Manufacturers are always looking to make products that are stronger, more durable, and more reliable, as well as in the automotive and aerospace sectors. In this pursuit, they frequently upgrade and replace material systems with lower density, better temperature and corrosion resistance metal alloys. This gives manufacturers a better foothold in the market.

Actually, that’s only half the story.

An even stronger strategic advantage is quantifiable certainty about a product’s strength, durability, and reliability.

Swapping out older materials for stronger ones can be a good start, but it also requires more advanced manufacturing processes that rely on cleaner and more efficient surface cleaning to create strong structures. Metals such as aluminum alloys and advanced materials such as carbon fiber polymer composites, often used in automotive and aerospace manufacturing, require bonding to reduce weight – when fasteners are used, weight is added to the structure – and to create more reliable joints.

Traditional aluminum finishing techniques include sandblasting, solvent wiping, followed by grinding (using a scouring pad) or anodizing. Adhesive bonding opens the door to more automated processes for which traditional finishes are not compatible.

Anodizing is more common in aerospace applications where this more expensive and more stringent preparation is used to meet stringent specifications. The inherent variability of sandblasting and manual abrasion techniques clearly shows that a more controlled process is in order.

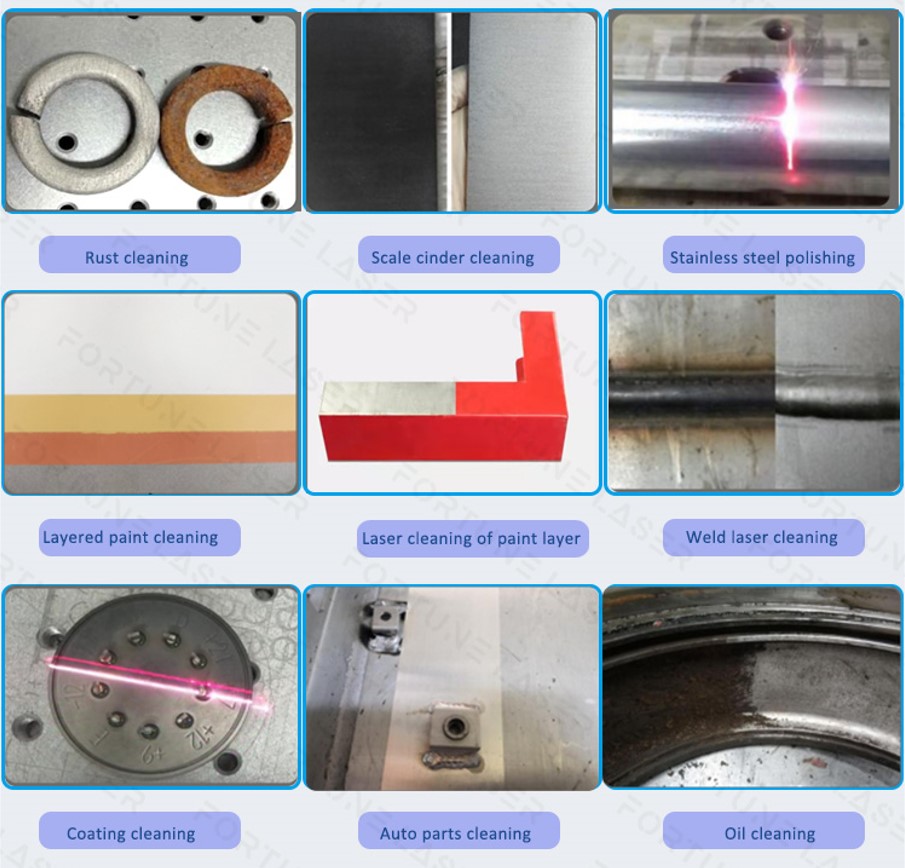

Laser cleaning or laser ablation fills this process gap as a more precise, environmentally friendly, automatable and efficient method of treating metal and composite surfaces for cleaning. The types of contamination found on the surface of these materials are easily removed by laser processing.

Because laser cleaning is so powerful, it’s critical to know exactly how it affects your surface. The difference between a properly treated surface and an under- or over-treated surface can be extremely difficult to assess. With quantitative process verification technology as sensitive and precise as the laser process itself, manufacturers can be confident that their metal and composite surfaces are fully ready for bonding.

The following Fortune laser will give you a detailed introduction to the reasons for choosing laser cleaning.

1 – What is Laser Cleaning?

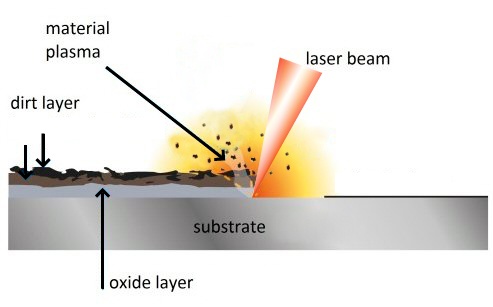

Laser treatment is an extremely precise, thermal cleaning technique that works by removing (ablation) tiny fractions of a material surface through a focused, often pulsed, laser beam. The laser irradiates the surface to remove atoms and can be used for drilling extremely small, deep holes through very hard materials, producing thin films or nanoparticles on a surface.

This surface cleaning process is so effective because of its ability to target such small layers of contaminants and residues. Aluminum surfaces contain oxides and lubricant oils that are detrimental to the adhesive joining and composites often retain residual mold releases and other silicone contaminants that can’t form strong chemical bonds with adhesives.

When an adhesive is applied to a surface with one of these residues present it will try to chemically adhere to the oils and silicone at the top few molecular layers of the material. These bonds are extremely weak and will inevitably fail either during performance tests or during use of the product. When joints break at the point where the surface and adhesive or coating meet this is called an interfacial failure. Cohesive failure during lap shear testing is when the break happens within the adhesive itself. This is indicative of a very strong bond and an assembled structure that is resilient and long-lasting.

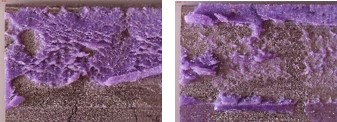

Cohesive failure of these composite samples that have been laser treated shows the adhesive on both sides of the materials being bonded.

Interfacial failure of these composite samples that were not treated shows that the adhesive only stuck to one of the sides and completely let go of the other.

When you have cohesive failure, you have an interfacial bond that isn’t letting go for nothing. Surface treatments aim at modifying the surface to remove contaminants and create or reveal a surface that will be able to chemically fuse with the adhesive for durable and reliable bonds.

2 - How to Know if Your Laser Treated Surface is Ready for Adhesion

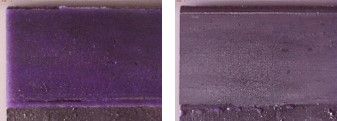

Contact angle measurements, like the ones mentioned in the IJAA paper used to understand the degradation of treatments overtime, are an exceptionally good way of monitoring and verifying laser cleaning processes.

A contact angle measurement is sensitive to the molecular changes that are occurring on a surface being laser treated. The drop of liquid placed on the surface will rise or fall in exact relation to the amount of microscopic contamination on the surface. Contact angle measurements are a relentless indicator of adhesion and can offer clarity and visibility into how aligned the strength of the treatment is with the cleaning needs of the materials.

Contact angle measurements correlate beautifully with the changes in contaminant levels picked up by spectroscopy methods. Most precision measurements of contaminants on surfaces are done with equipment that isn’t feasible for manufacturers to purchase and couldn’t be used on real parts actually being manufactured anyway.

Contact angle measurements can be performed immediately before and after treatment on the production line with manual or automated measurement tools. Just as laser cleaning replaces outmoded surface preparation methods due to the automation needs of high-volume, high-precision manufacturing, contact angle measurements also make subjective and imprecise surface quality tests like dyne inks and water break tests obsolete.

Strength performance tests only examine a sample of the materials being processed, adding to scrap rate and not giving any indication of how to create a stronger bond. Contact angles, when employed throughout a production line can point to exactly where the process requires tweaking, and can provide insight into what needs to be tweaked and to what extent.

3 - Why Use Laser Cleaning?

There’s been lots of great research on the ways laser surface treatment improves adhesion. For instance, a paper published in the Journal of Adhesion explored just how much joint strength is enhanced by laser cleaning as opposed to the traditional methods.

“Experimental results indicate that preadhesion laser surface treatment significantly improved the shear strength of modified-epoxy bonded aluminum specimens compared with untreated and anodized substrates. The best results were obtained with laser energy of about 0.2 J/Pulse/cm2 where single lap shear strength was improved by 600-700% compared with that of untreated Al alloy, and by 40% compared with chromic acid anodizing pretreatment.

The mode of failure changed from adhesive to cohesive as the number of laser pulses increased during treatment. The latter phenomenon has been correlated with morphology changes as revealed by electron microscopy, and chemical modification as indicated by Auger and infrared spectroscopy.”

Another interesting effect of laser ablation is the power it has to create a surface that doesn’t degrade over time.

Fortune Laser has done great work looking into how laser cleaning interacts with surfaces in some surprising ways. Laser treatment of aluminum creates tiny craters in the surface that melt and almost simultaneously solidifies into a micro crystalline layer on the surface that is even more corrosion resistant than the aluminum itself.

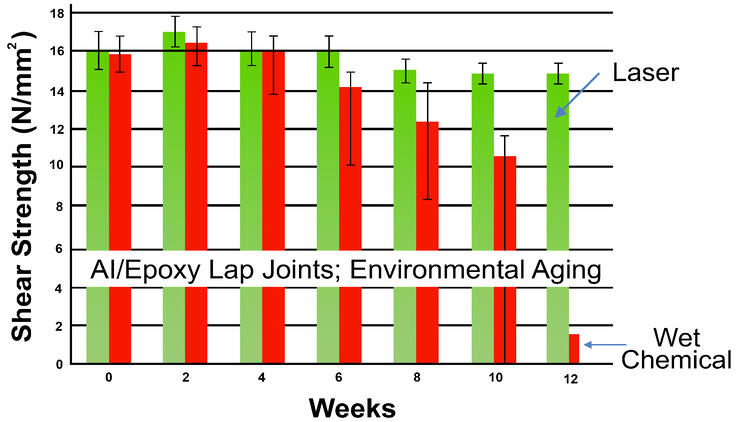

Looking at the chart below, it shows the difference between the shear strength of a bond using aluminum that has been laser treated and aluminum that has been chemically treated. Over time, as the surfaces have been exposed to a moist environment, the ability of the chemically treated surface to bond well decreases significantly because the moisture begins to corrode the surface, while the laser treated surface retains its corrosion resistance after weeks of exposure.

Post time: Aug-12-2022