Laser cutting machines have revolutionized manufacturing with their precision and efficiency. One of the key factors determining the quality of laser cutting is the precision of the focus. With the advancement of technology, laser cutting machine autofocus has become a game changer. In this article, we'll delve into the details of this cutting-edge technology that enables seamless cutting of different materials with minimal manual intervention.

Cutting different materials: a focused challenge

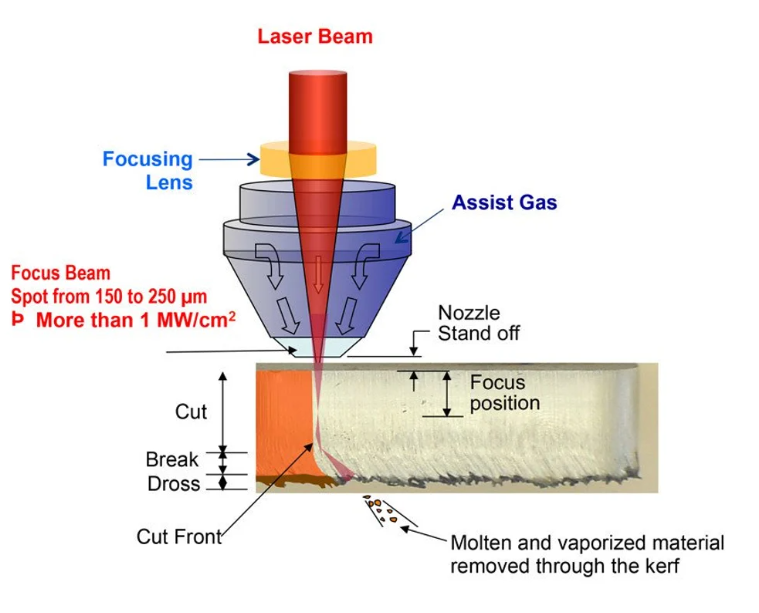

During laser cutting, the focal point of the laser beam needs to be precisely positioned on the material being cut. This is critical because the focus determines the width and quality of the cut. Different materials have different thicknesses, so focus needs to be adjusted accordingly.

Traditionally, the focal length of the focusing mirror in the laser cutting machine is fixed, and the focus cannot be adjusted by changing the focal length. This limitation presents a significant challenge in achieving optimal cutting results in materials of varying thicknesses. However, this problem has been overcome thanks to advances in autofocus technology for laser cutting machines.

Autofocus Method: How Does It Work?

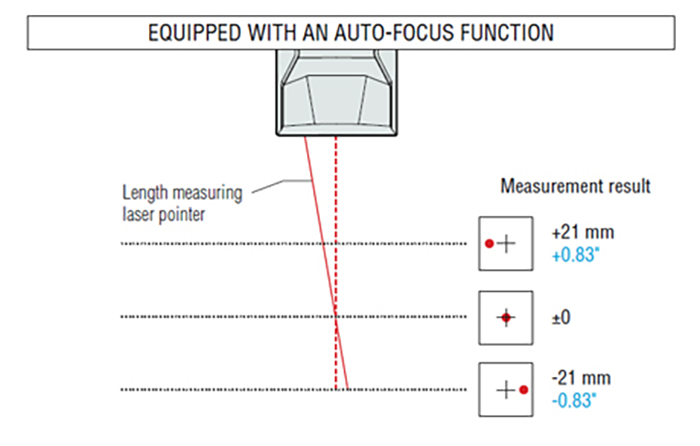

The core of laser cutting machine automatic focusing technology is the use of variable curvature mirror, also known as adjustable mirror. This mirror is placed before the laser beam enters the focusing mirror. By changing the curvature of the adjustable mirror, the reflection angle and divergence angle of the laser beam can be adjusted, thereby changing the position of the focal point.

As the laser beam passes through the adjustable mirror, the shape of the mirror changes the angle of the laser beam, redirecting it to a specific location on the material. This ability enables the laser cutting machine to automatically adjust the focus according to the requirements of cutting different materials.

Advantages of automatic focusing of laser cutting machine

1. Enhanced precision: The laser cutting machine automatically adjusts the focus, which can precisely adjust the focus, regardless of the difference in material thickness, and can ensure accurate cutting results. This high accuracy minimizes the need for additional manual adjustments, increasing overall productivity.

2. Time efficiency: One of the advantages of auto focus technology is to shorten the punching time of thick plates. By quickly and automatically adjusting the focus to the proper position, the laser cutter significantly reduces processing time. This not only saves time, but also increases overall productivity.

3. Increased flexibility: When processing workpieces of different materials and thicknesses, traditional focusing methods often require manual intervention to adjust the focus. However, with autofocus, machines can be adjusted quickly without relying on human labor, resulting in more flexible and efficient production.

4. Improved cut quality: The ability to precisely control focus improves cut quality. By ensuring that the laser beam is precisely focused on the material, laser cutter autofocus minimizes burrs, reduces dross, and produces clean, high-quality cuts. This level of precision is critical for industries such as aerospace, automotive and electronics.

The automatic focusing technology of laser cutting machine eliminates the limitations of traditional focusing methods and brings a revolution to the manufacturing industry. Focus can be adjusted accurately and quickly with adjustable mirrors, increasing precision, time efficiency, flexibility and improving cut quality.

As this technology continues to develop, we can expect even more advanced laser cutting machines capable of seamlessly cutting a variety of materials with the utmost precision. The adoption of automatic focusing of laser cutting machines not only improves production efficiency, but also opens up new possibilities for manufacturing, making precision cutting easier and more economical.

For businesses seeking to stay ahead in a competitive market, investing in a laser cutting machine equipped with autofocus technology is a smart choice. The technology's ability to accommodate different materials and thicknesses enables manufacturers to deliver high-quality products in a timely manner, ultimately improving customer satisfaction and business growth.

Post time: Sep-11-2023