Ts'epe e sa hloekang e sebelisoa haholo liindastering tse fapaneng ka lebaka la thepa ea eona e ikhethang joalo ka ho hanyetsa kutu le sebopeho. Ka tsoelo-pele ea theknoloji, welding laser e se e le mokhoa o mocha oa ho tjheseletsa, o nang le melemo e mengata ha o bapisoa le mekhoa ea khale ea ho tjheseletsa. Leha ho le joalo, e 'ngoe ea liqholotso tsalaser tjheseletsake deformation ea tšepe e sa hloekang. Sehloohong sena, re tla tšohla mokhoa oa ho qoba tšepe e se nang tšepe laser welding deformation le ho hlahlobisisa lintlha tse amanang le eona.

Taba ea pele, hoa hlokahala ho utloisisa hore na ke hobaneng ha welding ea laser e baka deformation ea tšepe e sa hloekang. Ho tjheseletsa ka laser ho kenyelletsa ho sebedisa lebone le nang le matla a phahameng a laser ho qhibiliha le ho kopanya bokaholimo ba likotoana tse peli tsa tšepe hammoho. Nakong ea ts'ebetso ena, ho futhumala ka potlako le ho pholile ho baka ho senyeha ha mocheso, ho bakang deformation ea sebaka se cheselitsoeng. Le hoja sena se bonahala se ke ke sa qojoa, ho na le mehato e mengata e ka nkoang ho fokotsa kapa ho felisa ho khopamisoa.

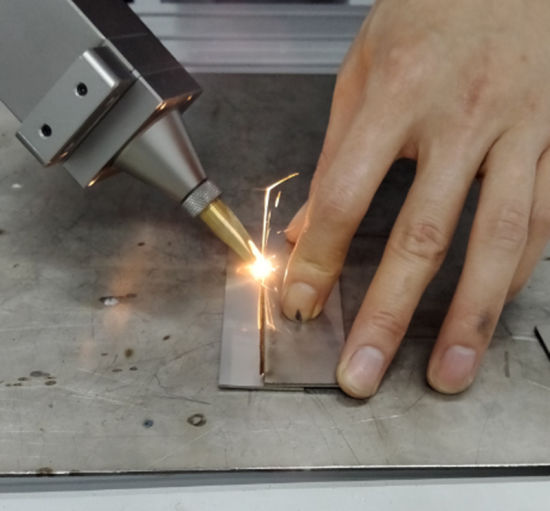

E 'ngoe ea mehato ea pele ea ho qobalaser tjheseletsaho sotha ke khetho e hlokolosi ea li-parameter tsa welding tsa laser. Lintlha tse kang matla a laser, lebelo la ho tjheseletsa, le ho tsepamisa maikutlo ho lokela ho ntlafatsoa ho fihlela boleng bo lakatsehang ba weld. Ka ho lokisa liparamente tsena, ho kenya mocheso ho ka laoloa 'me ho senyeha ha mocheso ho bakang ho sotha ho ka fokotsoa. Ho feta moo, ho sebelisa pulsed mode ho fapana le maqhubu a tsoelang pele ho thusa ho fokotsa sebaka se amehileng ke mocheso le deformation e latelang.

Ntho e 'ngoe ea bohlokoa eo ho nahanoang ka eona ke moralo oa sehokelo ka boeona. Sebopeho, boholo le tlhophiso ea lenonyeletso li ka ama haholo palo ea deformation e etsahalang nakonglaser tjheseletsa. Ho fokotsa ho khopama, ho kgothaletswa ho sebelisa li-welds tse pharaletseng le ho qoba likhutlo tse bohale kapa tse bohale. Sena se aba mocheso ka ho lekana le ho fokotsa khatello ea maikutlo ea mocheso. Ho feta moo, ts'ebeliso ea li-welds tsa fillet (li-welds tse nang le libopeho tsa concave kapa convex curve) le tsona li thusa ho fokotsa ho khopama.

Ntle le liparamente tsa welding le moralo o kopaneng, khetho ea botenya ba thepa le eona e bapala karolo ea bohlokoa ho qoba ho khopama. Lishiti tse teteaneng tsa tšepe tse sa hloekang li na le tšekamelo ea ho holofala ka lebaka la conductivity ea tsona e phahameng ea mocheso. E le ho fokotsa sena, ho kgothaletswa hore o sebelise mashiti a masesaane a sa hloekang kapa a sebelise mocheso oa mocheso kapa mokhoa o pholileng nakong ea ts'ebetso ea soldering. Mekhoa ena ea ho pholisa e thusa ho qhala mocheso o feteletseng le ho fokotsa likhahla tsa mocheso, ho fokotsa ho khopama.

Ho feta moo, ho sebelisa mekhoa e nepahetseng ea ho lokisa le ho koala ho ka thusa haholo ho qoba ho sotha ha laser welding. Sesebelisoa se bolela ho beoa le ho lokisoa ha sesebelisoa nakong ea ts'ebetso ea welding. Ke habohlokoa ho etsa bonnete ba hore workpiece e tšehetsoa ka ho lekaneng le ho lumellana ho thibela ho sisinyeha leha e le hofe kapa ho loana nakong ea welding. Ka lehlakoreng le leng, clamping e kenyelletsa ho ts'oara sesebedisoa sebakeng se sebelisa li-jigs kapa li-fixtures tse entsoeng ka ho khetheha. Ho koala hantle ho thusa ho boloka boemo bo lakatsehang ba ho tsamaisana le ho fokotsa monyetla oa ho loana.

Qetellong, kalafo ea mocheso ka mor'a weld e ka sebelisoa ho imolla khatello ea maikutlo e setseng le ho fokotsa ho khopama. Ho kopanya, ho imolla khatello ea maikutlo, esita le mekhoa e bonolo ea ho pholisa moea e thusa ho tsitsisa meaho e cheselitsoeng le ho fokotsa ho khopama. Tšebeliso ea lisebelisoa tse khethehileng tsa phekolo ea mocheso le mekhoa e ka fana ka libaesekele tse hlokahalang tsa mocheso ho etsa bonnete ba hore tšepe e entsoeng ka tšepe e sa tsitsang e lula e tsitsitse ebile e se na deformation.

Ka kakaretso,laser tjheseletsae fana ka melemo e mengata ho feta mekhoa ea khale ea ho tjheseletsa ho latela lebelo, ho nepahala le boleng. Leha ho le joalo, deformation ea tšepe e sa hloekang e baka liphephetso ts'ebetsong ea welding ea laser. Stainless steel laser welding distortions ka sebetsanoa ka katleho ka khetho e hlokolosi le ho ntlafatsa litekanyo tsa tjheseletsa, moralo oa tlhophiso e nepahetseng ea kopanelo, ho nahanoa ka botenya ba thepa, ho kengoa ts'ebetsong ha mekhoa e nepahetseng ea ho lokisa le ho koala, le ts'ebeliso ea kalafo ea mocheso ka mor'a weld. Mehato ena, e kopantsoe le thepa ea tlhaho ea tšepe e sa hloekang, e kenya letsoho ho li-welds tsa boleng bo phahameng tse nang le ho sotha ho fokolang.

Haeba u batla ho ithuta ho eketsehileng ka laser welding, kapa u batla ho u rekela mochine o motle ka ho fetisisa oa laser welding, ka kopo siea molaetsa hosaeteng ea rona 'me u re romelle imeile ka ho toba!

Nako ea poso: Jul-18-2023