Aluminum alloys are widely used in semiconductor and microelectronics industries due to their good physical and chemical properties and excellent mechanical properties. As modern industrial products develop toward high strength, lightweight, and high performance, aluminum alloy laser cutting methods are also developing toward precision, efficiency, and flexibility. Laser cutting has the advantages of narrow cutting slit, small heat-affected zone, high efficiency, and no mechanical stress in cutting edges. It has become an important method for precision processing of aluminum alloys.

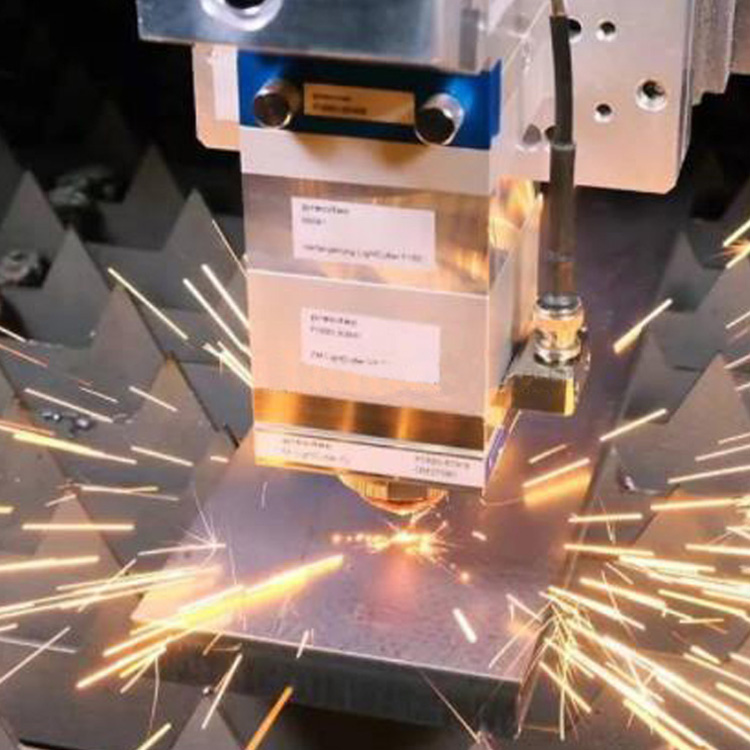

Existing aluminum alloy laser cutting generally uses a cutting head plus auxiliary gas. Its working mechanism is that the laser focuses on the inside of the aluminum alloy, high-energy gasification melts the aluminum alloy, and the high-pressure auxiliary gas blows away the melted material.

This cutting method mainly uses two lasers with wavelengths of about 10640nm and 1064nm, both of which belong to the infrared wavelength range. For precision cutting of aluminum alloy sheets with cutting size accuracy at the micron level, due to its large light spot and large heat-affected area, it is easy to Slag and micro-cracks occur at the cutting edge, which ultimately affects the accuracy and effect of cutting.

The aluminum alloy laser cutting system and method of the embodiment realizes cutting of the workpiece to be cut in a non-contact manner by utilizing the smaller pulse width and shorter wavelength of the laser beam, avoiding the contact stress loss of the workpiece to be cut by mechanical methods, and during cutting During the processing, problems such as micro-cracks and slag hanging are caused by the thermal processing mechanism; by using a specific fixture to fix the workpiece to be cut horizontally, while keeping the slit position in the air, the cutting area of the workpiece to be cut is supported from the back to prevent it from falling at the moment of cutting. Produces stress to destroy the cutting edge effect; uses the circulating cooling water in the water tank device to cool the workpiece to be cut, weakens the impact of heat on the surrounding materials, and further improves the cutting quality; cuts through a combination of multiple cutting paths to expand the cutting seam Width improves cutting efficiency.

The above embodiments are preferred implementations, but the implementation is not limited by the above embodiments. Any other changes, modifications, substitutions, combinations, and simplifications that do not deviate from the spirit and principles should be made as follows. Effective replacement methods are all included in the scope of protection of aluminum alloy laser cutting methods.

Post time: May-23-2024