NEWS&BLOG

NEWS&BLOG

-

Laser cleaning V.S traditional cleaning for ships

The rise of the world’s great powers all start from shipbuilding and go through the ocean. As an important symbol of a country’s industrial level, the shipbuilding industry, as the “crown of comprehensive industries”, has a high degree of industrial expansion and strong in...Read more -

How does laser cleaning work in aviation?

Laser cleaning technology is mainly used in the surface treatment of aircraft body in the aerospace industry. When repairing and maintaining an aircraft, it is basically necessary to remove the old paint on the surface in order to spray new oil sandblasting or steel brush sanding and other tradit...Read more -

Why More and More People Use Laser Cleaning Machines in Automotive Industry

In the automotive manufacturing process, drawing lubricants or cooling lubricants and anti-rust oils used can contaminate automotive components and severely degrade the quality of subsequent high-energy joining or bonding processes. In this process, welds and bonds in powertrain components must b...Read more -

What can be cleaned with a laser?

According to statistics, most of the cleaning processes currently used by shipyards are sandblasting and water sandblasting, which can be matched with 4 to 5 spray guns, with an efficiency of 70 to 80 square meters per hour, and the cost is about 5 million yuan, and the working environment is poo...Read more -

Application of laser cleaning on cultural relics

For the cleaning of cultural relics, there are many traditional cleaning methods, but most methods have many different shortcomings, such as: slow efficiency, which may damage the cultural relics. Laser cleaning has replaced many traditional cleaning methods. So what are the advantages of laser c...Read more -

Introduction to the use of laser cleaning in various fields

Laser cleaning technology is a new cleaning technology that has developed rapidly in the past 10 years. It has gradually replaced traditional cleaning processes in many fields with its own advantages and irreplaceability. Laser cleaning can be used not only to clean organic pollutants, but also t...Read more -

Why Choose Laser Cleaning?

Manufacturers are always looking to make products that are stronger, more durable, and more reliable, as well as in the automotive and aerospace sectors. In this pursuit, they frequently upgrade and replace material systems with lower density, better temperature and corrosion resistance metal all...Read more -

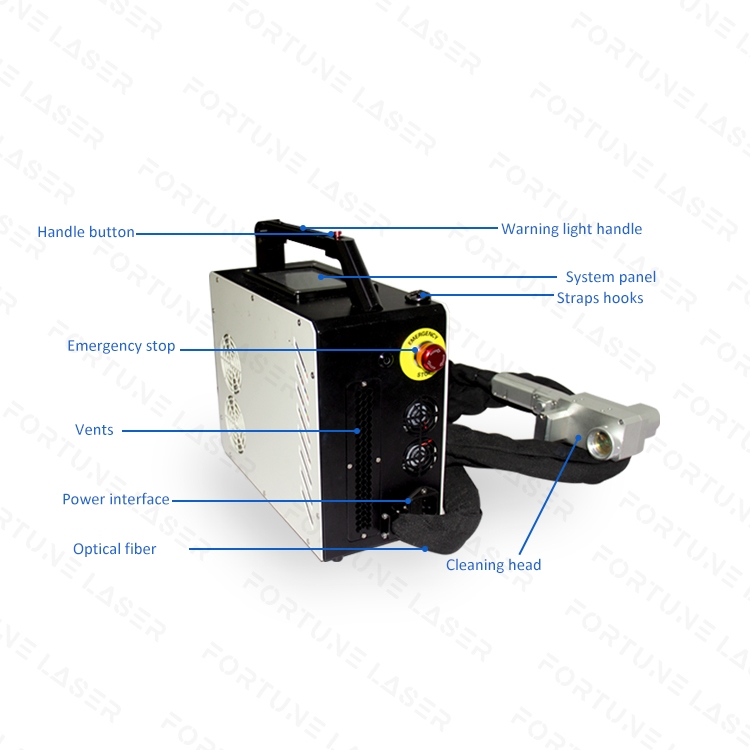

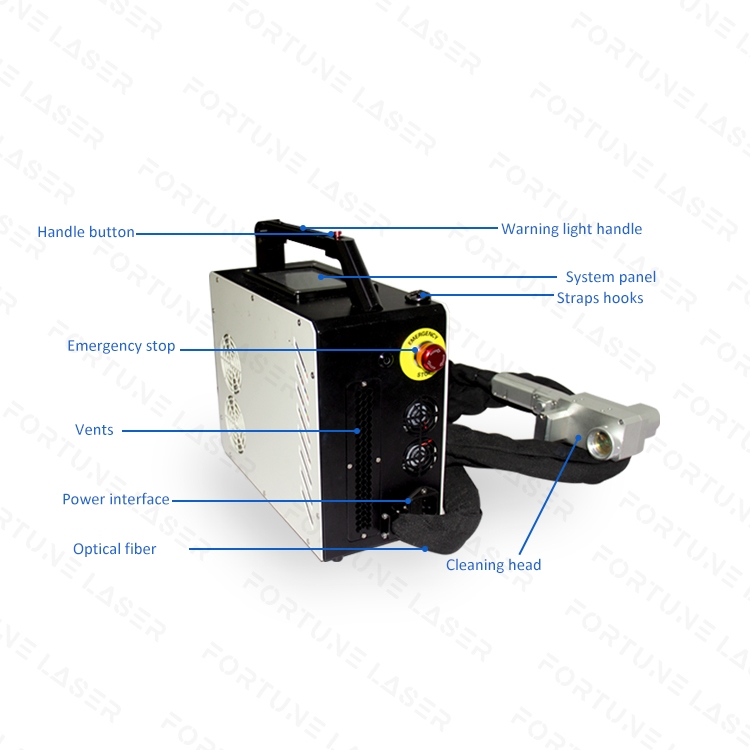

How to choose a suitable laser cleaning machine for your applications?

Nowadays, laser cleaning has become one of the most feasible way for surface cleaning, especially for the metal surface cleaning. Laser Cleaning is considered to be environmental friendly as there is no use of chemical agents and cleaning fluids as in traditional methods. The traditional Cleaning...Read more -

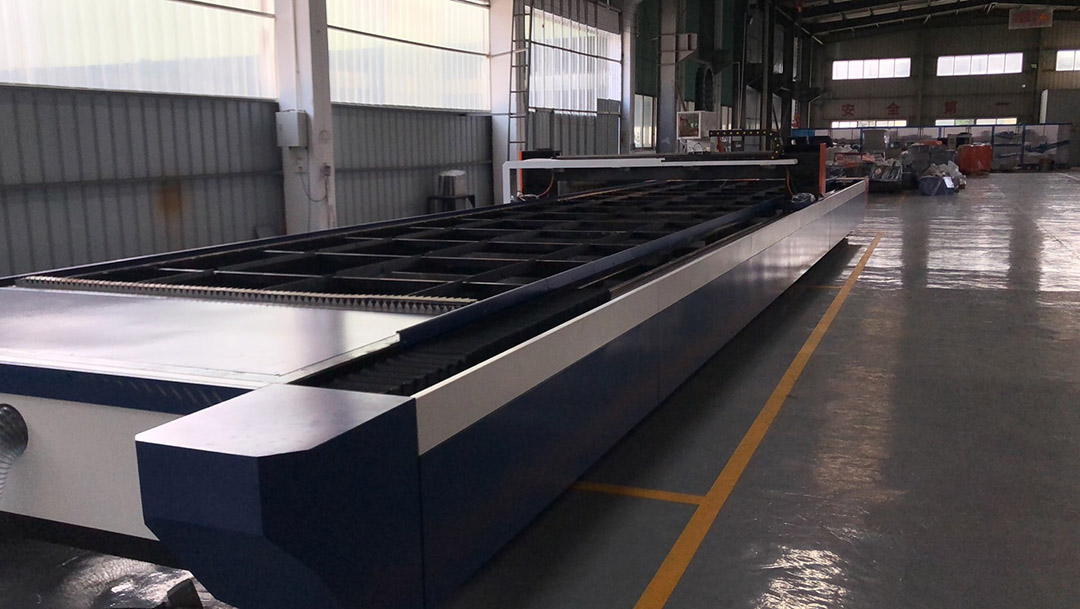

A General Guide for Operation Process of Laser Cutting Machine from FORTUNE LASER

Preparation before using the laser cutting machine 1. Check whether the power supply voltage is consistent with the machine’s rated voltage before use to avoid unnecessary damage. 2. Check whether there are matter residues on the machine table surface, so as not to affect the normal cutting...Read more -

Fiber Laser Cutting VS CO2 Laser Cutting: Pros and Cons

1. Compare from the structure of laser equipment In the carbon dioxide(CO2) laser cutting technology, CO2 gas is the medium that generates the laser beam. However, fiber lasers are transmitted through diodes and fiber optic cables. The fiber laser system generates a laser beam through multiple di...Read more -

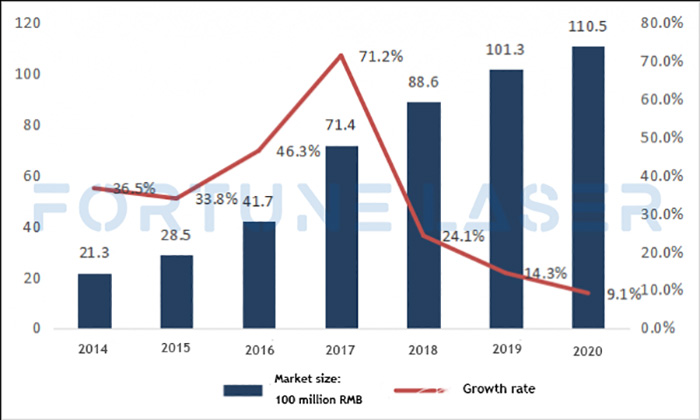

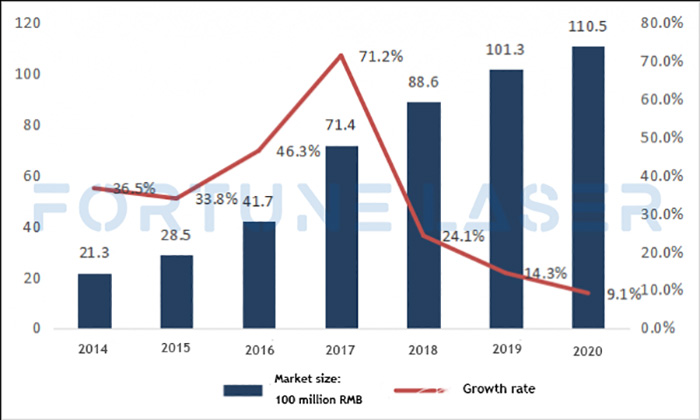

Laser welding may become the fastest growing laser application market

In the past few years, metal laser cutting equipment based on fiber lasers developed rapidly, and it only slowed down in 2019. Nowadays, many companies hope that the equipment of 6KW or even more than 10KW will once again leverage the new growth point of laser cutting. In the past few years, lase...Read more -

Industry Status and Competitive Landscape Analysis of Laser Welding

Laser welding refers to a processing method that uses the high energy of laser to join metals or other thermoplastic materials together. According to different working principles and adapting to different processing scenarios, laser welding can be divided into five types: heat conduction welding,...Read more -

Precautions and Daily Maintenance of Fiber Laser Cutting Machine

Daily maintenance for the fiber laser cutting machine are very necessary to keep the machine good performance and prolong its service life. Here are some tips for your laser cutting machines. 1. Both lasers and laser cutting machines need to be cleaned daily to keep them clean and tidy. 2. Check...Read more