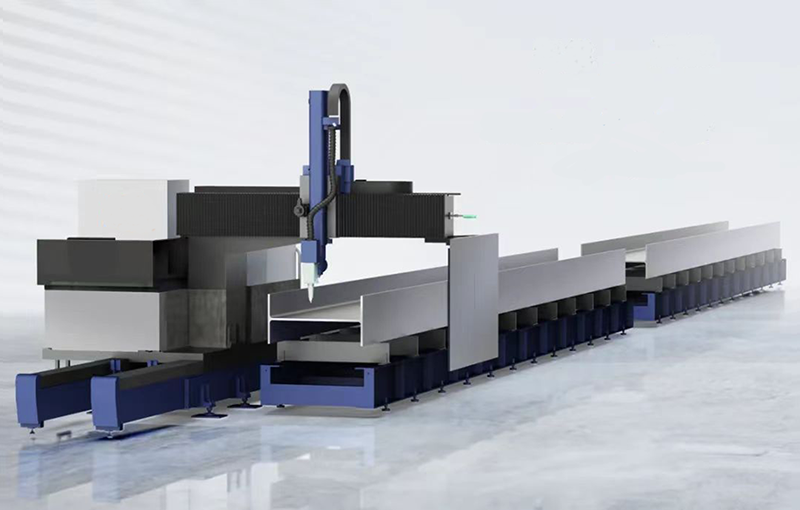

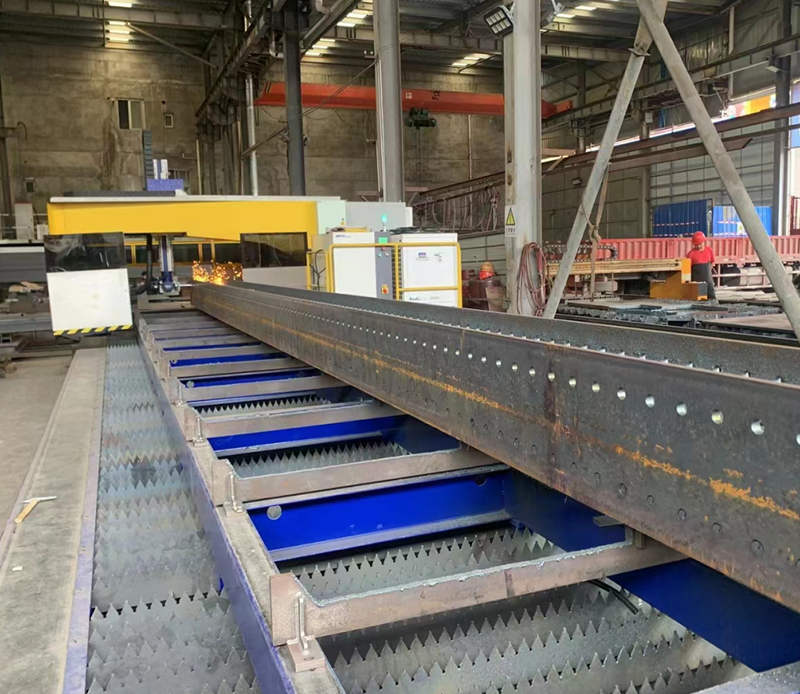

From the perspective of the construction industry, urbanization has driven the rapid development of the construction industry, which in turn has driven the market demand for H-beam laser cutting machines. In the construction of steel structure buildings, H-shaped steel is the main stress-bearing component, and the cutting process during its manufacturing process is crucial. Therefore, the demand for H-shaped steel laser cutting machines is high in this industry. Similarly, in bridge construction, since large-scale bridge construction requires a large number of steel structures, there is also a great demand for H-shaped steel laser cutting machines. The laser cutting machine can efficiently and accurately complete the cutting task of H-shaped steel in the bridge manufacturing process. These machines are crucial in meeting the demand for steel components in the construction of large bridges. In addition, the demand for H-shaped steel laser cutting machines is also high in the field of machinery manufacturing. H-shaped steel is widely used in various mechanical equipment and mechanical parts such as cranes, excavators, loaders, etc. The cutting process of H-shaped steel is crucial to meet the manufacturing needs of mechanical equipment, resulting in a high demand for laser cutting machines in this industry.

One of the industries suitable for H-shaped steel laser cutting machines is the construction industry. Urbanization has driven the rapid development of the construction industry, resulting in strong market demand for H-beam laser cutting machines. In the construction of steel structure buildings, H-shaped steel is the main stress-bearing component. The cutting process in its manufacturing process is very critical and laser cutting machines are in high demand in this industry. Laser cutting machines offer many advantages in the construction industry, including high precision, fast cutting speeds, and the ability to cut a variety of materials. These advantages make the H-shaped steel laser cutting machine very suitable for the construction industry. It can efficiently and accurately complete the cutting task of H-shaped steel and meet the high demand for steel components in steel structure building construction.

The advantages of H-beam laser cutting machines are many, making them suitable for a wide range of industries. In the construction industry, the rapid development of the construction industry has led to a large market demand for H-beam laser cutting machines. These machines offer many advantages, including high accuracy, fast cutting speeds, and the ability to cut a variety of materials. In addition, the cutting process during H-beam manufacturing is crucial for the construction of steel structures, making the demand for laser cutting machines high in this industry. In bridge construction, laser cutting machines also have similar advantages and can efficiently and accurately complete the cutting task of H-shaped steel in the bridge manufacturing process. There is also a great demand for H-shaped steel laser cutting machines in the field of machinery manufacturing. H-shaped steel is widely used in various mechanical equipment and mechanical parts. Laser cutting machines are crucial to meet the manufacturing needs of machinery and equipment, thereby driving high demand for these machines in the industry.

The operating method of H-shaped steel laser cutting machine is crucial to ensure its efficient and accurate performance to meet high market demand. In the construction of steel structure buildings, H-shaped steel is the main stress-bearing component, and the cutting process during its manufacturing process is crucial. The laser cutting machine has high precision and fast cutting speed, ensuring efficient cutting of H-shaped steel. In bridge construction, since large-scale bridge construction requires a large amount of steel structures, there is also a great demand for laser cutting machines. In the field of machinery manufacturing, laser cutting machines are crucial to meeting the manufacturing needs of mechanical equipment and ensuring efficient and precise cutting of H-beams. These operating methods play a decisive role in meeting the high market demand for H-beam laser cutting machines in various industries.

In summary, due to the many advantages of H-shaped steel laser cutting machines and the high market demand for H-shaped steel products, the demand for H-shaped steel laser cutting machines is rising in various industries. In the construction industry, the rapid development of the construction industry has driven the market demand for laser cutting machines, and H-shaped steel is the main stress-bearing component in steel structure building construction. Similarly, in the fields of bridge construction and machinery manufacturing, laser cutting machines also have many advantages and can complete the cutting task of H-shaped steel efficiently and accurately. These machines are crucial to meet the high market demand for steel components across various industries. The operating method of H-beam laser cutting machine plays a key role in ensuring its efficient and accurate performance to meet high market demand. With the continuous advancement of urbanization and the development of various industries, the demand for H-beam laser cutting machines will remain at a high level.

Post time: Dec-27-2023