OEM China Pipe Laser Cutter - High Precision Fiber Laser Cutting Machine and Fabrication Services – Fortune

OEM China Pipe Laser Cutter - High Precision Fiber Laser Cutting Machine and Fabrication Services – Fortune

OEM China Pipe Laser Cutter - High Precision Fiber Laser Cutting Machine and Fabrication Services – Fortune Detail:

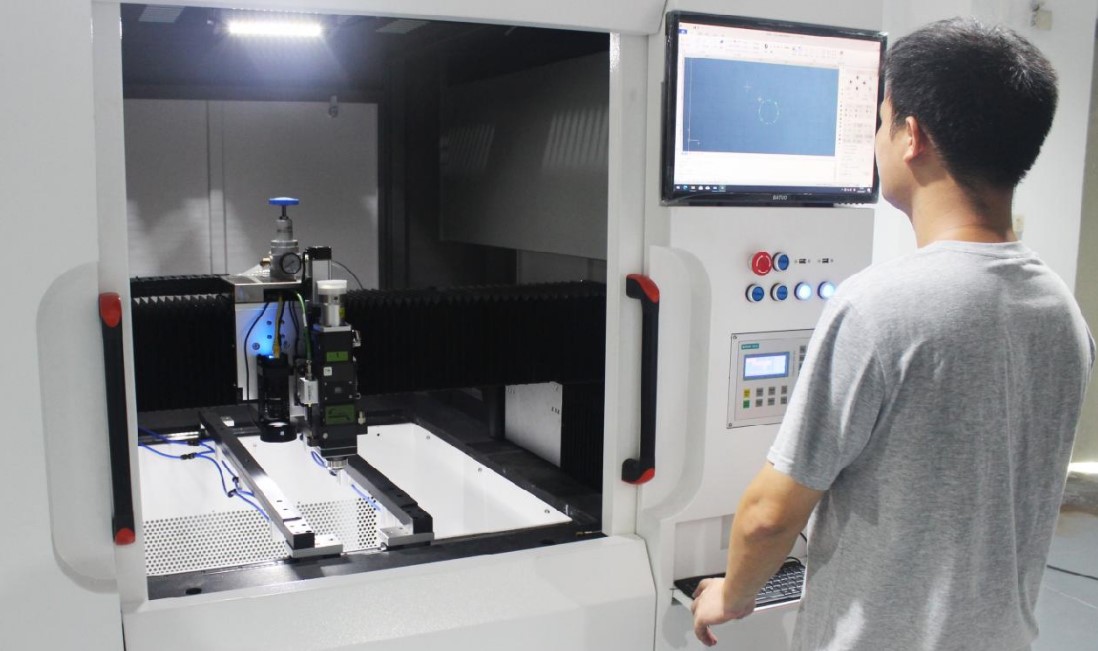

Machine Features

1. Good interactive control system, which expands the tolerance range and cutting width of the processed parts, solves the overall small disadvantage, and the cutting shape is better; the cutting section is smooth and burr-free, without deformation, and the post-processing is easier;

2. High safety. With a safety alarm, the light will be automatically locked after the workpiece is removed;

3. High positioning accuracy, sensitive response, shockproof design, no need to manually move the product, automatic movement for cutting;

4. A variety of power cutting heads can be configured to meet the cutting needs of different products

Product Description

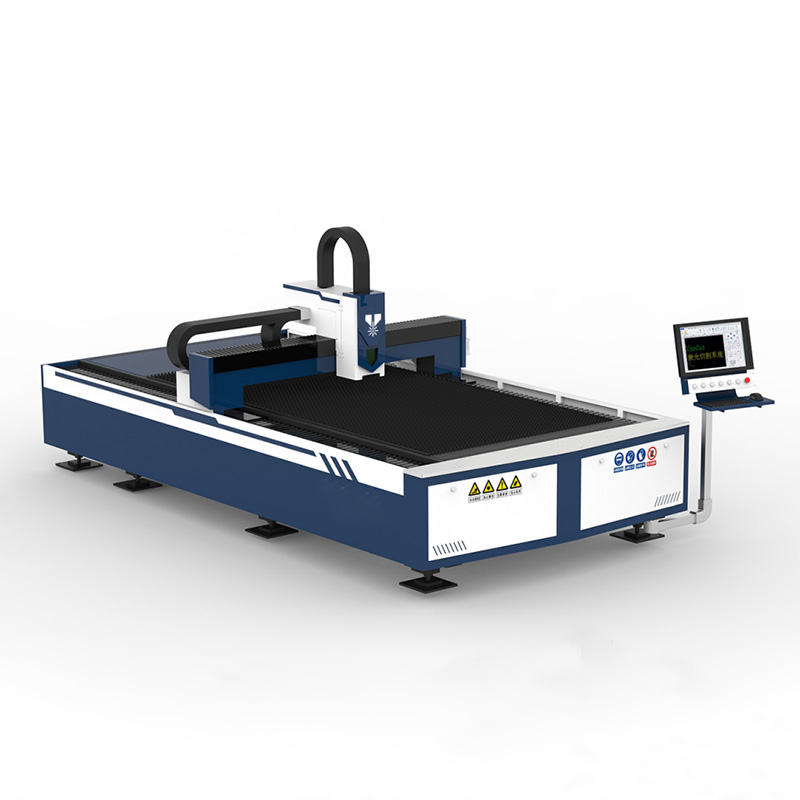

A precision laser cutter is a machine that uses a laser beam to cut very precise shapes and designs into a variety of materials, including metal, plastic and wood. The machine uses a computer-controlled process to precisely direct a laser beam to cut material with extreme precision and accuracy, making it a popular tool in many manufacturing industries for making precision and intricate parts and assemblies.

Fortune Laser FL-P6060 Series high-speed precision cutting machine is suitable for precise non-deformation cutting of metals, electronic components, ceramic materials, crystals, hard alloys, and other precious metal materials.

The equipment is driven by imported magnetic levitation linear motor, with high positioning accuracy; large speed range; strong cutting ability; built-in circulating cooling system; preset feed speed; menu control; liquid crystal display; users can freely define cutting methods; airtight Safe cutting room. It is one of the ideal equipment for industrial and mining finishing enterprises and scientific research institutes to prepare high-quality samples.

Fortune Laser uses a customized fully enclosed cutting control system and imported linear motors, which have high precision and fast speed, and the ability to handle small products is twice as fast as that of the screw platform; the integrated design of the marble platform frame is reasonable in structure, safe and reliable, and the imported linear motor platform.

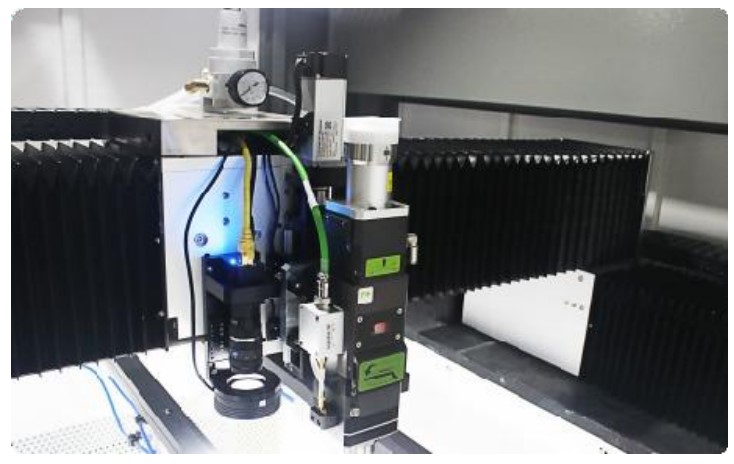

The high-speed cutting head can be equipped with any manufacturer’s fiber laser; the CNC system adopts a dedicated laser control system and an imported non-contact height tracking system, which is sensitive and accurate, and can process any graphics without being affected by the shape of the work piece; the guide rail adopts fully enclosed protection , Reduce dust pollution, imported high-precision linear motor drive, imported high-precision linear guide rail guidance.

Other cutting size(working area) for option, 300mm*300mm, 600mm*600mm, 650*800mm, 1300mm*1300mm.

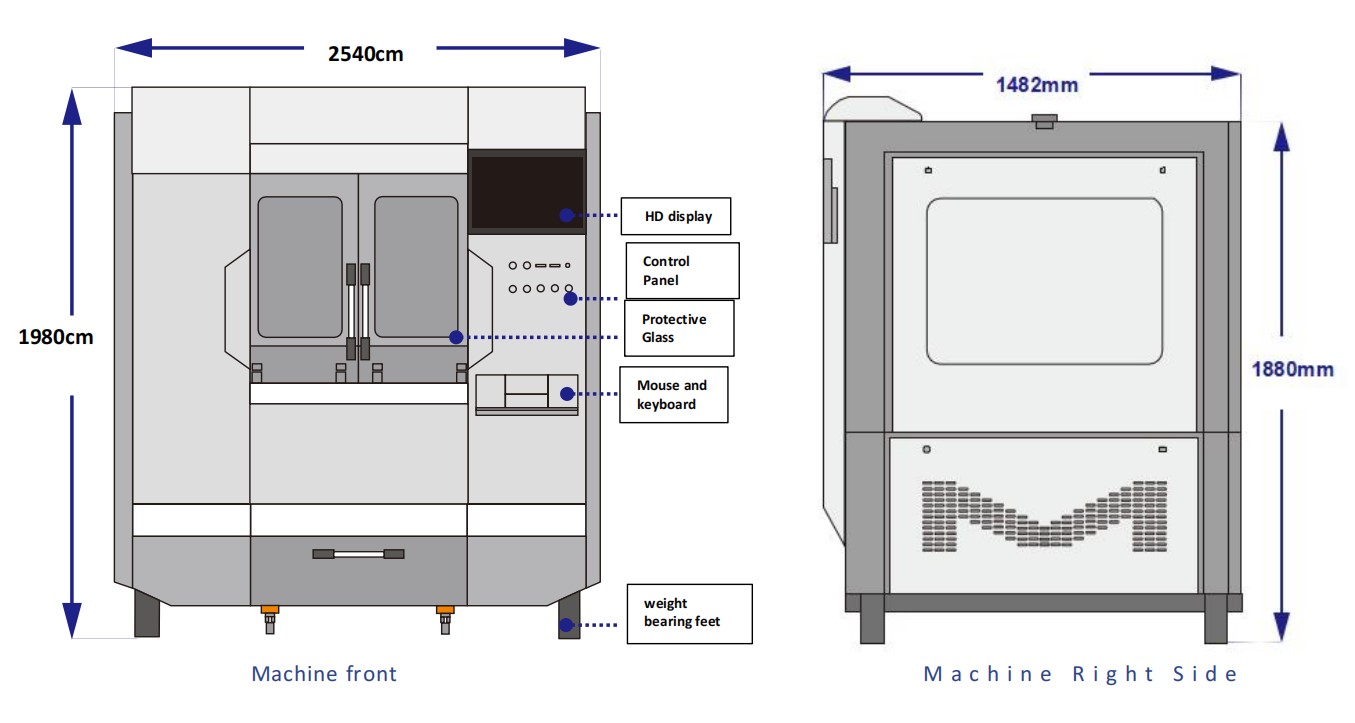

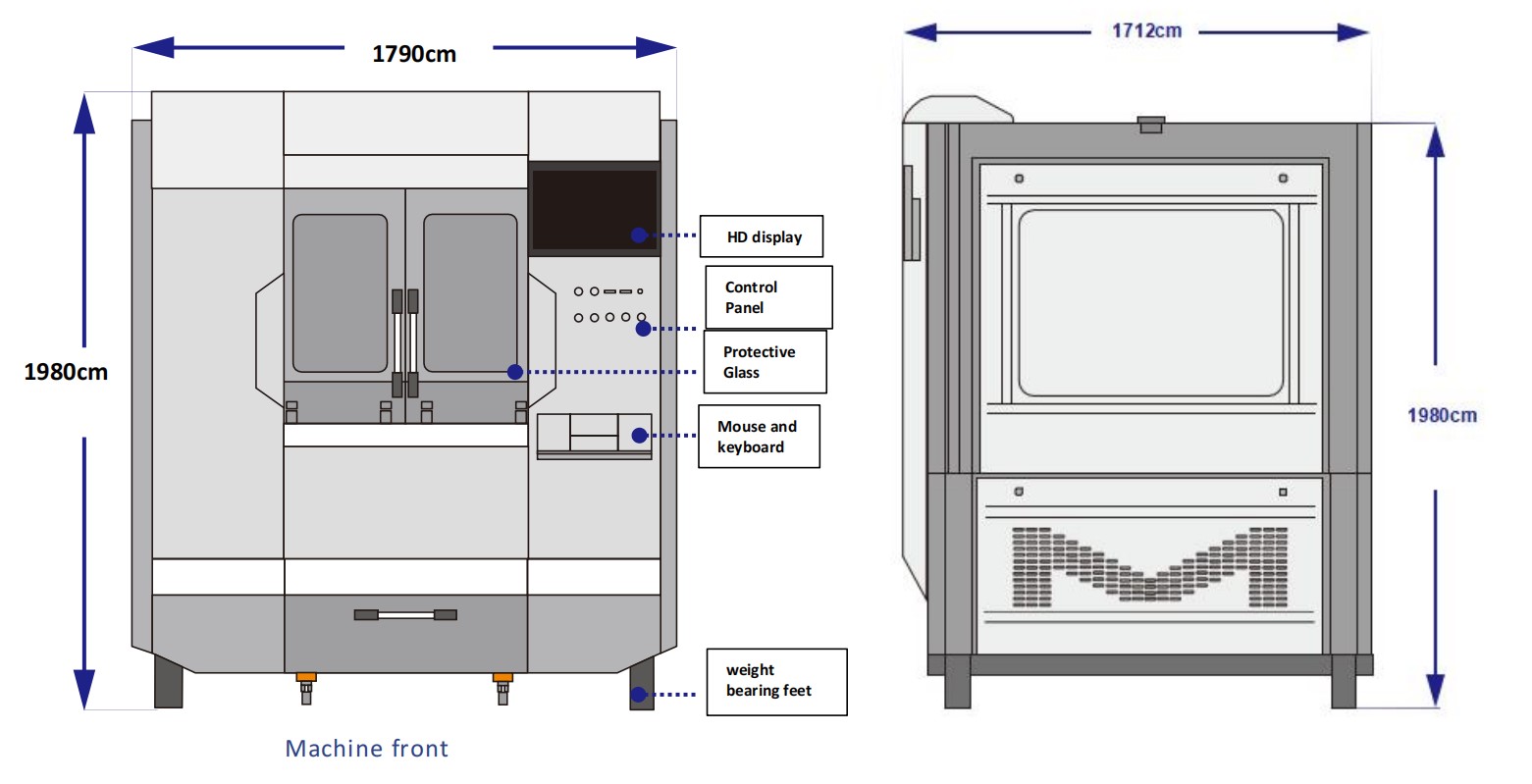

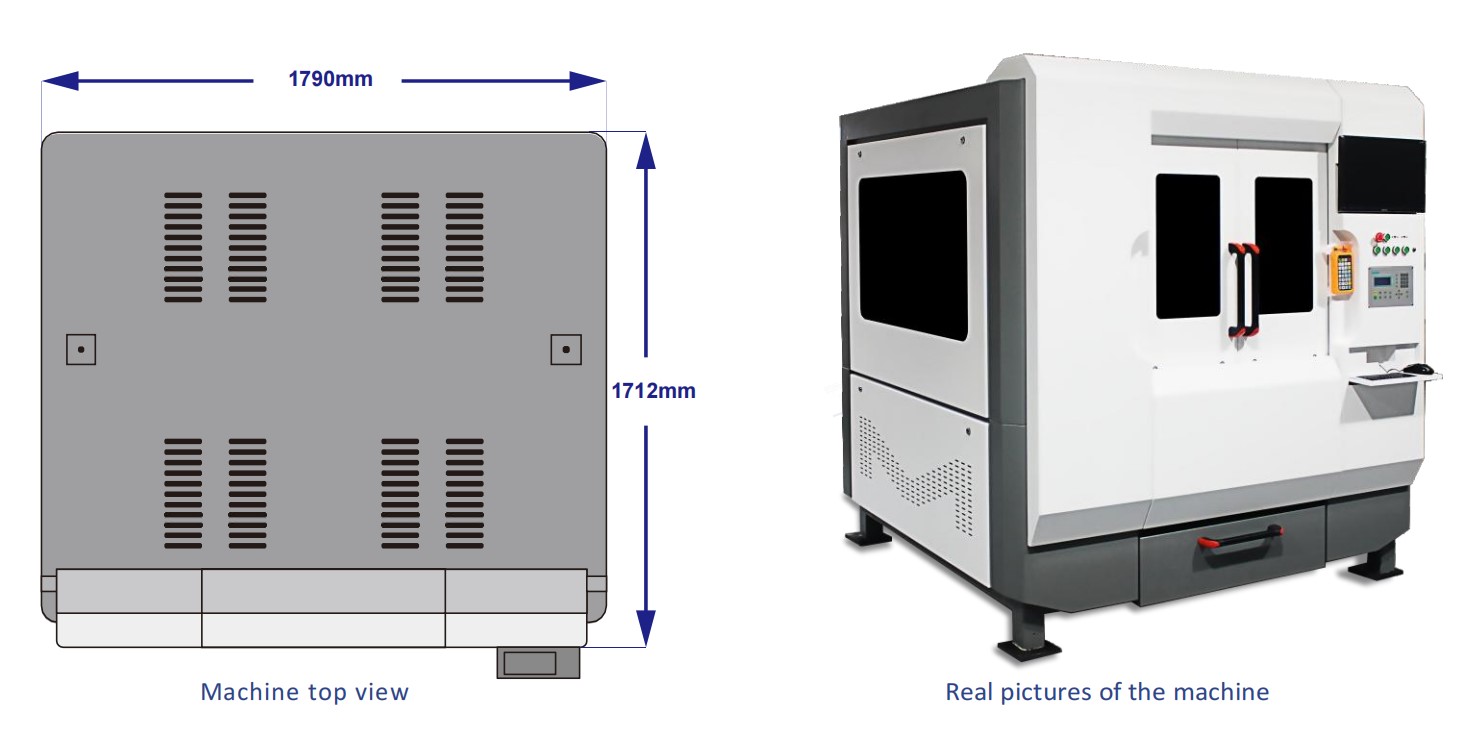

Machine size(FL-P6060)

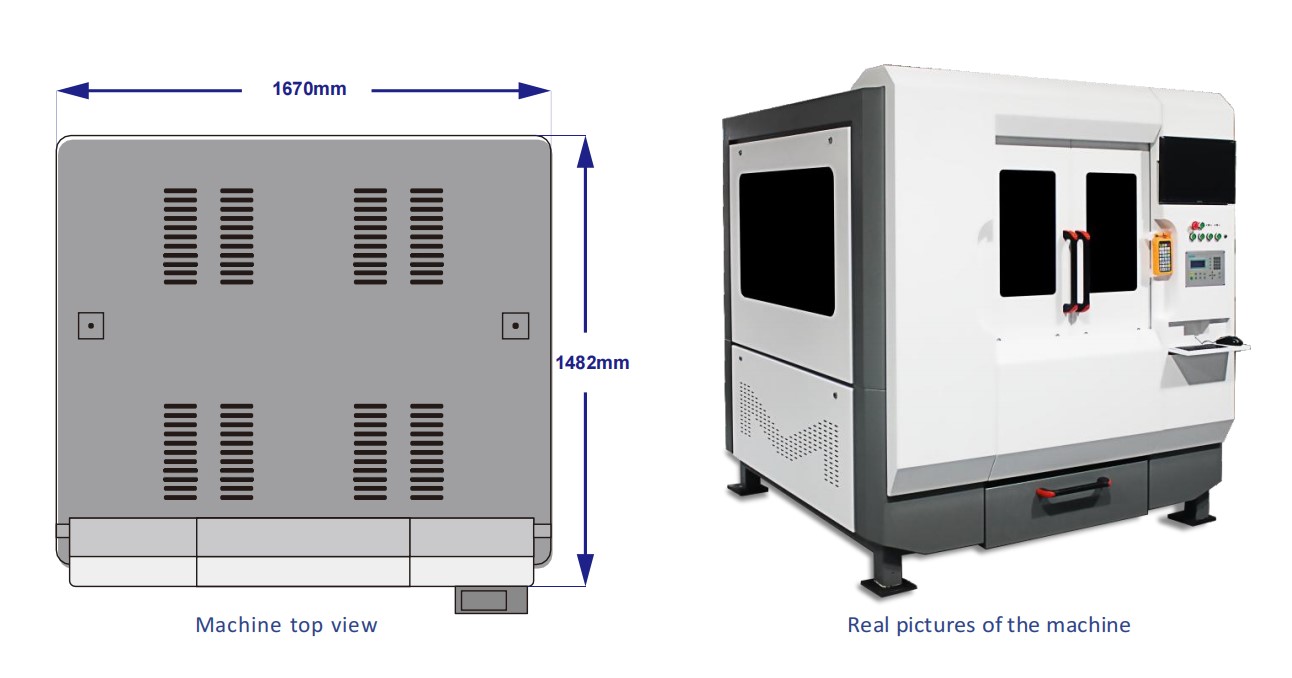

Machine size(FL-P3030)

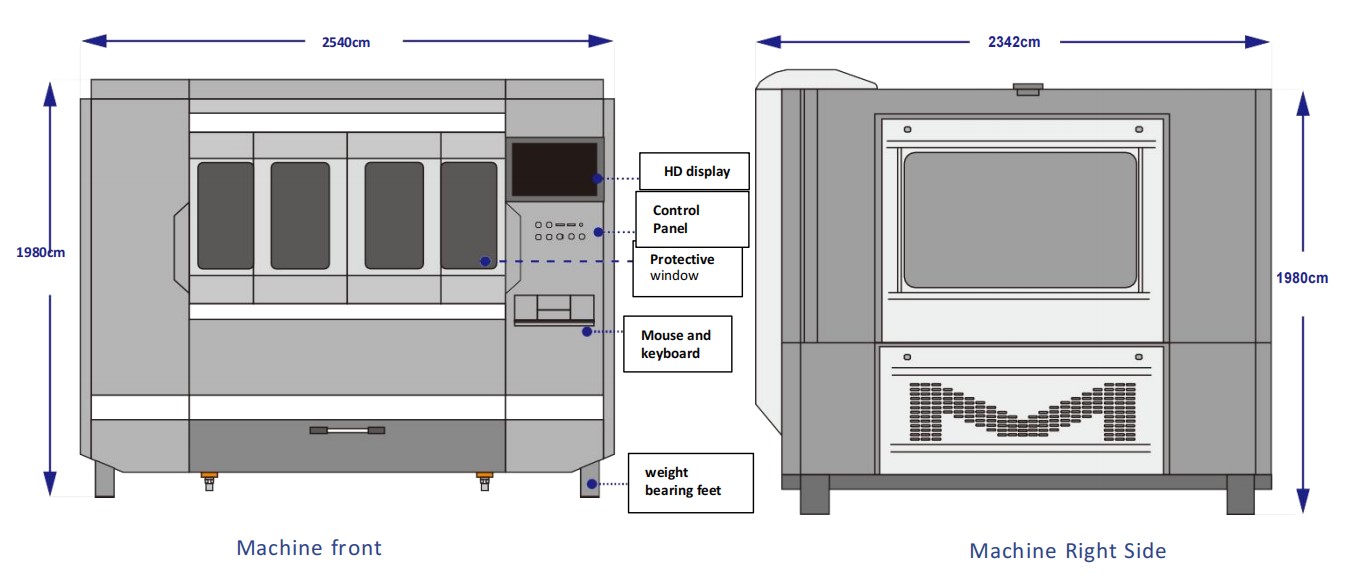

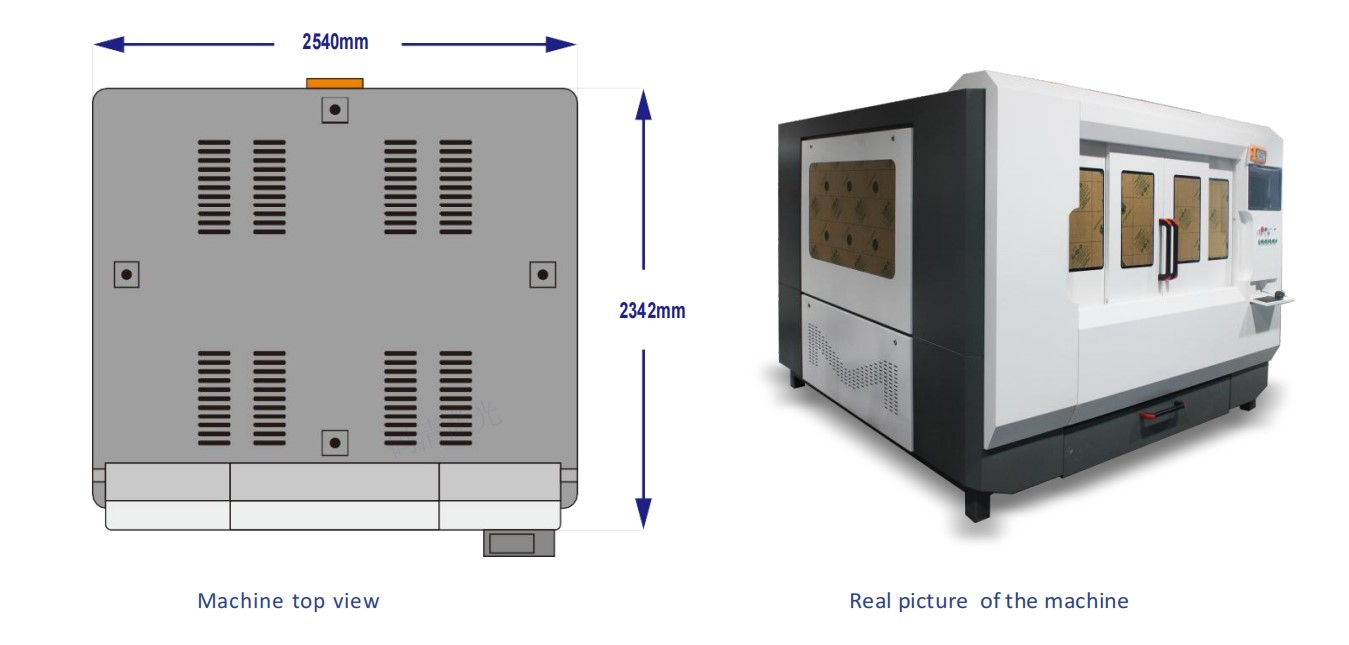

Machine size(FL-P6580)

Machine size(FL-P1313)

|

Model series |

FL-P6060 Series |

||||

|

Model |

FL-P6060-1000 |

FL-P6060-1500 |

FL-P6060-2000 |

FL-P6060-3000 |

FL-P6060-6000 |

|

Output Power |

1000w |

1500w |

2000w |

3000w |

6000w |

|

Type |

continuous |

||||

|

Cutting product precision |

0.03mm |

||||

|

Cut through hole minimum aperture |

0.1mm |

||||

|

Processing material |

Aluminum, copper, stainless steel metal materials |

||||

|

Effective cutting size |

600mm×600mm |

||||

|

Fixed way |

Pneumatic edge clamping and jig support |

||||

|

Drive System |

Linear Motor |

||||

|

Positioning accuracy |

+/-0.008mm |

||||

|

Repeatability |

0.008mm |

||||

|

CCD alignment accuracy |

10um |

||||

|

Cutting gas source |

air, nitrogen, oxygen |

||||

|

Cutting line width and fluctuation |

0.1mm±0.02mm |

||||

|

Cut surface |

Smooth, no burr, no black edge |

||||

|

Overall Warranty |

1 year (except wearing parts) |

||||

|

Weight |

1700Kg |

||||

|

Cutting thickness/ability |

Stainless steel: 4MM (air) Aluminum plate: 2MM (air) Copper plate: 1.5MM (air) |

Stainless steel: 6MM (air) Aluminum plate: 3MM (air) Copper plate: 3MM (air) |

Stainless steel: 8MM (air) Aluminum plate: 5MM (air) Copper plate: 5MM (air) |

Stainless steel: 10MM (air) Aluminum plate: 6MM (air) Copper plate: 6MM (air) |

Stainless steel: 10MM (air) Aluminum plate: 8MM (air) Copper plate: 8MM (air) |

Precision laser cutting machines are commonly used in industries such as manufacturing, aerospace, automotive, engineering, and even in the production of medical devices. It is frequently used by tool and die makers, metal fabricators and fabricators who need to produce high quality, complex parts quickly and efficiently. Additionally, hobbyists and artists can also use laser cutters to create unique and intricate designs.

Application field

▪ Aerospace industry

▪ Electronic

▪ Hardware industry

▪ Automotive industry

▪ Machinery factories, chemical plants

▪ Mold processing industry

▪ Aluminum-based circuit board

▪ New energy materials

And many more.

Machine Advantages

Strong function

1.A variety of workbenches and fixtures are optional

2.It is widely used and can easily realize precision cutting of any metal material

Excellent laser source

1.Using advanced laser, stable quality and high reliability

2.No consumables and maintenance-free, the design life is about 100,000 working hours

3.It can be flexibly applied to metal materials and some non-metal materials

Cost-effective

1.Powerful function, affordable price, very cost-effective

2.Stable performance, long service life, one-year warranty and lifetime maintenance

3.It can operate efficiently for 24 hours continuously, improve production efficiency and save costs

Friendly operation interface

1.Computer configuration, mouse and keyboard operation can be

2.The control software is powerful, supports multi-language switching, and is easy to learn

3.Support text, patterns, graphics, etc.

Machine main configurations

High Speed Cutting Head

High-speed cutting head, stable and strong beam, fast cutting speed, good cutting edge quality, small deformation, smooth and beautiful appearance; it can automatically and accurately adjust the focus according to the material thickness, high- speed cutting, saving time.

Laser source

High-quality beam quality, the beam can be focused close to the diffraction limit to achieve precision processing, high performance

Reliable, modular all-fiber design.

High-performance matching cooling system

The high-performance supporting cooling system adopts a high-performance professional chiller, and obtains high- quality, high-efficiency, and low-noise performance by using a filter thermal expansion valve.

Magnetic levitation linear motor

Screw slide module, high positioning accuracy, fast speed, quiet and stable, cost-effective.

Samples Display

Product detail pictures:

Related Product Guide:

We not only will try our greatest to present fantastic expert services to each purchaser, but also are ready to receive any suggestion offered by our prospects for OEM China Pipe Laser Cutter - High Precision Fiber Laser Cutting Machine and Fabrication Services – Fortune , The product will supply to all over the world, such as: Frankfurt, Honduras, Saudi Arabia, We aspire to meet the demands of our customers globally. Our range of merchandise and services is continuously expanding to meet customers' requirements. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.