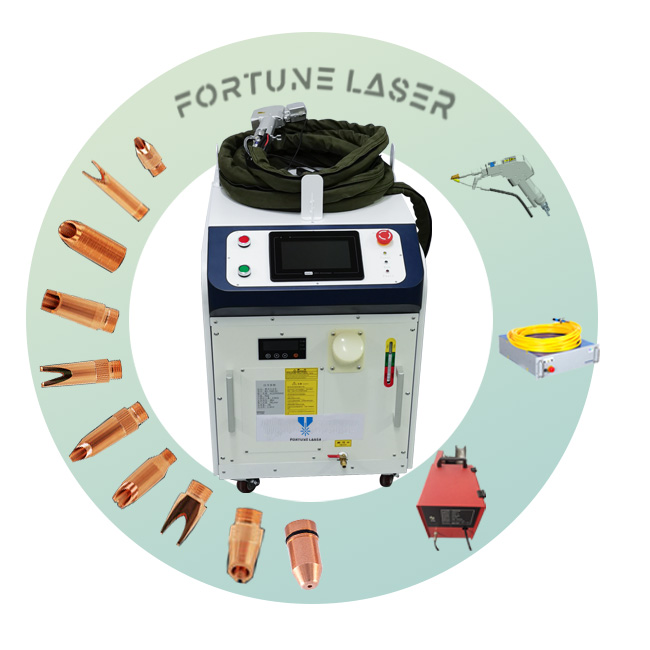

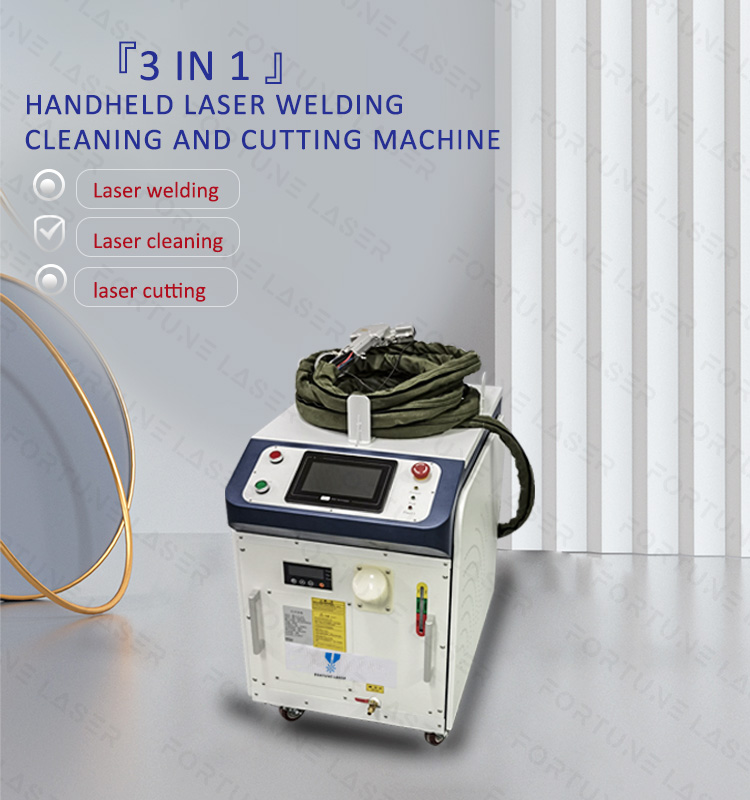

Handheld 3 in 1 Laser Welding Cleaning Setting Machine

Handheld 3 in 1 Laser Welding Cleaning Setting Machine

3 In 1 Handheld Laser Cutting, Welding, Cleaning Machine Features

1. Joalo kalaser cleaner, ke mokhoa o "tala" oa ho hloekisa. Ha e hloke ho sebelisa lik'hemik'hale leha e le life le tharollo ea ho hloekisa. Litšila tse hloekisitsoeng ha e le hantle ke phofo e tiileng. E nyane, ho bonolo ho e boloka ebile e ka sebelisoa hape. E ka rarolla bothata ba tšilafalo ea tikoloho e bakoang ke ho hloekisa lik'hemik'hale habonolo.

2. Joalo kalaser welder, seam se cheselletsang se boreleli ebile se setle, ha se hloke ho bentša, ha ho na leqeba la deformation kapa welding, ho tjheseletsa ho tiileng ha karolo. Boloka nako le ho ntlafatsa tshebetso.

3. Joalo kalaser seha, ho bonolo haholo ho sebetsa ho khaola mefuta eohle ea litšepe.

4.Sethunya sa laser se nkehang se na le sebopeho se bonolo sa letsoho 'me se bonolo ho se jara. E na le skrine ea ho ama, e bonolo ho fetola liparamente nakong ea mosebetsi le ho nolofatsa ts'ebetso. Boima ba 'mele ke 0.8kg, e bonolo ho e sebelisa ntle le mokhathala.

5.E amohela mohloli oa profeshenale oa fiber laser o nang le sekhahla se tlase sa liphoso, tšebeliso e tlase ea matla, mahala ea tlhokomelo, 'me ho bonolo ho e kopanya.

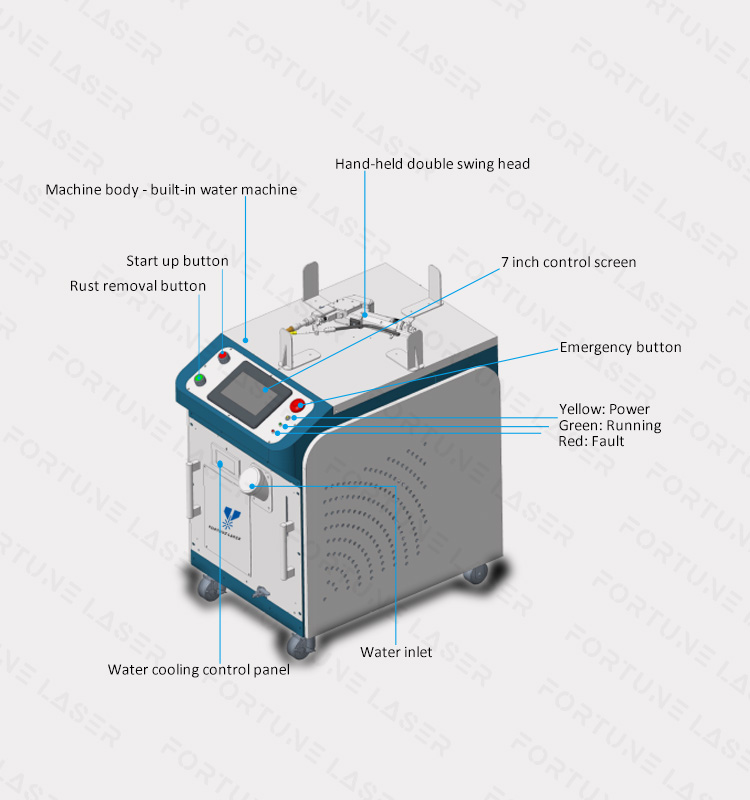

6.Industrial kamehla mocheso metsi cooling chiller e etselitsoe ka ho khetheha. Sehlahisoa sa metsi se na le sefe, se nang le ts'ebetso e bolokehileng, e tšoarellang, e tsitsitseng le bophelo bo bolelele ba ts'ebeletso. Sistimi e matla le e tsitsitseng ea ho futhumatsa metsi e tla netefatsa hore mohloli oa fiber laser o sebetsa hantle.

7. Moqapi o nkehang: Moqapi o tiileng, oa ergonomic, o nang le mabili a tsamaeang ka bolokolohi.

| Fortune Laser Portable 3 in 1 Laser Welding Cleaning Cutting Machine | |||

| Matla a Laser | 1000W | 1500W | 2000W |

| Mohloli oa Laser | GW 25um core diameter fiber laser (Raycus/JPT/MAX/IPG boikhethelo) | ||

| Wavelength (nm) | 1064 - 1080 | ||

| Mokhoa oa Laser | Laser Welding/ Laser Cutting/ Ho hloekisa Laser | ||

| Bolelele ba Fiber | 10M(e ka tloaeleha) | ||

| Mokhoa oa ho sebetsa | Tsoela pele/ Ho feto-fetoha ha modumo | ||

| Hlooho ea laser | Dual Axis | ||

| Sehokedi | QBH | ||

| Bophara ba Welding | 0.2-0.5mm(e ka fetoloang) | ||

| Tlhahlobo ea Laser | Tlhahlobo e Kopantsoeng ea Leseli le Lefubelu | ||

| Litlhoko tsa lekhalo la welding | ≤1.2mm | ||

| Botenya ba tjheseletsa | 0.5-3 limilimithara | ||

| Lebelo la Welding | 0-120mm/s (e ka feto-fetoha) | ||

| Bolelele ba tsepamiso e arotsoeng | 75 limilimithara | ||

| Tsepamiso/Bolelele bo Hloekileng ba Tsepamiso | F150mm/F500mm | ||

| Sebaka sa ho tsubella | 0.1-5 limilimithara | ||

| Leqhubu la ho sisinyeha | 0-300Hz | ||

| Ho phodisa | Sehlahisoa sa Metsi se Kopantsoeng | ||

| Puo | Sechaena/Senyesemane/Serussia/Sekorea/Le lipuo tse ling ha ho hlokahala. | ||

| Phepelo ea motlakase | AC 220V, 50Hz/60Hz | AC 380V, 50Hz/60Hz | |

| Tlhophiso ea Parameter | Sehlopha sa ho ama | ||

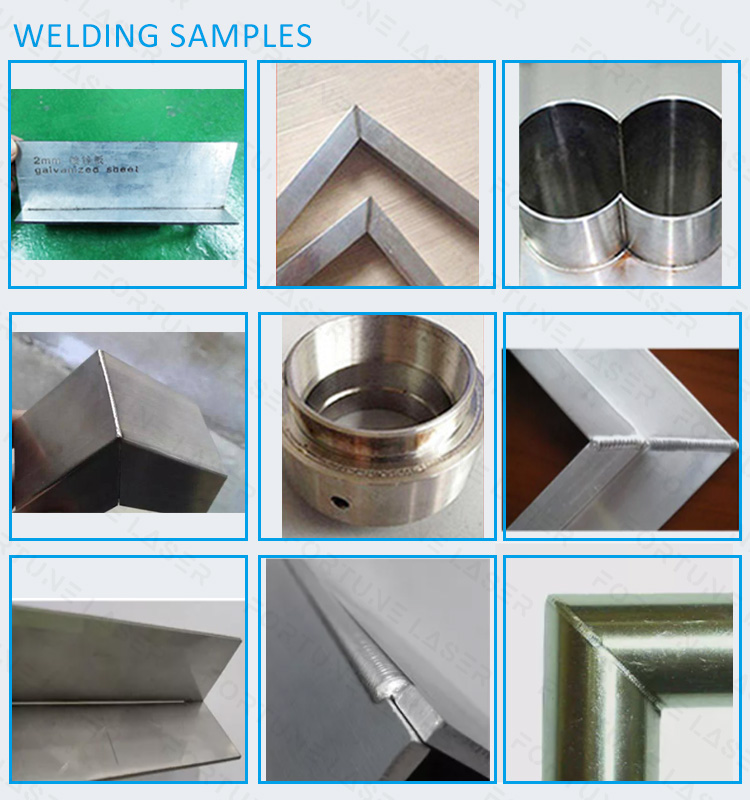

| Lisebelisoa tsa Welding | Carbon Steel, Stainless Steel, Aluminium, Brass, Alloy joalo-joalo. | ||

| Ambient Mocheso | 10 ~ 40°C | ||

| Boikokobetso ba Tikoloho | <70% Ntle le Condensation | ||

| LIEKETSENG LASER CHESESO | ||

| Lintho tse bonahalang | Matla a Laser (watt) | Ho Kena ho Felletseng (mm) |

| Ts'epe e sa beng le mabali | 1000 | 0.5-3 |

| Ts'epe e sa beng le mabali | 1500 | 0.5-4 |

| Tšepe ea Carbon | 1000 | 0.5-2,5 |

| Tšepe ea Carbon | 1500 | 0.5-3.5 |

| Aluminium Alloy | 1000 | 0.5-2,5 |

| Aluminium Alloy | 1500 | 0.5-3 |

| Leqephe la Galvanized | 1000 | 0.5-1.2 |

| Leqephe la Galvanized | 1500 | 0.5-1.8 |

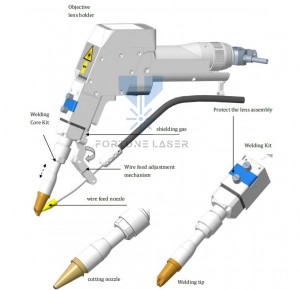

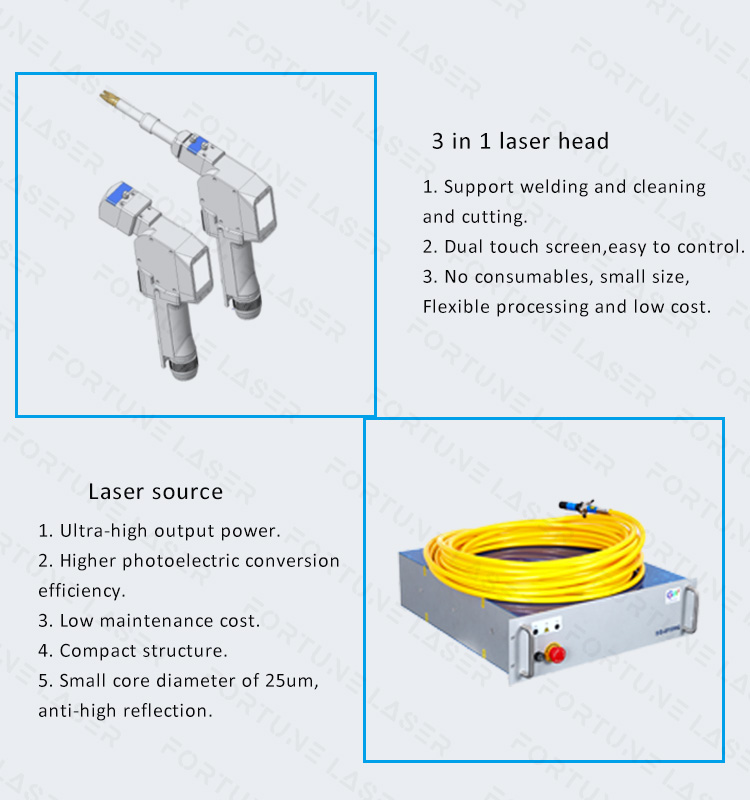

Sethunya sa laser se tšoaroang ka letsoho se ka etsa tjheseletsa, ho hloekisa le ho seha ka taolo e bohlale, e bonolo ho e sebelisa bakeng sa machining e tenyetsehang, e nkehang ka boholo bo nyane, theko e tlase ntle le lisebelisoa. Basebelisi ba ka beha liparamente ka skrineng ea ho ama ka sethunya sa laser, se bonolo haholo ebile se bonolo ho se sebelisa.

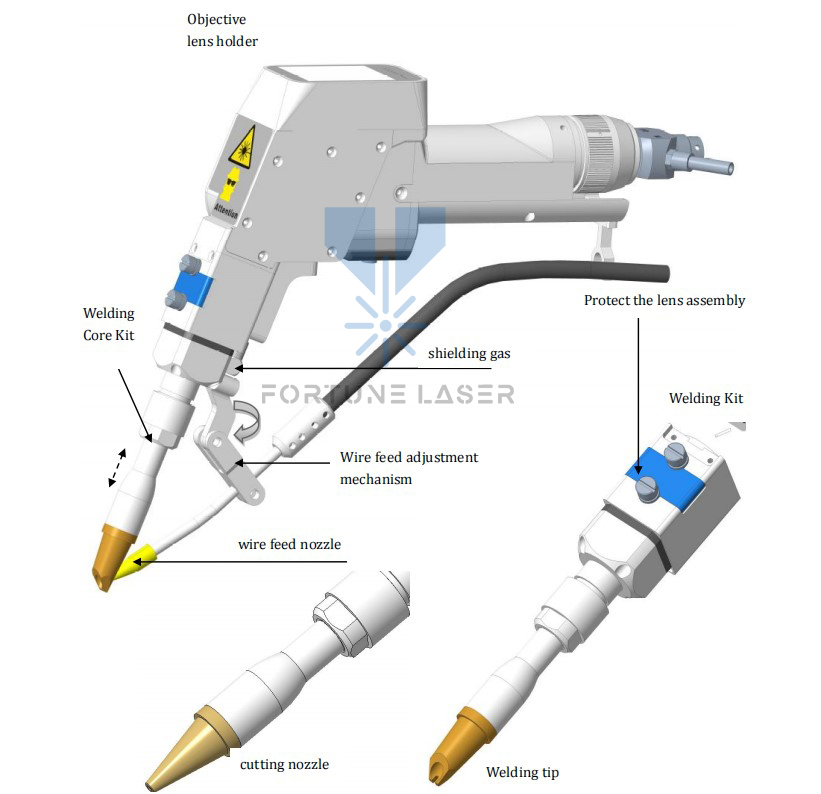

Habeli pendulum handheld tjheseletsa hlooho Features:

A. Hlooho ena ea ho tjheseletsa e na le melemo e matla ho tšepe e sa hloekang, aluminium alloy welding, le lisebelisoa tse nyane le tse mahareng tsa matla a ho tjheseletsa. Ke hlooho ea li-welding e bolokang chelete e ngata.

B. Hlooho ea ho tjheseletsa e amohela lense e khannoang ka enjene ea X, Y-axis vibrating lens, e nang le mekhoa e mengata ea ho sisinyeha, 'me swing welding e lumella mosebetsi hore o be le welding e sa tloaelehang, likheo tse kholoanyane le lisebelisoa tse ling tsa ts'ebetso, tse ka ntlafatsang haholo boleng ba ho cheselletsa.

C. Sebopeho sa ka hare sa hlooho ea welding se tiisitsoe ka ho feletseng, se ka thibelang karolo ea optical hore e se ke ea silafatsoa ke lerōle.

D.Ka boikhethelo li-welding/cutting kits le lisebelisoa tsa ho hloekisa ka sebele li ka finyella mesebetsi e meraro ea ho cheselletsa, ho itšeha le ho hloekisa.

E. Lense e sireletsang e nka mohaho oa li-drawer, oo ho leng bonolo ho o nkela sebaka.

F.E ka ba le lisebelisoa tse fapaneng tsa lasers tse nang le likhokahano tsa QBH.

G. Nyenyane e nyane, ponahalo e ntle le maikutlo.

HA touch screen ke boikhethelo hloohong ea welding, e ka hokahanngoang le sethala sa sethala bakeng sa boiphihlelo bo betere ba taolo ea mochini oa motho.

Fiber Laser jenereithara

GW (JPT, Raycus, MAX, RECI le IPG lijenereithara tsa laser ke boikhethelo) ka katleho e phahameng ea phetoho ea photoelectric, tekanyo e tlaase ea phoso, tšebeliso e tlaase ea matla, mahala ea tlhokomelo, le mohaho o kopanetsoeng.

Moqapi o hahiloeng ka har'a Metsi a Chiller

E ka qoba mahlaahlela a lithapo ho ikamahanya le libaka tse ngata, 'me e na le liphello tse ntle tse thibelang lerole le ho thibela condensation. Smart Control Panel Letoto la litokiso tse hahelletsoeng ka har'a li-parameter li kholo, 'me senotlolo se le seng se bonolo ebile se bonolo ho se sebelisa.

3 In 1 Handheld Laser Cleaning, Welding, Cutting Machine Applications

Mochini oa laser oa mefuta e mengata o sebelisoa ho etsa, likoloi, kitchenware, lishelefo, lifti, mabokose a kabo, lionto, thepa ea ka tlung ea tšepe, lisebelisoa tsa elektroniki, puisano ea optical, sensor, lisebelisoa tsa koloi, meno a porcelain, likhalase, matla a letsatsi le ho etsa likarolo tse nepahetseng.

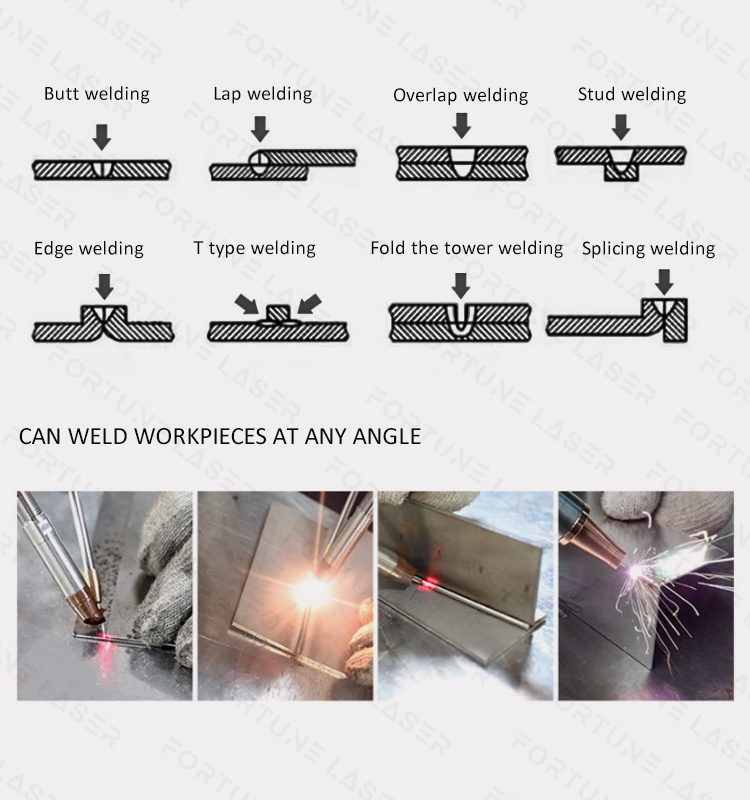

1.Ka sethunya sa laser welding, ke laser welder e nkehang habonolo ho cheselletsa aluminium, tšepe e sa hloekang, titanium, khauta, silevera, koporo, nickel, chromium, le litšepe tse ling kapa lialloys, e ka boela ea sebelisoa ka mefuta e fapaneng ea li-welds pakeng tsa litšepe tse fapaneng, tse kang titanium-khauta, koporo-brass-copper-brass, nickel-copper, nickel-copper, nickel-copper le nickel-copper.

2.Ka sethunya sa ho hloekisa laser, ke sesebelisoa sa laser se nkehang habonolo ho tlosa mafome, resin, ho roala, oli, matheba, pente, litšila bakeng sa kalafo ea holim'a batho ba ratang ho itlosa bolutu le tlhahiso ea indasteri, e ka fokotsa litšenyehelo tsa tlhokomelo ea mochini ka katleho le ho ntlafatsa phello ea tlhoekiso ea indasteri.

3.Ka sethunya sa ho itšeha laser, ke seha se le seng se nkehang ka letsoho sa laser bakeng sa mefuta eohle ea ho itšeha ka tšepe.

(E loketse feela poleiti ea tšepe e tšesaane.)

Lintlha tse tharo ho One Handheld Laser tjheseletsa ho hloekisa mochini o pakang lintlha

Setsebifiber laser welding ho hloekisa mochini oa ho itšehamoetsi oa khoebo ea tšebeletso ea indasteri ea tšepe ea tšepe. Laser welder, laser cleaner le laser cutter e rekisoa Algeria, Armenia, Argentina, Austria, Australia, Azerbaijan, Bangladesh, Belgium, Bulgaria, Bolivia, Brazil, Belarus, Canada, Chile, China, Colombia, Czech, Cyprase, Jeremane, Denmark, , Ecuador, Estonia, Egypt, Spain, Finland, France, Georgia, Greece, Hungary, Indonesia, Kastan, Ireland, Kuwait, Ireland, Ireland, Hungary, Indonesia, Ireland, Ireland, Ireland, Hungary, Korea, Ireland, Ireland, Ireland, Hungary, Ireland, Ireland, Ireland, Ireland, Ireland, Hungary, Ireland, Ireland, Ireland. Lebanon, Latvia, Morocco, Malta, Mexico, Malaysia, Netherlands, Norway, New Zealand, Oman, Peru, Philippines, Poland, Portugal, Paraguay, Qatar, Romania, Russia, Saudi Arabia, Switzerland, Sweden, Singapore, Slovenia, Slovakia, Swaziland, Afrika Boroa, Thailand, Tunisia, Turkey, United Kingdom, UAE, USA, Uruguay, Venezuela, Uzbe.

Li-welder tse nkehang tsa laser le lihloekisi tsa laser li ntse li tsebahala haholoanyane. Hore na o batla mochini oa welding kapa sesebelisoa sa ho hloekisa bakeng sa ts'ebeliso, kapa o rera ho qala khoebo ea ts'ebeletso ea welding le ho hloekisa, mochini ona oa 3 ho 1 oa laser ke khetho e ntle haholo. Ka kopo ikopanye le rona kajeno bakeng sa lintlha tse ling.