In today's fast-paced world, automation has become an important aspect of industries across the globe. In particular, the use of laser welding robots has revolutionized manufacturing processes in several fields. These robots offer many advantages, from precision and accuracy to increased efficiency and reduced labor costs. In this article, we explore the wide range of applications for laser welding robots and how they are changing various industries.

The automotive industry greatly benefits from the integration of laser welding robots. These robots are widely used in body welding and component welding processes. With their exceptional precision and speed, laser welding robots ensure perfect joint formation and contribute to the overall durability and strength of the car. This automated process not only increases productivity, but also reduces the margin for error, resulting in higher quality vehicles that meet and exceed customer expectations.

Electronics manufacturing is another area where the use of laser welding robots has grown significantly. These robots are used for part welding, ensuring efficient and reliable connections within electronic devices. In addition, laser welding robots play a vital role in circuit board welding, ensuring precise connections between individual components. By streamlining the manufacturing process, these robots improve the quality and durability of electronic products while minimizing the risk of defects and failures.

The aerospace industry, known for its strict quality standards, has also started using laser welding robots. These robots are widely used in component welding, ensuring the integrity and strength of critical aircraft components. For example, laser welding robots help weld aircraft wings, helping to improve the overall safety and robustness of these vital structures. By automating the welding process, these robots not only increase precision and accuracy, but also minimize the risk of human error, which could compromise the structural integrity of the aircraft.

he medical device manufacturing industry relies heavily on laser welding robots for component welding and medical device assembly processes. These robots ensure precise and consistent welding of complex medical device components such as surgical instruments and implants. By maintaining high quality standards during the manufacturing process, laser welding robots help to improve the safety and effectiveness of these medical devices, ultimately benefiting patient outcomes. Moreover, their automated nature increases production efficiency, allowing manufacturers to meet the rising demand for these life-saving devices.

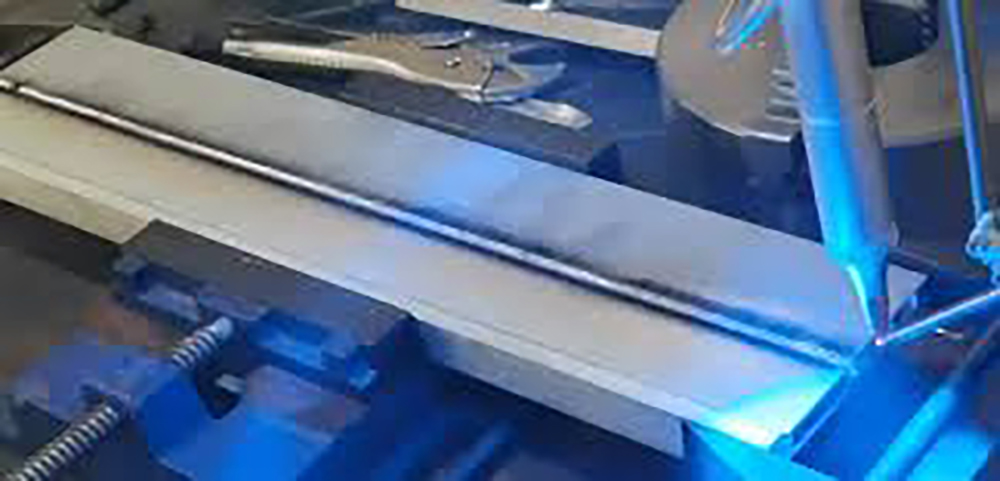

In the construction industry, laser welding robots have found their place in pipe welding and floor welding applications. The ability of these robots to perform precise welds in tight spaces has greatly contributed to improving the quality and strength of pipes used in pipeline and infrastructure projects. In addition, laser welding robots help to weld floor structures, ensuring durability and long service life of construction projects. These robots increase productivity and speed up the construction process, resulting in timely completion of projects while maintaining the highest quality standards.

In addition to industrial applications, laser welding robots make significant contributions to education and scientific research. These robots have proven invaluable in research and development, university laboratories and scientific research institutions. Laser welding robots enable researchers to explore new welding techniques and materials, advancing the field of welding technology. Their automated nature and high precision allow scientists to perform experiments with unparalleled accuracy, leading to breakthrough discoveries and innovations in various fields.

In summary, the application of laser welding robots has changed numerous industries, revolutionized manufacturing processes and improved product quality. From automobile manufacturing to electronics, aerospace, medical device manufacturing, construction, and education and scientific research, the impact of laser welding robots is undeniable. By automating welding tasks, these robots provide unrivaled precision, consistency and efficiency, ultimately increasing productivity and reducing costs. As industries continue to embrace automation, the future of laser welding robots looks promising as they continue to advance and revolutionize the world of manufacturing.

Post time: Aug-15-2023