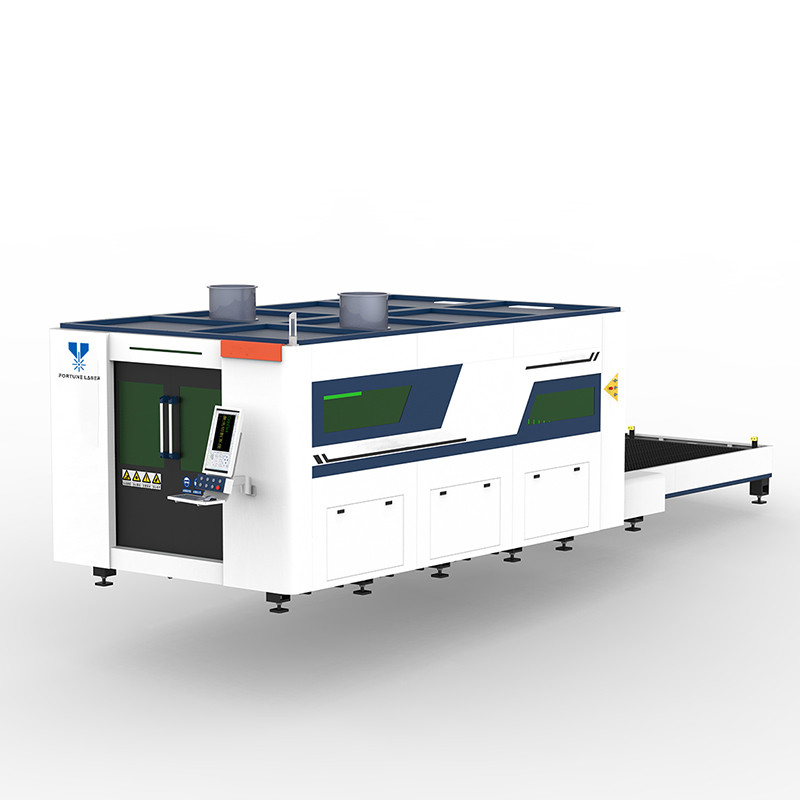

OEM manufacturer Fibre Laser Welding Machine - Continuous Laser Welding Machine – Fortune

OEM manufacturer Fibre Laser Welding Machine - Continuous Laser Welding Machine – Fortune

OEM manufacturer Fibre Laser Welding Machine - Continuous Laser Welding Machine – Fortune Detail:

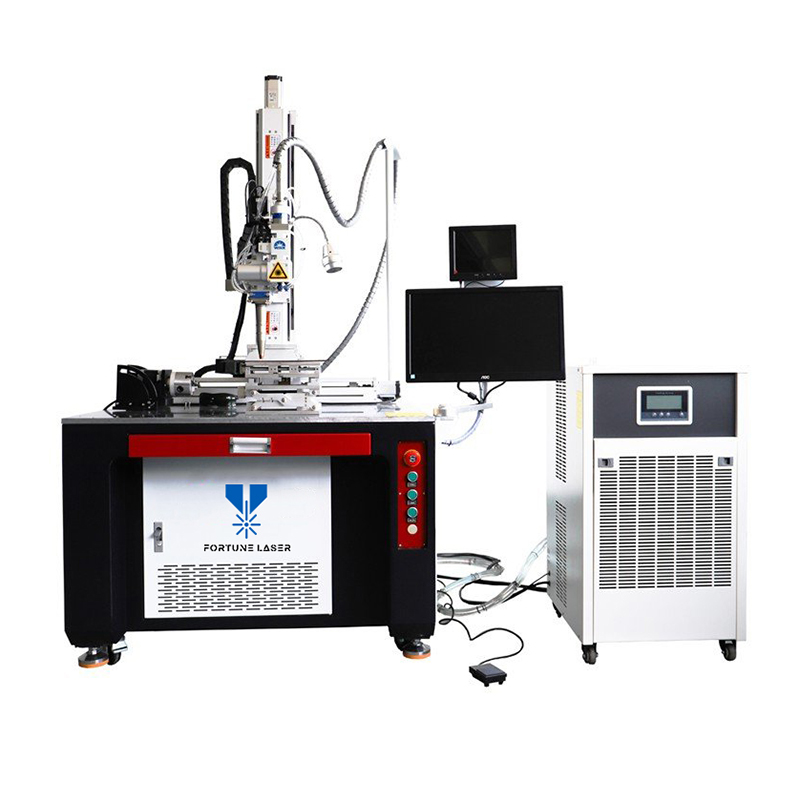

Fiber CW Laser Welding Machine Features

1. Excellent laser beam quality, accurate and fast welding for complex parts, logo, metal words, etc.

2. Solid and perfect welds fully meet the welding requirements of different industries and projects;

3. Controlled by PC, with special control software assisted, and it’s easy to learn the operation. The work-piece can be used for plane trajectory movement, which supports to weld any point, straight line, circle, square or any plane graphic composed of straight line and arc;

4. With CCD liquid crystal camera monitoring system, users can clearly observe the real-time positioning and welding effect;

5. High electro-optic conversion rate, low energy consumption, and no consumables. Can save a lot of processing cost for users after long term use;

6. The welding line is fine, the welding depth is large, the taper is small, and the precision is high. The appearance is smooth, flat and beautiful;

7. Support 360°rotation welding, with large welding range, and flexible welding of hard-reach position;

8. The welding machine can be upgraded with a handheld welding gun to achieve manual welding;

9. Suitable for 24 hours industrial mass production and processing.

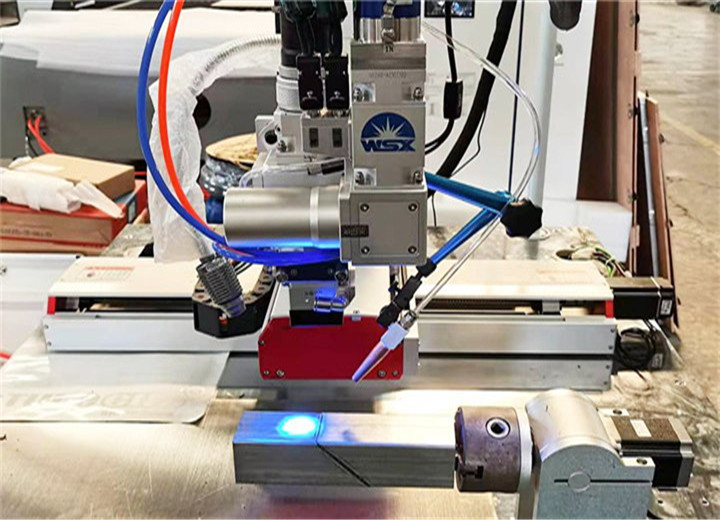

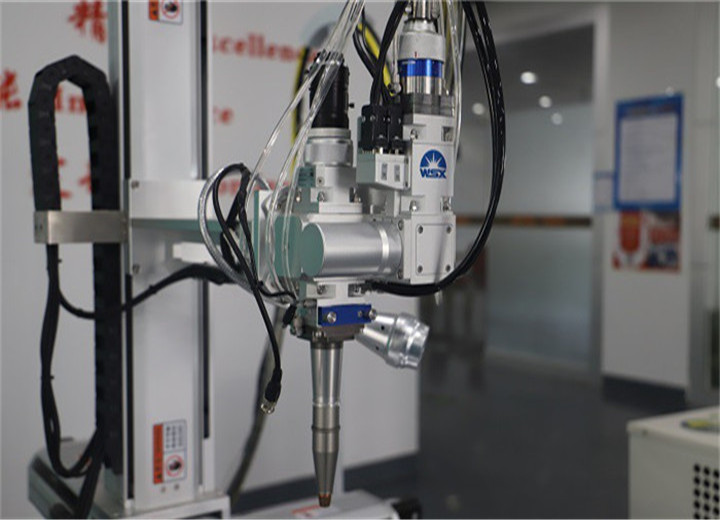

Welding Head Features

The swaying welding head has a strong advantage in high-reflective material welding, wide range of application, it is very cost effective

The welding head adopts motor-driven X- and Y-axis vibrating lenses, it has various swing modes and able to work on irregular shapes, larger welding spot and other processing parameters setting can improve markedly in welding quality

The internal structure of the welding head is completely sealed to avoid dust contamination of the optical part

Equipped with air curtain components to reduce contamination of dust and splash residues.

The protective lens has a drawer structure and is easy to replace. Can be equipped with various QBH connector laser sources.

Parameters

|

Model |

FL-CW1000 / FL-CW1500 / FL-CW2000 |

|

Laser Source |

1000W / 1500W / 2000W |

|

Laser Head |

Automatic |

|

Welding Depth |

0.8-1mm |

|

X/Y/Z Axis positioning accuracy |

±0.025mm |

|

X/Y/Z Axis Repositioning accuracy |

±0.02mm |

|

Laser working method |

CW/Modulated |

|

Emission Wavelength |

1085±5nm |

|

Modulation Frequency |

50-20kHz |

|

Spot Size |

Φ0.2-1.8mm |

|

Power Supply |

AC 220V 50Hz single phrase/AC 380V 50Hz single phrase |

|

Electric Current |

10-32A |

|

Total Power |

6KW/8KW/10KW |

|

Operating Temperature |

10-40℃< 70% Humidity |

|

Cooling Method |

Water cooling 1000w/1500W/200W(optional) |

|

Rotary |

For option |

|

Material |

SS, CS, Brass, Aluminum,Galvanized sheet, etc. |

|

Weight |

400kg |

|

Package Dimension |

161*127*145cm |

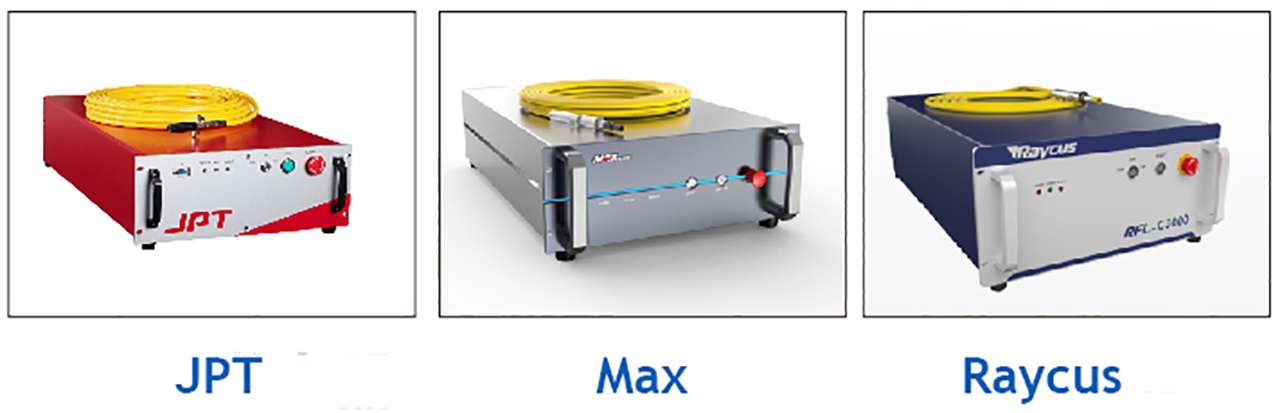

Fiber Laser Generator for option

Supported Welding Material

Carbon steel, stainless steel, Titanium, aluminum, copper, gold, silver, cooper-brass, cooper-titanium, nickel cooper, cooper-titanium and many other dissimilar metals.

Industry Application

● Automotive industry: engine cylinder head gasket, hydraulic tappet seal welding, spark plug welding, filter welding, etc.

● Hardware industry: impeller, kettle, handle, etc., welding of insulated cups, complex stamping parts and castings.

● Sanitary industry: welding of water pipe joints, reducers, tees, valves, and showers.

● Glasses industry: precision welding of glasses, such as stainless steel and titanium alloy, and the outer frame.

● Household hardware, kitchen utensils, stainless steel door handles, electronic components, sensors, watches, precision machinery, communications, handicrafts, and other industries, automotive hydraulic tappets and other high-intensity industry products welding.

● Medical industry: welding of medical instruments, medical equipment, stainless steel seals, structural parts.

● Electronics industry: solid-state relay seal welding, welding of connector connectors, welding of metal casings and structural parts such as mobile phones and MP3s. Welding of motor housings and wires, fiber optic connector connectors, etc.

Samples Display

Product detail pictures:

Related Product Guide:

We've our have sales staff, style and design staff, technical crew, QC team and package workforce. We've strict excellent control procedures for each system. Also, all of our workers are experienced in printing field for OEM manufacturer Fibre Laser Welding Machine - Continuous Laser Welding Machine – Fortune , The product will supply to all over the world, such as: Chile, Croatia, Vietnam, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.