The Laser Welding Robot Operating Manual serves as a comprehensive guide providing basic information on the use and operation of automated equipment that uses laser beams for welding. This manual is designed to help users understand the installation steps, debugging processes and operating procedures required to use laser welding robots efficiently and safely. With its advantages of high efficiency, high precision, and high quality, laser welding robots are widely welcomed in various industries such as automobile manufacturing, aerospace, and electronics.

Product Description

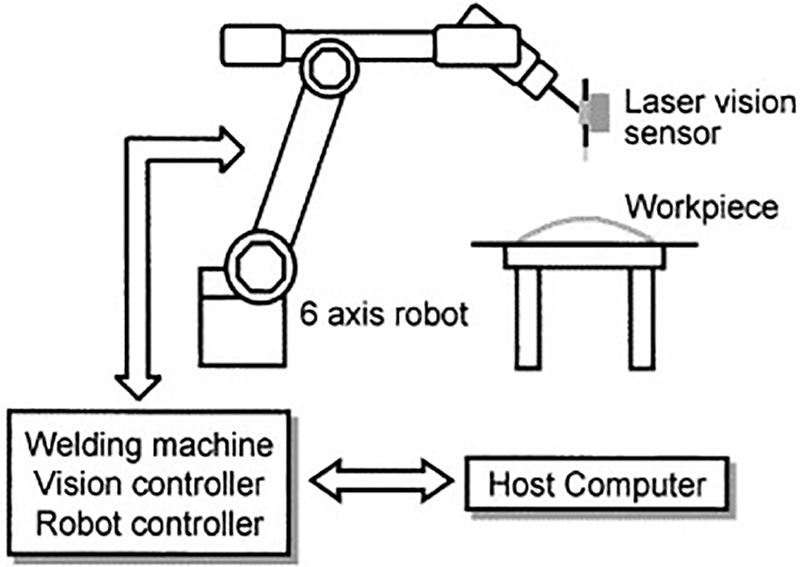

A laser welding robot is an automated device that uses a laser beam to perform welding operations. The main purpose of laser welding is to heat and melt the welded parts, effectively bonding and fusing the materials together. This process allows for precise welding, resulting in a high-quality product. Laser welding robots are renowned for their ability to deliver superior welding results, making them ideal for industries that demand perfection and reliability.

Installation steps

Proper installation of a laser welding robot is critical to its optimal performance and longevity. The following steps outline the installation process:

1. Mechanical structure installation: First assemble and install the mechanical structure of the laser welding robot. Make sure all components are securely connected and aligned to provide stability during operation.

2. Control system installation: Install the control system of the laser welding robot. This system is responsible for controlling the robot's movements and functions and plays a vital role in achieving precise welding results.

3. Power supply and signal line connection: Correctly connect the power supply and signal line of the laser welding robot to ensure reliable and uninterrupted power supply. Carefully follow the wiring diagram provided and make sure all connections are accurate.

Debugging steps

After the laser welding robot is installed, it must be thoroughly debugged to optimize its performance. The following steps outline the debugging process:

1. Laser beam focus and intensity adjustment: Adjust the focus and intensity of the laser beam to achieve the ideal welding effect. This step requires precise and careful calibration to ensure accurate welding.

2. Mechanical structure movement accuracy adjustment: Fine-tune the movement accuracy of the mechanical structure to eliminate inconsistencies or inaccuracies. This step is critical to achieving a precise and even weld.

Operational process

To ensure safe and efficient operation, correct operating procedures must be followed. The following steps outline the typical operating flow of a laser welding robot:

1. Start preparation: Before starting the laser welding robot, conduct a thorough inspection of all components and connections to ensure that they are in normal working condition. Check for any potential hazards or malfunctions.

2. Laser beam adjustment: Carefully adjust the laser beam parameters according to the welding requirements. Make sure focus, intensity, and other settings comply with required welding specifications.

3. Welding process control: start the welding process according to specific requirements. Monitor and control welding parameters throughout the entire operation for precise and consistent welds.

4. Shutdown: After completing the welding process, execute a series of shutdown procedures to safely turn off the power of the laser welding robot. This includes ensuring proper cooling and shutdown control systems.

Security considerations

When operating a laser welding robot, safety must be prioritized to prevent harm to personnel and equipment. The laser beam used in this process can be dangerous if not handled properly. Therefore, it is important to adhere to the following safety guidelines:

1. Personal Protective Equipment (PPE): Ensure that all personnel involved in the operation wear appropriate PPE, including safety glasses with specific laser protection and other necessary equipment.

2. Laser beam shield: Provide a properly enclosed working space for the laser welding robot with appropriate shielding materials to prevent accidental exposure of the laser beam.

3. Emergency Stop: Install an easy-to-operate emergency stop button and make it familiar to all operators. This can be used as a safety measure in the event of an emergency hazard or breakdown.

4. Regular equipment maintenance: Establish a daily maintenance plan to ensure that the laser welding robot is in normal working condition. Regularly check and clean all parts of the robot, including laser systems, mechanical structures, control systems, etc.

In conclusion

The Laser Welding Robot Operation Manual is an important resource for users of automated equipment that utilizes laser beams for precise, efficient welding operations. By paying attention to the installation steps, commissioning procedures and operating procedures outlined in this manual, users can maximize the capabilities of laser welding robots in various industries. Prioritizing safety and following the guidance provided in this manual is critical to the well-being of personnel and the longevity of the equipment. With the advantages of high efficiency, high precision and high quality welding, laser welding robots continue to innovate welding processes and contribute to the progress of automobile manufacturing, aerospace, electronics and other fields

Post time: Nov-22-2023