le ho sebelisana ha mechine. Thepa e felisitsoe ka botlalo bakeng sa ho hloekisa likarolo tsa mochini indastering ea lifofane. Ho hloekisa ka laser ho ka boela ha sebelisoa bakeng sa ho tlosa oli le ester ha ho etsoa likarolo tsa mochini.

7. Ho hloekisa lipeipi tsa mochini oa matla a nyutlelie

Lits'ebetso tsa ho hloekisa ka laser li boetse li sebelisoa ho hloekiseng liphaephe ho li-reactor tsa polante ea matla a nyutlelie. E sebelisa li-fiber tsa optical ho hlahisa marako a laser a matla a phahameng ka har'a reactor ho tlosa lerole la radioactive ka kotloloho, 'me lisebelisoa tse hloekisitsoeng li bonolo ho li hloekisa. 'Me kaha e sebetsoa hole, ho ka netefatsoa tšireletseho ea basebetsi.

Ho akaretsa, ho hloekisa ka laser ho phetha karolo ea bohlokoa likarolong tse ngata, 'me ho sebelisoa ho etsa likoloi, ho hloekisa liphaephe tsa semiconductor, ho sebetsa ka mokhoa o nepahetseng le ho etsa lihlahisoa, ho hloekisa lisebelisoa tsa sesole, ho hloekisa lerako la ka ntle, tšireletso ea litloaelo tsa setso, ho hloekisa boto ea potoloho, likarolo tse nepahetseng Ho sebetsa le ho etsa, ho hloekisa kristale ea metsi, ho tlosa masala a chewing gum le likarolo tse ling li ka phetha karolo ea bohlokoa.

Ts'ebeliso ea ho hloekisa ka laser ho ts'ireletso ea naha le lisebelisoa tsa sesole: joalo ka ho hlobola pente le ho tlosoa ha mafome a lifofane tse fapaneng, lisebelisoa tse fapaneng tsa likepe, ho tlosoa ha mafome a libetsa tse fapaneng, ho tlosa mafome a likoloi tse fapaneng le lithunya, likarolo tse fapaneng tsa ho tlosa mafome, joalo-joalo, ka tebello e pharaletseng, mokhoa oa nts'etsopele o na le monyetla o moholo. Haholo-holo, ho hloekisa ka laser ho na le melemo e hlakileng joalo ka ts'ireletso ea tikoloho, boiketlo, polokeho, le ts'ebeliso e theko e tlase. Ke theknoloji e ncha, e sebetsang hantle le e bolokehileng.

Haeba u na le lits'ebetso tse ling tseo u batlang ho li hlahloba hore na mochini o hloekisang oa laser o ka sebelisoa, ka kopo ikopanye le rona ka WhatsApp kapa lengolo-tsoibila! Fortune laser e tla u fa tšehetso e ntle ka ho fetisisa ea tekheniki le mechini.

Nako ea poso: Aug-26-2022