Fiber laser cutting machine is an essential tool for precision cutting in the manufacturing industry. However, to achieve the desired cut quality, certain parameters need to be paid attention to. Parameters that affect cut quality include cut height, nozzle type, focus position, power, frequency, duty cycle, air pressure, and speed. When the cutting quality of the fiber laser cutting machine is poor, it is recommended to conduct a comprehensive inspection first. This article will introduce how to optimize the parameters and hardware conditions of the fiber laser cutting machine to improve the cutting quality.

One of the basic parameters to consider when optimizing the parameters of a fiber laser cutting machine is the cutting height. The cutting height is the distance between the cutting nozzle and the workpiece. The optimum cutting height depends on the material being cut. Setting the correct cutting height ensures that the laser beam is focused on the material for precise cutting. Furthermore, the cutting nozzle type plays a vital role in the cutting process. The choice of nozzle type depends on the material being cut and it affects the quality of the final product.

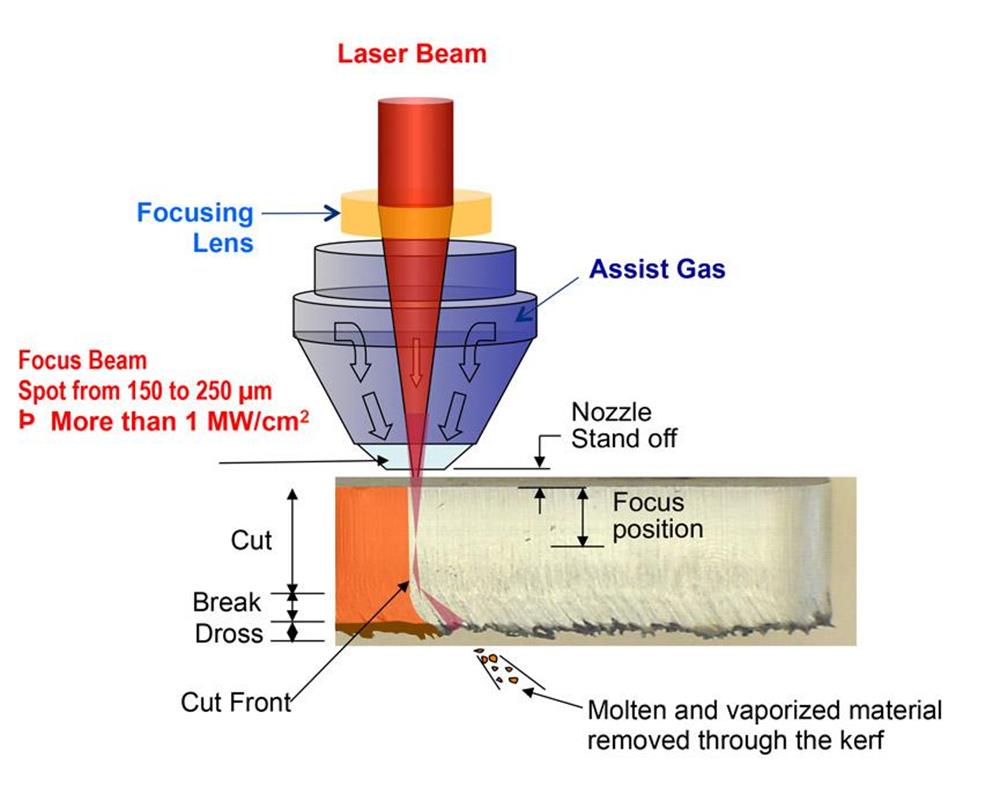

Another key parameter is focus position. The focus position is the distance between the lens and the workpiece. The focus position determines the size and shape of the laser beam. A properly set focus position contributes to clean cut edges and reduces the need for post-cut handling.

Cutting power and frequency are other parameters that significantly affect the quality of the cut. Cutting power refers to the amount of energy delivered to the material by the laser beam. Frequency, on the other hand, refers to the number of laser pulses delivered to the material per unit of time. Cutting power and frequency need to be properly optimized to achieve the desired cut. High power and frequency can cause excessive melting of the material, while low power and frequency can cause incomplete cutting.

The duty cycle is also an important parameter to consider when optimizing the parameters of the fiber laser cutting machine. The duty cycle determines the ratio of the time the laser is on to the time the laser is off. The duty cycle affects the temperature of the laser beam and must be set correctly to achieve the desired cut quality. High duty cycles cause increased heat generation, which not only reduces cut quality, but can also damage the machine.

Cutting air pressure is another parameter that is often overlooked when optimizing fiber laser cutting machine parameters. Cutting air pressure is the pressure at which compressed air is delivered to the cutting nozzle. Appropriate cutting air pressure ensures that the debris of the material is blown away, reducing the chance of fire and improving the cutting quality.

Finally, cutting speed is the speed at which the laser beam travels through the material. Adjusting the cutting speed can significantly affect the quality of the cut. High cutting speeds will result in incomplete cuts, while low cutting speeds will cause the material to melt.

Hardware conditions are also critical to achieving excellent cut quality. Protective optics, gas purity, plate quality, condenser optics, and collimating optics are some of the hardware conditions that can significantly affect cut quality.

Protective lenses ensure the quality output of the laser beam and must be checked regularly for damage or contamination. Gas purity is also critical to achieving precise cuts. High gas purity reduces the possibility of contamination and reduces the need for additional post-cutting processes.

Sheet quality also has an impact on cutting quality. Shiny sheets tend to reflect the laser beam causing distortion, while rough sheets can result in incomplete cuts. Condenser and collimator lenses ensure that the laser beam is properly focused on the material for precise cutting.

In conclusion, optimizing fiber laser cutting machine parameters and hardware conditions is crucial to achieve ideal cutting quality. Cut height, nozzle type, focus position, power, frequency, duty cycle, air pressure and speed are some of the parameters that must be optimized. Hardware conditions such as protective lenses, gas purity, printing plate quality, collection lenses, and collimating lenses must also be considered. With proper parameter optimization, manufacturers can improve cut quality, reduce post-cut operations and increase productivity.

If you want to learn more about laser cutting, or want to buy the best laser cutting machine for you, please leave a message on our website and email us directly!

Post time: Jun-09-2023