Fortune Laser Handheld Fiber Laser Welding Machine

Fortune Laser Handheld Fiber Laser Welding Machine

Fortune Laser Handheld Laser Welder Technical Parameters

| Mohlala | FL-HW1000 | FL-HW1500 | FL-HW2000 |

| Mofuta oa Laser | 1070nm Fiber Laser | ||

| Nominal Laser Matla | 1000W | 1500W | 2000W |

| Mokhoa oa ho Pholisa | Pholiso ea Metsi | ||

| Mokhoa oa ho sebetsa | Tsoela pele/ Ho feto-fetoha ha modumo | ||

| Lebelo la lebelo la welder | 0~120 mm/s | ||

| Focal Spot Diameter | 0.5 limilimithara | ||

| Boemo ba mocheso o tikolohong | 15 ~ 35 ℃ | ||

| Lethathamo la mongobo oa tikoloho | <70% ntle le condensation | ||

| Botenya ba tjheseletsa | 0.5-1.5 limilimithara | 0.5-2 limilimithara | 0.5-3 limilimithara |

| Litlhoko tsa lekhalo la welding | ≤1.2mm | ||

| Voltage e sebetsang | AC 220V/50HZ 60HZ/ 380V±5V 50HZ 60HZ 60A | ||

| Boemo ba Kabinete | 120 * 60 * 120cm | ||

| Lehong Package Dimension | 154 * 79 * 137cm | ||

| Boima ba 'mele | 285KG | ||

| Bolelele ba fiber | 10M e tloaelehileng, bolelele bo bolelele ka ho fetisisa bo hlophisitsoeng ke 15M | ||

| Kopo | Ho cheselletsa le ho lokisa tšepe e sa hloekang, tšepe ea khabone, motsoako oa aluminium. | ||

Portable Handheld Laser Welder bakeng sa Metals

| Lintho tse bonahalang | Matla a tsoang (W) | Boholo ba ho kenella (mm) |

| Ts'epe e sa beng le mabali | 1000 | 0.5-3 |

| Ts'epe e sa beng le mabali | 1500 | 0.5-4 |

| Ts'epe e sa beng le mabali | 2000 | 0.5-5 |

| Tšepe ea carbon | 1000 | 0.5-2,5 |

| Tšepe ea carbon | 1500 | 0.5-3.5 |

| Tšepe ea carbon | 2000 | 0.5-4.5 |

| Motsoako oa aluminium | 1000 | 0.5-2,5 |

| Motsoako oa aluminium | 1500 | 0.5-3 |

| Motsoako oa aluminium | 2000 | 0.5-4 |

| Letlapa la Galvanized | 1000 | 0.5-1.2 |

| Letlapa la Galvanized | 1500 | 0.5-1.8 |

| Letlapa la Galvanized | 2000 | 0.5-2,5 |

Mebala e Meraro bakeng sa Likhetho tsa Hao

Melemo ea Handheld Laser Welding Machine

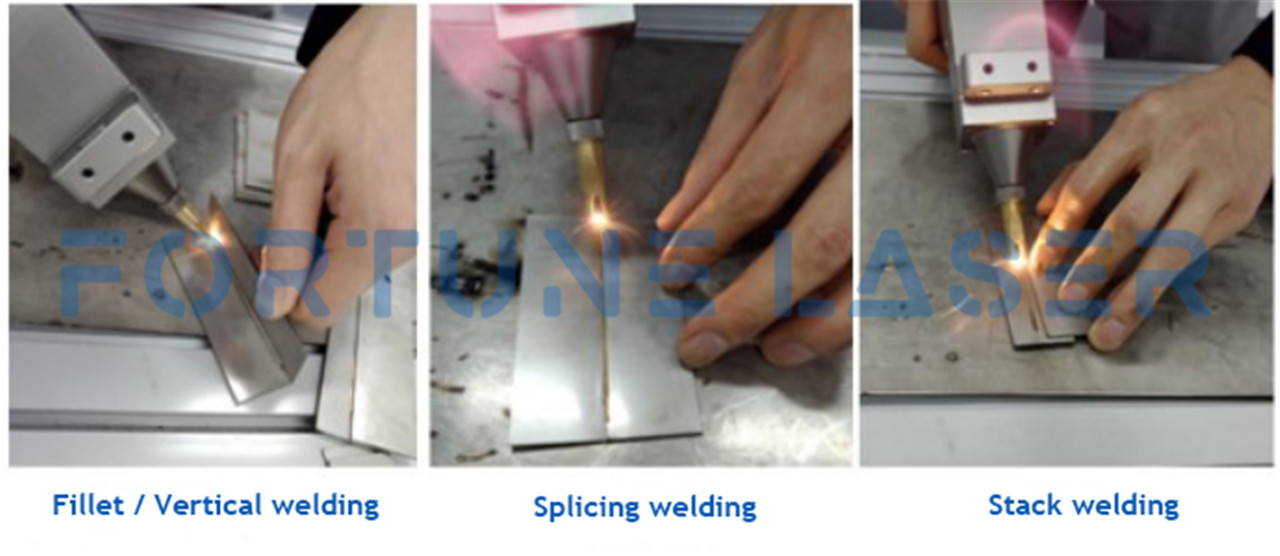

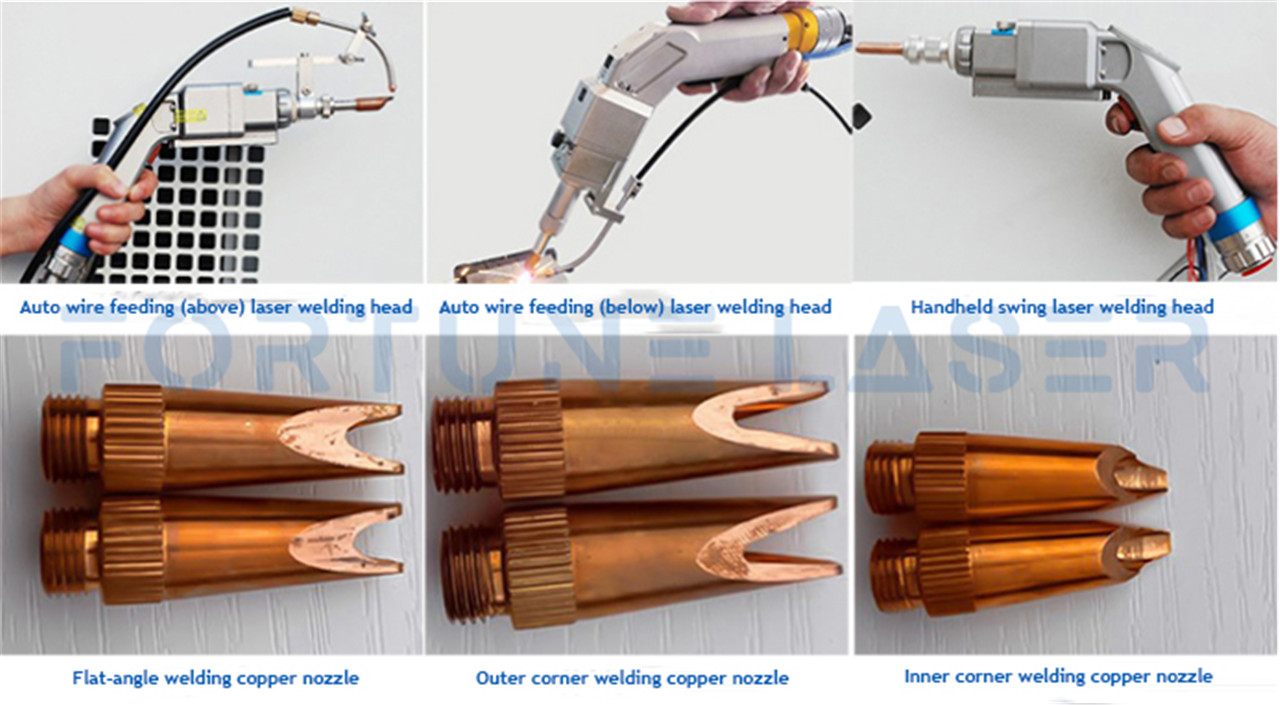

1. Mefuta e mengata ea li-welding:

Hlooho e ts'oaretsoeng ka letsoho e na le 10M ea pele ea optical fiber (bolelele bo bolelele ka ho fetisisa bo hlophisitsoeng ke 15M), e hlōlang mefokolo ea sebaka sa workbench, 'me e ka chesetsoa ka ntle le ho cheselletsa sebaka se selelele;

2. E bonolo ebile e bonolo ho e sebelisa:

Welding laser e tšoaroa ka letsoho e na le li-pulleys tse tsamaeang, tse phutholohileng ho li tšoara, 'me li ka fetola seteishene ka nako leha e le efe, ntle le seteishene se tsitsitseng, se lokolohileng le se bonolo,' me se loketse maemo a fapaneng a tikoloho ea ho sebetsa.

3. Mekhoa e mengata ea ho tjheseletsa:

Ho tjheseletsa ka lehlakoreng le leng le le leng ho ka hlokomeloa: ho tjheseletsa ho tjheseletsa, ho tjheseletsa ha butt, welding e otlolohileng, ho tjheseletsa fillet e bataletseng, ho tjheseletsa fillet ka hare, ho tjheseletsa ka ntle ho fillet, joalo-joalo, 'me ho ka tjheseletsa likarolo tse fapa-fapaneng tse rarahaneng tse entsoeng ka lisebelisoa le likarolo tse kholo tsa mosebetsi tse nang le libopeho tse sa tloaelehang. Lemoha welding ka lehlakoreng le leng. Ho phaella moo, e ka boela ea phethela ho itšeha, ho cheselletsa le ho itšeha ho ka fetoloa ka bolokolohi, ho fetola nozzle ea koporo ea welding ho nozzle ea koporo e sehang, e leng ntho e loketseng haholo.

4. Phello e ntle ea welding:

Welding ea laser e tšoaroang ka letsoho ke tjheseletsa ea thermal fusion. Ha ho bapisoa le li-welding tse tloaelehileng, welding ea laser e na le matla a phahameng a matla 'me e ka finyella liphello tse ntle tsa welding. Sebaka sa welding se na le tšusumetso e fokolang ea mocheso, ha ho bonolo ho holofala, ho ntšo, 'me ho na le mesaletsa ka morao. Botebo ba ho tjheseletsa bo boholo, ho qhibiliha ho lekane, 'me ho tiile ebile ho ka tšeptjoa,' me matla a weld a fihla kapa a feta tšepe ea motheo ka boeona, e ke keng ea tiisetsoa ke mechine e tloaelehileng ea li-welding.

5. Seam se cheselletsang ha se hloke hore se benngoe.

Ka mor'a ho cheselletsa ka mokhoa oa setso, ntlha ea ho cheselletsa e lokela ho belisoa ho netefatsa hore e boreleli ebile ha e thata. Mochine oa laser o tšoaroang ka letsoho o bonahatsa ka nepo melemo e mengata molemong oa ts'ebetso: ho tjheseletsa ho tsoelang pele, sekala se boreleli le se se nang tlhapi, se setle ebile ha se na maqeba, le mekhoa e fokolang ea ho pholisa.

6. Welding kasephepelo sa terata se iketsang.

Ho ea ka maikutlo a batho ba bangata, ts'ebetso ea ho cheselletsa ke "li-goggles tsa letsoho le letšehali, terata ea letsoho le letona". Empa ka mochini oa welding oa laser o tšoaroang ka letsoho, welding e ka phethoa habonolo, e fokotsang litšenyehelo tsa thepa tlhahisong le ts'ebetsong.

7. E sireletsehileng bakeng samosebeletsi.

Ka li-alarms tse ngata tsa tšireletso, ntlha ea welding e sebetsa feela ha sesebelisoa se ama ha se ama tšepe, 'me lebone le notleloa ka boeona ka mor'a hore karolo ea mosebetsi e tlosoe,' me mochine oa ho ama o na le mocheso oa 'mele oa mocheso. Tšireletseho e phahame ho netefatsa polokeho ea opareitara nakong ea mosebetsi.

8. Boloka litšenyehelo tsa basebetsi.

Ha ho bapisoa le li-welding tsa arc, litšenyehelo tsa ho sebetsa li ka fokotsoa ka hoo e ka bang 30%. Ts'ebetso e bonolo, e bonolo ho ithuta, 'me e potlakile ho qala. Boemo ba tekheniki ba basebelisi ha bo phahame. Basebetsi ba tloaelehileng ba ka nka mesebetsi ea bona ka mor'a koetliso e khutšoanyane, e ka finyellang liphello tsa boleng ba boleng bo phahameng habonolo.

9. Ho bonolo ho fetola ho tloha mekhoeng e tloaelehileng ea ho tjheseletsa ho ea ho fiber laser welding.

U ka ithuta mokhoa oa ho sebelisa Fortune Laser fiber laser welding mochini ka mor'a lihora tse 'maloa,' me ha u na hlooho ea ho batla litsebi tsa welding, u se ke ua tšoenyeha ka kemiso e thata ea ho fana ka thepa. Ho feta moo, ka theknoloji ena e ncha le matsete, u tla ba ka pele ho 'maraka' me u amohele menyetla e eketsehileng ea phaello ho feta mekhoa ea khale ea ho cheselletsa.

Libaka tsa Kopo tsa Mochini oa Welding oa Laser oa Handheld

The handheld laser welder ke haholo-holo bakeng sa tšepe e kholo le e mahareng, likhabinete, chassis, lemati la aluminium alloy le liforeimi tsa lifensetere, likotlolo tsa ho hlatsoa tšepe e sa hloekang le lisebelisoa tse ling tse kholo, joalo ka angle e ka hare e nepahetseng, lehlakoreng le letona la ka ntle, weld weld, sebaka se senyenyane se anngoeng ke mocheso nakong ea welding, deformation e nyane, le botebo ba welding E kholo, e matla.

Mechini ea welding ea laser ea Fortune Laser e sebelisoa haholo lits'ebetsong tse rarahaneng le tse sa tloaelehang tsa indasteri ea kichineng le ea ho hlapela, indasteri ea lisebelisoa tsa lapeng, indasteri ea papatso, indasteri ea hlobo, indasteri ea lihlahisoa tsa tšepe e sa hloekang, indasteri ea boenjiniere ea tšepe, indasteri ea mamati le lifensetere, indasteri ea matsoho, indasteri ea thepa ea ntlo, indasteri ea thepa ea ka tlung, indasteri ea likarolo tsa likoloi, jj.

Papiso ea Handheld Laser Welding Machine le Argon Arc Welding

1. Papiso ea tšebeliso ea matla:Ha ho bapisoa le li-welding tsa setso tsa arc, mochini oa welding oa laser o boloka hoo e ka bang 80% ho isa ho 90% ea matla a motlakase, 'me litšenyehelo tsa ho sebetsa li ka fokotsoa ka hoo e ka bang 30%.

2. Papiso ea phello ea welding:tjheseletsa e tšoaroang ka letsoho ea laser e ka tlatsa tšepe e sa tšoaneng le tšepe e sa tšoaneng. Lebelo le potlakile, deformation e nyane, 'me sebaka se amehileng ke mocheso se nyane. The weld seam e ntle, e boreleli, ha e na / e nyenyane porosity, 'me ha e na tšilafalo. Mochini oa welding oa laser o tšoaroang ka letsoho o ka sebelisoa bakeng sa likarolo tse nyane tse bulehileng le welding e nepahetseng.

3. Papiso ea ts'ebetso ea ho latela:mocheso o tlase o kenya letsoho nakong ea tjheseletsa e ts'oaroang ka letsoho ea laser, deformation e nyane ea sesebedisoa, sebaka se setle sa welding se ka fumanoa, ha ho na kapa kalafo e bonolo feela (ho latela litlhoko tsa phello ea welding holim'a metsi). Mochini o ts'oaretsoeng ka letsoho oa laser o ka fokotsa haholo litšenyehelo tsa mosebetsi oa ts'ebetso e kholo ea ho belisa le ho betla.

| Mofuta | Argon arc welding | tjheseletsa ya YAG | E tshoeroeng ka letsohoLasertjheseletsa | |

| Boleng ba welding | Ho kenya mocheso | E kholo | Nyenyane | Nyenyane |

|

| Deformation/ undercut ya workpiece | E kholo | Nyenyane | Nyenyane |

|

| Ho etsa weld | Mohlala oa tekanyo ea litlhapi | Mohlala oa tekanyo ea litlhapi | Boreleli |

|

| Ts'ebetso e latelang | Sepolishe | Sepolishe | Ha ho letho |

| Sebelisa ts'ebetso | Lebelo la welding | Butle | Hare | Ka potlako |

|

| Bothata ba ts'ebetso | E thata | Bonolo | Bonolo |

| Tšireletso le polokeho ea tikoloho | Tšilafalo ea tikoloho | E kholo | Nyenyane | Nyenyane |

|

| Kotsi ea 'mele | E kholo | Nyenyane | Nyenyane |

| Litšenyehelo tsa welder | Lintho tse ka sebelisoang | Molamu oa welding | Laser kristale, lebone la xenon | Ha ho hlokahale |

|

| Tšebeliso ea matla | Nyenyane | E kholo | Nyenyane |

| Sebaka sa fatše sa lisebelisoa | Nyenyane | E kholo | Nyenyane | |