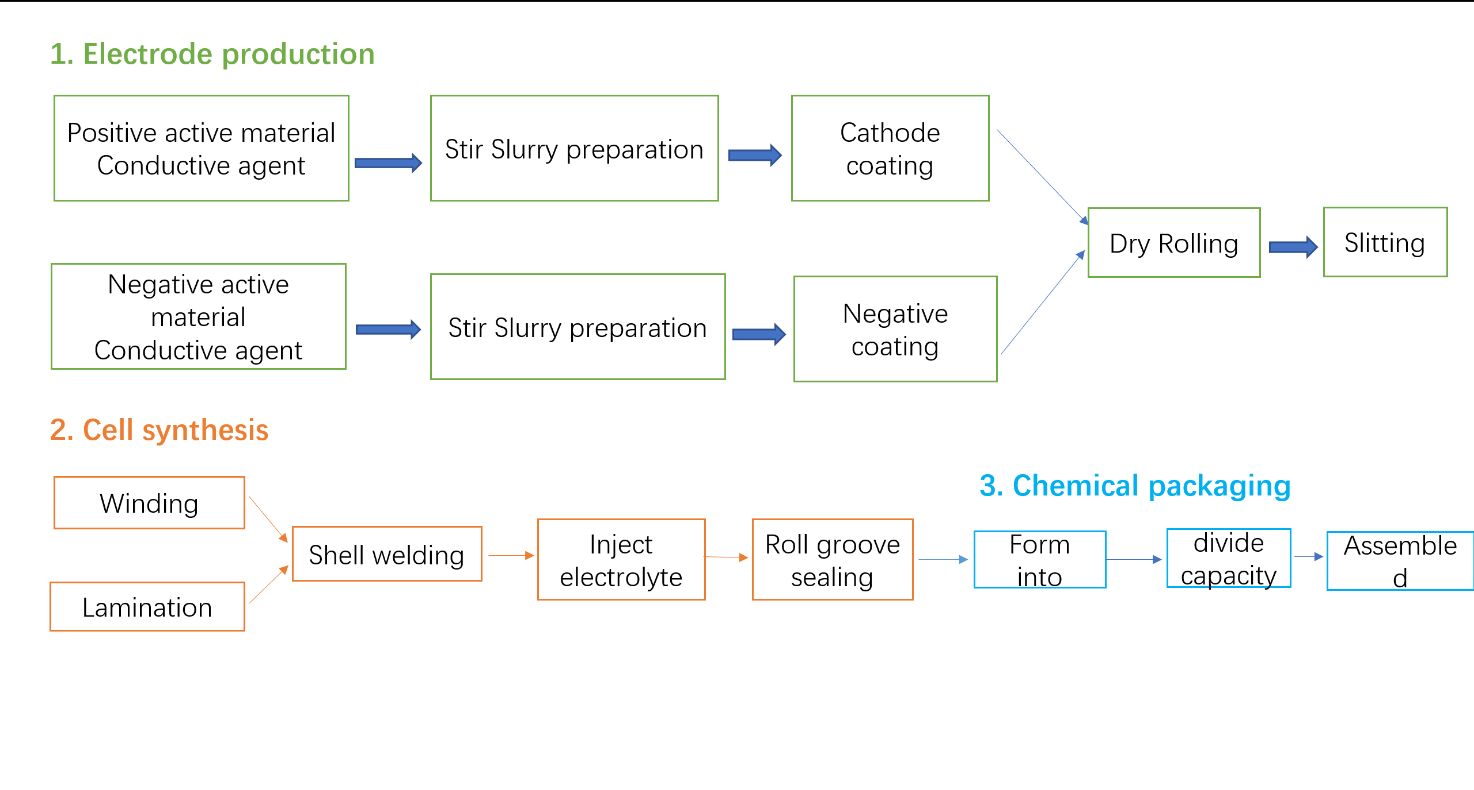

The production of lithium batteries is a “roll-to-roll” process. Whether it is a lithium iron phosphate battery, a sodium-ion battery or a ternary battery, it needs to go through the processing process from thin film to single battery, and then to battery system. The preparation process of lithium batteries can be roughly divided into three stages: electrode sheet production, cell synthesis, and chemical packaging.

There are several key processes in these three major processes, which will directly affect the battery’s power storage capacity, product safety and service life. Therefore, the performance of batteries produced by different production processes varies greatly. In these links, laser cleaning can currently participate in more than a dozen preparation processes, which can greatly improve the quality rate of lithium batteries.

|

Application process of laser cleaning on power battery |

|||

|

Front section of battery |

Cell segment |

Module segment |

PACK battery pack |

|

Pole cleaning |

Sealing nail cleaning |

Pole cleaning |

Pallet CMT Weld Seam Cleaning |

|

Cleaning before rolling |

Cleaning the tabs before soldering |

Cell blue film cleaning |

Cover plate electrophoretic paint cleaning |

|

Cleaning after rolling |

Cell Silicone Cleaning |

Cabinet sealant oxide layer cleaning |

|

|

Cell coating cleaning |

Oxide cleaning of protective bottom plate before welding |

||

| Injection hole cleaning |

Foil Label Cleaning |

||

|

busbar cleaning |

|||

As the demand for power batteries continues to increase, the demand for laser cleaning equipment will also increase. Next, we will focus on some of the application processes and comparative advantages.

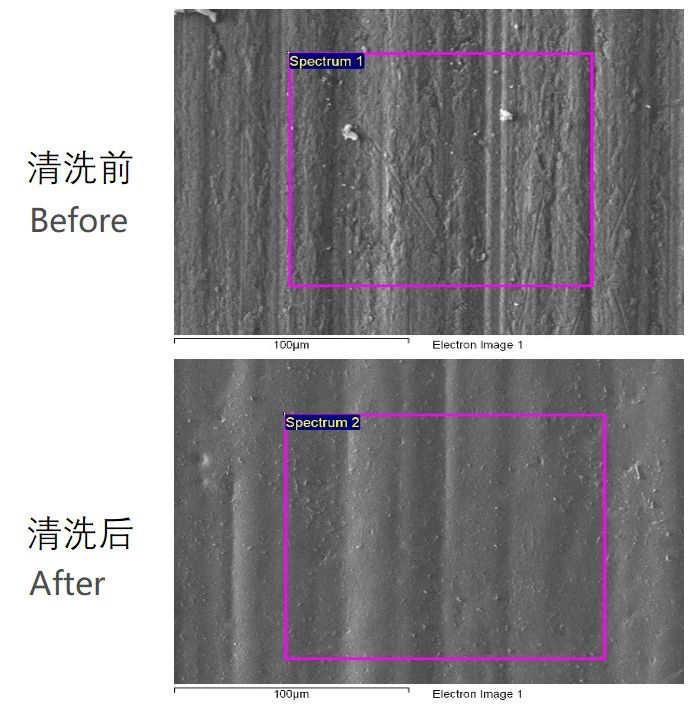

1. Laser cleaning of copper and aluminum foil before pole piece coating

The positive and negative electrodes of the lithium battery are made by coating the positive and negative electrodes of the lithium battery on the aluminum foil and copper foil. If particles, debris, dust and other media are mixed in the coating process, it will cause a micro-short circuit inside the battery, and in severe cases, the battery will catch fire and explode.

Therefore, the foil needs to be cleaned before coating to obtain a completely clean, oxide-free surface.

The existing battery pole pieces are generally cleaned by ultrasonic waves, and an ethanol solution is used as a cleaning agent as a cleaning process before coating. This approach has the following flaws:

1. When ultrasonically cleaning metal foil parts, especially aluminum alloy workpieces, affected by the frequency, cleaning time and power, the cavitation effect of ultrasonic waves can easily corrode the aluminum foil, resulting in fine pores. The longer the action time, the larger the pores.

The foil used for the lithium battery pole piece is generally a single zero foil with a thickness of 10 μm, which is more prone to tearing into holes due to cleaning process problems.

2. The use of ethanol solution as a cleaning agent is not only easy to cause damage to other parts of the lithium battery, but also prone to “hydrogen embrittlement”, which affects the mechanical properties of the aluminum foil.

3. Although the cleaning effect is worse than that of traditional wet chemical cleaning, the cleanliness is still not as good as that of laser cleaning. Occasionally there are still contaminants on the surface, which will cause the coating to separate from the foil or produce shrinkage holes.

As a dry cleaning without consumables, laser cleaning is close to zero defects in terms of cleanliness and hydrophilicity of the surface treatment of aluminum foil, ensuring the effect of sizing and coating on the pole piece to the greatest extent.

The use of laser cleaning metal foil can not only improve the efficiency of the cleaning process and save cleaning resources, but also establish real-time monitoring of cleaning process data and quantitative determination of cleaning results, which can effectively improve the consistency of batch production of pole pieces.

2. Laser cleaning of battery tabs before welding

The tabs are metal strips that lead out the positive and negative electrodes from the battery cell, and are the contact points when the battery is charged and discharged. Surface contaminants such as grease, corrosion inhibitors and other compounds in the process can cause problems such as poor welds, cracks and porosity in the weld.

The cleanliness of the contact surface can greatly affect the reliability and durability of the electrical connection.

The existing electrode cleaning mostly adopts manual cleaning, wet chemical cleaning or plasma cleaning:

● Manual cleaning is inefficient and costly;

● Although the wet process water cleaning line improves the efficiency, the length of the line is long, it occupies a large area of the factory, and the chemical agent is also easy to damage other lithium battery parts;

● Although plasma cleaning does not require liquid medium, it also requires process gas as a consumable material, and gas ionization will cause the positive and negative electrodes of the battery to be easily turned on. When applying, it is often necessary to flip the battery several times to separate the positive and negative electrodes for cleaning. The actual efficiency Not high.

Laser cleaning can effectively remove dirt, dust, etc. on the end face of the battery pole, and prepare for battery welding in advance.

Because laser cleaning does not require any consumables such as solid, liquid and gas, the structure is compact, the space occupied is small, and the cleaning effect is remarkable, which can greatly improve the production cycle and reduce the manufacturing cost;

It can roughen the welding surface on the basis of thoroughly removing organic matter and tiny particles, and improve the reliability of subsequent laser welding. It is one of the best choices for tab cleaning.

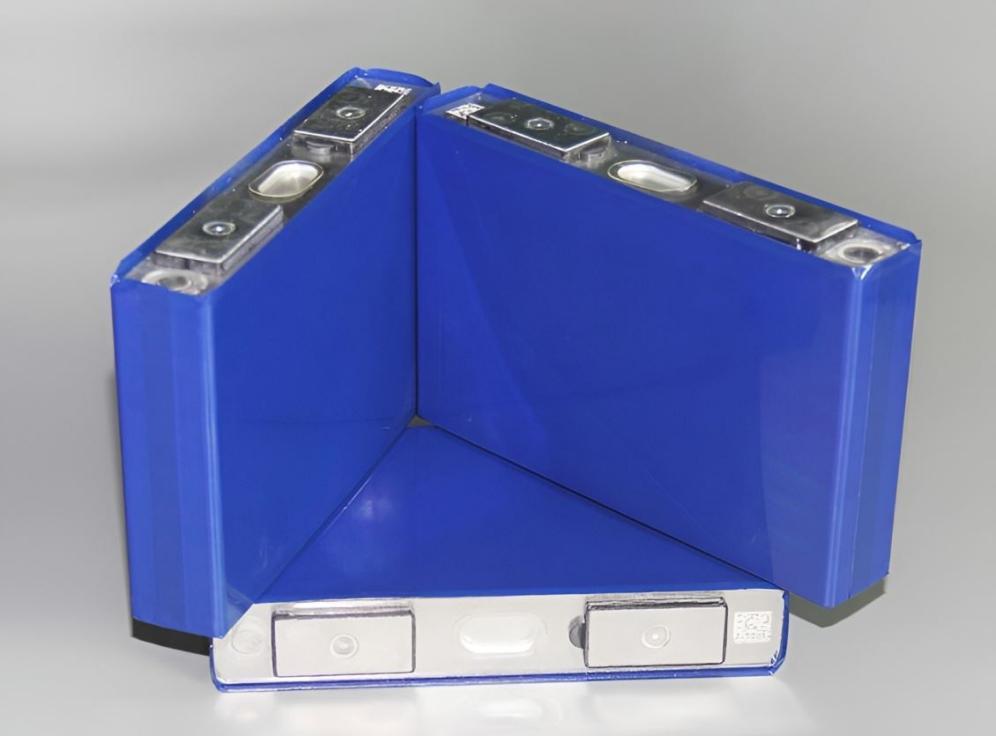

3. Cleaning of external adhesive during assembly

In order to prevent safety accidents of lithium batteries, it is generally necessary to apply glue to the lithium battery cells to play an insulating role, prevent short circuits, protect circuits, and prevent scratches.

When the outer film of the uncleaned cell is tested by CCD, there will be wrinkles, air bubbles, scratches and other defects in appearance, and air bubbles with a diameter of ≥ 0.3mm can often be detected. There is the possibility of leakage and rust corrosion, which reduces the battery life and also has potential safety hazards.

Laser cleaning can reach Sa3 level in the cleaning ability of the cell surface, and the removal rate is more than 99.9%; and there is no stress on the surface of the cell.Compared with other cleaning methods such as ultrasonic cleaning or mechanical grinding, it can ensure that the physical and chemical indicators such as the surface hardness of the battery cells do not change to the greatest extent, and prolong the service life of the battery.

In addition to the above-mentioned examples, laser cleaning also has great alternative advantages in other dozen processes such as battery cover electrophoretic paint removal and foil label cleaning.

If you want to learn more about laser cleaning, or want to buy the best laser cleaning machine for you, please leave a message on our website and email us directly!

Post time: Oct-19-2022