Special Price for 2kw Fiber Laser Cutting Machine - Fully Enclosed Metal CNC Laser Cutter Machine – Fortune

Special Price for 2kw Fiber Laser Cutting Machine - Fully Enclosed Metal CNC Laser Cutter Machine – Fortune

Special Price for 2kw Fiber Laser Cutting Machine - Fully Enclosed Metal CNC Laser Cutter Machine – Fortune Detail:

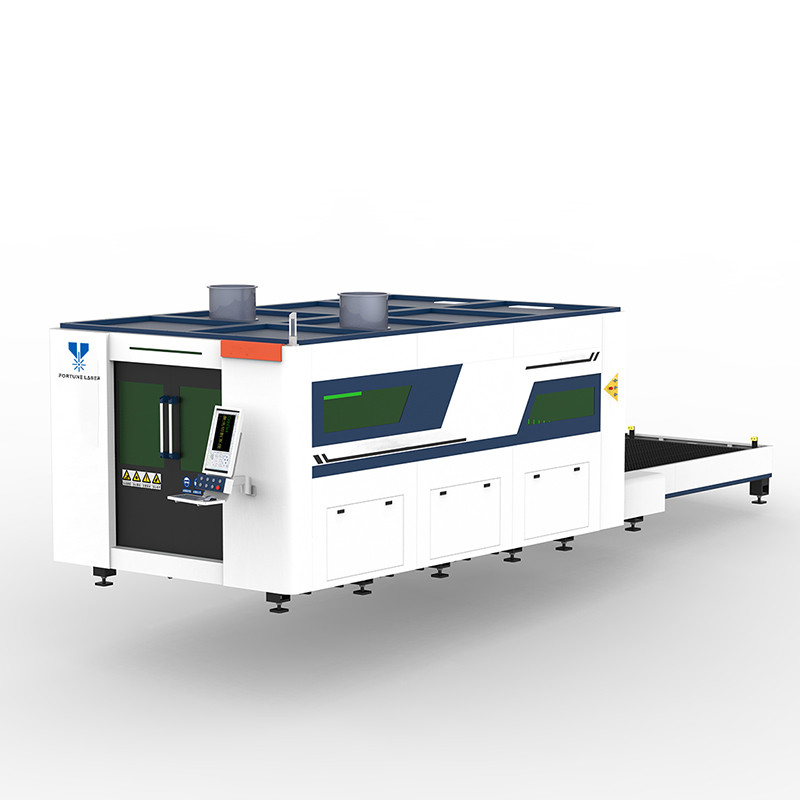

Fully Enclosed Protective Cover

● The large size screen and the integrated design of monitoring and operation provide users with the ultimate experience;

● The protective cover has a built-in camera to monitor the machine without stopping the machine during operation, which is convenient for the operator to observe the cutting process in real time;

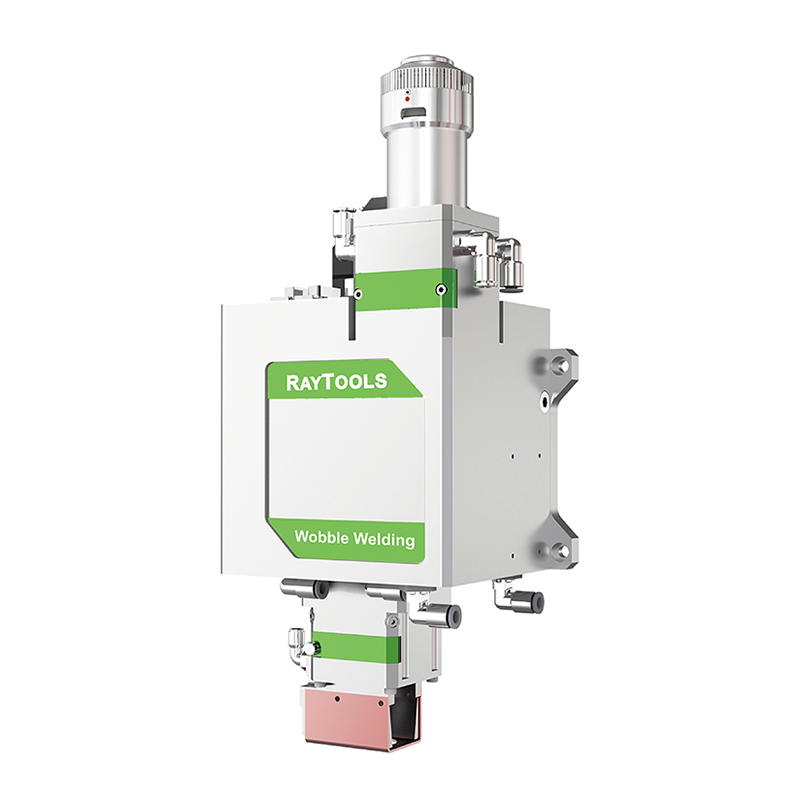

Professional Auto Focus Laser Cutting Head

Laser head with auto focus function, can adjust the focus automatically, don’t need to adjust by manual. The software can change different focusing lenses automatically and quickly to meet the cutting of different thickness plates, simple, convenient, fast and accurate in operation.

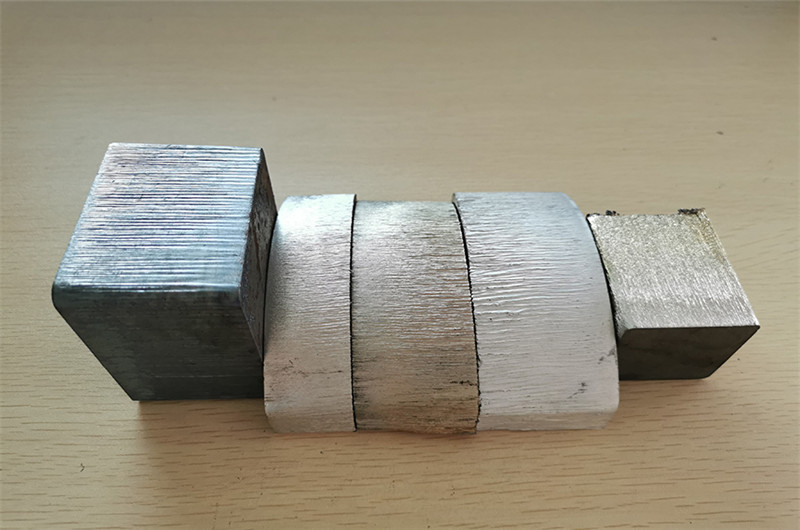

Cast Aluminum Beam

Using low-pressure steel film casting process, the beam has high compactness, the surface quality of the beam is smooth, and the integrity and rigidity are excellent. At the same time, it has good toughness, ductility and corrosion resistance. Reduce the load of the servo motor, reduce the inertia, while saving electricity costs, it improves the operating speed of the equipment.

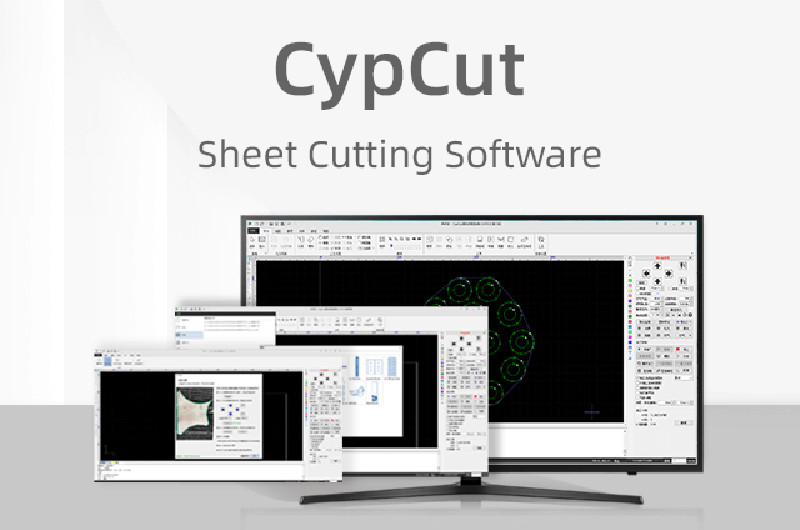

Cypcut CNC Control System

Cypcut controller, a fiber laser cutting machine control system, is designed for sheet metal processing industry launched a full-featured open loop control system. It’s easy to install and adjust, with excellent performance and complete solutions for the laser cutting machines.

Machine Characters

● Servo dual-drive gantry structure: Bridge gantry structure, rack rail drive, the use of centralized lubrication device, easy maintenance;

● Stable and practical: Reinforced welding bed, high temperature tempering treatment vibration to eliminate stress, machine tool deformation can be controlled at ± 0.02mm;

● Industrial aesthetics design: Export standards in Europe and America, the appearance of aesthetic design, simple atmosphere;

● The operation is simple and easy to use: More than 20000 users, global technology leading CNC laser cutting system, flexible operation is simple, has the function of laser power adjustment, to ensure the quality of cutting, the operation is simple and convenient;

● High-quality cutting: High-precision anti-collision professional laser cutting head, to ensure the best cutting effect;

● Efficient material: Used in the standard specifications of metal sheet cutting, saving time and material;

● Fiber laser: Use stable and reliable power top brand laser, performance guaranteed;

(For the FL-SC Series, both with and without exchange platform are available.)

Machine Parameters

|

Model |

FL-SC2015 |

FL-SC3015 |

FL-SC4020 |

FL-SC6020 |

|

Working Area (L*W) |

2000*1500mm |

3000*1500mm |

4000*2000mm |

6000*2000mm |

|

X/Y Axis Position Accuracy |

±0.03mm/1000mm |

±0.03mm/1000mm |

±0.03mm/1000mm |

±0.03mm/1000mm |

|

X/Y Axis Repeat Position Accuracy |

±0.02mm |

±0.02mm |

±0.02mm |

±0.02mm |

|

Max Moving Speed |

80000mm/min |

80000mm/min |

80000mm/min |

80000mm/min |

|

Max Acceleration |

1.2g |

1.2g |

1.2g |

1.2g |

|

Machine Dimension (L*W*H) |

6502*1800*2100mm |

8502*2600*2100mm |

10502*3030*2100mm |

16000*3030*2100mm |

|

Max Loading Weight |

|

600kg |

600kg |

|

|

Machine Weight |

|

2000kg |

4500kg |

|

|

Laser Source Power(Optional) |

1kW/1.5kW/2kW/2.5kW/3kW/4kW/6kW/8kW/10kW/12kW/15kW/20kW |

|||

Applications

Suitable for processing metal sheet such as stainless steel, carbon steel, alloy steel, silicon steel, galvanized steel plate, nickel-titanium alloy, inconel, titanium alloy, etc.

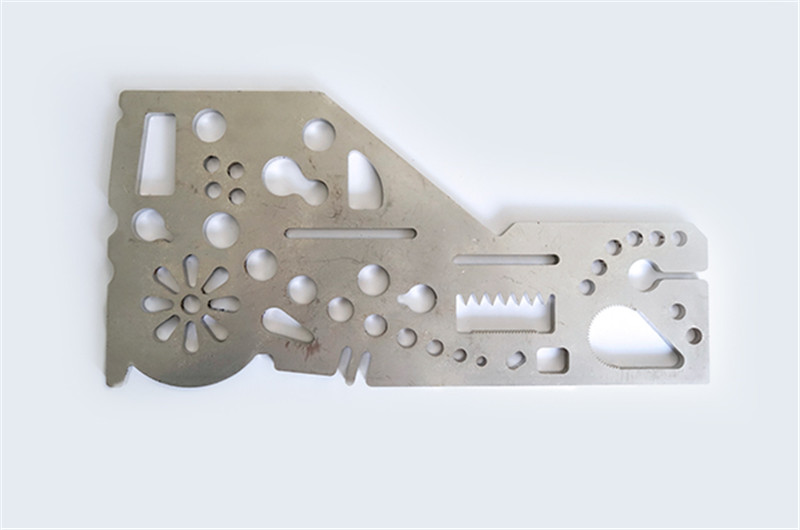

Samples Display

Product detail pictures:

Related Product Guide:

Our intention should be to fulfill our consumers by offering golden provider, superior price and superior quality for Special Price for 2kw Fiber Laser Cutting Machine - Fully Enclosed Metal CNC Laser Cutter Machine – Fortune , The product will supply to all over the world, such as: Uganda, South Africa, Cancun, Our company has always insisted on the business principle of "Quality, Honest, and Customer First" by which we have won the trust of clients both from at home and abroad. If you are interested in our products, please do not hesitate to contact us for further information.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.