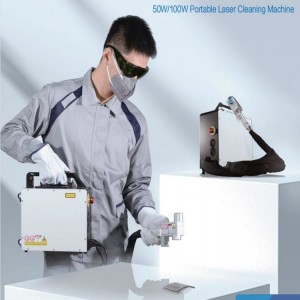

Fortune Laser Pulses 200W/300W Handheld Laser Cleaning Machine

Fortune Laser Pulses 200W/300W Handheld Laser Cleaning Machine

Ha ho bapisoa le ho hloekisa ka tloaelo, litšobotsi tsa ho hloekisa ka laser ke life?

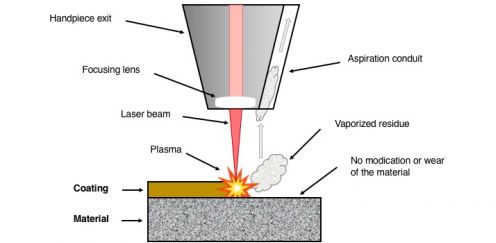

(1) Ke ho hloekisa "o omileng", ha ho hloke ho hloekisa metsi kapa tharollo ea lik'hemik'hale tse ling, 'me bohloeki bo phahame haholo ho feta mokhoa oa ho hloekisa lik'hemik'hale;

(2) mefuta e mengata ea ho tlosoa ha litšila le lisebelisoa tsa motheo tse sebetsang li pharaletseng haholo;

(3) Ka ho fetola mekhoa ea lisebelisoa tsa laser, motheong oa ho se senye holim'a substrate, litšila li ka tlosoa ka katleho, e le hore bokaholimo bo be bo tsofetseng joaloka bo bocha;

(4) Ho hloekisa ka laser ho ka lemoha ts'ebetso ea othomathike habonolo;

(5) Thepa ea laser decontamination e ka sebelisoa nako e telele, litšenyehelo tse tlase tsa ts'ebetso;

(6) Theknoloji ea ho hloekisa laser ke mokhoa oa ho hloekisa "botala", ho felisoa ha litšila ke phofo e tiileng, boholo bo nyane, bo bonolo ho bo boloka, ha e le hantle ha bo silafatse tikoloho.

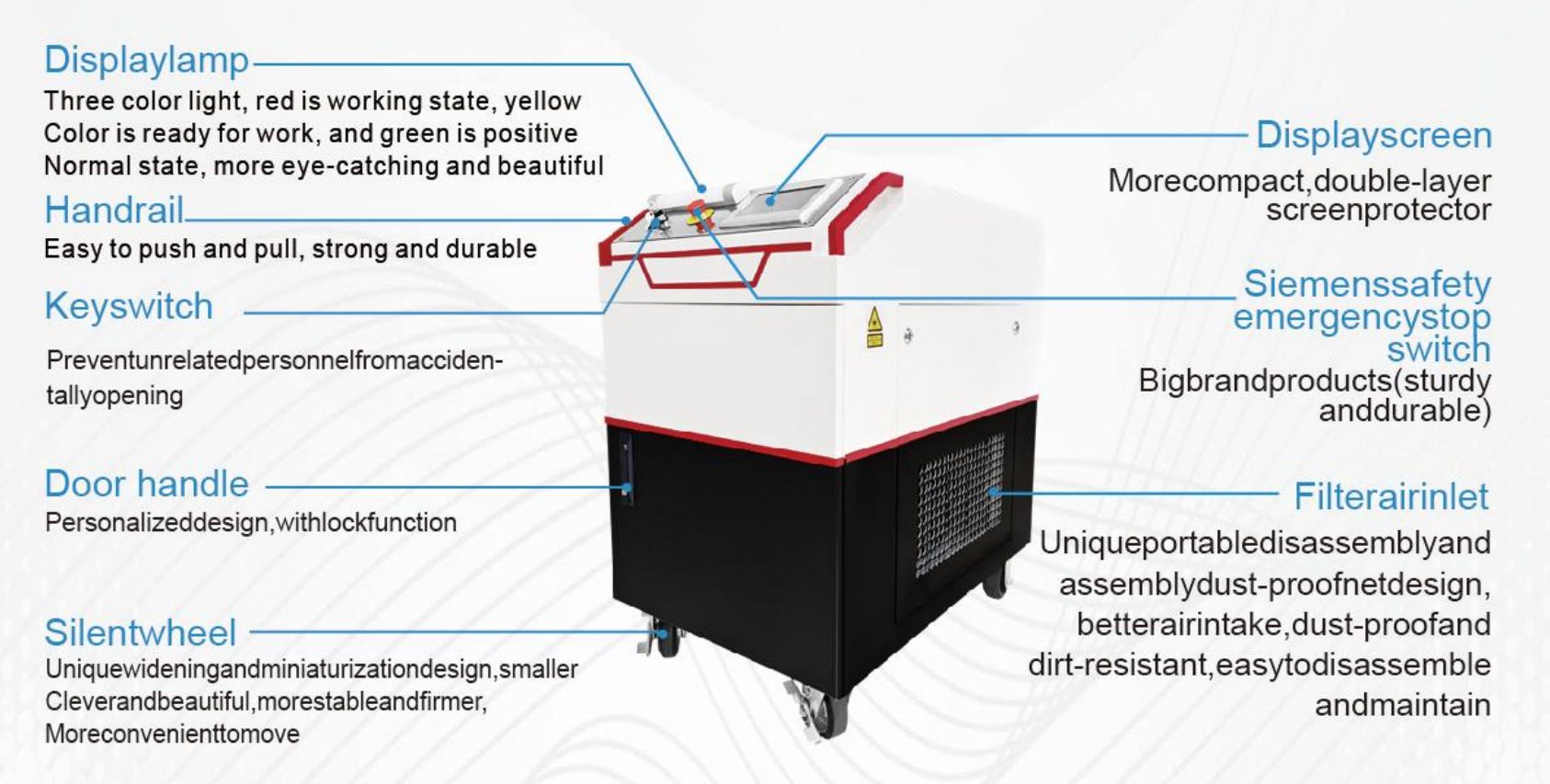

200W 300W Likarolo tsa Mochini oa ho Hloekisa Laser:

● Mokhoa oa ho laola linyeoe tsa trolley tsa 22-inch: Mohloli oa laser o hahiloeng ka hare, hlooho ea laser le lisebelisoa;

● Opereishene e le 'ngoe e bonolo: mosebelisi ea tsoetseng pele le e tloaelehileng ea basebelisi ba habeli;

● Hlooho ea laser e sebelisoang ka makhetlo a mabeli: nako e ts'oaretsoeng le ea robotic <metsotsoana e 5;

● Focus Lens: 160/254/330/420 bakeng sa boikhethelo e loketseng maemo a fapaneng. E khona ho skena mola o otlolohileng, selikalikoe, spiral, khutlonnetsepa, lisekoere, ho tlatsa ho pota-pota, ho tlatsa ka mahlakoreng a mabeli joalo-joalo E ka eketsa mokhoa o nepahetseng oa ho hlahloba ho latela tlhoko ea bareki;

● Leseli la pontšo, senotlolo sa tšireletso: pontšo ea laser emission, senotlolo sa tšireletso ho;

● khokahanyo ea mohloli oa laser: e loketseng bakeng sa ho itšehla thajana, QCS QBH e atisang ho sebelisoa lihokelo tsa laser 'marakeng.

Fortune Laser Mini Laser Welding Machine Technical Parameters

| Mohlala | FL-HC200 | FL-HC300 | |

| Mofuta oa Laser | Nanosecond Pulse Fiber ea Lehae | ||

| Matla a Laser | 200W | 300W | |

| Cooling Tsela | Pholiso ea Metsi | Pholiso ea Metsi | |

| Laser Wavelength | 1065±5nm | 1065±5nm | |

| Matla a Taolo ea Matla | 10-100% | ||

| Ho se tsitse ha Matla a Output | ≤5% | ||

| Ho se tsitse ha Matla a Output | 10-50kHz | 20-50kHz | |

| Bolelele ba Pulse | 90-130ns | 130-140ns | |

| Bolelele ba Fiber | 5 kapa 10m | ||

| Boholo ba Monopulse Energy | 10mJ | 12.5mJ | |

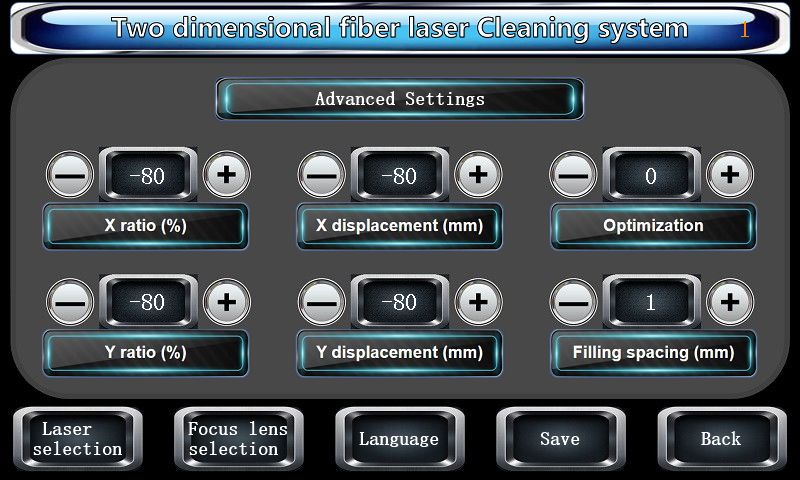

Tlhophiso e kholo:

● l Moloko oa bone oa bobeli morero oa laser hlooho Handheld le jarolla ka ho iketsa, 2D laser hlooho. Ho bonolo ho tšoara le ho kopanya le automation; e bonolo ho sebetsa ebile e na le mesebetsi e fapaneng;

● SOFTWARE E SEBELISANG

PRESTORE EA MEFUTA PARAMETER GRAPHICS

1. Lisebelisoa tse bonolo khetha liparamente tse bolokiloeng ka kotloloho

2. Boloka mefuta eohle ea mefuta ea litšoantšo tsa paramethara tse tšeletseng e ka khethang mola o otlolohileng/spiral/circle/rectangle/rectanglefilling/circle filling

3. Ho bonolo ho e sebelisa le ho sebetsa

4. Sehokelo se bonolo

5. Mefuta e fapaneng ea 12 e ka fetoloa le ho khethoa

ka potlako ho nolofatsa tlhahiso le ho lokisa bothata

6. Puo e ka ba Senyesemane / Sechaena kapa lipuo tse ling (ha ho hlokahala)

Mochini oa ho hloekisa laser oa pulse laser o hloekisa eng?

1. Ho tlosoa ka holim'a tšepe kapa khalase, ho tlosa pente ka potlako

2. Ho tlosoa ha mafome ka potlako, le li-oxide tse sa tšoaneng;

3. Tlosa mafura, resin, sekhomaretsi, lerōle, matheba, masala a tlhahiso;

4. Sebaka sa tšepe se thata;

5. Ho penta, ho tlosa mafome, ho tlosoa ha oli, oxide ea post-welding le phekolo ea masala pele ho tjheseletsa kapa ho kopanya;

6. Ho hloekisa hlobo, joalo ka hlobo ea mabili, hlobo ea elektronike, hlobo ea lijo;

7. Ho tlosoa ha letheba la oli ka mor'a tlhahiso le ts'ebetso ea likarolo tse nepahetseng;

8. Tlhoekiso e potlakileng ea tlhokomelo ea likarolo tsa matla a nyutlelie;

9. Phekolo ea oksijene, ho tlosa pente, le ho tlosa mafome nakong ea

tlhahiso kapa tlhokomelo ea libetsa le likepe tsa sefofane;

10. Ho hloekisa holim'a tšepe ka libaka tse nyenyane.

Litaba tse hlokang ho eloa hloko ha u sebelisa mochini o hloekisang oa laser:

1. Kamehla hloekisa laser chiller hang ka halofo ea khoeli, tšela metsi a litšila ka mochine, 'me u tlatse hape ka metsi a macha a hloekileng (metsi a litšila a tla ama phello ea tlhahiso ea leseli);

2. Hoa hlokahala ho hloekisa kamehla le ka bongata letsatsi le leng le le leng, ho tlosa li-sundries tafoleng, li-limiter le seporo sa tataiso, le ho fafatsa oli ea lubricating holim'a seporo sa tataiso;

3. Seipone le lense e lebisang tlhokomelo e lokela ho hlatsuoa ka tharollo e khethehileng ea ho hloekisa lihora tse ling le tse ling tse 6-8. Ha u hohla, sebelisa swab ea k'hothone kapa swab ea k'hothone e kenngoeng ka tharollo ea ho hloekisa ho senya ho tloha bohareng ba seipone se lebisang tlhokomelo ho ea moeling ka tsela e khahlanong le oache, 'me u be hlokolosi ho thibela mengoallo lense;

Video

Phello ea ho hloekisa mochini oa laser: