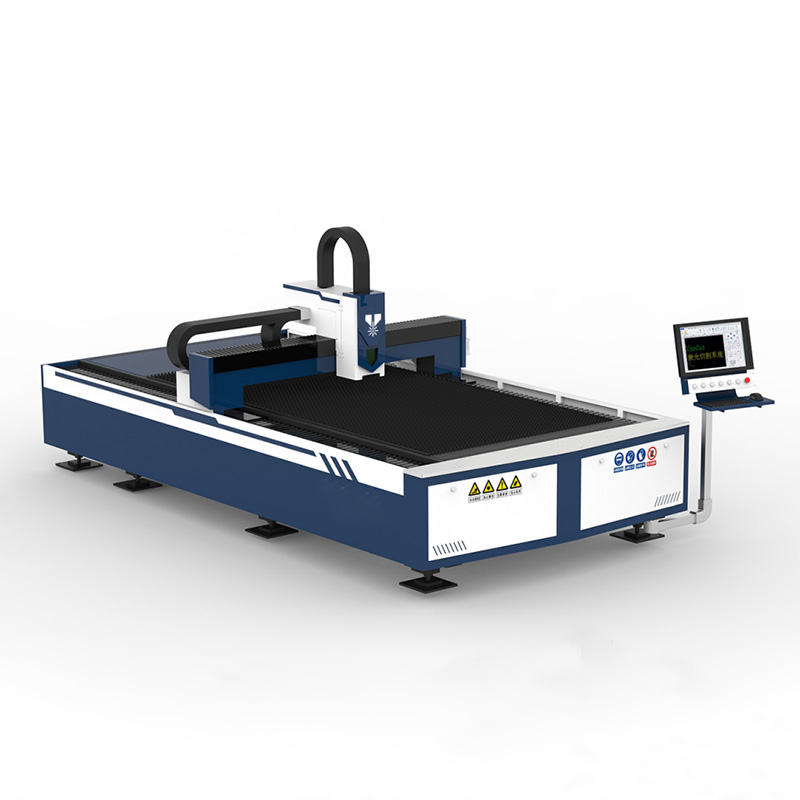

OEM manufacturer 1000w Fiber Laser Cutter - Dual-use Sheet and Tube Laser Cutting Machine – Fortune

OEM manufacturer 1000w Fiber Laser Cutter - Dual-use Sheet and Tube Laser Cutting Machine – Fortune

OEM manufacturer 1000w Fiber Laser Cutter - Dual-use Sheet and Tube Laser Cutting Machine – Fortune Detail:

High Rigidity Enhanced Lathe Bed

● 30 days’ strict manufacturing process, high-temperature annealing treatment to eliminate weld seams and bed stress;

● 72 hours vibration aging treatment, high strength, rigidity, tensile strength;

● High purity steel plate with thickness of 10mm, heavy chassis.

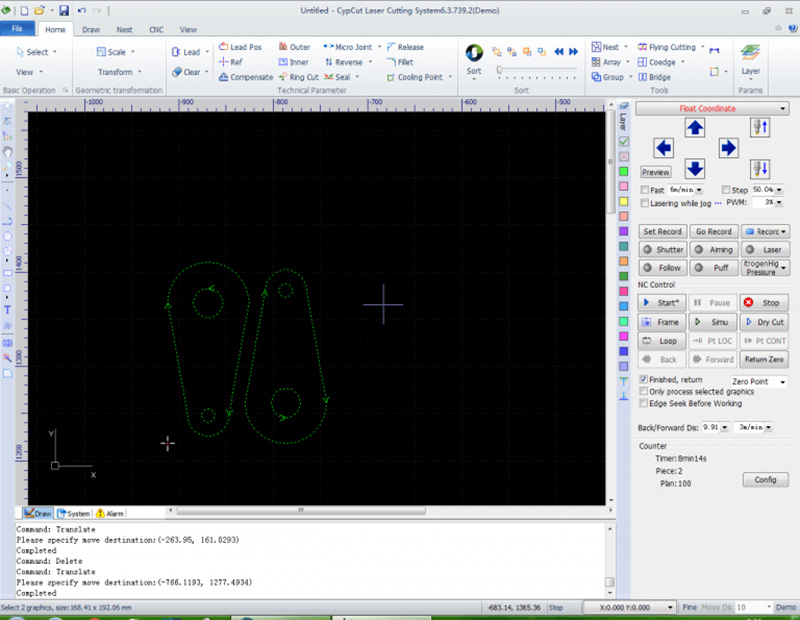

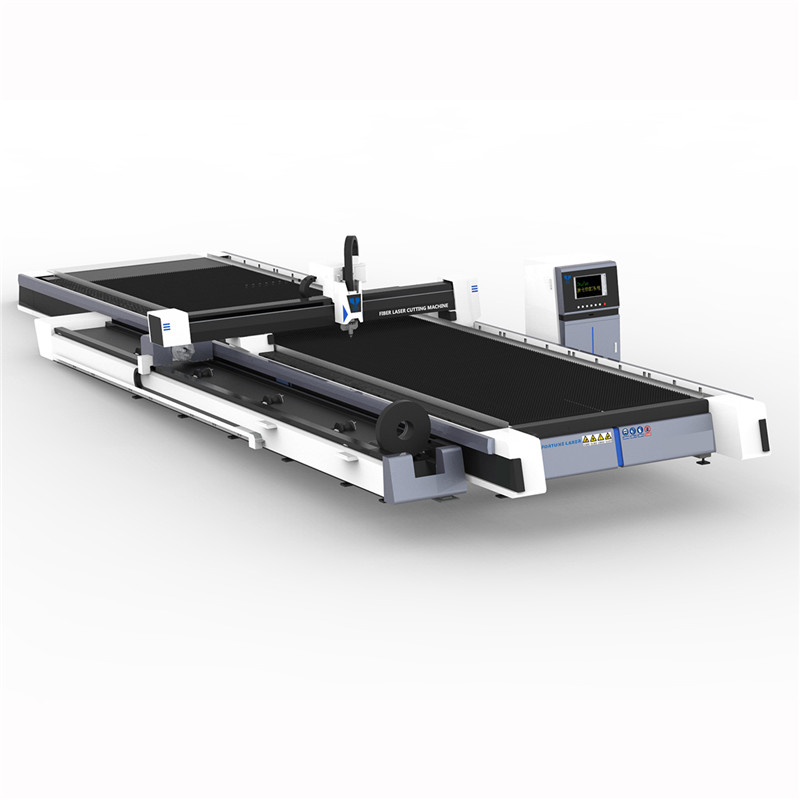

Professional Sheet & Tube Cutting System

● Cypcut Laser Cutting System

● More user-friendly human-machine interaction;

● Simple, economical, practical and convenient;

● Highly integrated and highly intelligent with file reading, design, output and processing control all in one.

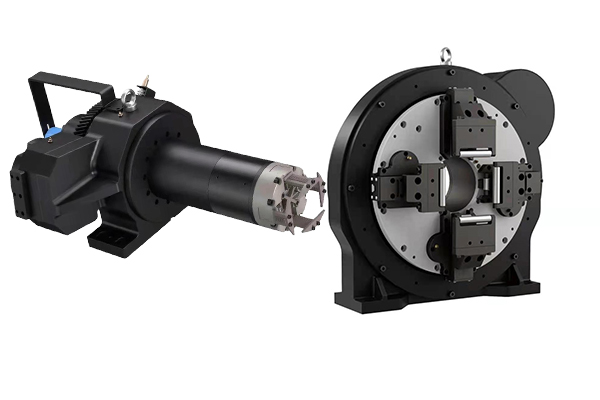

Pneumatic Chuck Design

The front and rear chuck clamping design is convenient for installation, labor-saving, and no wear and tear.Ensure the stability of feeding and cutting accuracy;Automatic adjustment of the center, suitable for various pipes, high chuck rotation speed,can improve processing efficiency.

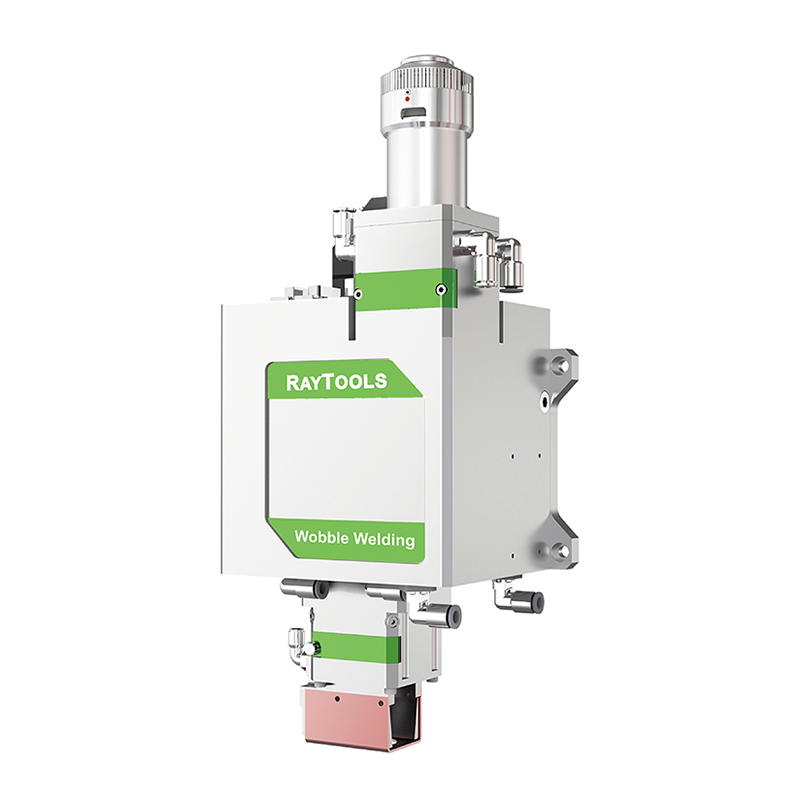

Auto-focus Laser Cutting Head

● Auto-focusing. Auto and continuous focusing, automatic cutting of plates of different thicknesses and materials, free your hand and improve cutting efficiency;

● Built-in double water-cooling structures can ensure the constant temperature of collimating and focusing components, perfectly solve the problem of heat dissipation.

● Optimized optical configuration, smooth and efficient airflow design, no longer jam due to rust;

S&A Industrial Water Chiller

● Automatically adjust the temperature according to different working environment, no need to change settings parameters;

● Intelligent dual temperature dual control mode to satisfy different needs of a fiber laser device and the optics;

● Multiple alarm protection;

Machine Parameters

|

Model |

FL-ST3015 |

|

|

Working area/ Tube length |

3050*1530mm/ 6000mm |

|

|

X axis stroke |

1530mm |

|

|

Y axis stroke |

3050mm |

|

|

Z axis stroke |

315mm |

|

|

Tube diameter |

20-220mm |

|

|

Accuracy |

X, Y axis positioning accuracy |

0.05mm |

|

|

X, Y axis repositioning accuracy |

0.03mm |

|

Speed |

W axis rotate angle |

n*360 |

|

|

W axis max. rotate speed |

80rpm/min |

|

|

X, Y axis max. running speed |

80m/min |

|

|

W axis max. running speed |

50m/min |

|

|

X, Y axis max. accelerated speed |

0.8G |

|

Power supply |

Phase |

3 |

|

|

Nominal voltage |

380V |

|

|

Frequency |

50/60Hz |

|

Machine body |

Max. working loading |

500kg |

|

|

Body weight |

5000kg |

|

|

Size(L*W*H) |

4450*2290*1920mm |

|

Laser power |

1000w/ 1500w/ 2000w/ 3000w |

|

|

Worktable optional |

4000*1500mm/ 6000*1500mm |

|

|

Tube length optional |

3000mm |

|

Samples Display

Product detail pictures:

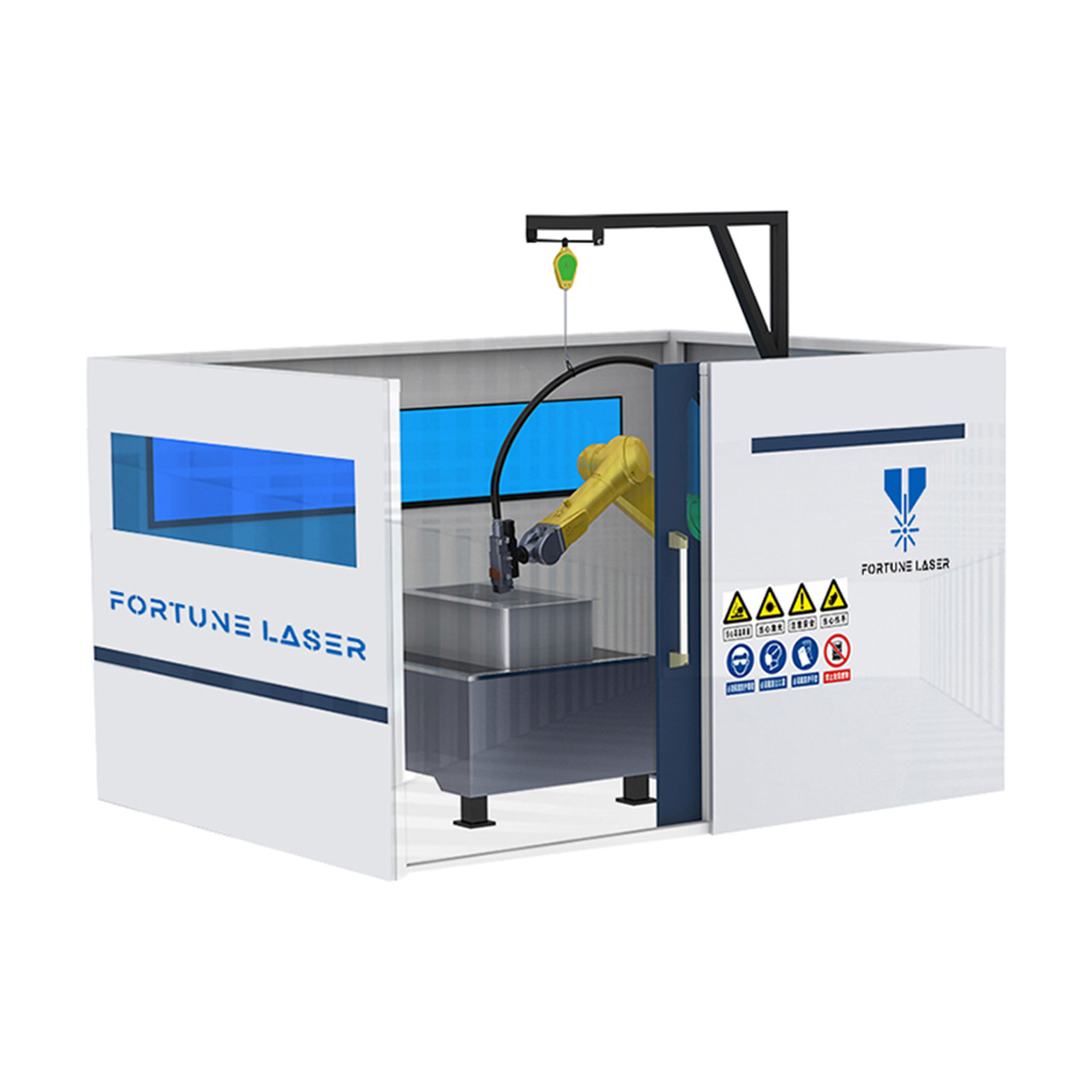

Related Product Guide:

We love an incredibly fantastic standing amid our consumers for our superb item high quality, aggressive rate and also the finest assistance for OEM manufacturer 1000w Fiber Laser Cutter - Dual-use Sheet and Tube Laser Cutting Machine – Fortune , The product will supply to all over the world, such as: Malawi, India, Madras, With the support of our highly experienced professionals, we manufacture and supply best quality products. These are quality tested at various occasions to ensure only flawless range is delivered to customers, we also customize the array as per the need of customers to meet the requirement of customers.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.