As we all know, the LED chip as the core component of the LED lamp is a solid-state semiconductor device, the heart of the LED is a semiconductor chip, one end of the chip is attached to a bracket, one end is a negative electrode, the other end is connected to the positive electrode of the power supply, so that the entire chip is encapsulated by epoxy resin. When sapphire is used as the substrate material, it is widely used in the production of LED chips, and the traditional cutting tool can no longer meet the cutting requirements. So how do you solve this problem?

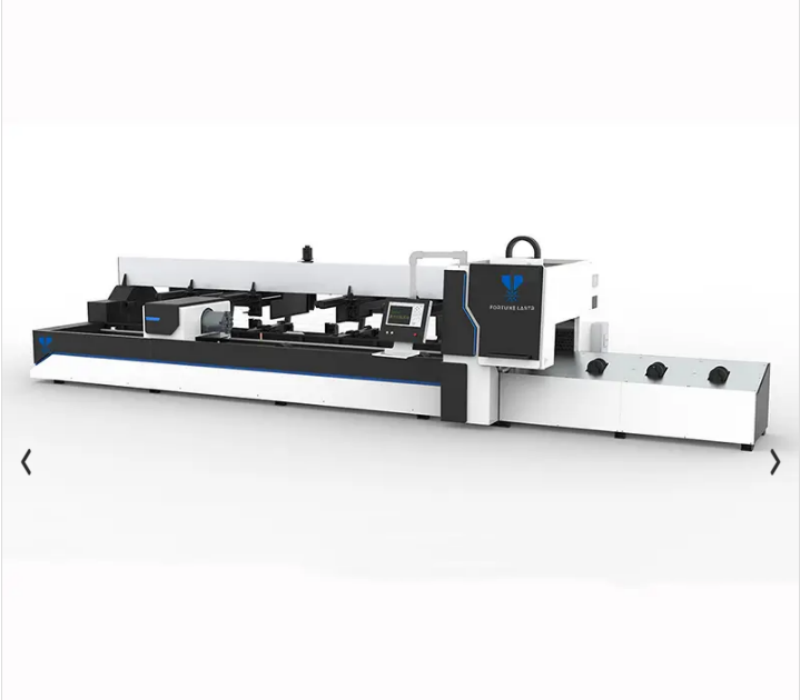

The short-wavelength picosecond laser cutting machine can be used to slice sapphire wafers, which effectively solves the difficulty of sapphire cutting and the requirements of the LED industry to make the chip small and the cutting path narrow, and provides the possibility and guarantee of efficient cutting for the large-scale mass production of LED based on sapphire.

Advantages of laser cutting:

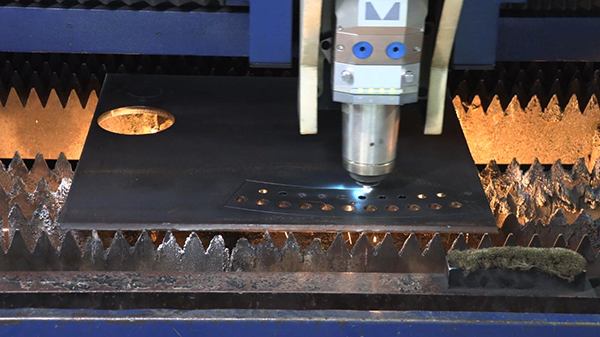

1, good cutting quality: due to the small laser spot, high energy density, cutting speed, so laser cutting can obtain better cutting quality.

2, high cutting efficiency: due to the transmission characteristics of the laser, the laser cutting machine is generally equipped with multiple numerical control tables, and the entire cutting process can be fully CNC. When operating, just change the numerical control program, it can be applied to cutting parts of different shapes, both two-dimensional cutting and three-dimensional cutting can be achieved.

3, the cutting speed is fast: the material does not need to be fixed in the laser cutting, which can save the fixture and save the auxiliary time of loading and unloading.

4, non-contact cutting: laser cutting torch and workpiece no contact, there is no tool wear. Processing parts of different shapes, do not need to replace the “tool”, just change the output parameters of the laser. Laser cutting process has low noise, low vibration and no pollution.

5, there are many kinds of cutting materials: for different materials, due to their thermal physical properties and different absorption rates of laser, they show different laser cutting adaptability.

Post time: Dec-02-2024