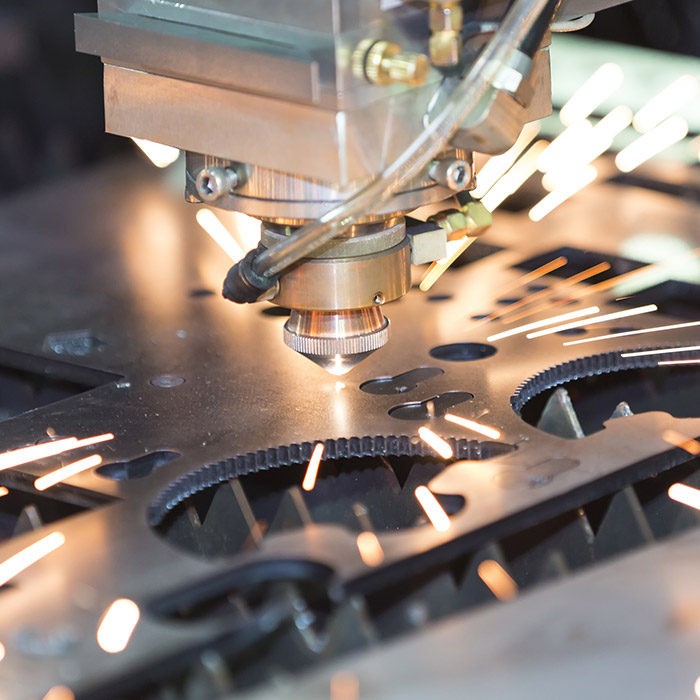

Kudula kwa laser, komwe kumadziwikanso kuti kudula kwa laser kapena CNC laser kudula, ndi njira yodulira yotentha yomwe imagwiritsidwa ntchito mobwerezabwereza pokonza zitsulo.

Posankha njira yodulira pulojekiti yopanga zitsulo zachitsulo, ndikofunikira kulingalira za kuthekera kwa chida chomwe mwasankha potengera zosowa za polojekiti yanu. Pazinthu zambiri zopanga zitsulo pogwiritsa ntchito zitsulo, kudula kwa laser ndikwabwinoko. Nazi ena ubwino kwa laser kudula makina muyenera kudziwa.

Pafupifupi Mtengo Wotsika

Poyerekeza ndi njira zina zodulira, kudula kwa laser ndikokwera mtengo kwambiri. Pogwiritsa ntchito makina a CNC, ndalama zogwirira ntchito ndizochepa, ndipo makinawo ndi osavuta kugwiritsa ntchito. Kuphatikiza apo, laser sikhala yopepuka kapena kuvala monga zida zina zodulira. Pachifukwa ichi, palibe kusintha kofunikira pakati pa ndondomekoyi, zomwe zimapangitsa kuti pakhale zokolola zabwino komanso nthawi yochepa yotsogolera. Pakakhala zosokoneza zochepa pakudula, ndalama zimakhala zotsika.

Kuthamanga Kwambiri ndi Mwachangu

Ma laser amatha kudula zida mwachangu kwambiri. Kuthamanga kwenikweni kudzadalira mphamvu ya laser, mtundu wa zinthu ndi makulidwe, kulolerana ndi kusakanikirana kwa zigawozo. Komabe, amayenda mofulumira kwambiri poyerekeza ndi zida zina zodulira. Kuphatikiza pa kuthamanga kwachangu, odula laser amatha kugwira ntchito kwa nthawi yayitali, ndikuwonjezera mphamvu yonse yodula.

Automation / CNC Control

Mmodzi mwa ubwino wa laser kudula ndi kuti makina kwathunthu kuthamanga ndi amazilamulira CNC, amene amatsogolera mbali ndi mankhwala ndi pang'ono kuti palibe kusiyana ndi zolakwika kwambiri zochepa. Makinawa amatanthauzanso kuti ntchito yocheperako ndiyofunikira kugwiritsa ntchito makinawo ndikugwira ntchito zake, zomwe zimapangitsa kuti ntchitoyi ikhale yabwino. Makina odulira okha amatsogolera kuchita bwino kwambiri, zinthu zapamwamba kwambiri, komanso kuwononga zotsala pang'ono. Kupatula kudula kwa 2D, odula laser ndi oyeneranso kudula kwa 3D. Makinawa ndi oyenerera kupanga ma prototypes, mitundu ndi nkhungu, chitoliro, chubu, zitsulo zamalata, zitsulo zokulitsidwa, masheya athyathyathya, ndi zina zambiri.

Kulondola Kwambiri

Ma laser cutters ali ndi mphamvu zambiri, amatha kupanga mabala ang'onoang'ono komanso kulolerana kolimba. Amapanga nsonga zoyera, zakuthwa, zosalala komanso zopindika. Kumaliza kwakukulu. Adzatulutsanso pang'ono (ngakhale ayi) akuwotcha chifukwa laser imasungunula zinthuzo, m'malo mozidula. Ma laser cutters ndiabwino kwambiri pokonza zitsulo zachitsulo chifukwa ndi olondola kwambiri ndipo amapanga mabala olondola, apamwamba kwambiri.

Mtengo wa ntchito, kuthamanga kwa makina, ndi kuwongolera kosavuta kwa CNC kumapangitsa odula a laser kukhala oyenera pazogulitsa ndi ntchito zambiri. Chifukwa ocheka a laser ndi olondola komanso olondola, mutha kukhala otsimikiza kuti zotsatira zake ndi zapamwamba kwambiri. Odula laser amatha kudula muzitsulo zosiyanasiyana, kuphatikizapo aluminiyamu, mkuwa, mkuwa, zitsulo zofewa, zitsulo za carbon, zitsulo zosapanga dzimbiri, ndi zina zomwe zimapangitsa kukhala njira yabwino yopangira mapepala. Makinawa amatha kuthana ndi kulekerera kolimba komanso mapangidwe ovuta, kuwonetsetsa kuti projekiti iliyonse ingakwanitse.

Takulandilani kuti mulumikizane ndi Fortune Laser kuti mumve zambiri za makina odulira zitsulo a laser pamapulojekiti anu opangira zitsulo lero!

KODI TIKUTHANDIZENI BWANJI MASIKU ANO?

Chonde lembani fomu ili pansipa ndipo tibweranso kwa inu posachedwa.