Fortune Laser Handheld Fiber Laser Welding Machine

Fortune Laser Handheld Fiber Laser Welding Machine

Fortune Laser Handheld Laser Welder Technical Parameters

| Chitsanzo | FL-HW1000 | FL-HW1500 | FL-HW2000 |

| Mtundu wa Laser | 1070nm Fiber Laser | ||

| Mwadzina Laser Mphamvu | 1000W | 1500W | 2000W |

| Kuzizira System | Madzi Kuzirala | ||

| Njira yogwirira ntchito | Kupitilira / Modulation | ||

| Kuthamanga kwa welder | 0-120 mm / s | ||

| Focal Spot Diameter | 0.5 mm | ||

| Kutentha kozungulira | 15-35 ℃ | ||

| Chinyezi cha chilengedwe | <70% popanda condensation | ||

| Kuwotcherera makulidwe | 0.5-1.5 mm | 0.5-2 mm | 0.5-3 mm |

| Zofunikira pakuwotcherera gap | ≤1.2mm | ||

| Voltage yogwira ntchito | AC 220V/50HZ 60HZ/ 380V±5V 50HZ 60HZ 60A | ||

| Cabinet Dimension | 120 * 60 * 120cm | ||

| Wooden Phukusi Dimension | 154 * 79 * 137cm | ||

| Kulemera | 285KG | ||

| Kutalika kwa fiber | Standard 10M, utali wokhazikika wokhazikika ndi 15M | ||

| Kugwiritsa ntchito | Kuwotcherera ndi kukonza chitsulo chosapanga dzimbiri, chitsulo cha carbon, aluminium alloy. | ||

Zonyamula Zam'manja Laser Welder kwa Zitsulo

| Zakuthupi | Mphamvu zotulutsa (W) | Kulowa kwambiri (mm) |

| Chitsulo chosapanga dzimbiri | 1000 | 0.5-3 |

| Chitsulo chosapanga dzimbiri | 1500 | 0.5-4 |

| Chitsulo chosapanga dzimbiri | 2000 | 0.5-5 |

| Chitsulo cha carbon | 1000 | 0.5-2.5 |

| Chitsulo cha carbon | 1500 | 0.5-3.5 |

| Chitsulo cha carbon | 2000 | 0.5-4.5 |

| Aluminiyamu alloy | 1000 | 0.5-2.5 |

| Aluminiyamu alloy | 1500 | 0.5-3 |

| Aluminiyamu alloy | 2000 | 0.5-4 |

| Pepala lagalasi | 1000 | 0.5-1.2 |

| Pepala lagalasi | 1500 | 0.5-1.8 |

| Pepala lagalasi | 2000 | 0.5-2.5 |

Mitundu Itatu Pazosankha Zanu

Ubwino wa Handheld Laser Welding Machine

1. Wide kuwotcherera osiyanasiyana:

The m'manja kuwotcherera mutu okonzeka ndi 10M original kuwala CHIKWANGWANI (kutalika makonda kutalika ndi 15M), amene amagonjetsa malire a workbench danga, ndipo akhoza welded panja ndi kuwotcherera mtunda wautali;

2. Yosavuta komanso yosinthika kugwiritsa ntchito:

Kuwotcherera kwa laser m'manja kumakhala ndi ma pulleys osunthika, omwe amakhala omasuka kugwira, ndipo amatha kusintha masiteshoni nthawi iliyonse, popanda malo okhazikika, aulere komanso osinthika, komanso oyenera malo osiyanasiyana ogwirira ntchito.

3. Njira zingapo zowotcherera:

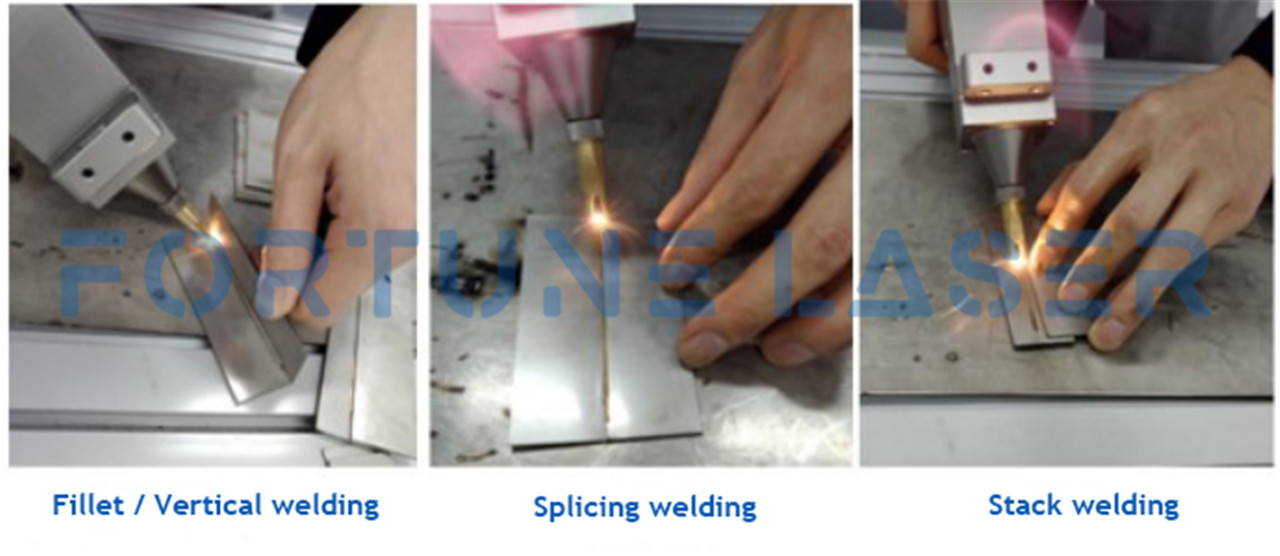

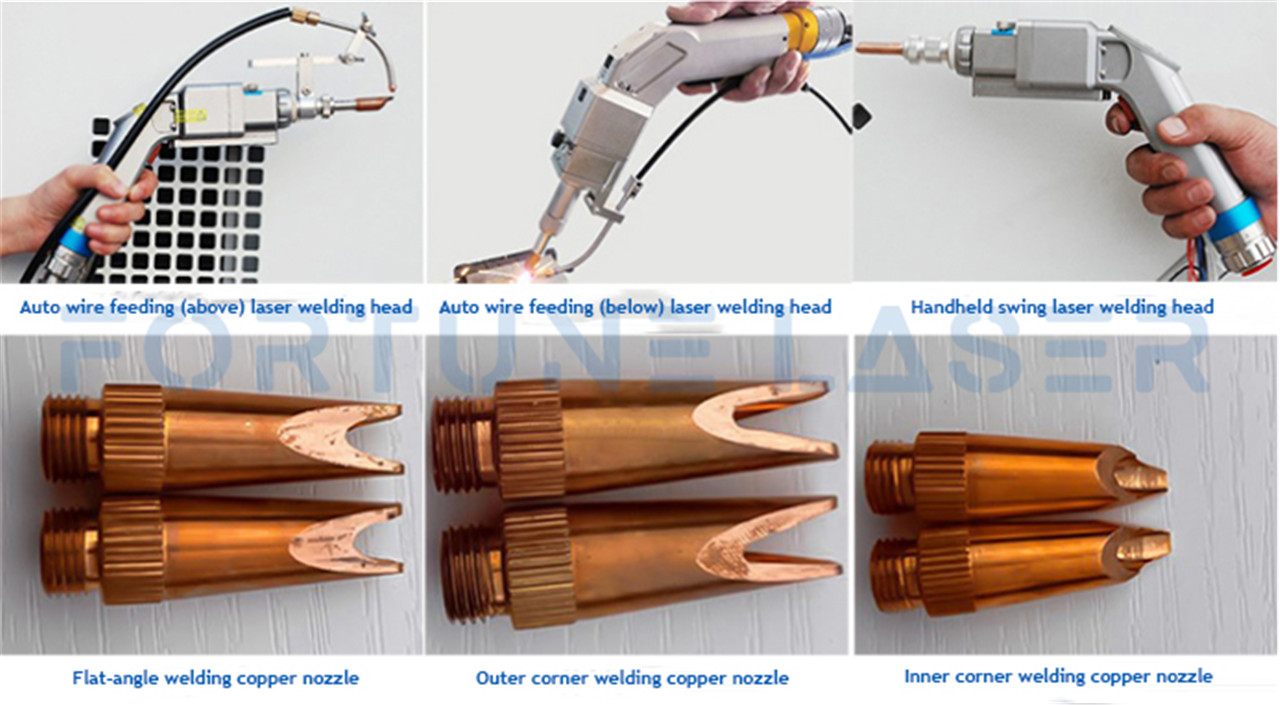

kuwotcherera pa ngodya iliyonse akhoza anazindikira: anagwirizana kuwotcherera, matako kuwotcherera ofukula kuwotcherera ofukula, kuwotcherera lathyathyathya fillet, mkati fillet kuwotcherera, kunja fillet kuwotcherera, etc., ndipo akhoza kuwotcherera zosiyanasiyana zovuta welded ntchito-zidutswa ndi lalikulu ntchito-zidutswa ndi akalumikidzidwa osasamba. Kuzindikira kuwotcherera pa ngodya iliyonse. Kuphatikiza apo, imathanso kumaliza kudula, kuwotcherera ndi kudula kumatha kusinthidwa momasuka, ingosinthani mphuno yamkuwa yowotcherera kuti ikhale yodula mkuwa, yomwe ndi yabwino kwambiri.

4. Zabwino kuwotcherera:

Kuwotcherera pamanja kwa laser ndi kuwotcherera kwamafuta ophatikizana. Poyerekeza ndi kuwotcherera miyambo, laser kuwotcherera ali apamwamba mphamvu kachulukidwe ndipo akhoza kupeza zotsatira zabwino kuwotcherera. Malo owotcherera ali ndi mphamvu zochepa zamatenthedwe, sizovuta kupunduka, zakuda, ndipo zimakhala ndi zizindikiro kumbuyo. Kuzama kwa kuwotcherera ndi kwakukulu, kusungunuka kumakhala kokwanira, ndipo kumakhala kolimba komanso kodalirika, ndipo mphamvu yowotcherera imafika kapena kupitirira zitsulo zoyambira zokha, zomwe sizingatsimikizidwe ndi makina otsekemera.

5. Kuwotcherera msoko sikuyenera kupukutidwa.

Pambuyo kuwotcherera kwachikhalidwe, nsonga yowotcherera imayenera kupukutidwa kuti iwonetsetse kuti ndi yosalala komanso yosalala. Kuwotcherera kwa laser m'manja kumawonetsa bwino kwambiri zabwino zake pakuwongolera: kuwotcherera mosalekeza, mamba osalala komanso opanda nsomba, okongola komanso opanda zipsera, komanso njira zochepera zopukutira.

6. kuwotcherera ndiautomatic waya feeder.

M'malingaliro a anthu ambiri, ntchito yowotcherera ndi "magalasi am'manja akumanzere, waya wakumanja wakumanja". Koma ndi m'manja laser kuwotcherera makina, kuwotcherera akhoza anamaliza mosavuta, amene amachepetsa mtengo zinthu kupanga ndi processing.

7. Otetezeka kwawoyendetsa.

Ndi ma alarm angapo otetezera, nsonga yowotcherera imangokhala yothandiza pamene chosinthiracho chikakhudza chitsulo, ndipo kuwala kumatsekedwa pokhapokha ntchitoyo itachotsedwa, ndipo chosinthira chokhudza chimakhala ndi kutentha kwa thupi. Chitetezo ndichokwera kuonetsetsa chitetezo cha wogwiritsa ntchito panthawi ya ntchito.

8. Sungani ndalama zogwirira ntchito.

Poyerekeza ndi kuwotcherera arc, mtengo wokonza ukhoza kuchepetsedwa ndi 30%. Opaleshoniyo ndi yosavuta, yosavuta kuphunzira, ndipo imayamba mwachangu. Chiwopsezo chaukadaulo cha ogwira ntchito sichokwera. Ogwira ntchito wamba akhoza kutenga maudindo awo pambuyo pa maphunziro afupiafupi, omwe amatha kupeza zotsatira zowotcherera mosavuta.

9. Zosavuta kusintha kuchokera ku njira zachikhalidwe zowotcherera kupita ku fiber laser kuwotcherera.

Mukhoza kuphunzira kugwiritsa ntchito Fortune Laser CHIKWANGWANI laser kuwotcherera makina mkati maola angapo, ndipo palibe mutu kuyang'ana akatswiri kuwotcherera, musadandaule za ndandanda zolimba yobereka. Kuonjezera apo, ndi luso latsopanoli ndi ndalama, mudzakhala patsogolo pa msika ndikulandira ndalama zowonjezera phindu kusiyana ndi njira zowotcherera.

Ntchito Minda ya Handheld Laser Welding Machine

Chowotcherera cham'manja cha laser chimakhala chachitsulo chachikulu komanso chapakati, makabati, chassis, chitseko cha aluminiyamu aloyi ndi mafelemu mazenera, mabeseni osapanga zitsulo zosapanga dzimbiri ndi zida zina zazikulu, monga ngodya yamkati yakumanja, ngodya yakunja yakumanja, kuwotcherera lathyathyathya, malo ang'onoang'ono omwe amakhudzidwa ndi kutentha panthawi yowotcherera, mapindikidwe ang'onoang'ono, ndi kuya kowotcherera Kukulu, kolimba.

Fortune Laser m'manja laser kuwotcherera makina chimagwiritsidwa ntchito mu njira zovuta kuwotcherera ndi kusakhazikika makampani khitchini ndi bafa, makampani kunyumba chamagetsi, malonda makampani, nkhungu makampani, zosapanga dzimbiri zitsulo malonda makampani, zitsulo zopangapanga makampani, zitseko ndi mazenera mafakitale, ntchito zamanja, mafakitale katundu wa m'nyumba, makampani mipando, magalimoto mbali makampani, etc.

Kuyerekeza kwa Handheld Laser Welding Machine ndi Argon Arc Welding

1. Kuyerekeza kugwiritsa ntchito mphamvu:Poyerekeza ndi kuwotcherera kwachikhalidwe cha arc, makina owotcherera a laser am'manja amapulumutsa pafupifupi 80% mpaka 90% ya mphamvu yamagetsi, ndipo mtengo wopangira ukhoza kuchepetsedwa ndi 30%.

2. Kuwotcherera zotsatira kuyerekeza:kuwotcherera kwa laser m'manja kumatha kumaliza chitsulo chosiyana ndi kuwotcherera chitsulo chosiyana. Liwiro liri mofulumira, mapindikidwe ndi ochepa, ndipo malo omwe amakhudzidwa ndi kutentha ndi ochepa. Msoko wowotcherera ndi wokongola, wosalala, wopanda / wocheperako, komanso wopanda kuipitsa. The m'manja laser kuwotcherera makina angagwiritsidwe ntchito mbali yaing'ono lotseguka ndi kuwotcherera mwatsatanetsatane.

3. Kutsata ndondomeko yofananira:Kutentha kwapang'onopang'ono pakuwotcherera kwa laser m'manja, mapindikidwe ang'onoang'ono a workpiece, malo okongola otsekemera amatha kupezeka, palibe kapena chithandizo chosavuta (malingana ndi zofunikira za kuwotcherera pamwamba). Makina ogwiritsira ntchito laser kuwotcherera m'manja amatha kuchepetsa kwambiri mtengo wantchito wa njira yayikulu yopukutira ndi kusanja.

| Mtundu | Kuwotcherera kwa Argon arc | kuwotcherera YAG | Kugwira m'manjaLaserkuwotcherera | |

| Welding khalidwe | Kuyika kwa kutentha | Chachikulu | Wamng'ono | Wamng'ono |

|

| Kusintha kwa workpiece / undercut | Chachikulu | Wamng'ono | Wamng'ono |

|

| Kupanga weld | Chitsanzo cha nsomba | Chitsanzo cha nsomba | Zosalala |

|

| Kukonzekera kotsatira | Chipolishi | Chipolishi | Palibe |

| Gwiritsani ntchito | Kuwotcherera liwiro | Pang'onopang'ono | Pakati | Mofulumira |

|

| Kuvuta kwa ntchito | Zovuta | Zosavuta | Zosavuta |

| Chitetezo ndi chitetezo cha chilengedwe | Kuipitsa chilengedwe | Chachikulu | Wamng'ono | Wamng'ono |

|

| Kuvulaza thupi | Chachikulu | Wamng'ono | Wamng'ono |

| Mtengo wa welder | Consumables | Ndodo yowotcherera | Laser crystal, nyali ya xenon | Posafunikira |

|

| Kugwiritsa ntchito mphamvu | Wamng'ono | Chachikulu | Wamng'ono |

| Zida pansi malo | Wamng'ono | Chachikulu | Wamng'ono | |