Laser welding machine is a kind of welding equipment commonly used in industrial production, and it is also an indispensable machine for laser material processing. From the early development of laser welding machine to the present technology has gradually matured, many types of welding machines have been derived, including the widely used handheld laser welding machine, a powerful assistant for welding operations.

Why use shielding gas when welding with handheld laser welding machine? Hand-held laser welding machine is a new type of welding method, mainly for welding thin-walled materials and precision parts, which can realize spot welding, butt welding, lap welding, sealing welding, etc., with high depth ratio, small weld width, and heat Small affected area, small deformation, fast welding speed, smooth and beautiful weld seam, no need to deal with or only need simple treatment after welding, high quality weld seam, no porosity, precise control, small focus spot, high positioning accuracy, easy to realize automation.

1. It can protect the focusing lens from metal vapor pollution and sputtering of liquid droplets

The shielding gas can protect the focusing lens of the laser welding machine from metal vapor pollution and sputtering of liquid droplets, especially in high-power welding, because the ejection becomes very powerful, and it is more necessary to protect the lens at this time.

2.Shielding gas is effective in dissipating plasma shielding from high power laser welding

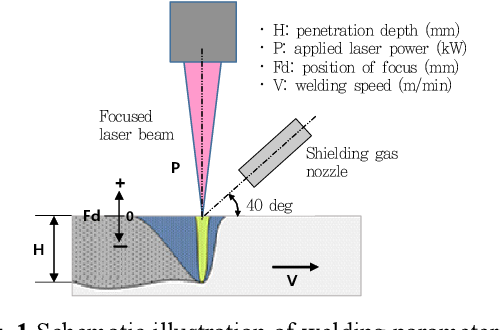

The metal vapor absorbs the laser beam and ionizes into a plasma cloud, and the protective gas around the metal vapor is also ionized due to heat. If too much plasma is present, the laser beam is somewhat consumed by the plasma. Plasma exists on the working surface as a second energy, which makes the penetration shallow and the surface of the weld pool widen.

The recombination rate of electrons is increased by increasing the three-body collisions of electrons with ions and neutral atoms to reduce the electron density in the plasma. The lighter the neutral atoms, the higher the collision frequency and the higher the recombination rate; on the other hand, only the protective gas with high ionization energy will not increase the electron density due to the ionization of the gas itself.

3.The protective gas can protect the workpiece from oxidation during welding

The laser welding machine must use a kind of gas for protection, and the program should be set in such a way that the protective gas is emitted first and then the laser is emitted, so as to prevent the oxidation of the pulsed laser during continuous processing. The inert gas can protect the molten pool. When some materials are welded regardless of the surface oxidation, the protection may not be considered, but for most applications, helium, argon, nitrogen and other gases are often used as protection to prevent the workpiece from being welded during welding. subject to oxidation.

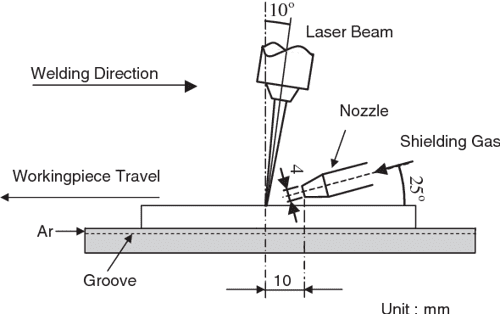

4.The design of nozzle holes

The shielding gas is injected at a certain pressure through the nozzle to reach the surface of the workpiece. The hydrodynamic shape of the nozzle and the diameter of the outlet are very important. It must be large enough to drive the sprayed shielding gas to cover the welding surface, but in order to effectively protect the lens and prevent metal vapor from contaminating or metal splashing from damaging the lens, the size of the nozzle should also be limited. The flow rate should also be controlled, otherwise the laminar flow of the shielding gas will become turbulent, and the atmosphere will be involved in the molten pool, eventually forming pores.

In laser welding, shielding gas will affect weld shape, weld quality, weld penetration and penetration width. In most cases, blowing shielding gas will have a positive effect on weld, but it may also bring come to an adverse effect.

Positive Role:

1) The correct blowing of shielding gas will effectively protect the weld pool to reduce or even avoid oxidation;

2) The correct blowing of shielding gas can effectively reduce the spatter generated during welding;

3) The correct blowing of the protective gas can promote the uniform spreading of the weld pool when it solidifies, making the weld shape uniform and beautiful;

4) The correct blowing of protective gas can effectively reduce the shielding effect of metal vapor plume or plasma cloud on laser, and increase the effective utilization rate of laser;

5) Correct blowing of shielding gas can effectively reduce weld porosity.

As long as the gas type, gas flow rate, blowing mode selection is correct, can obtain the ideal effect. However, incorrect use of protective gas will also bring adverse effects on welding.

Adverse Effect:

1) Improper insufflation of shielding gas may result in poor welds:

2) Choosing the wrong type of gas may cause cracks in the weld, and may also lead to a decrease in the mechanical properties of the weld;

3) Choosing the wrong gas blowing flow rate may lead to more serious oxidation of the weld (whether the flow rate is too large or too small), and may also cause the weld pool metal to be seriously disturbed by external forces, resulting in weld collapse or uneven forming;

4) Choosing the wrong gas injection method will cause the weld to fail to achieve the protection effect or even basically have no protection effect or have a negative impact on the weld formation;

5) Insufflation of protective gas will have a certain impact on the weld penetration, especially when welding thin plates, it will reduce the weld penetration.

Generally, helium is used as the protective gas, which can suppress the plasma to the greatest extent, thereby increasing the penetration depth and increasing the welding speed; and it is light in weight and can escape, and it is not easy to cause pores. Of course, from our actual welding effect, the effect of using argon protection is not bad.

If you want to learn more about laser welding, or want to buy the best laser welding machine for you, please leave a message on our website and email us directly!

Post time: Feb-04-2023