Fortune Laser Handheld Fiber Laser Welding Machine

Fortune Laser Handheld Fiber Laser Welding Machine

Fortune Laser Handheld Laser Welder Technical Parameters

| Model | FL-HW1000 | FL-HW1500 | FL-HW2000 |

| Laser Type | 1070nm Fiber Laser | ||

| Nominal Laser Simba | 1000W | 1500W | 2000W |

| Kutonhodza System | Mvura Kutonhora | ||

| Nzira yekushanda | Kuenderera mberi / Modulation | ||

| Speed renji ye welder | 0~120 mm/s | ||

| Focal Spot Diameter | 0.5mm | ||

| Ambient tembiricha range | 15 ~ 35 ℃ | ||

| Environmental humidity range | <70% pasina condensation | ||

| Welding ukobvu | 0.5-1.5mm | 0.5-2mm | 0.5-3mm |

| Welding gap zvinodiwa | ≤1.2mm | ||

| Kushanda Voltage | AC 220V/50HZ 60HZ/ 380V±5V 50HZ 60HZ 60A | ||

| Cabinet Dimension | 120*60*120cm | ||

| Wooden Package Dimension | 154*79*137cm | ||

| Kurema | 285KG | ||

| Fiber urefu | Yakajairwa 10M, iyo yakareba yakagadziridzwa kureba ndeye 15M | ||

| Application | Welding uye kugadzirisa Stainless simbi, kabhoni simbi, aruminiyamu alloy. | ||

Inotakurika Handheld Laser Welder yeSimbi

| Material | Simba rekubuda (W) | Kupinzwa kwakanyanya (mm) |

| Simbi isina ngura | 1000 | 0.5-3 |

| Simbi isina ngura | 1500 | 0.5-4 |

| Simbi isina ngura | 2000 | 0.5-5 |

| Carbon steel | 1000 | 0.5-2.5 |

| Carbon steel | 1500 | 0.5-3.5 |

| Carbon steel | 2000 | 0.5-4.5 |

| Aluminium alloy | 1000 | 0.5-2.5 |

| Aluminium alloy | 1500 | 0.5-3 |

| Aluminium alloy | 2000 | 0.5-4 |

| Galvanized sheet | 1000 | 0.5-1.2 |

| Galvanized sheet | 1500 | 0.5-1.8 |

| Galvanized sheet | 2000 | 0.5-2.5 |

Matatu Mavara eSarudzo Dzako

Zvakanakira Handheld Laser Welding Machine

1. Wide welding range:

Musoro wakabatwa neruoko wakashongedzerwa ne 10M yepakutanga optical fiber (yakareba yakagadziriswa kureba ndeye 15M), iyo inokunda zvisingakwanisi nzvimbo yebasa rekushanda, uye inogona kusungirirwa kunze uye kureba kureba;

2. Yakanaka uye inochinjika kushandisa:

Hand-yakabatwa laser welding ine inofambiswa pulleys, iyo yakagadzika kubata, uye inogona kugadzirisa chiteshi chero nguva, isina yakatarwa-poinzi chiteshi, yemahara uye inochinjika, uye yakakodzera kune akasiyana siyana enzvimbo yekushanda.

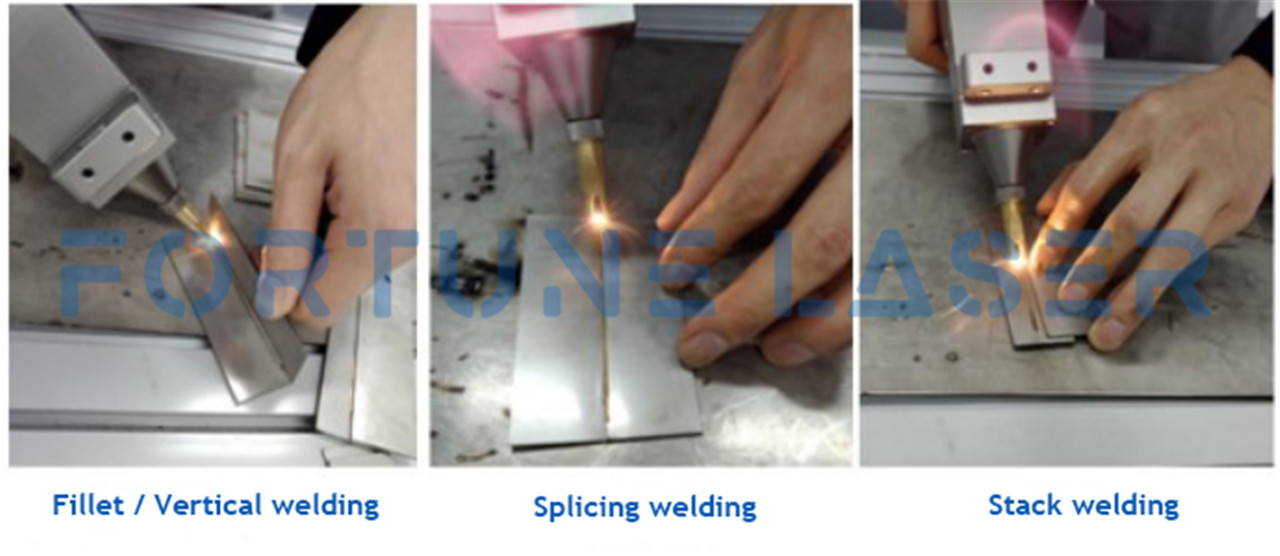

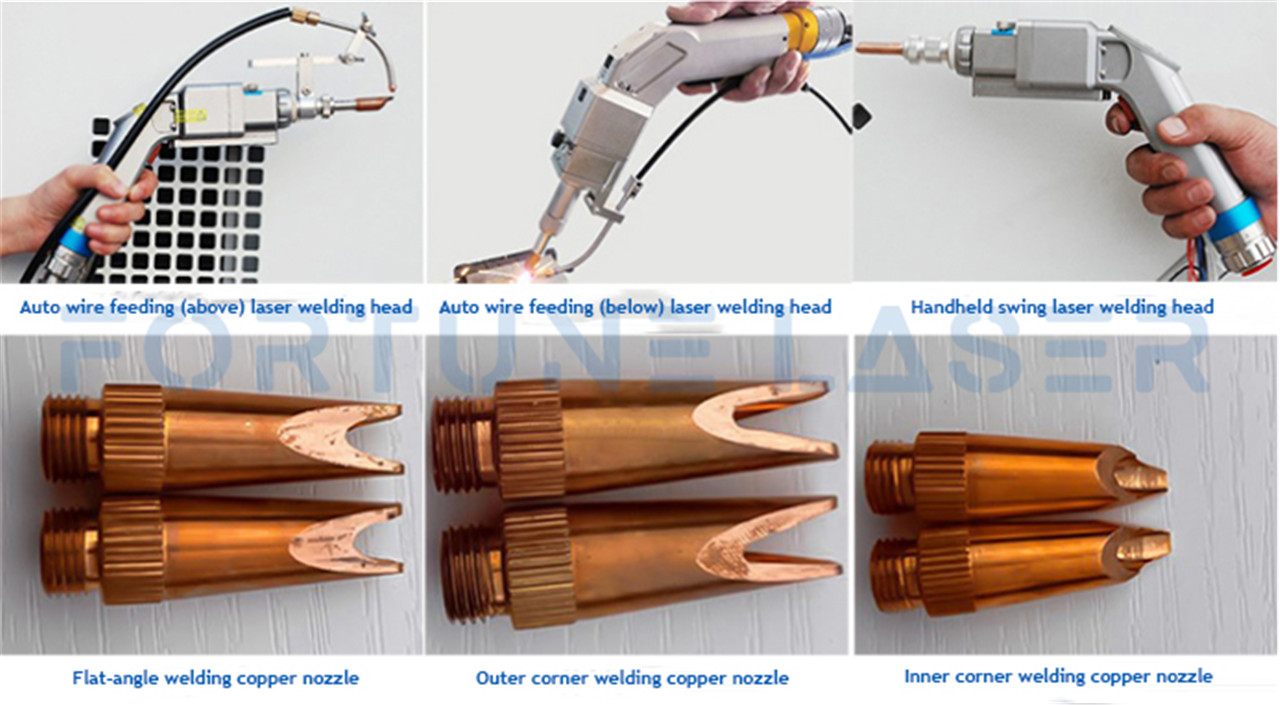

3. Multiple welding nzira:

Welding pane chero kona inogona kuwanikwa: kupindirana welding, butt welding, vertical welding, flat fillet welding, yemukati fillet welding, yekunze fillet welding, nezvimwewo, uye inogona weld dzakasiyana dzakaomesesa welded work-piece uye mahombe ebasa ane maumbirwo asina kujairika. Ziva welding chero kona. Mukuwedzera, inogonawo kupedzisa kucheka, kusungirirwa uye kucheka kunogona kuchinjwa zvakasununguka, kungoshandura mhepo yemhangura yemhangura kune yekucheka mhangura yemhangura, iyo yakanyatsonaka.

4. Good welding effect:

Hand-held laser welding is thermal fusion welding. Kuenzaniswa neyechinyakare welding, laser welding ine yakakwira simba density uye inogona kuwana zvirinani welding mhedzisiro. Iyo welding nzvimbo ine zvishoma kupisa pesvedzero, haisi nyore kukanganisa, dema, uye ine maronda kumashure. Kudzika kwewelding kwakakura, kunyunguduka kwakakwana, uye kwakasimba uye kwakavimbika, uye simba re weld rinosvika kana kudarika base simbi pachayo, isingagone kuvimbiswa nemichina yakajairwa welding.

5. Welding seam haidi kukwenenzverwa.

Pashure pechinyakare welding, welding point inoda kukwenenzverwa kuti ive nechokwadi kuti yakatsetseka uye haina kushata. Iyo inobatwa nemaoko laser welding inonyatso ratidza mamwe mabhenefiti mukugadzirisa mhedzisiro: kuenderera mberi kwewelding, yakatsetseka uye isina zviyero zvehove, yakanaka uye isina mavanga, uye mashoma ekutevera ekupukuta maitiro.

6. Welding neotomatiki waya feeder.

Mukufunga kwevanhu vazhinji, kushanda kwewelding ndeye "kuruboshwe magirazi, ruoko rwerudyi clamp welding waya". Asi neruoko rwakabata laser welding muchina, welding inogona kupedzwa nyore, izvo zvinoderedza mutengo wezvinhu mukugadzira uye kugadzirisa.

7. Yakachengeteka kuneopareta.

Iine maaramu akawanda ekuchengetedza, iyo welding tip inoshanda chete kana switch yabatwa kana ichibata simbi, uye mwenje unovharika otomatiki mushure mekunge chidimbu chebasa chabviswa, uye switch yekubata ine tembiricha inonzwa. Kuchengetedzwa kwakakwirira kuti kuve nechokwadi chekuchengetedzwa kwemushandisi panguva yebasa.

8. Sevha mutengo webasa.

Kuenzaniswa nearc welding, mutengo wekugadzirisa unogona kudzikiswa ne30%. Oparesheni iri nyore, iri nyore kudzidza, uye inokurumidza kutanga. Iyo tekinoroji chikumbaridzo chevashandisi haina kukwirira. Vashandiwo zvavo vanogona kutora zvigaro zvavo mushure mekudzidziswa kwenguva pfupi, izvo zvinogona kuwana mhedzisiro yemhando yepamusoro-welding.

9. Nyore kushandura kubva mutsika welding nzira kune faibha Laser welding.

Iwe unogona kudzidza mashandisiro eFortune Laser fiber laser welding muchina mukati memaawa mashoma, uye hapana musoro wekutarisa welding nyanzvi, hapana kunetseka nezve yakaomesesa yekutumira hurongwa. Chii zvakare, neiyi tekinoroji nyowani uye kudyara, iwe unenge uri pamberi pemusika uye uchimbundikira yakawedzera purofiti miganho pane yechinyakare welding nzira.

Kushandisa Minda yeHandheld Laser Welding Machine

Iyo handheld laser welder inonyanya kuve yakakura uye yepakati-saizi sheet simbi, makabati, chassis, aruminiyamu alloy gonhi nemahwindo mafuremu, Stainless simbi yekugezera mabheseni uye mamwe mahombe ebasa-zvidimbu, senge mukati mekona yekurudyi, kona yekunze yekurudyi, flat weld welding, diki kupisa-kukanganisa nzvimbo panguva yewelding, diki deformation, uye welding kudzika Yakakura, yakasimba welding.

Fortune Laser handheld laser welding michina inoshandiswa zvakanyanya muakaomesesa uye asina kujairika welding maitiro ekicheni uye yekugezera indasitiri, indasitiri yemidziyo yemba, indasitiri yekushambadzira, indasitiri yekuumba, indasitiri yezvigadzirwa zvesimbi, indasitiri yesimbi isina tsvina, indasitiri yemagonhi nemahwindo, indasitiri yemaoko, indasitiri yemidziyo yemumba, indasitiri yefenicha, auto zvikamu indasitiri, nezvimwe.

Kuenzanisa kweHandheld Laser Welding Machine uye Argon Arc Welding

1. Kuenzanisa kwekushandiswa kwesimba:Kuenzaniswa neyechinyakare arc welding, iyo handheld laser welding muchina inochengetedza inenge 80% kusvika 90% yemagetsi emagetsi, uye mutengo wekugadzirisa unogona kudzikiswa ne30%.

2. Welding effect kuenzanisa:laser ruoko-inobata welding inogona kupedzisa dissimilar simbi uye dissimilar simbi welding. Iyo yekumhanyisa inokurumidza, deformation idiki, uye nzvimbo inobatwa nekupisa idiki. Iyo weld seam yakanaka, yakatsetseka, isina / shoma porosity, uye haina kusvibiswa. Iyo handheld laser welding muchina inogona kushandiswa kune madiki akavhurika zvikamu uye chaiyo welding.

3. Kuenzanisa kwemaitiro ekutevera:yakaderera kupisa kupinza panguva laser ruoko-inobata welding, diki deformation yeworkpiece, yakanaka welding nzvimbo inogona kuwanikwa, kwete kana chete kurapwa kwakapusa (zvichienderana nezvinodiwa zvewelding surface effect). Iyo handheld laser welding muchina unogona kudzikisa zvakanyanya mutengo webasa weiyo hombe yekupukuta uye yekuyera maitiro.

| Type | Argon arc welding | YAG welding | HandheldLaserwelding | |

| Welding quality | Kuisa kupisa | Big | Diki | Diki |

|

| Workpiece deformation/undercut | Big | Diki | Diki |

|

| Weld kugadzira | Hove-scale pattern | Hove-scale pattern | Smooth |

|

| Kutevera kugadzirisa | ChiPolish | ChiPolish | Hapana |

| Shandisa kushanda | Welding speed | Slow | Pakati | Fast |

|

| Kushanda zvakaoma | Zvakaoma | Easy | Easy |

| Kuchengetedzwa kwezvakatipoteredza uye kuchengeteka | Kusvibiswa kwezvakatipoteredza | Big | Diki | Diki |

|

| Kukuvadza kwemuviri | Big | Diki | Diki |

| Welder mutengo | Consumables | Welding tsvimbo | Laser crystal, xenon rambi | Hapana chikonzero |

|

| Simba rekushandisa | Diki | Big | Diki |

| Equipment pasi nzvimbo | Diki | Big | Diki | |