Laser cleaning is a modern way to clean surfaces. This amazing technology uses powerful laser beams to remove dirt, old paint, and rust from different materials in a highly controlled and precise way. The laser hits the unwanted material. When this happens, the dirt or coating either turns into vapor or breaks away from the surface because the laser makes it heat up and expand very quickly. Laser cleaning is better for the environment than old cleaning methods. This technology can clean things very exactly without damaging what’s underneath.

Many different industries now use laser cleaning to do their work. Companies that make airplanes, cars, electronics, and even people who fix old historical items have found that lasers are great for cleaning. The method works really well for cleaning tire-making equipment. Workers also use it to strip paint off airplanes and carefully clean old museum pieces that need special care.

Before laser cleaning, people used several other ways to clean things:

1.Sandblasting shoots tiny bits of sand at high speeds to clean surfaces. While this method works well, it can scratch things up and create dust that’s bad to breathe.

2.Chemical cleaning uses special liquids to break down dirt. These chemicals can hurt the environment and sometimes damage the things being cleaned.

3.Ultrasonic cleaning creates tiny bubbles using sound waves you can’t hear. This gentle method works well for small, delicate items but isn’t practical for cleaning big things.

4.Dry ice cleaning uses special machines to shoot frozen carbon dioxide at dirty surfaces. The method leaves no mess behind, but running the equipment costs a lot of money.

Laser cleaning has many benefits compared to other cleaning methods. These helpful features make it stand out as a better choice for many cleaning jobs:

Using lasers means nothing touches the surface being cleaned. The laser light removes dirt and old coatings without scratching or damaging what’s underneath, making it perfect for cleaning valuable items. This method doesn’t use any harmful chemicals. Since no dangerous waste is created, laser cleaning helps protect our environment.

Lasers can clean very specific spots with great accuracy. The cleaning process saves money over time because it uses less supplies and needs fewer workers to get the job done.

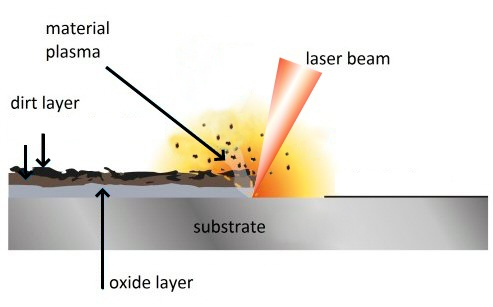

How do laser cleaners work? When laser light hits dirt or rust, the unwanted material soaks up the laser’s energy. This makes the dirt either break apart, turn to vapor, or burn away quickly. People running the laser can adjust how strong it is and how long it runs to get the best results.

There are two main ways to clean with lasers:

1.The first way uses just the laser by itself. Quick bursts of laser light hit the dirty surface, making the dirt either heat up and pop off or shake loose from tiny vibrations. This method works well for tough cleaning jobs.

2.The second way starts by putting a thin layer of liquid on the surface. When the laser hits this wet coating, it turns the liquid into vapor so fast that it creates a tiny explosion. This small blast helps push off the dirt without hurting delicate surfaces that might get damaged by direct laser light.

· Computer Chip and Electronics Industry Making computer chips requires extremely clean conditions. The tiniest speck of dirt can ruin these delicate electronic parts, so manufacturers use laser cleaning to remove small particles without causing any damage. This helps keep the production line running smoothly. Special tools like lasers make sure every surface is perfectly clean, which helps the chips last longer.

· Metal Treatment Lasers are great for cleaning metal. Before painters or welders can work on metal surfaces, they need to remove rust, dirt, and old coatings using powerful laser beams that strip away unwanted materials without hurting the metal underneath. This method works especially well for cleaning airplanes, cars, and ships, where having clean surfaces is really important for safety and quality.

· Airplane and Car Industries Airplanes need special care when being cleaned. Laser cleaning helps workers safely remove old paint and dirt from airplane parts without weakening the metal, which could be dangerous if done wrong. The car industry also uses lasers to clean tire molds, make better welds, and remove dirt from important engine parts in a way that’s fast and safe.

· Art and History Preservation Old artwork needs gentle cleaning to stay in good shape. Museum workers use lasers to carefully remove dirt and age-related damage from old statues and paintings without risking harm to these precious items. This careful cleaning method has helped save many old artworks that might have been ruined by harsher cleaning methods.

· Factory Work Factories use laser cleaning to keep their machines running well. This modern cleaning method helps remove grease and dirt quickly, which means machines don’t have to stay turned off for long periods during cleaning. Workers can clean parts more effectively with lasers, helping the machines work better and last longer.

Laser Cleaning Technology: Benefits

Laser cleaning is changing how we clean things in many different industries today. It uses powerful beams of light to remove dirt, rust, and other unwanted materials from surfaces. This new way of cleaning helps protect our environment by not creating any harmful waste. The technology works by carefully targeting only the dirt while leaving the surface underneath completely safe.

Companies can save money with laser cleaning over time. Installing the equipment costs a lot at first, but businesses won’t need to keep buying cleaning chemicals or materials after that. Workers stay safer when using laser cleaning instead of harsh chemicals. The technology can be used on many different materials and in various industries, from cleaning heavy factory equipment to restoring old artwork.

Challenges Getting started with laser cleaning can be difficult. The machines are expensive, which makes it hard for smaller companies to buy them. Some materials don’t work well with lasers, and companies need to test them first. Workers need special training to use the equipment correctly. Laser cleaning can also take longer than regular cleaning methods when working on big projects.

Looking Ahead More companies want cleaner and greener ways to work. Better laser cleaning systems are being developed all the time. New improvements will make the technology faster and cheaper to use. These systems might soon be used in more places, like cleaning medical equipment or making tiny electronic parts.

Wrapping Up Laser cleaning offers a new and better way to clean things. This technology gives companies more control and helps protect the environment at the same time. While there are some problems to solve, laser cleaning keeps getting better. The technology will become more common as more businesses learn about its benefits.

Companies should learn about laser cleaning before deciding to use it. As more industries need precise and earth-friendly cleaning methods, this technology will become more important. Laser cleaning will keep improving and finding new uses in different industries. This advancement will help shape how we clean things in the future.

Laser cleaning is a useful way to use lasers in engineering. This advanced method works by using the laser’s concentrated energy to heat up dirt and unwanted materials on surfaces, making them separate from the surface through quick heating, melting, or turning into gas, which creates a powerful cleaning effect that can handle many different types of dirt and contamination. Laser cleaning is quick and doesn’t hurt the environment. This technology has proven valuable in cleaning tire molds, removing paint from airplanes, and fixing old artifacts that need careful restoration.

Regular cleaning methods include physical scrubbing like sandblasting and pressure washing, using chemicals, using sound waves, and cleaning with dry ice. These different ways of cleaning are used in many different industries and businesses today. Sandblasting can clean metal spots, smooth rough metal edges, and remove protective coatings from circuit boards by using different types of cleaning materials. Chemical cleaning is used everywhere, from removing oil and dirt from equipment to cleaning build-up in boilers and oil pipes. While these older cleaning methods work well and have been used for a long time, they have some problems. Sandblasting can damage the things being cleaned, while chemical cleaning can be bad for the environment and might harm the cleaned surface if not done correctly.

Laser cleaning has changed how we clean things completely. This new method takes advantage of the laser’s focused energy, exact targeting, and quick heating to get better results than older cleaning methods. Laser cleaning works much better than traditional methods in many ways. When you compare it to older cleaning approaches that use chemicals, laser cleaning won’t harm the environment or damage the surface being cleaned.

What exactly is laser cleaning?

When you point a laser beam at something dirty, it removes unwanted stuff from hard or sometimes liquid surfaces in a very special way. If you use a weaker laser beam, it heats up the dirt until it turns into gas and floats away. Using a stronger laser beam turns the unwanted material into a super-hot gas called plasma, which completely removes it from the surface.

Types of laser cleaning technology

1) Laser dry cleaning: Dry laser cleaning is when a pulsed laser is directly irradiated to clean the workpiece, causing the substrate or surface contaminants to absorb energy and increase in temperature, resulting in thermal expansion or thermal vibration of the substrate, thereby separating the two. This method can be roughly divided into two cases: one is that the surface contaminants absorb the laser and expand; the other is that the substrate absorbs the laser and produces thermal vibration.

2) Laser wet cleaning: Before the pulsed laser is irradiated on the workpiece to be cleaned, a liquid film is pre-coated on the surface. Under the action of the laser, the temperature of the liquid film rises rapidly and vaporizes. At the moment of vaporization, a shock wave is generated, which acts on the contaminant particles and causes them to fall off the substrate. This method requires that the substrate and the liquid film cannot react, so the range of application materials is limited.

Application of laser cleaning technology

Let’s talk about cleaning computer chips and special glass parts. These items go through the same steps when they’re being made, with cutting and smoothing that can leave tiny bits of dirt behind. This dirt is really hard to get rid of and keeps coming back no matter how many times you clean it. When dirt gets on computer chips, they won’t work as well or last as long. The same kind of dirt can cause problems when it gets on special glass pieces, making them less clear and wearing out faster than they should. Using just lasers to clean these parts can easily damage them. Instead, people have found better success using a mix of laser cleaning methods, especially one that creates special waves to push the dirt away.

1) Semiconductor field

Cleaning of semiconductor wafers and optical substrates Semiconductor wafers and optical substrates have the same process in the processing process, that is, the raw materials are processed into the required shape by cutting, grinding, etc. In this process, particulate pollutants are introduced, which are difficult to remove and have serious problems of repeated pollution. Pollutants on the surface of semiconductor wafers will affect the quality of circuit board printing, thereby shortening the service life of semiconductor chips. Pollutants on the surface of optical substrates will affect the quality of optical devices and coatings, and may cause uneven energy and shorten the service life. Since laser dry cleaning can easily cause damage to the substrate surface, this cleaning method is rarely used in the cleaning of semiconductor wafers and optical substrates. Laser cleaning and laser plasma shock wave cleaning have more successful applications in this field.

2) Metal material field

Cleaning of metal material surface Compared with the cleaning of semiconductor wafers and optical substrates, the pollutants cleaned by cleaning the surface of metal materials belong to the macroscopic category. The pollutants on the surface of metal materials mainly include oxide layer (rust layer), paint layer, coating, other attachments, etc., which can be divided into organic pollutants (such as paint layer, coating) and inorganic pollutants (such as rust layer) according to the type of pollutants. The cleaning of pollutants on the surface of metal materials is mainly to meet the requirements of subsequent processing or use. For example, before welding titanium alloy parts, the oxide layer about 10um thick on the surface of the material needs to be removed. During aircraft overhaul, the original paint coating on the skin surface needs to be removed for re-spraying. Rubber tire molds need to be regularly cleaned of rubber particles attached to them to ensure the cleanliness of the surface and thus ensure the quality of the tires produced and the life of the mold. The damage value of metal materials is higher than the laser cleaning threshold of their surface pollutants. By selecting the appropriate power laser, a better cleaning effect can be achieved.

3) Cultural Relics

Cleaning of Cultural Relics and Paper Surfaces Metal and stone cultural relics have a long history, and pollutants such as dirt and ink stains will appear on their surfaces. These pollutants need to be cleaned to restore the cultural relics. Paper such as calligraphy and painting will grow mold and form plaques on its surface when stored improperly. These plaques seriously affect the original appearance of the paper, especially for paper with high cultural or historical value, which will affect its appreciation and protection.

As people’s requirements for green, environmentally friendly, high-precision and high-efficiency cleaning increase, the research and development and application of laser cleaning technology has also received more and more widespread attention. At present, laser cleaning technology has been applied in the fields of microelectronics, rail transportation, aviation, and cultural relics restoration, but it still faces many challenges to further improve its application scenarios, scale and effects. In short, the development prospects of laser cleaning technology are very broad. It will be applied in more fields in the future, and with the advancement of technology and the expansion of market share, its scale and industrialization will be further improved.

As people’s requirements for green, environmentally friendly, high-precision and high-efficiency cleaning increase, the research and development and application of laser cleaning technology has also received more and more widespread attention. At present, laser cleaning technology has been applied in the fields of microelectronics, rail transportation, aviation, and cultural relics restoration, but it still faces many challenges to further improve its application scenarios, scale and effects. In short, the development prospects of laser cleaning technology are very broad. It will be applied in more fields in the future, and with the advancement of technology and the expansion of market share, its scale and industrialization will be further improved.

Post time: Feb-13-2025