OEM Supply Laser Beam Welding Tool - Fortune Laser Mini 1000W/1500W/2000W/3000W Fiber Handheld Laser Welding Machine – Fortune

OEM Supply Laser Beam Welding Tool - Fortune Laser Mini 1000W/1500W/2000W/3000W Fiber Handheld Laser Welding Machine – Fortune

OEM Supply Laser Beam Welding Tool - Fortune Laser Mini 1000W/1500W/2000W/3000W Fiber Handheld Laser Welding Machine – Fortune Detail:

Basic Principles of Laser Welding

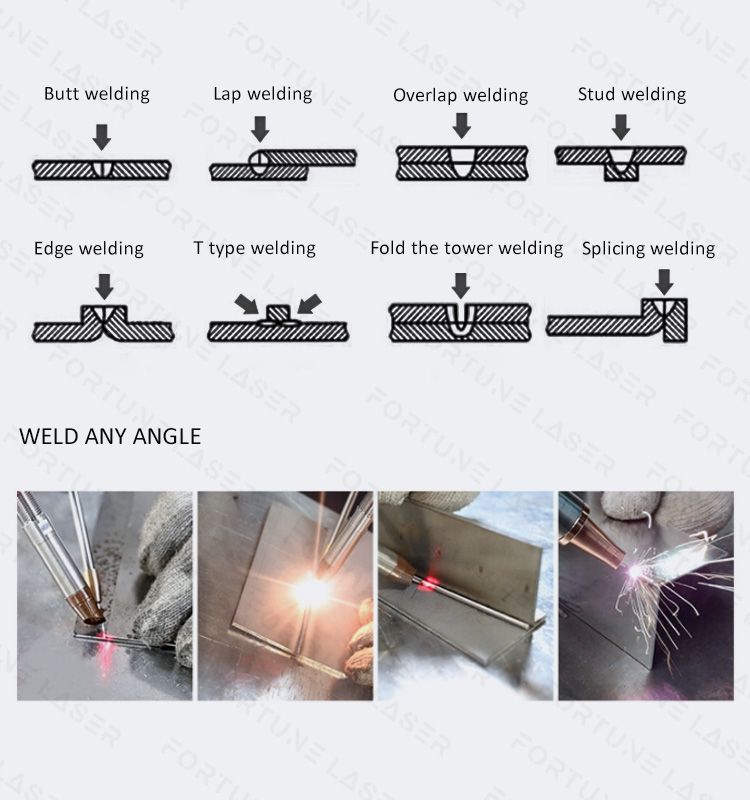

Laser welding is to use a single pulse of high-efficiency energy laser to heat a small area of the material. The power of the laser radiation source spreads to the inside of the material according to the heat conduction, and the material is melted to produce a special molten pool. It is a new type of welding method, which is mainly used for the welding of thick-walled raw materials and high-precision parts, and can be used for welding, butt welding, stitch welding, sealing welding, etc. Small deformation, faster welding speed, smooth welding, beautiful appearance, no need for disposal or simple solution after welding, high welding quality, no air outlet, maneuverable, small focus spot, high precision level, easy to complete automation technology.

1000W 1500w 2000w 3000W Mini Laser Welding Machine Features:

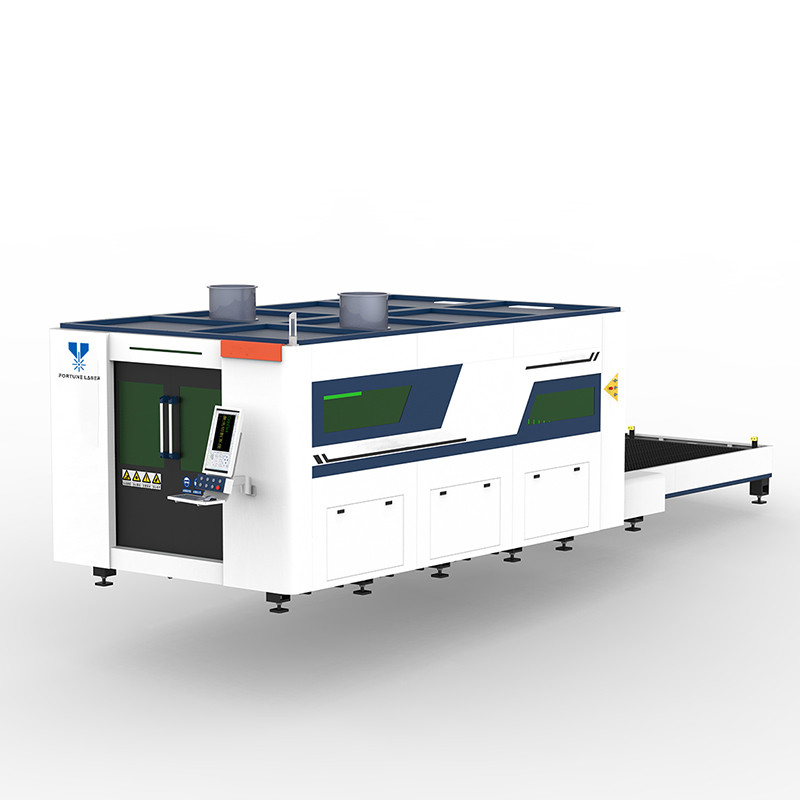

● Small Size: The size and weight of this welding machine is twice smaller than ordinary ones, the size is: 100*68*45cm, the weight is only 165kg, it is convenient to carry and can save transportation cost;

● The hand-held welding head is light and flexible, which can meet a variety of angles and multi-position welding;

● Fixed optical path, flexible and convenient, long-distance laser welding;

● Infrared positioning, the welding position is more accurate, and the welding seam is more beautiful;

● Fast welding speed, simple operation, reducing time and cost;

● Deep laser welding depth, the weld ability is strong, and it is suitable for all kinds of complex welding.

Fortune Laser Mini Laser Welding Machine Technical Parameters

|

Model |

FL-HW1000M |

FL-HW1500M |

FL-HW2000M |

FL-HW3000M |

|

Laser Power |

1000W |

1500W |

2000W |

3000W |

|

Cooling Way |

Water Cooling |

Water Cooling |

Water Cooling |

Water Cooling |

|

Laser Wavelength |

1080nm |

1080nm |

1080nm |

1080nm |

|

Way of Working |

Continuous/ Modulation |

|||

|

Fiber Length |

Standard 10m, the longest customized length 15m |

|||

|

Dimension |

100*68*45cm |

|||

|

Weight |

165kg |

|||

|

Options |

Portable |

|||

|

Speed range of welder |

0-120mm/s |

|||

|

Temperature |

15-35℃ |

|||

|

Operating Voltage |

AV 220V |

|||

|

Focal Spot Diameter |

0.5mm |

|||

|

Welding thickness |

0.5-5mm |

|||

What parts does our machine consist of?

● Laser Source: Internationally famous laser source(Max/Raycus/BWT/IPG), support accessory brand designation, stable laser power, long life, good welding effect and beautiful welding seam;

● Water Cooling: Constant temperature cold water machine, condensation and repaid cooling, to ensure the constant temperature;

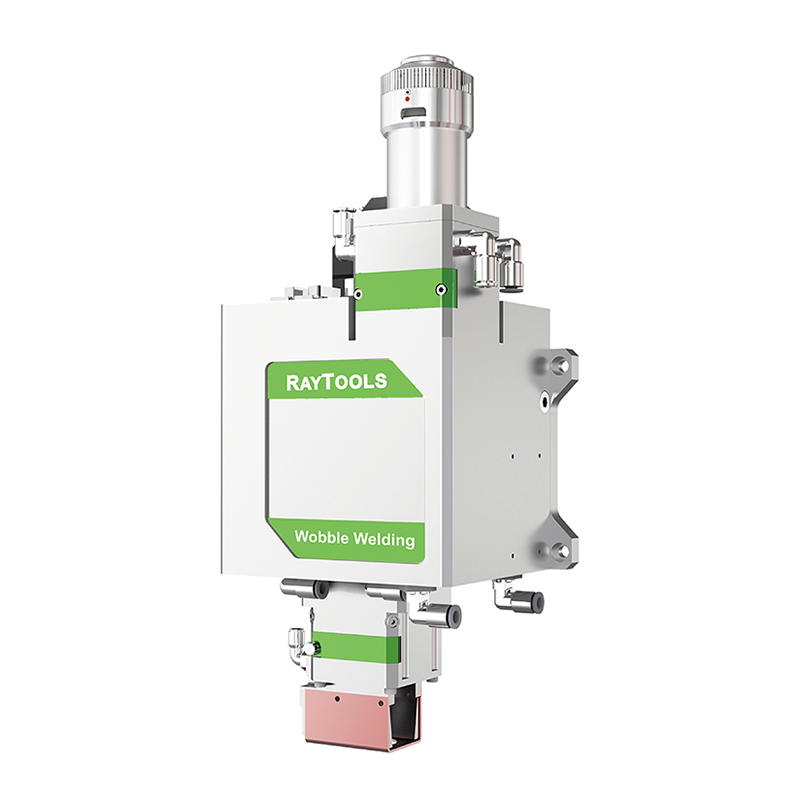

● Laser Welding Head: Also support brand designation of laser head(Sup/Qilin/Ospri/Exclusive custom touch screen laser head), good at precision welding of metal materials)

● Operation Panel: Simple operation, different fiber types and widths can be set.

Which industries are hand-held laser welding machines mainly used for?

1. Kitchen and bathroom cabinets

At present, people often need to use a variety of kitchen cabinets, including some stainless steel kitchen utensils. The stainless steel kitchen utensils are usually made by splicing various plates in the production process, and the plates naturally need to be cut in the production process, and most of the cutting is done with a hand-held laser welding machine.

2. Stairs and elevators

In the process of making elevators and stairs, especially some edges and corners need to be welded with an easy-to-operate hand-held laser welding machine to ensure that every edge and corner can be welded in place and ensure the aesthetics of stairs and elevators, so the evaluation is high The application of hand-held laser welding machines in stair elevators is also relatively common.

3. Door and window guardrails

More and more stainless steel materials are used in the process of modern home improvement, including some stainless steel doors and windows and guardrails, and stainless steel doors and windows and guardrails also need to be welded with welding equipment during the construction process. The well-received handheld laser welding machine plays such a role in ensuring that the display effect of doors, windows and guardrails will not be affected after welding.

Can laser welding wire feed? And the specific choice of welding wire?

Can feed wire, standard automatic wire feeder, 1000W is suitable for 0.8-1.0 wire, 1500W is suitable for 0.8-1.6 wire, 2000-3000W is suitable for 2.0 wire;

Specific selection of welding wire:

According to the different welding plates, we need to use different welding wires (gas shielded solid core welding wire)

Stainless steel = stainless steel wire such as: ER304

Carbon steel/galvanized sheet=iron wire

Aluminum = aluminum wire (We recommend using alloy aluminum above 5 series for aluminum welding wire, which has high hardness and is not easy to get stuck)

Does laser welding require shielding gas? And the specific choice of shielding gas in the welding process?

● There are two common types of nitrogen gas or argon gas. We recommend using nitrogen gas for welding stainless steel, and the welding effect is better. Do not use mixed/nitrogen dioxide gas

● Air pressure requirements: the flow meter is not less than 15, and the pressure gauge is not less than 3;

Video

What materials can hand-held laser welding be used for?

The fiber laser hand-held welding machine can weld 0.4-8.0mm thick stainless steel, galvanized sheet, iron sheet, red copper, aluminum and other metal materials due to the selected power. It depends on the power/process. The higher the power, the stronger the welding ability.

Product detail pictures:

Related Product Guide:

Our group through specialist training. Skilled expert knowledge, sturdy sense of assistance, to fulfill the provider needs of shoppers for OEM Supply Laser Beam Welding Tool - Fortune Laser Mini 1000W/1500W/2000W/3000W Fiber Handheld Laser Welding Machine – Fortune , The product will supply to all over the world, such as: Niger, Luxemburg, Burundi, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.