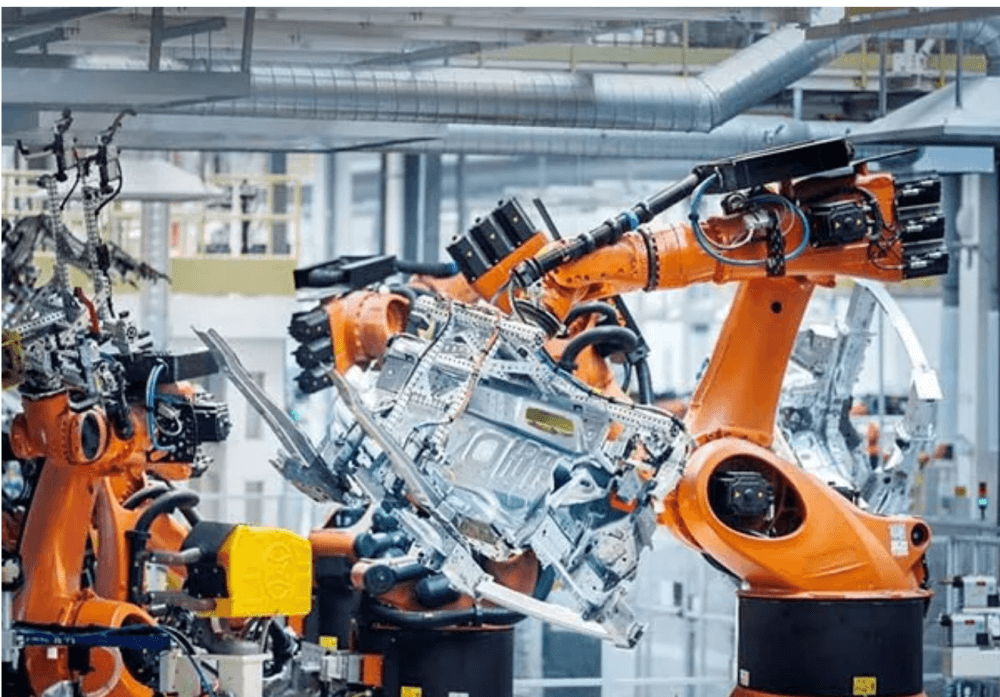

Laser welding robots have revolutionized the field of welding by introducing advanced features that increase efficiency and productivity. These robots offer a wide range of functions that simplify the welding process, increase precision and ensure maximum safety. This article aims to delve into the capabilities of laser welding robots, emphasizing their role in increasing welding efficiency and complete automation. We will also explore various product descriptions such as swing function, self-protection function, welding sensing function, anti-collision function, fault detection function, welding sticky wire contact function, arc break restart function.

1. Swing function:

One of the key features of a laser welding robot is its oscillating function. This feature allows the robot to move in an oscillating motion, covering a larger area than traditional welding techniques. The oscillating feature ensures that the laser beam covers a wider surface area, reducing welding time required for larger projects. By maximizing coverage area, the swing feature helps achieve higher productivity and efficiency in welding applications.

2. Self-protection function:

Laser welding robots are equipped with self-protection features to ensure their longevity and prevent potential damage. This feature acts as a protective barrier against adverse conditions such as overheating, voltage deviations or power fluctuations. The robot's self-protection features not only protect its internal components, but also prevent any external damage from welding sparks or debris. By maintaining its integrity, the robot can consistently deliver high-quality welding results and extend its lifespan.

3. Welding sensing function:

Weld sensing capabilities are an integral part of laser welding robots, enabling them to detect and respond to changes in the welding environment. This feature uses advanced sensors to accurately measure variables such as metal thickness, joint alignment and ambient temperature. By adapting to these changes in real time, the welding robot ensures precise welding along the desired path, resulting in impeccable weld quality and reducing the need for manual adjustments.

4. Anti-collision function:

Safety is paramount in any industrial environment, and laser welding robots are equipped with anti-collision features to prevent collisions from causing accidents or damage. This feature utilizes a combination of sensors, cameras, and software algorithms to detect obstacles in the robot's path. Once detected, the robot automatically adjusts its trajectory to avoid collisions. This feature not only protects the robot from damage, but also ensures the safety of nearby workers and equipment, eliminating the risk of accidents and costly repairs.

5. Fault detection function:

In order to ensure continuous and uninterrupted welding operation, the laser welding robot has a fault detection function. This feature continuously monitors the performance of the robot, including components such as cables, power supplies, and cooling systems. By identifying potential malfunctions or failures at an early stage, robots can take preventive action or notify operators of the problem. Timely detection and resolution of failures can help increase efficiency, reduce downtime and increase productivity.

6. Welding sticky wire contact function and restart function after arc break:

A distinctive feature of laser welding robots is the ability to handle sticky wire contacts and seamlessly restart the welding process after an arc break. The welding sticky wire contact function enables the robot to sense and adjust the contact with the welding wire, ensuring the best welding results even for challenging materials. In addition, the arc break restart function allows the robot to automatically resume welding after a temporary interruption without human intervention. These features enable consistent high-quality welds, minimize defects and improve overall welding efficiency.

In conclusion:

Laser welding robots offer a host of advanced features that increase welding efficiency and enable full automation in a variety of applications. Oscillating feature facilitates precise, fast coverage, maximizing productivity. Self-protection, welding sensing, anti-collision, fault detection and other functions ensure safe, accurate and continuous operation. In addition, welding sticky wire contact and arc break restart functions help to improve welding quality and overall efficiency. By utilizing these advanced capabilities, laser welding robots have significantly changed the field of welding, enabling manufacturers to achieve superior welding results through increased automation and productivity.

Post time: Aug-03-2023