News

News

-

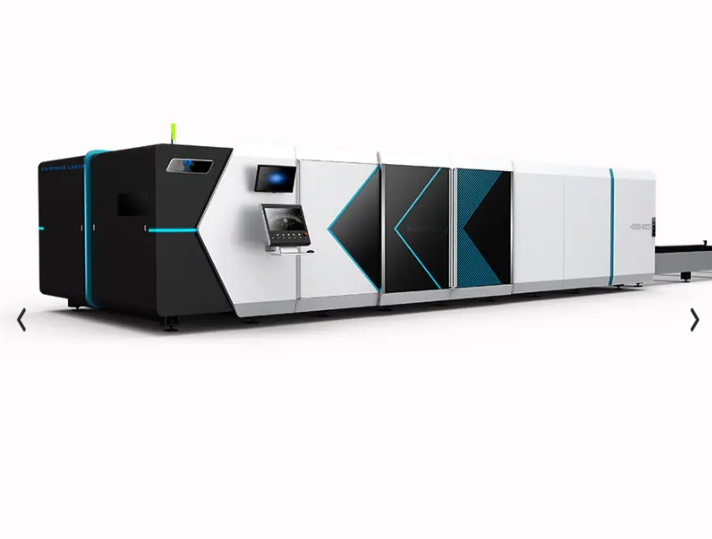

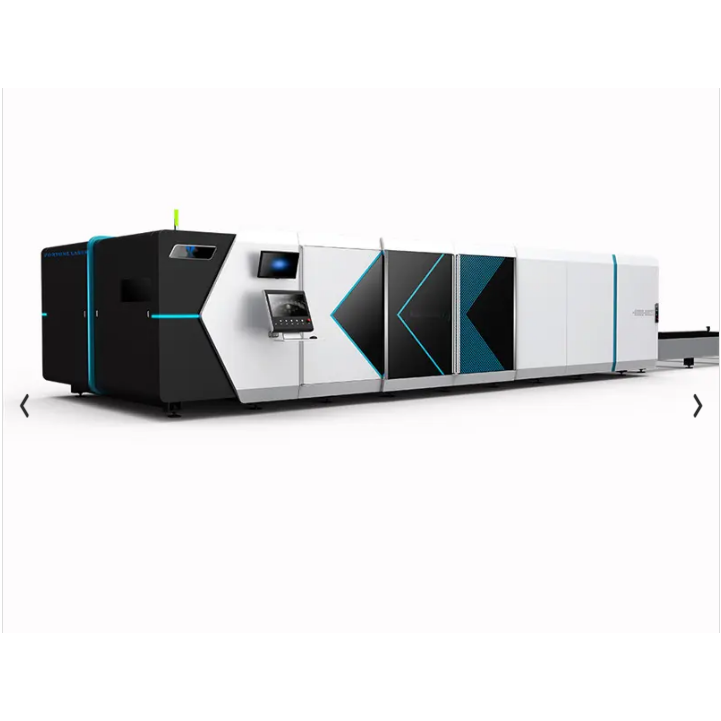

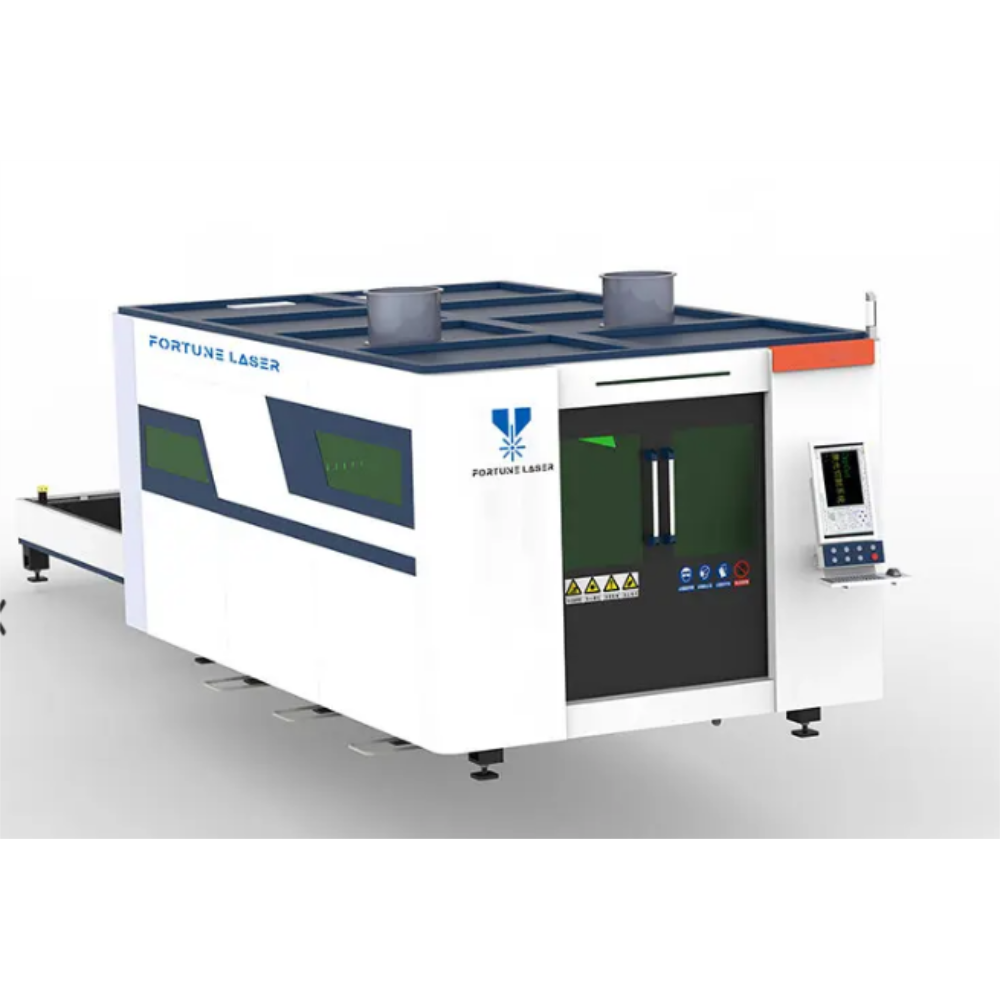

Advantages of Gantry Laser Cutting Machine

In today's rapidly evolving technological world, the requirements for precision and efficiency in manufacturing processes have never been higher. Gantry laser cutting machines have become a reliable and efficient solution with numerous advantages over traditional cutting...Read more -

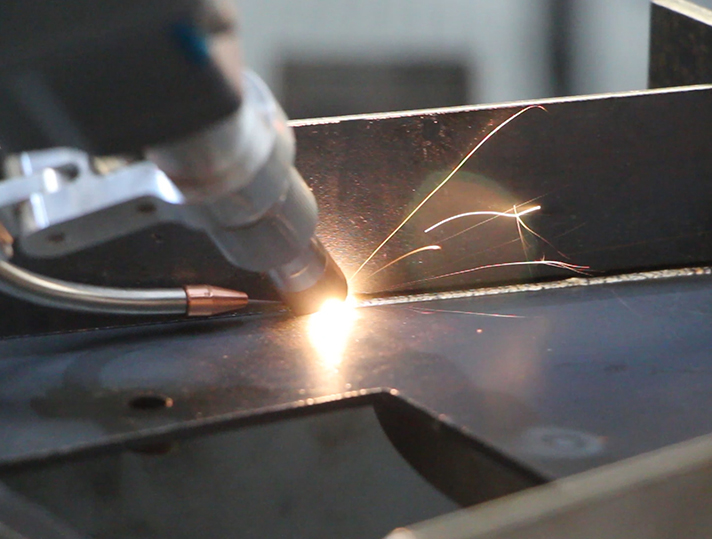

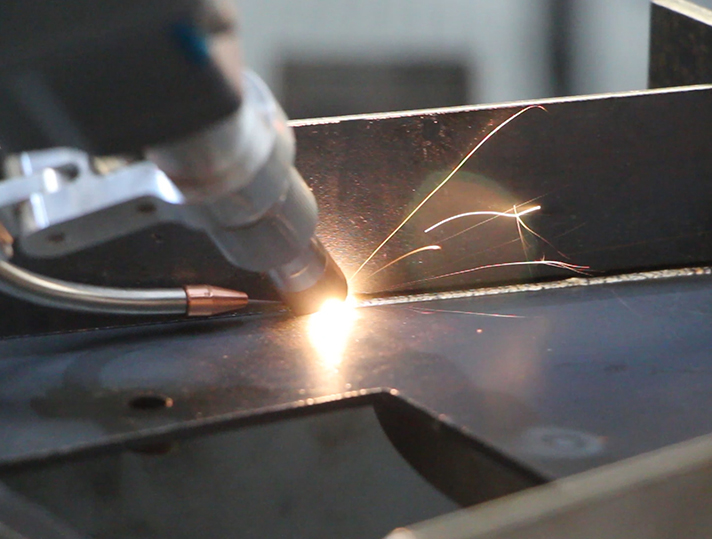

The difference between two different cooling methods of handheld laser welding machine

When it comes to laser welding machines, there are many types on the market. Among them, two popular options are water-cooled handheld laser welding machines and air-cooled handheld laser welding machines. The two machines differ not only in their cooling methods, but al...Read more -

Laser welding machine manufacturers teach you how to use the cutting function of 3 in 1 laser machine?

Handheld laser welding machines are popular in various industries due to their versatility and efficiency. In addition to their primary welding capabilities, these machines also offer cutting capabilities, which adds to their usefulness. In this article, we’ll explore a ...Read more -

Laser cutting machine automatic focus technology detailed explanation

Laser cutting machines have revolutionized manufacturing with their precision and efficiency. One of the key factors determining the quality of laser cutting is the precision of the focus. With the advancement of technology, laser cutting machine autofocus has become a g...Read more -

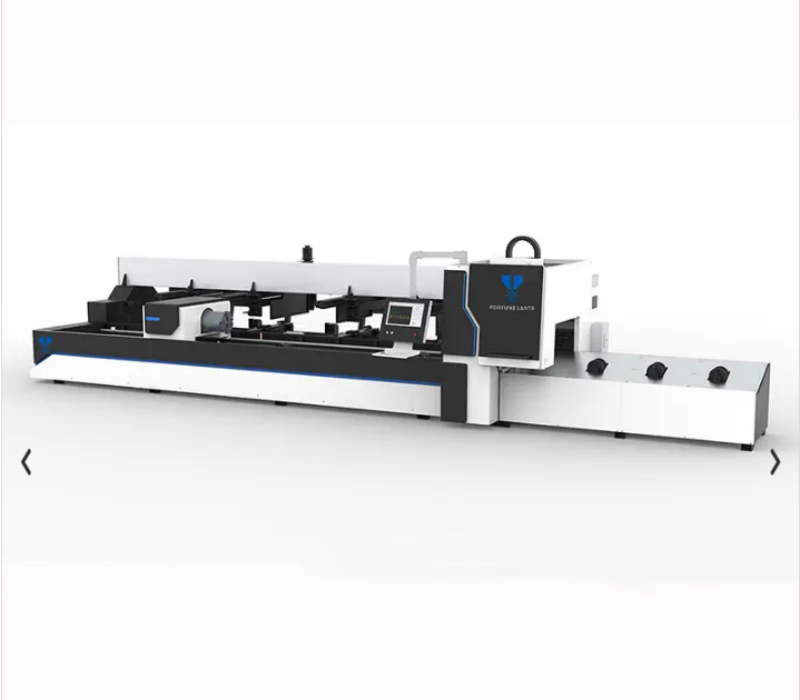

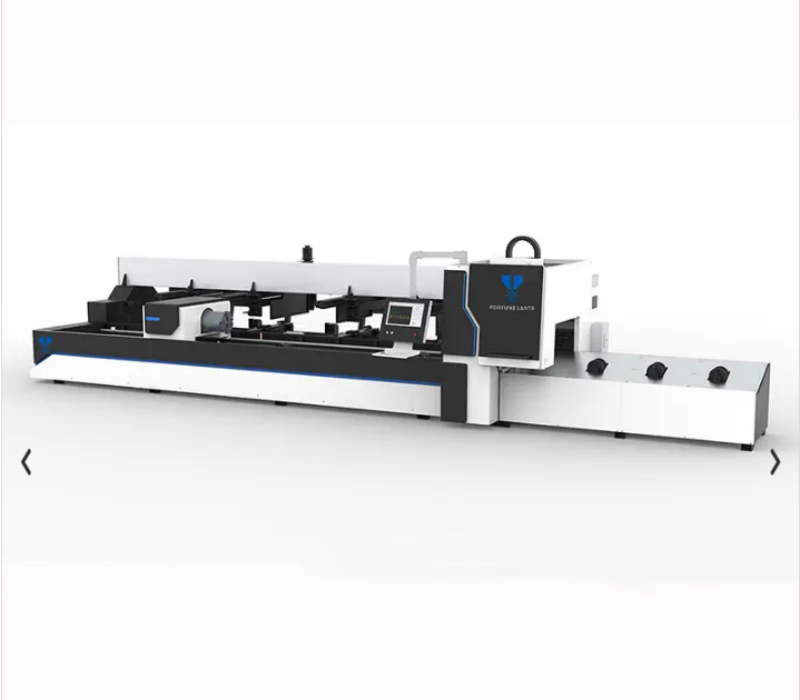

Can the laser round tube cutting machine only cut round tubes?

Laser cutting technology has revolutionized the metalworking industry with its exceptional precision and high-quality results. One of the most widely used applications of laser cutting is pipe cutting, which provides a fast and efficient method of forming metal pipes to ...Read more -

Robotic laser welding in the automotive industry: a revolution in productivity

Production processes in the automotive industry have undergone significant changes in recent years due to technological advances. A particular innovation that has gained a huge boost is the use of laser welding robots. The application of these high-efficiency machines ha...Read more -

What are the advantages of robotic laser welding?

Laser welding has become an increasingly popular method in the field of welding due to its many advantages. One of the most powerful advances in laser welding technology is the integration of robotic systems. Robotic laser welding has several key advantages, enabling hig...Read more -

Application fields of laser welding robots: promoting automation in various industries

In today's fast-paced world, automation has become an important aspect of industries across the globe. In particular, the use of laser welding robots has revolutionized manufacturing processes in several fields. These robots offer many advantages, from precision and accu...Read more -

Exploring the capabilities of laser welding robots for increased efficiency and full automation

Laser welding robots have revolutionized the field of welding by introducing advanced features that increase efficiency and productivity. These robots offer a wide range of functions that simplify the welding process, increase precision and ensure maximum safety. This ar...Read more -

How to check the welding quality of laser welding robot?

In the age of advanced technology, industrial processes have become more efficient and precise. One such advancement is the use of laser welding robots in manufacturing operations. These robots provide high-quality and precise welds, ensuring the durability and reliabili...Read more -

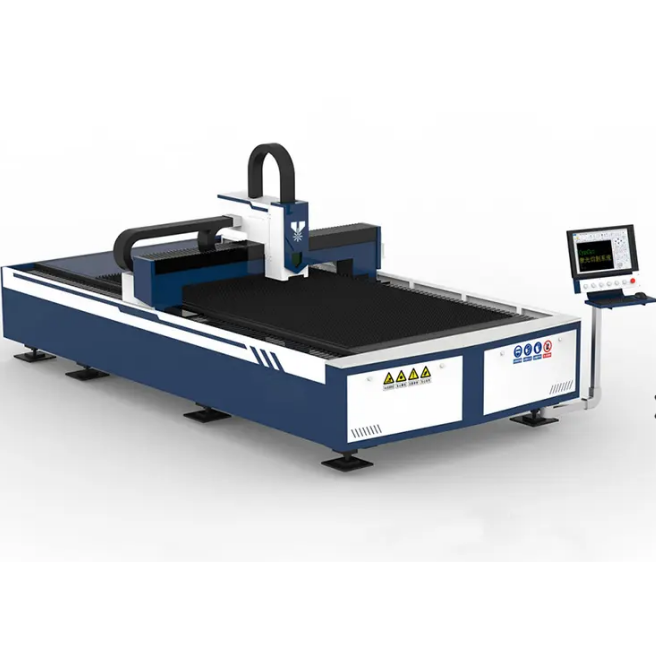

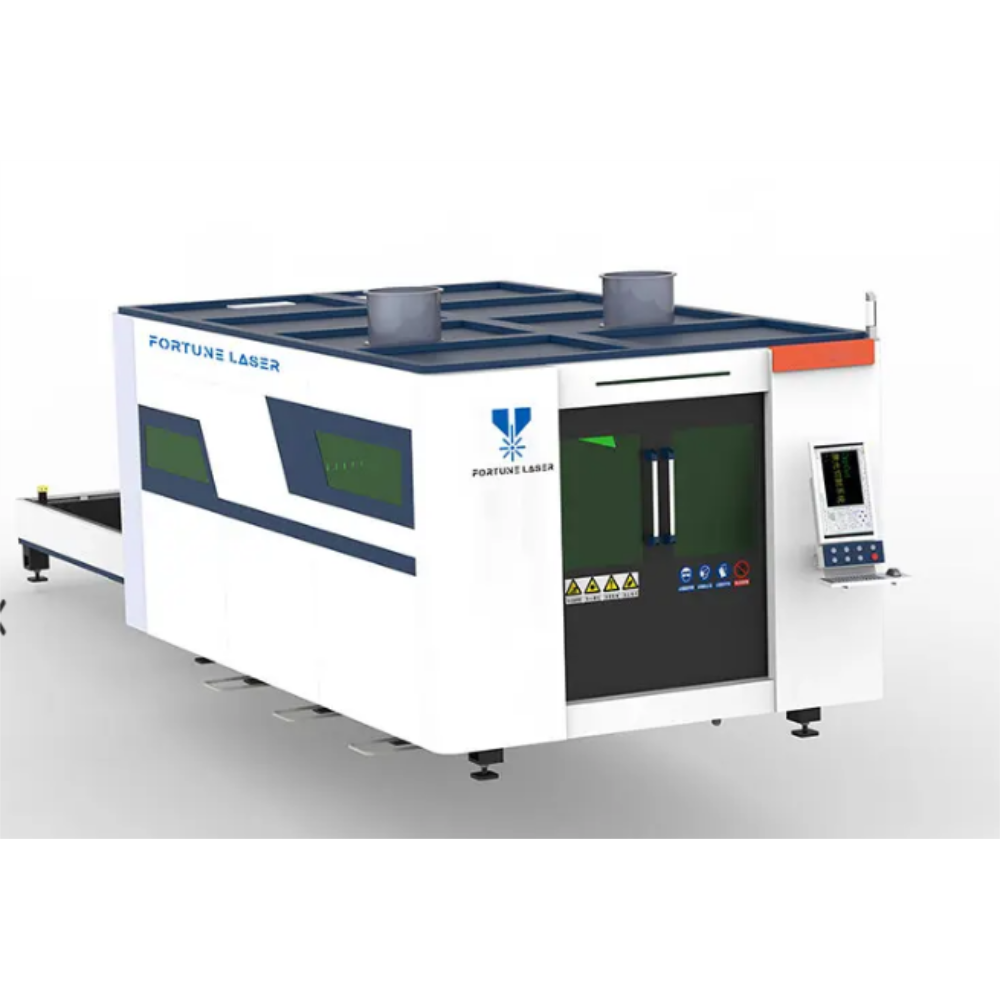

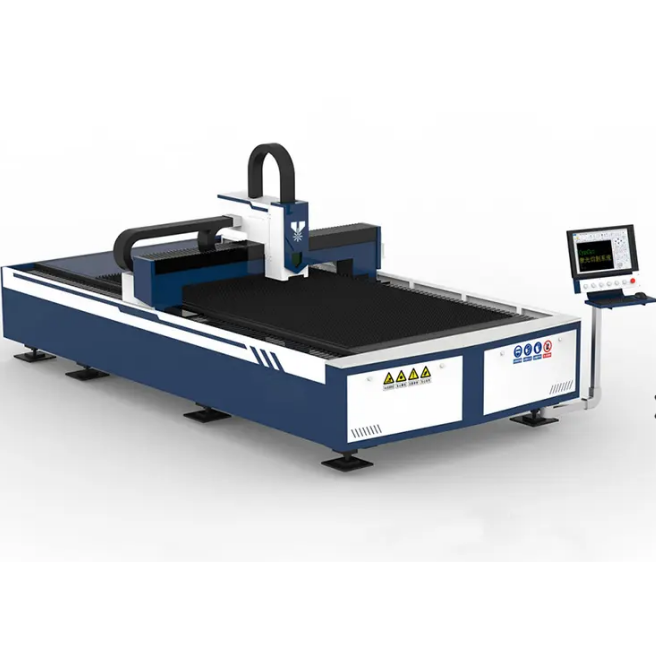

How to choose a laser cutting machine?

In the industrial cutting process, laser cutting machines have become an indispensable part of various industries. These machines offer precision and efficiency, making them highly sought after by companies requiring precise cuts. However, choosing the right laser cutter for your business can be ...Read more -

How to deal with laser welding deformation?

Stainless steel is widely used in various industries due to its unique properties such as corrosion resistance and formability. With the advancement of technology, laser welding has become a new welding method, which has many advantages compared with traditional welding techniques. However, one o...Read more -

Analysis of the Advantages of Robot Laser Welding Machine Seam Tracking

Laser welding is an increasingly popular method in manufacturing because of its precision and efficiency. One of the key components of a laser welding machine is the seam tracking system, which ensures precise positioning of the laser. In this article, we will analyze th...Read more -

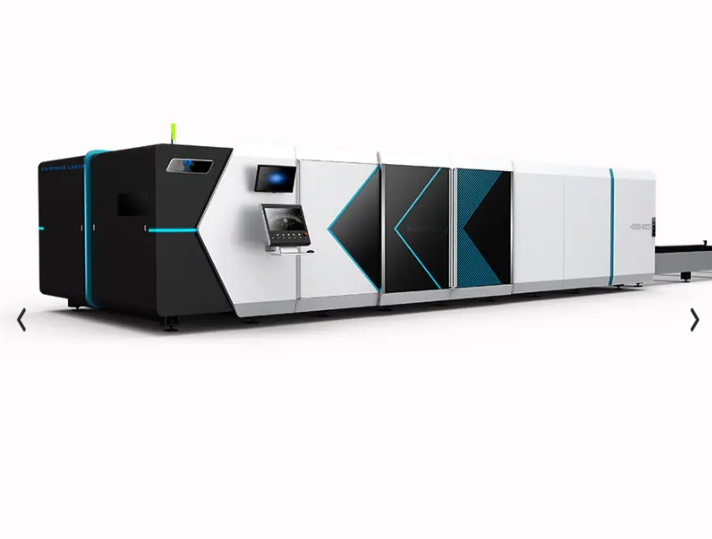

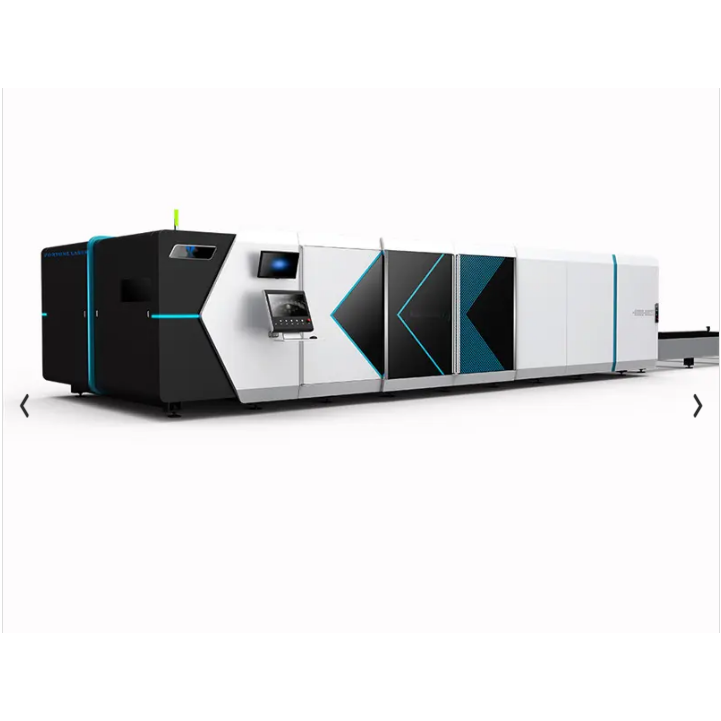

Market Research Analysis and Development Prospect Forecast of Fiber Laser Cutting Machine in Automobile Industry

With the rapid advancement of technology, the automotive industry is also constantly evolving, and fiber laser cutting machines play a vital role in this change. This article will deeply discuss the definition and classification of automotive fiber laser cutting machines...Read more -

How to debug the parameters of fiber laser cutting machine?

Fiber laser cutting machine is an essential tool for precision cutting in the manufacturing industry. However, to achieve the desired cut quality, certain parameters need to be paid attention to. Parameters that affect cut quality include cut height, nozzle type, focus position, power, frequency,...Read more