Laser cleaning technology is mainly used in the surface treatment of aircraft body in the aerospace industry. When repairing and maintaining an aircraft, it is basically necessary to remove the old paint on the surface in order to spray new oil sandblasting or steel brush sanding and other traditional methods of cleaning the surface paint film.

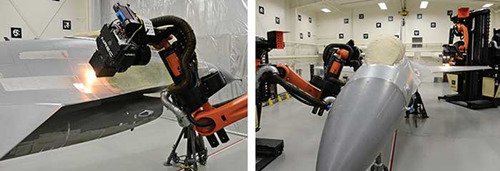

In the world, laser cleaning systems have long been used in the aviation industry. The surface of the aircraft needs to be repainted after a certain period of time, but the original old paint needs to be completely removed before painting. The traditional mechanical paint removal method is easy to cause damage to the metal surface of the aircraft, which brings hidden dangers to safe flight. Using multiple laser cleaning systems, the paint can be completely removed from an A320 Airbus within two days without damaging the metal surface.

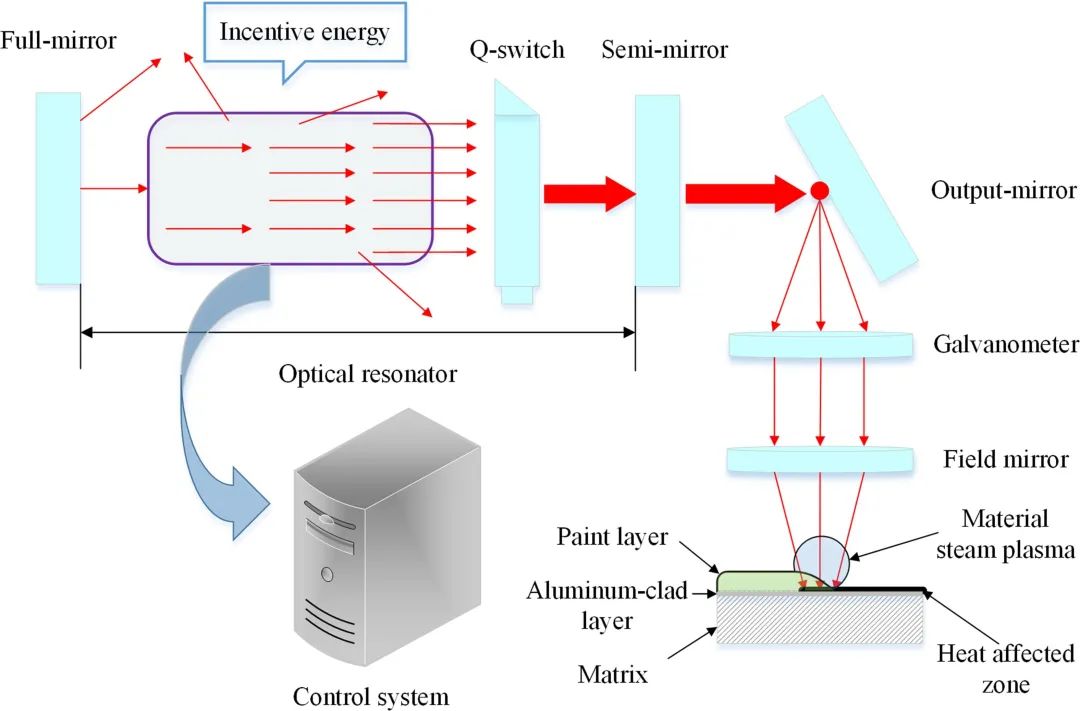

The physical principle of laser cleaning in aircraft surface cleaning:

1. The beam emitted by the laser is absorbed by the contamination layer on the surface to be treated.

2. The absorption of large energy forms a rapidly expanding plasma (highly ionized unstable gas), which produces a shock wave.

3. The shock wave breaks the contaminants into fragments and is rejected.

4. The light pulse width must be short enough to avoid heat build-up that would damage the surface being treated.

5. Experiments show that when there is oxide on the metal surface, plasma is generated on the metal surface.

Laser depainting (laser cleaning) experiments on aircraft skins were carried out at laser fluences of 2–6 J/cmexp. After SEM and EDS analysis experiments, the optimal laser paint removal process parameters are 5 J/cmex. The flight safety of the aircraft is of the utmost importance, and no accidental loss is allowed. Therefore, if the laser paint removal technology is to be widely used in the maintenance of the aircraft, the non-destructive cleaning of the aircraft must be realized.

Under different laser energy density conditions, the fretting friction and wear properties of the rivet holes of the aircraft skin after cleaning were studied by the laser cleaning process, and the friction and wear properties of other parts in the skin were evaluated. Comparisons were made with samples after mechanical grinding and laser cleaning. The results showed that laser cleaning did not reduce the friction and wear properties of any component on the surface of the aircraft skin.

The residual stress, microhardness and corrosion performance of the aircraft skin surface after laser cleaning were evaluated. Compared with mechanical grinding and laser cleaning, the results show that laser cleaning does not reduce the microhardness and corrosion resistance of aircraft skin surface. However, after laser cleaning, the surface of the aircraft skin will produce plastic deformation, which is a problem that needs special attention when using the laser cleaning technology to treat the surface of the aircraft skin.

During aircraft maintenance. Paint on aircraft surfaces must be removed, and aircraft skin surfaces must be inspected for corrosion defects and fatigue cracks to avoid flight accidents. Therefore, in the process of carefully removing the paint on the surface of the aircraft skin, it is necessary to pay special attention that the paint removal process must ensure that the substrate is not damaged.

Traditional paint removal processes include mechanical cleaning, ultrasonic cleaning, and chemical cleaning. Although the above cleaning technologies are relatively mature cleaning technologies, there are still many deficiencies. For example, the cleaning method of mechanical grinding is very easy to cause damage to the base material, the method of chemical cleaning will pollute the environment, and the method of ultrasonic cleaning is limited by the size of the workpiece, and it is not easy to clean large-sized parts.

In recent years, with the rapid development of laser technology, laser cleaning technology has become a cleaning technology that is more automated, clearer, and cheaper. Laser cleaning technology has been widely used in paint and rust removal, tire mold cleaning, cultural relic protection, nuclear purification, etc.

If you want to learn more about laser cleaning, or want to buy the best laser cleaning machine for you, please leave a message on our website and email us directly!

Post time: Oct-09-2022