Nowadays, laser cleaning has become one of the most feasible way for surface cleaning, especially for the metal surface cleaning. Laser Cleaning is considered to be environmental friendly as there is no use of chemical agents and cleaning fluids as in traditional methods. The traditional Cleaning method is contact type which can damage object, resulting in improper cleaning while laser cleaning is non-contact solution. Moreover, laser can reach to difficult parts which is not possible with traditional methods.

Fortune laser cleaning machine removes various impurities on the surface achieving a degree of cleanliness that cannot be achieved by traditional method. Surely, Laser cleaning is an alternative of traditional abrasive and chemical process used in heavy industries such as aerospace and ship building. And the process can be made cost-effective in coating removal by the use of laser solution. Hence choosing laser cleaning is a smart choice. The laser cleaning will be more and more popular.

But, how to choose a suitable laser cleaning machine for your applications?

Before we can choose the right laser solution for your needs, we need to know the details as below,

● General size, area, and geometry of the parts needing to be cleaned

● Material substrate(s)

● Current cleaning type, rate, and cycle

● Coating/contaminant type and thickness

● Desired cleaning rate

● Next steps after cleaning

● Previous processing steps in the part life cycle

● Operational details surrounding the laser process

Once we have a better understanding of your application and feel we have a solution, we’ll test our laser solutions to determine the best laser setup for your needs. Our lab provides the ideal conditions for testing our laser solutions, but we’re also able to test your product on-site at your location when needed. Ultimately, whether our laser solutions will work for you boils down to one thing: can we accomplish the desired result? This includes not only from a technical standpoint but also an operational one. Fortune laser will help you choose the best laser cleaning machine for your use in this article.

There are two main elements to assessing whether an item can be cleaned with a laser.

1. What material is the substrate of the object to be cleaned, and whether it is easily affected by heat.

2. What is the coating that needs to be removed, and whether light can react with this layer of material.

And, there are three main options to consider when choosing a cleaning laser: delivery system, power mode and power level.

CHOOSING THE RIGHT LASER DELIVERY SYSTEM

There are two delivery options available for laser cleaning: handheld and automatic. Handheld options work exceptionally well for projects requiring mobility, unique surface geometries, and varying parts numbers. For regular, repeated cleanings, however, an automated delivery system is the better choice. By working with several robotics options, we can create a laser cleaning solution that integrates into your production line and increases the efficiency of your processes.

CHOOSING THE RIGHT LASER MODE

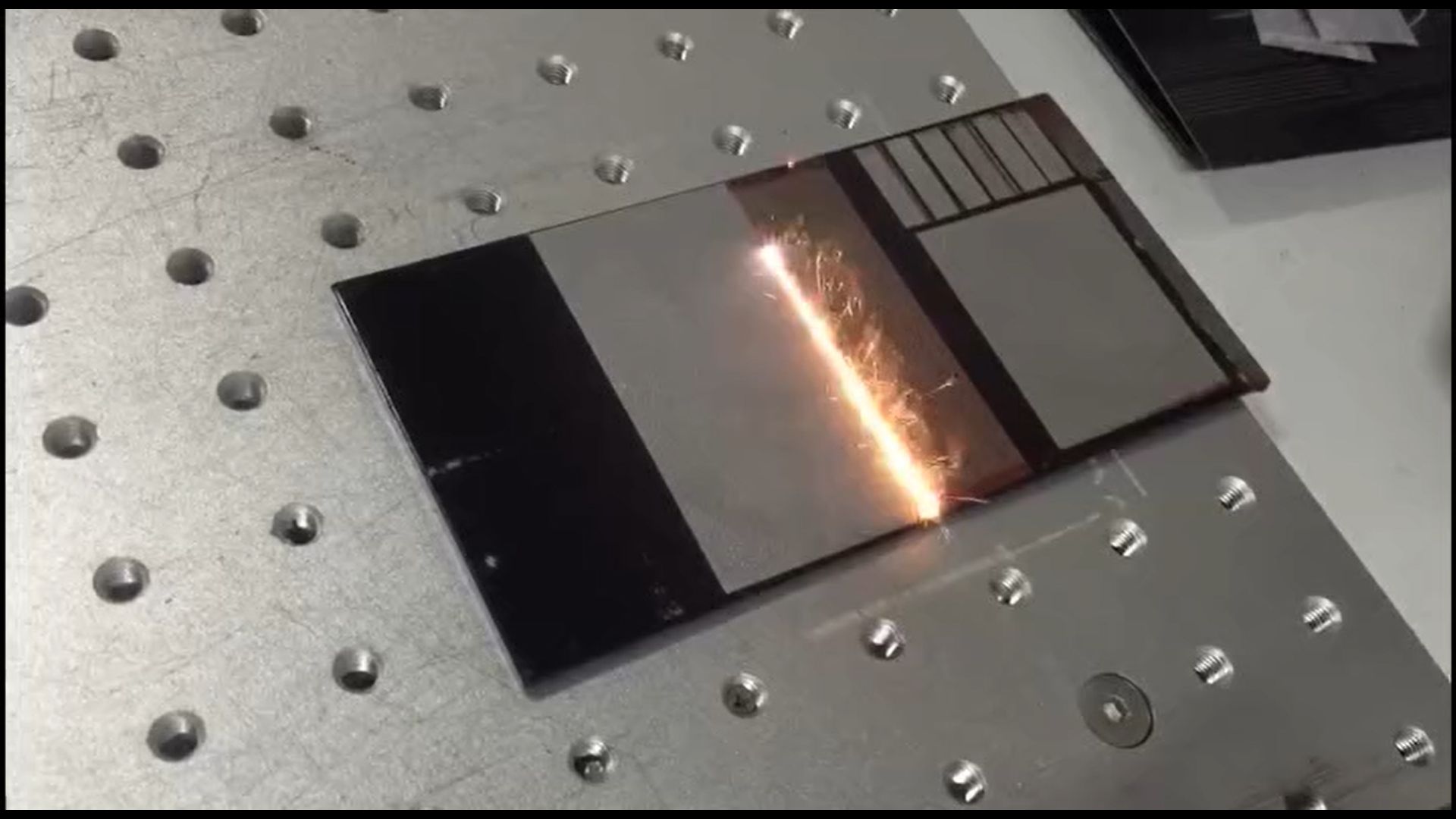

There are two modes of cleaning machines based on laser light sources.

One is CW fiber laser cleaning machine

And second one is Pulse laser cleaning machine

CW fiber laser cleaning machine use handheld clean head with continuous laser source. The advantage of CW cleaning machine is that the clean speed is fast and the clean head is light. High cost performance。

If you have low requirements for laser cleaning and only remove rust or thin paint of stainless steel , mild steel and iron, CW laser cleaning machine can meet the requirements.

CW laser cleaning machine power support 1000W 1500W 2000W , the laser source you can choose Raycus, Max JPT and IPG brand.

Pulse laser cleaning machine with pulse laser source and galvo clean head.

If you have high-value products need clean that must be use pulsed laser cleaning machine system.

What the pulsed laser cleaning machine can do?

● Depainting

● High Power Laser Surface Cleaning

● High Power Laser Surface Treatment Induced Surface Improvement

● Uniform Surface with Low HAZ

● High Power Laser Paint Removal

● Subtractive Surface Treatment

● Surface Texturing

● Cosmetic Surface Conditioning (Replaces Bead Blasting)

● Tire Mold Cleaning

● Mold Cleaning

● Selective Paint Removal

● Metal Parts Cleaning

● Anodizing Removal 3D Surface Cleaning and Conditioning

CHOOSING THE RIGHT POWER LEVEL

With laser cleaning, there’s no one-size-fits-all approach. That’s why we offer three different power levels of cleaning lasers.

Low-powered laser doesn’t equate to ineffective. In fact, our low-power laser solutions provide a gentle, high-precision cleaning perfect for historic restoration, de-coating, and small treatment areas. It uses short pulses of laser light and has the same intensity as other powered cleaners, but is ideal for products such as:

● Historical artifacts

● Valuable heirlooms

● Small automotive parts

● Rubber/Injection molds

● Any application where gentle cleaning is required

● MID-POWER LASER SOLUTIONS

Mid-power laser has a quicker cleaning rate and allows for larger surface area cleaning. It’s digitally controlled and user-friendly. Each laser is controlled from their supporting optics system and is perfect for:

● Oxide or lubricant removal prior to welding

● Targeted corrosion removal on aircraft wings

● Composite and tire molds

● Historic restoration

● Paint removal on aircraft

● HIGH-POWER LASER SOLUTIONS

High-power laser solutions are some of the most powerful on the market. The application is easy to use and features a touch-screen display and real-time controls. It produces larger amounts of energy per pulse of laser light, making it ideal for industrial use and:

● Eliminating corrosion from metals

● Hazardous coating removal

● Pre-treatment of welding seams

● Nuclear decontamination

● Cleaning prior to non-destructive testing/investigation

Post time: Aug-04-2022