Short Lead Time for Laser Welding Tool - Fortune Laser Industrial Robot Laser Welding Machine – Fortune

Short Lead Time for Laser Welding Tool - Fortune Laser Industrial Robot Laser Welding Machine – Fortune

Short Lead Time for Laser Welding Tool - Fortune Laser Industrial Robot Laser Welding Machine – Fortune Detail:

Scope of application:

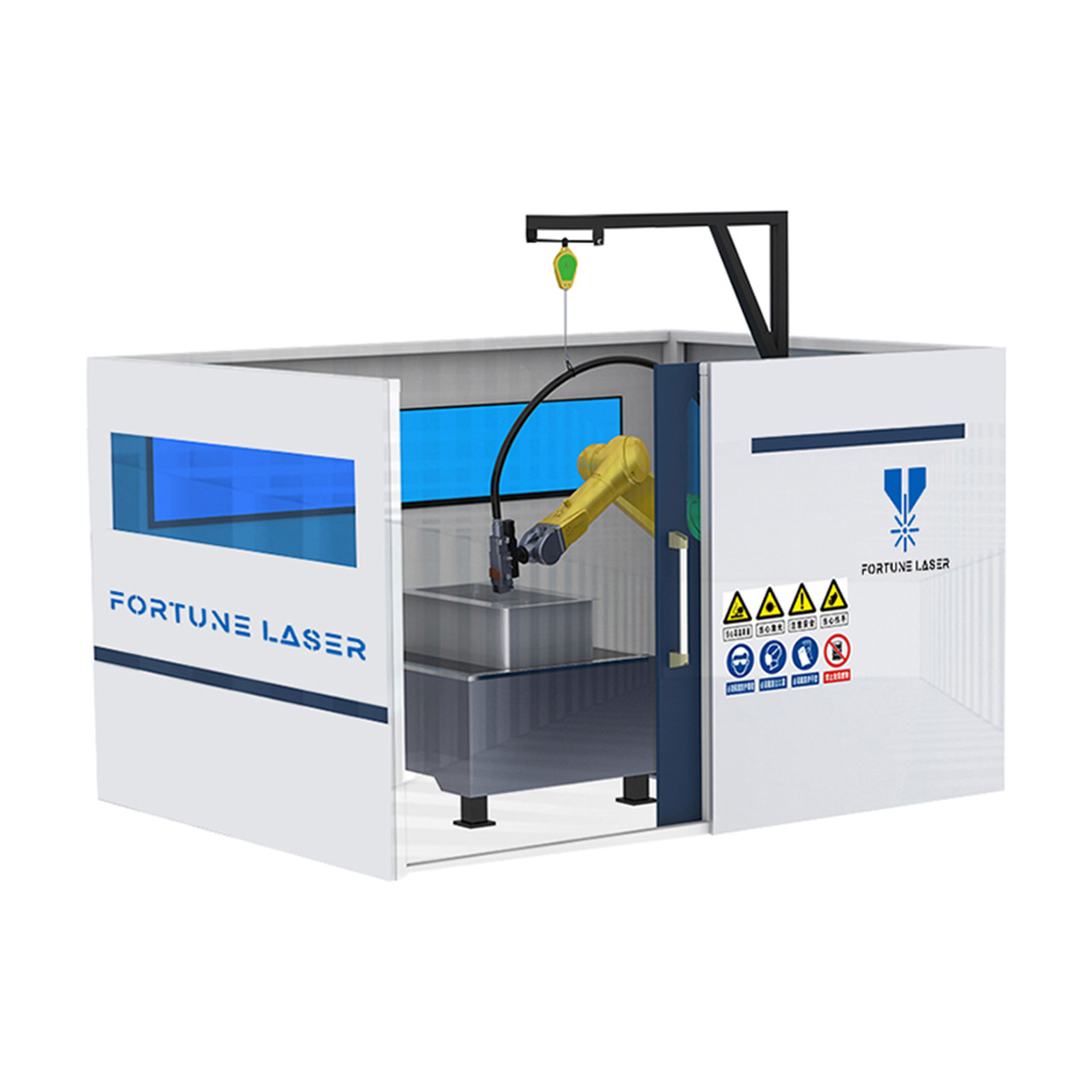

The robot laser welding machine has a wide range of applications and is suitable for welding various high-precision and high-quality metal materials. It is especially suitable for automobile manufacturing, aerospace, construction machinery, and other fields, and can be used for welding car bodies, aero engines, mechanical equipment, etc.

Technical advantages:

1.High-precision welding: Robot laser welding machines can achieve high-precision welding, and the welding quality is stable and reliable. It is also widely used in the field of production and processing.

2.High efficiency and energy saving: Since the robot laser welding machine uses very little energy to complete the welding work, it also has great advantages in terms of energy saving. It is also very easy to maintain when working continuously for a long time.

3.High-speed production: Robot laser welding machines can complete a large number of welding operations in a short period of time, and have great advantages in terms of speed. And since the welding process is done by robots, the welding efficiency is higher.

Main Technical Parameters of the robot laser welding machine

1. Robot

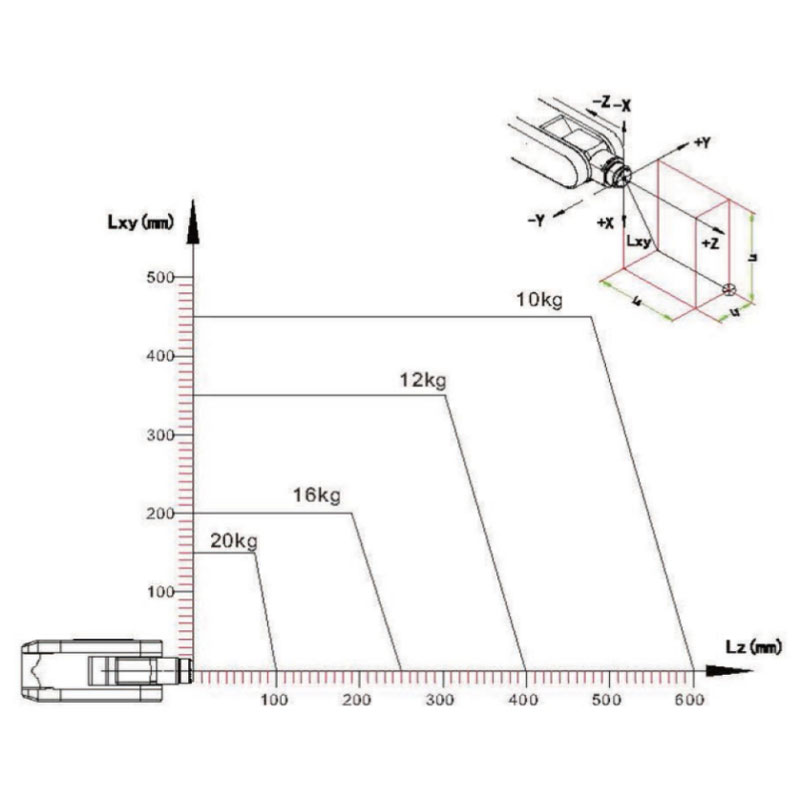

Robot load graph:

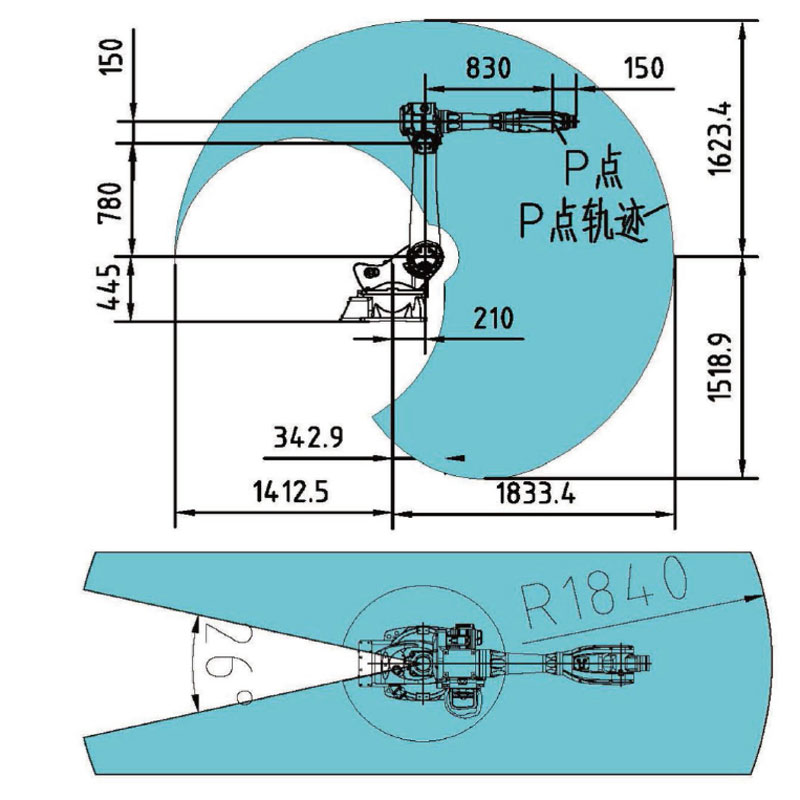

Dimensions and action range Unit: mm

P point action range

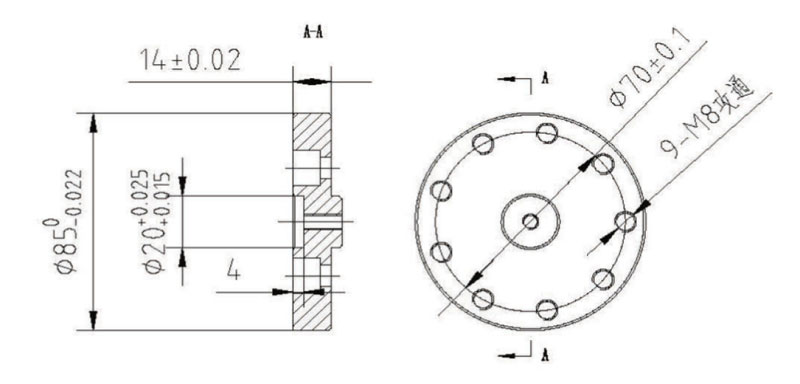

End flange mounting dimensions.

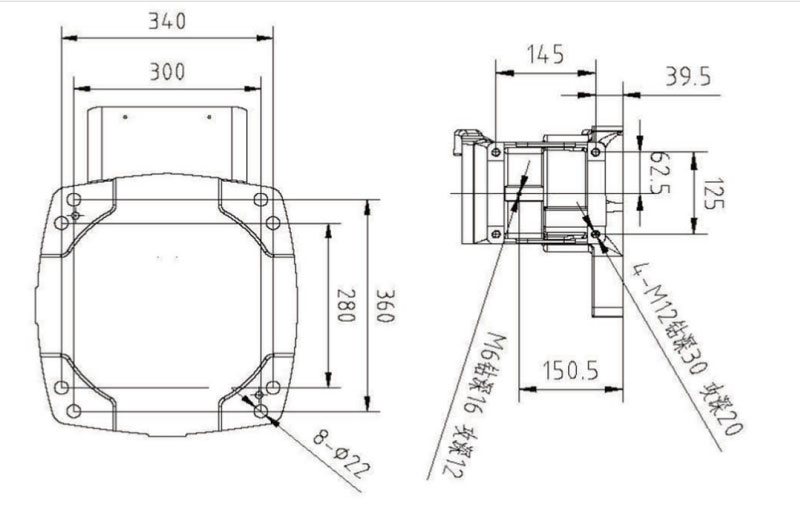

Base installation dimensions Four-axis installation size

Robot body standard specifications

| Number of axes | 6 axis |

| radius of motion | 1840mm |

| payload | 25 KG |

| Degree of protection | JL J2 axis IP56 (J3, J4, J5, J6 axis IP67) |

| installation method | Floor type/stand type/upside down type |

| power capacity | 4.5KVA |

| input/output signal | Standard 16 in/16 out 24VDC |

| robot weight | 260KG |

| Repeatability | ±0.05 |

| Range of motion | |

| 1 axis S | ±167° |

| 2axisL | +92° to -150° |

| 3axisU | + 110° To -85° |

| 4axisR | ±150° |

| 5axisB | + 20° To -200° |

| 6axisT | ±360° |

| Movement speed | |

| 1axisS | 200°/s |

| 2axisL | 198°/s |

| 3axisU | 163°/s |

| 4axisR | 296°/s |

| 5axisB | 333°/s |

| 6axisT | 333°/s |

| Application field | Laser welding, cutting, loading and unloading, spraying, handling |

| 4 axis R(N.m) | 103.5 |

| 5axisS(N.m) | 101.6 |

| 6 axis T(N.m) | 63.5 |

| built-in air tube | Φ10 |

| installation method | Floor, wall, inclined, upside down |

| Installation Environment | Temperature0-45°CHumidity 20~80%RH (no condensation)Vibration acceleration 4.9m/S: (0.5G) or lessAltitude below 1000m |

| otherNon-flammable, corrosive gas, liquidNo splashing water, less oil, dustkeep away from electromagnetic sourcesstay away from magnetic fields |

Control cabinet

|

Specification |

|

| Power Specifications | Three-phase AC380V 50/60HZ (built-in AC380V to AC220V isolation transformer) |

| grounding | Industrial grounding (special grounding with grounding resistance below 1000) |

| Input and output signals | General signal: input 16, output 16 (16 in 16 out) two 0-10V analog output |

|

Position control m ethod |

Serial communication method EtherCAT.TCP/IP |

| Memory Capacity | JOB:200000steps, 10000 robot commands (200M in total) |

| LAN (host connection) | Ethercat (1) TCP/IP (1) |

| Serial port I/F | RS485 (one) RS422 (one) RS232 (one) CAN interface (one) USB interface (one) |

| control method | Software Servo <Position Control> |

| Drive unit | Servo package for AC servo (total 6axis); external axis can be added |

| ambient temperature | When energized: 0~+45℃, when stored: -20~+60℃ |

| Relative humidity | 10%~90% (no condensation) |

| altitude | Altitude below 1000mOver 1000m, the maximum ambient temperature will decrease by 1% for every 100m increase, and the maximum ambient temperature can be used at 2000m. |

| vibration | Below 0.5G |

| other | Non-flammable, corrosive gas, liquid |

| No dust, cutting fluid (including coolant), organic solvents, oil fume, water, salt, chemicals, anti-rust oil | |

| No strong microwave, ultraviolet, X-ray, radiation exposure |

Specifications of the programming pendant

|

Dimensions |

280 (W) X22O (D) X120 (H) mm |

|

Weight |

0.6KG |

|

material |

reinforced plastic |

|

Manipulator |

Selection key, axis operation key, numerical value/application key, switch mode key with key/ (teaching mode, playback mode, remote mode), emergency stop key, start key, USB port 1 |

|

display screen |

8-inch color LCD, touch screen 640×480 pixels |

|

Degree of protection |

IP54 |

|

cable length |

Standard: 5m; Optional: 15m |

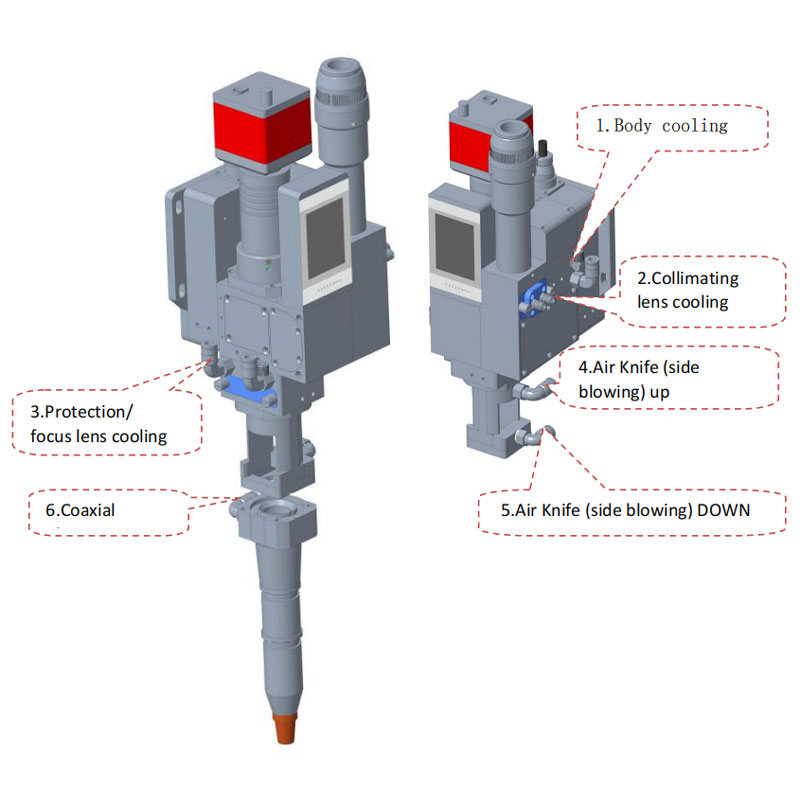

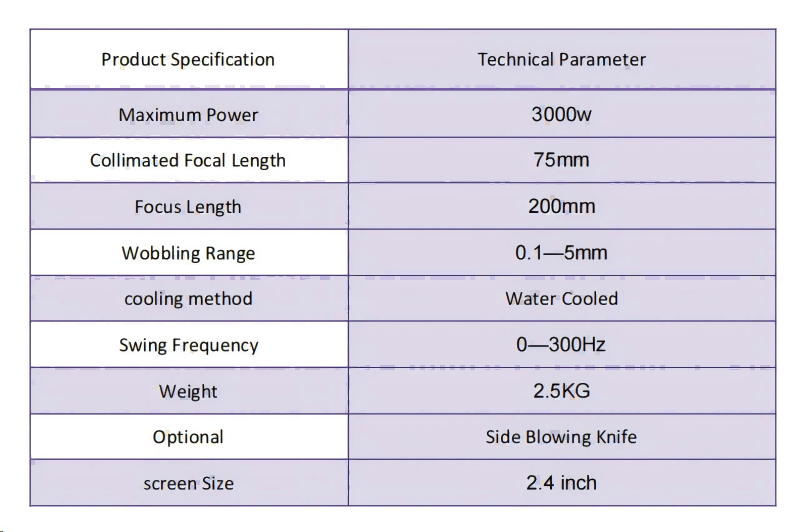

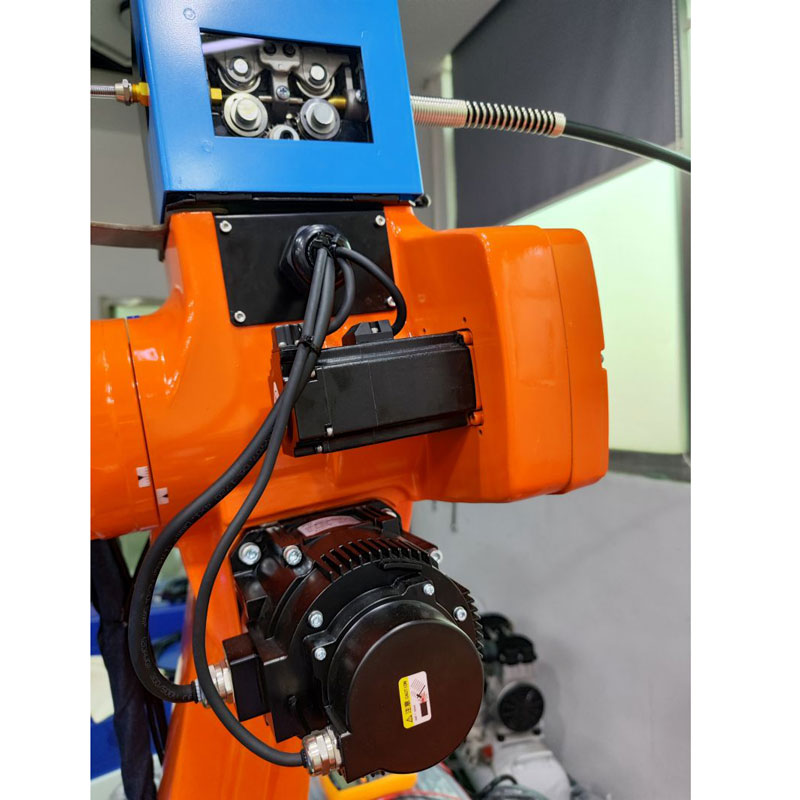

2.Welding Head

3.Laser welding system(Laser source&Chiller&Control System) and wire feeder

1). 1500W/2000W/3000W Maxphotonics laser source for option

2). Water chiller

3). Control System

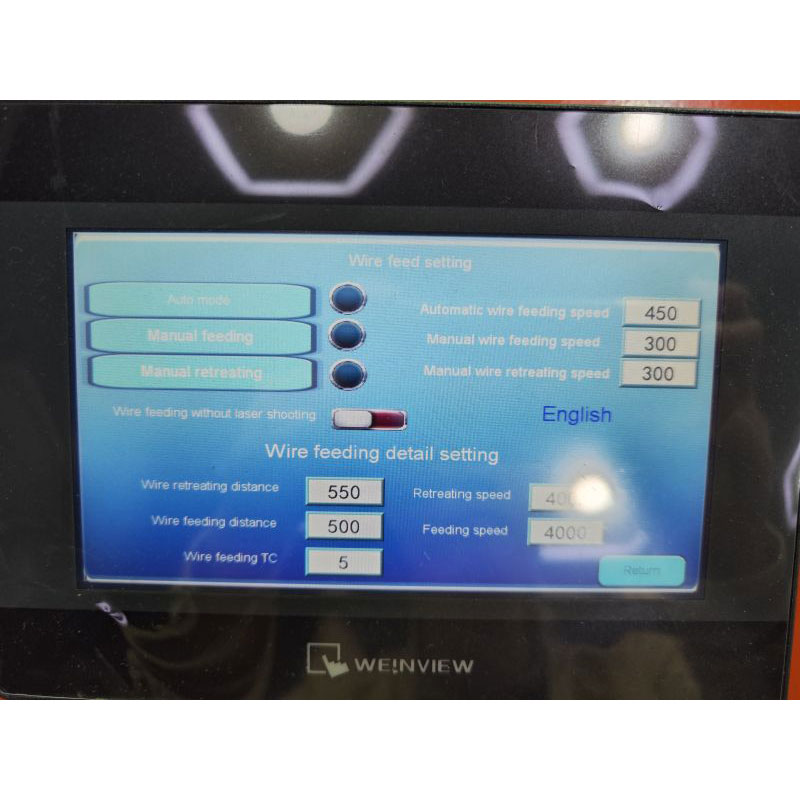

4). Auto Wire feeder

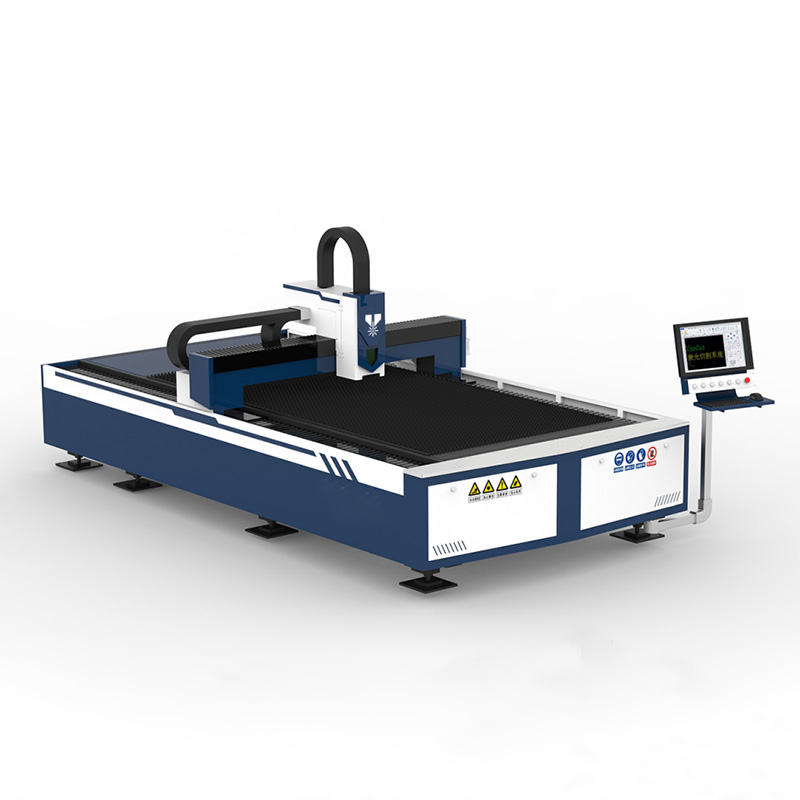

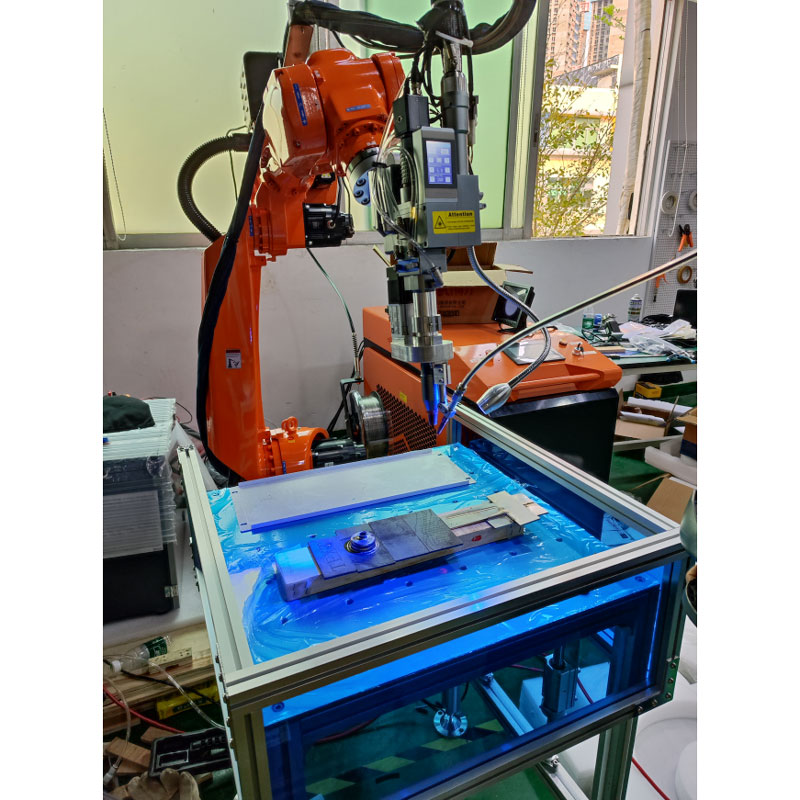

Fortune Laser Robot laser welding machine details

Blue and orange colors for option

Auto-wire feeder

Easy to learn and operate

Laser welding user Interface

Touch screen on the laser welding head

Product detail pictures:

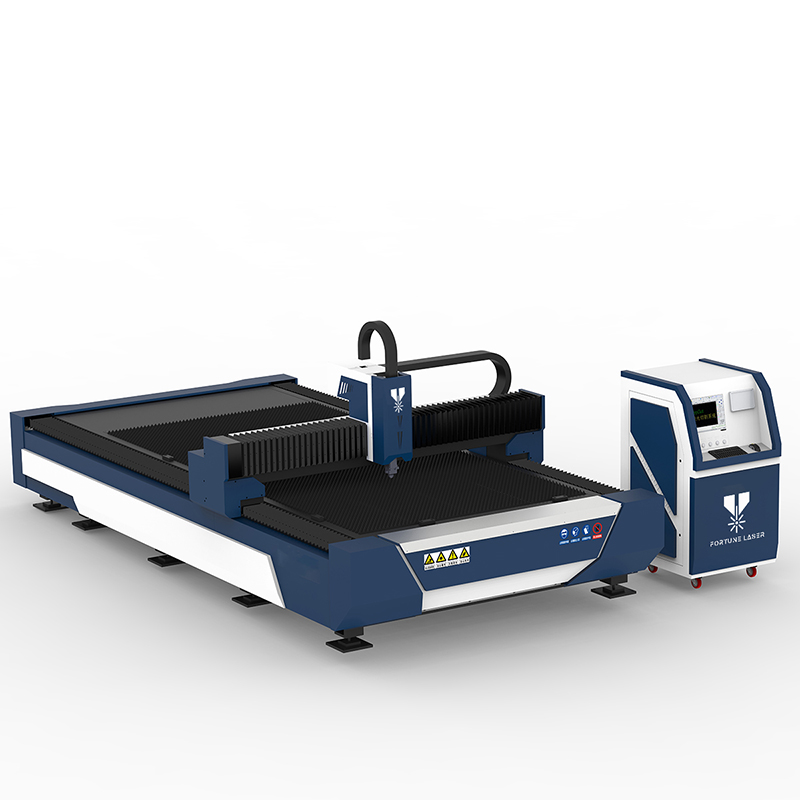

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Short Lead Time for Laser Welding Tool - Fortune Laser Industrial Robot Laser Welding Machine – Fortune , The product will supply to all over the world, such as: Georgia, Frankfurt, Guinea, Due to good quality and reasonable prices, our items have been exported to more than 10 countries and regions. We are looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.