As we all know, fiber laser cutting machines are experts at cutting metal sheets and are widely used. So what are the effects of cutting imperfect metal sheets – rusty metal sheets and what aspects should be paid attention to?

1. Cutting rusty plates will reduce the processing efficiency, the cutting quality will also be worse, and the product scrap rate will also increase accordingly. Therefore, if conditions permit, during the sheet metal processing process, try to use as little rusty plates as possible or treat the rusty plates before processing them. use.

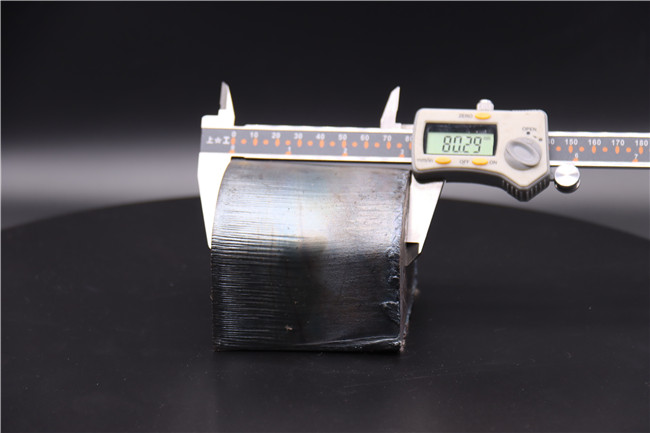

2. During the plate cutting process, especially when punching and cutting, holes may explode, which will contaminate the protective lens. This requires us to deal with the rusted plate first, such as using a grinder to remove rust. Of course, plates below 5MM The impact is not big, mainly due to rusty thick plates, but the cutting quality will still be affected, which is not as good as the quality of cutting qualified plates.

3. The overall uniformity of the cutting effect is better than the uneven rusty plate. The overall uniformity of the rusty plate absorbs the laser relatively uniformly, so it can be better cut. For unevenly rusted sheet metal, it is recommended to treat the surface to make the surface of the sheet uniform and then perform sheet metal laser cutting.

Post time: Apr-10-2024