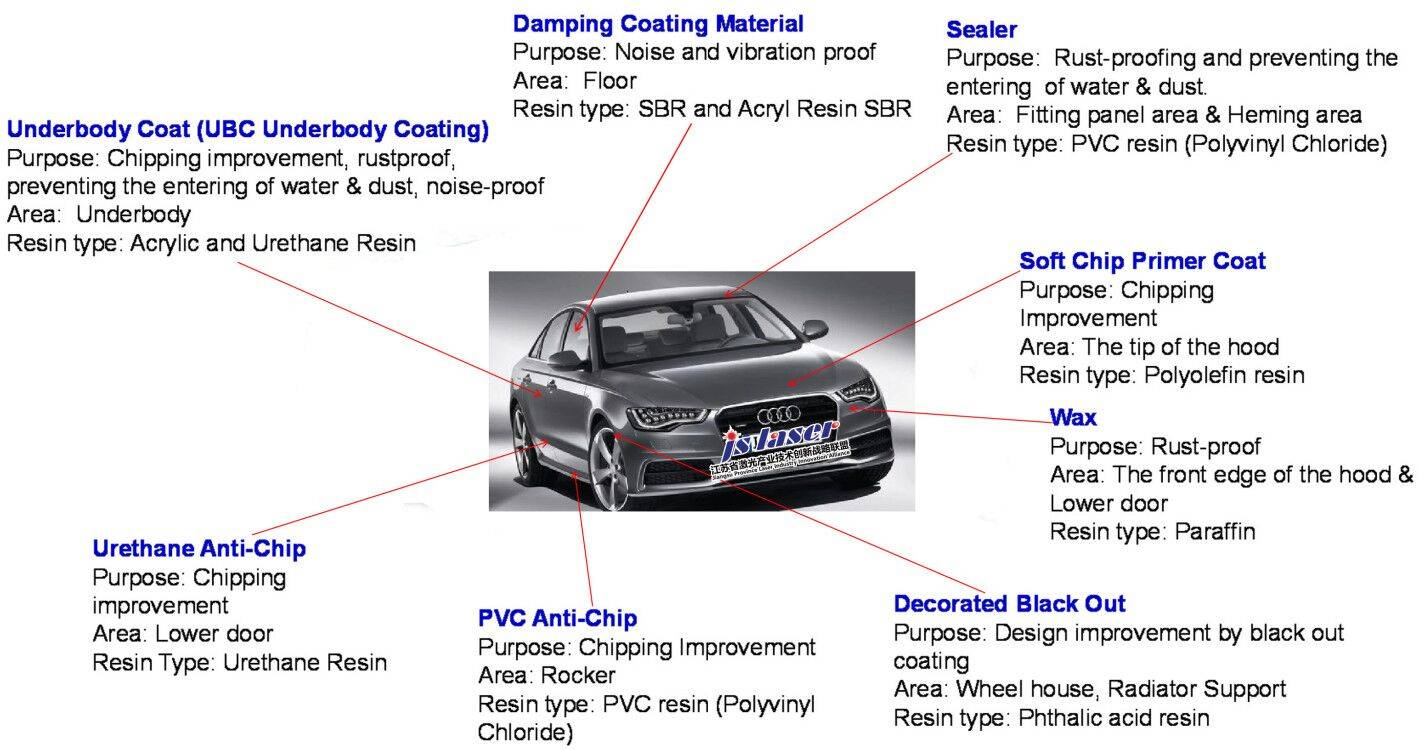

Mukuita kwekugadzira mota, kudhirowa mafuta ekuzora kana mafuta ekutonhodza nemafuta anodzivirira ngura anoshandiswa anogona kusvibisa zvikamu zvemotokari uye kushatisa zvakanyanya kunaka kweanotevera akakwira-simba rekujoinha kana kubatanidza maitiro. Mune thismuitiro, welds uye zvisungo mu powertrain zvinoriumba anofanira kuva akasimba unhu mwero akasangana. Nokudaro, nzvimbo dzakabatana dzinofanira kunyatsocheneswa.

Sei vanhu vakawanda isueLaser yekuchenesa kutsiva echinyakare kuchenesa? Ndeupi musiyano uripo pakati pekuchenesa nelaser uye kucheneswa kwechinyakare mumashandisi emotokari?

Muindasitiri yemotokari, pendi yekare iri pamusoro inoda kubviswa kuitira kuti pendi itsva ishandiswe muviri usati wagadziridzwa.

Kune akawanda echinyakare emota muviri pendi yekuchenesa nzira, kunyanya inosanganisira mechanic uye makemikari nzira. Kumakina maitiro, anosanganisira yakakwira-kumanikidza mvura jet kubviswa pendi, sandblasting uye simbi brashi kukuya. Uye nzira dzemakemikari dzinonyanya kutaura nezvemakemikari reagents ekubvisa pendi. Idzi nzira dzine hurema hwakadai sekudhura kwakanyanya, kushandiswa kwesimba kwakanyanya, kusvibiswa kuri nyore, uye kukuvadza kuri nyore pamusoro peiyo substrate, uye zvishoma nezvishoma zvakatadza kuzadzisa zvinodiwa zvemazuva ano zvekuchengetedza kwezvakatipoteredza nzira dzekuchenesa.

Iko kukurumidza, otomatiki hunhu hwelaser yekuchenesa inobvumira kucheneswa kwakakwana kwezvisaririra zvepasi, zvichikonzera yakasimba, isina- uye micro-crack-isina welds uye mabhondi. Pamusoro pezvo, kuchenesa laser kwakapfava uye maitiro acho anokurumidza kukurumidza kupfuura dzimwe nzira, mabhenefiti akazivikanwa neindasitiri yemotokari.

Mumunda wemaindasitiri, kuitira kuchengetedza simbi kana zvimwe zvinhu zvepasi, nzvimbo yacho inowanzopendwa kudzivirira ngura, oxidation, uye corrosion. Kana pendi yependi ichibviswa zvishoma kana kuti pamusoro payo inoda kupendwazve nekuda kwezvimwe zvikonzero, pendi yepakutanga inoda kucheneswa zvachose.

Mukupindura mamiriro ezvinhu aya, matekinoroji mazhinji matsva ekuchenesa akabuda, uye kuchenesa laser, seimwe yenzira dzakakosha, kwakaratidza hukuru hwayo zvishoma nezvishoma. Saizvozvo, isu tichasuma yekuchenesa application yelaser yekuchenesa muchina muindasitiri yemotokari.

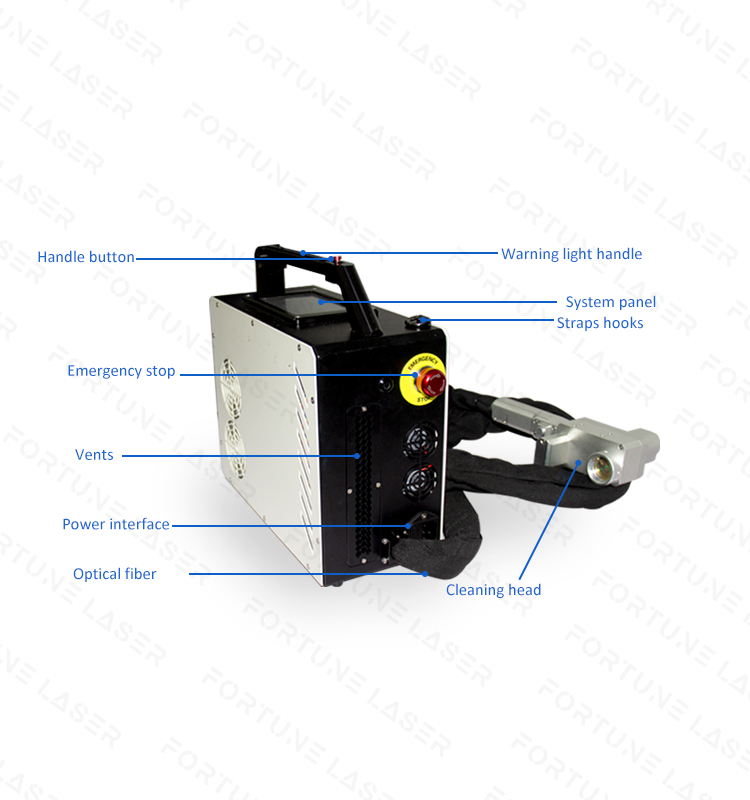

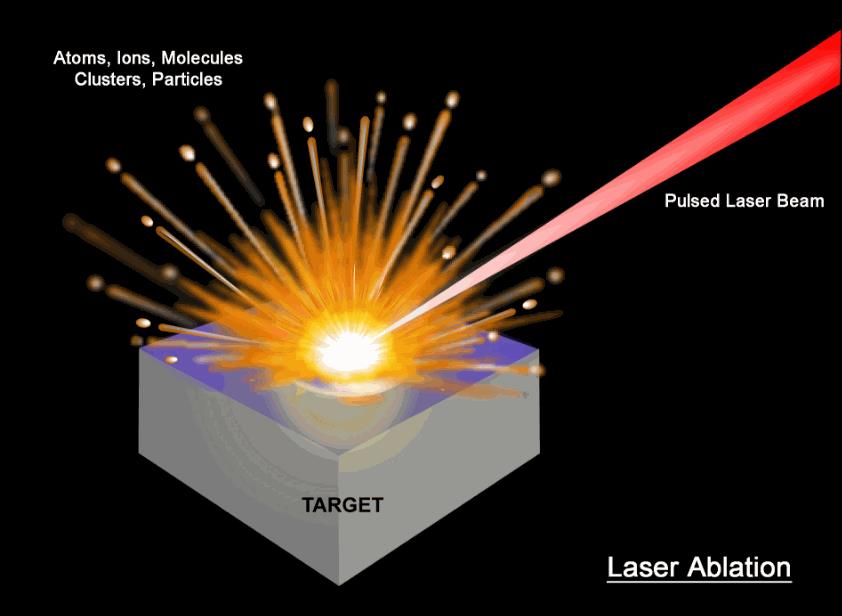

1. Pane imwe nzira yakakwana yekubvisa pendi pamusoroyemotokari uye maitiro ekubvisa primer yesimbi mahwendefa. Laser beam inofambiswa neoptical fiber uye inoramba ichiongororwa kuti ibvise pendi layer uye primer pamusoro peplate resimbi, ichisiya nzvimbo yakachena pamusoro pesimbi ndiro, iyo yakakodzera kupendazve kana mamwe maitiro.

Iko kushandiswa kweiyi laser yekuchenesa tekinoroji kuchenesa mota mabhureki pads inzira yakakwana kune yechinyakare yekuchenesa nzvimbo. Iyo yechinyakare yekuchenesa maitiro emota brake pads, senge sandblasting, haina kunetsa kuchenesa kuseri kwepaneru. Iko kushandiswa kweiyo adaptive laser yekuchenesa tekinoroji inogona kuwana otomatiki nzira yekuchenesa iyo yekumashure ndiro yebrake pad kusangana neinozotevera yekubikira maitiro. Kubvisa kusarudzwa, hapana kukuvara kwe substrate, uye nekukurumidza kuchenesa mitengo ndizvo zvakakosha zvinogonesa zvinhu zvelaser yekuchenesa pendi.

2. Kana mota dzevanhu dzakasakara dzichida kuvandudzwa kuti dzidzorere runako rwadzo rwepakutanga kana kushongedzazve zvinhu zvadzo zvekare, nekuwedzera kwelaser simba,Laser yekuchenesa tekinorojiichaita basa guru. Yemazuva ano yekuchenesa laser inogona kuchenesa uye kubvisa zvisingadiwe zvekare nzvimbo pane chero zvikamu zvekare zvemota. Semuenzaniso, kunyange iyo chrome-plated surface layer inogona kubviswa zvakakwana. Kazhinji, iyo yepamusoro yakavharidzirwa yakavharidzirwa pamotokari inoda kubviswa zvachose pendi itsva isati yaiswa. Sezvo iyo yemuviri uye yemakemikari zvimiro zveyepamusoro pendi zvakasiyana neiyo primer, iyo simba uye frequency yelaser inogona kusetwa kuti ibvise chete pamusoro pepende.

Novel welding matekiniki kana maitiro ekujoinha anogamuchirwa mukuenderera mberi kwehunyanzvi hwemotokari tekinoroji inoda kurapwa kwakaringana kweakasungwa kana kujoinwa nzvimbo, uye panguva ino kuchenesa laser kunogona kupa yakaoma, chaiyo uye isina-abrasive Kuchenesa marapirwo, nepo echinyakare kunyorova kwemakemikari kuchenesa kana mechanic kukuya nzira dzekurapa dzinowanzo kunetsa kusangana, uye zvikamu zvizhinji zvave kucheneswa laser.

Uyelaser kuchenesa kune zvakawanda zvakanakirapamusoro pekuchenesa kwechinyakare:

1. Automated assembly line: Iyo laser yekuchenesa muchina inogona kubatanidzwa neCNC muchina zvishandiso kana marobhoti kuti iite kudzora kure uye kuchenesa, iyo inogona kuona otomatiki yemidziyo, kuumba chigadzirwa kusangana mutsara mashandiro, uye kushanda nehungwaru.

2. Kumira kwakarurama: shandisa optical fiber transmission kutungamira laser kuti iite kushanduka, uye kudzora nzvimbo yechiedza kuti ifambe nekumhanya kukuru kuburikidza neyakagadzirwa-in scanning galvanometer, iyo yakanakira isiri-inobata zvakaoma-kusvika-kusvika zvikamu zvakadai sezvikamu zvakakosha-zvakaumbwa, maburi, uye grooves iyo yakaoma kusvika nenzira dzechinyakare dzekuchenesa. pasi laser kuchenesa.

3.No kukuvadza: kukanganisa kwenguva pfupi hakuzopisa simbi yesimbi, uye hapana kukuvadza kune substrate.

4.Kugadzikana kwakanaka: Iyo pulsed laser inoshandiswa mumushini wekuchenesa laser ine hupenyu hurefu hwebasa, kazhinji kusvika maawa 100,000, ine hutano hwakagadzikana uye kuvimbika kwakanaka.

5. Mutengo wekuchengetedza wakaderera: hapana zvinodyiwa zvinodyiwa panguva yekushandiswa kwemashini ekuchenesa laser, uye mari yekushanda yakaderera. Muchikamu chekupedzisira, lens chete inoda kucheneswa kana kuchinjwa nguva dzose, uye mari yekugadzirisa yakaderera, iyo iri pedyo nekugadzirisa-isina.

Izvo zviri pamusoro ndezvekuchenesa maapplication uye zvakanakira laser yekuchenesa michina muindasitiri yemotokari. Iko kushandiswa kwelaser polishing, kucheneswa kwepamusoro uye kubvisa coating kuri kukurumidza kuwedzera. Zvichienderana nekushandiswa, iyo pulse frequency, simba uye wavelength yelaser inofanirwa kunyatso kusarudzwa kuchenesa, kupururudza uye kubvisa izvo zvinonangwa. Panguva imwecheteyo, chero nzira ipi zvayo yekukuvadza kune nheyo yezvinhu inofanira kudzivirirwa.

Kana iwe uchida kudzidza zvakawanda nezve laser yekuchenesa, kana uchida kukutengera yakanakisa laser yekuchenesa muchina, ndapota siya meseji pane yedu webhusaiti uye titumire email zvakananga!

Nguva yekutumira: Sep-26-2022