OEM/ODM Supplier Handheld Fiber Laser Welder Supplier - Robotic Fiber Laser Welding Machine – Fortune

OEM/ODM Supplier Handheld Fiber Laser Welder Supplier - Robotic Fiber Laser Welding Machine – Fortune

OEM/ODM Supplier Handheld Fiber Laser Welder Supplier - Robotic Fiber Laser Welding Machine – Fortune Detail:

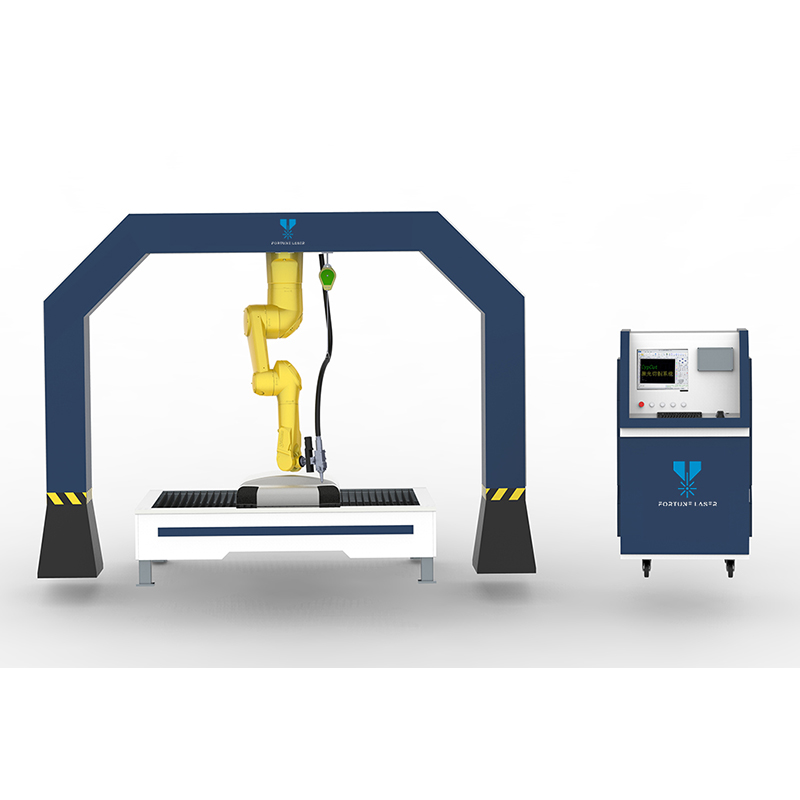

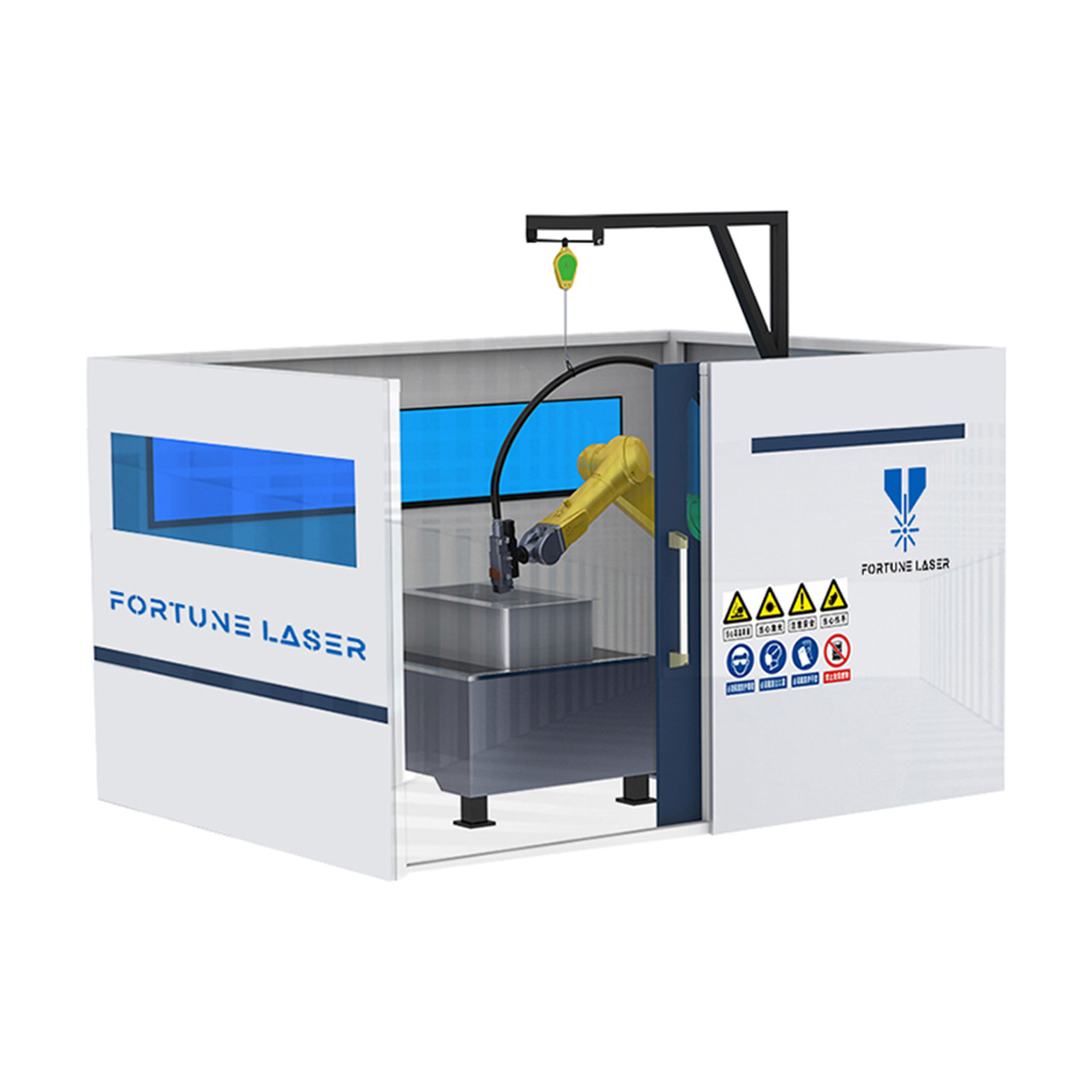

Robot Laser Welding Machine Features

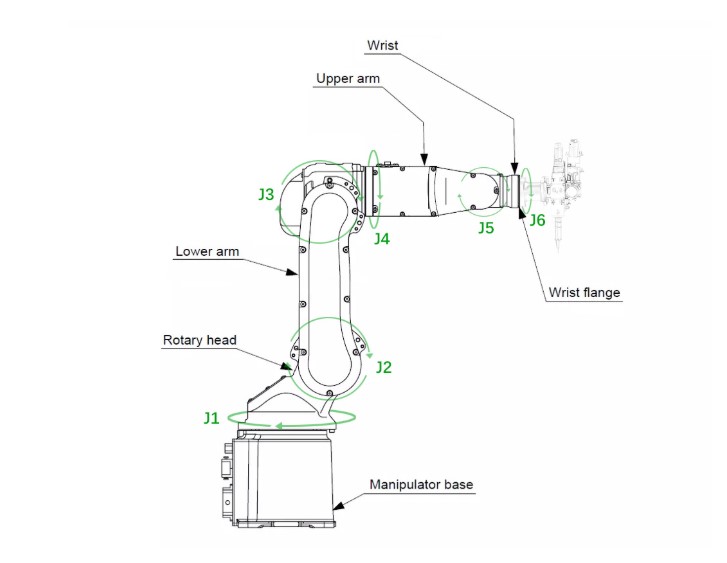

1. The robot laser welding machine has six-axis linkage, high positioning accuracy, large processing range, and easy welding of three-dimensional workpieces.

2. Compared with the traditional argon arc welding, the laser welding speed is increased by 5 to 10 times, and the power consumption and the consumption of consumables are lower, and the welding quality is very stable.

3. The heat affected area of welding is smaller, which can better guarantee the quality of welding products.

4. Robot laser welding has good adaptability to the size and shape of welding materials and welding parts, and can realize automatic control and long-distance welding;

Machine Parameters

|

Model |

FL-RW Series Robotic Welding Machine |

|

Structure |

Multi-joint robot |

|

Number of control axis |

6 Axis |

|

Arm span(Optional) |

750mm/950mm/1500mm/1850mm/2100mm/2300mm |

|

Laser source |

IPG2000~1PG6000 |

|

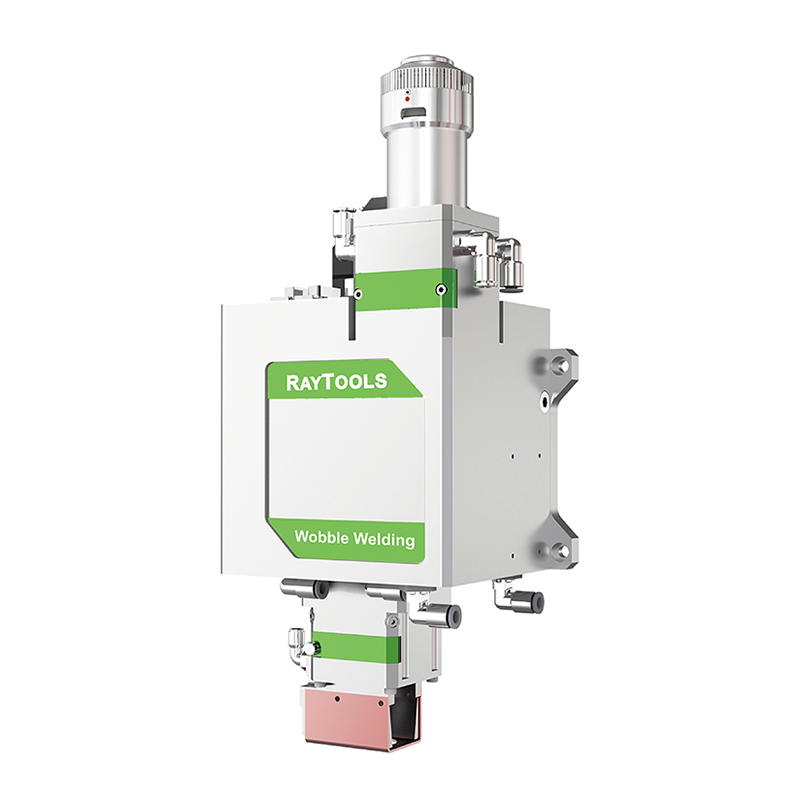

Welding head |

Precitec |

|

Installation method |

Ground, Top, Bracket/holder installation |

|

Maximum motion axis speed |

360°/s |

|

Repeat positioning accuracy |

±0.08mm |

|

Max Loading Weight |

20kg |

|

Robot weight |

235kg |

|

Working temperature and humidity |

-20~80℃,Usually below 75% RH (no condensation) |

Portable Handheld Laser Welder for Metals

|

Material |

Output power (W) |

Maximum penetration (mm) |

|

Stainless steel |

1000 |

0.5-3 |

|

Stainless steel |

1500 |

0.5-4 |

|

Stainless steel |

2000 |

0.5-5 |

|

Carbon steel |

1000 |

0.5-2.5 |

|

Carbon steel |

1500 |

0.5-3.5 |

|

Carbon steel |

2000 |

0.5-4.5 |

|

Aluminum alloy |

1000 |

0.5-2.5 |

|

Aluminum alloy |

1500 |

0.5-3 |

|

Aluminum alloy |

2000 |

0.5-4 |

|

Galvanized sheet |

1000 |

0.5-1.2 |

|

Galvanized sheet |

1500 |

0.5-1.8 |

|

Galvanized sheet |

2000 |

0.5-2.5 |

Applications

Widely used in aerospace, automobiles, ships, machinery manufacturing, elevator manufacturing, advertising production, household appliances manufacturing, medical equipment, hardware, decoration, metal processing services and other industries.

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for OEM/ODM Supplier Handheld Fiber Laser Welder Supplier - Robotic Fiber Laser Welding Machine – Fortune , The product will supply to all over the world, such as: Lesotho, Naples, Maldives, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we've been committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have now passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.