New Arrival China Jpt Laser - Laser Cooling System for Laser Cutter Welder – Fortune

New Arrival China Jpt Laser - Laser Cooling System for Laser Cutter Welder – Fortune

New Arrival China Jpt Laser - Laser Cooling System for Laser Cutter Welder – Fortune Detail:

Features

1. Dual channel design for cooling fiber laser and the laser head, no need of a two-chiller solution;

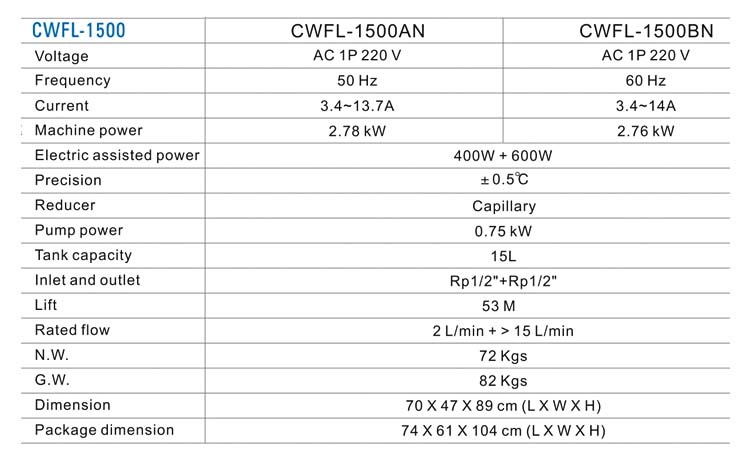

2. ±0.5℃ precise temperature control;

3. Temperature control range: 5-35 ℃;

4. Constant temperature and intelligent temperature control modes;

5. Built-in alarm functions to avoid water flow problem or temperature problem;

6. CE, RoHS, ISO and REACH compliant;

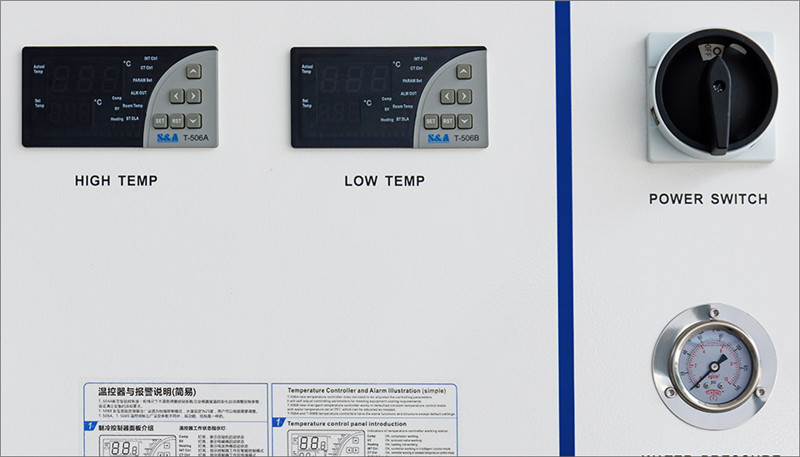

7. User-friendly temperature controllers for easy operation

8. Optional heater and water filter.

Note:

1. The working current can be different under different working conditions; The above information is for reference only. Please subject to the actual delivered product;

2. Clean, pure, impurity free water should be used. The ideal one could be purified water, clean distilled water, deionised water, etc.;

3. Change out the water periodically (every 3 months is suggested or depending on the actual working environment);

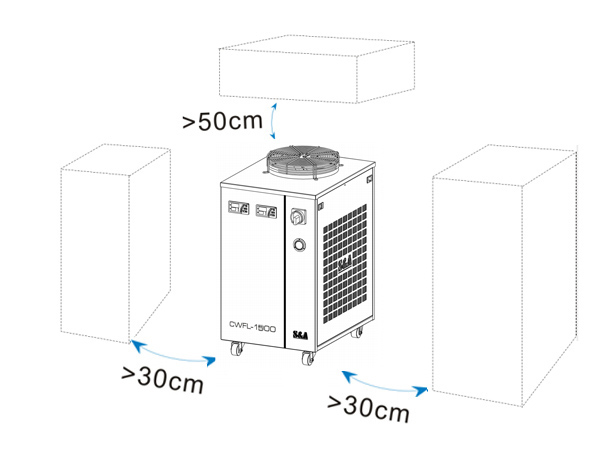

4. Location of the chiller should be well ventilated environment. There must be at least 50cm from the obstacles to the air outlet which is on the top of the chiller and should leave at least 30cm between obstacles and the air inlets which are on the side casing of the chiller.

User-friendly temperature controllers for easy operation

Equipped with drain port and universal wheels

Dual inlet and dual outlet port made of stainless steel to prevent potential corrosion or water leakage

Water level check lets you know when it’s time to refill the tank

Cooling fan of famous brand installed. With high quality and low failure rate.

Alarm description

CWFL-1500 water chiller is designed with built-in alarm functions.

E1 – ultrahigh room temperature

E2 – ultrahigh water temperature

E3 – ultralow water temperature

E4 – room temperature sensor failure

E5 – water temperature sensor failure

E6 – external alarm input

E7 – water flow alarm input

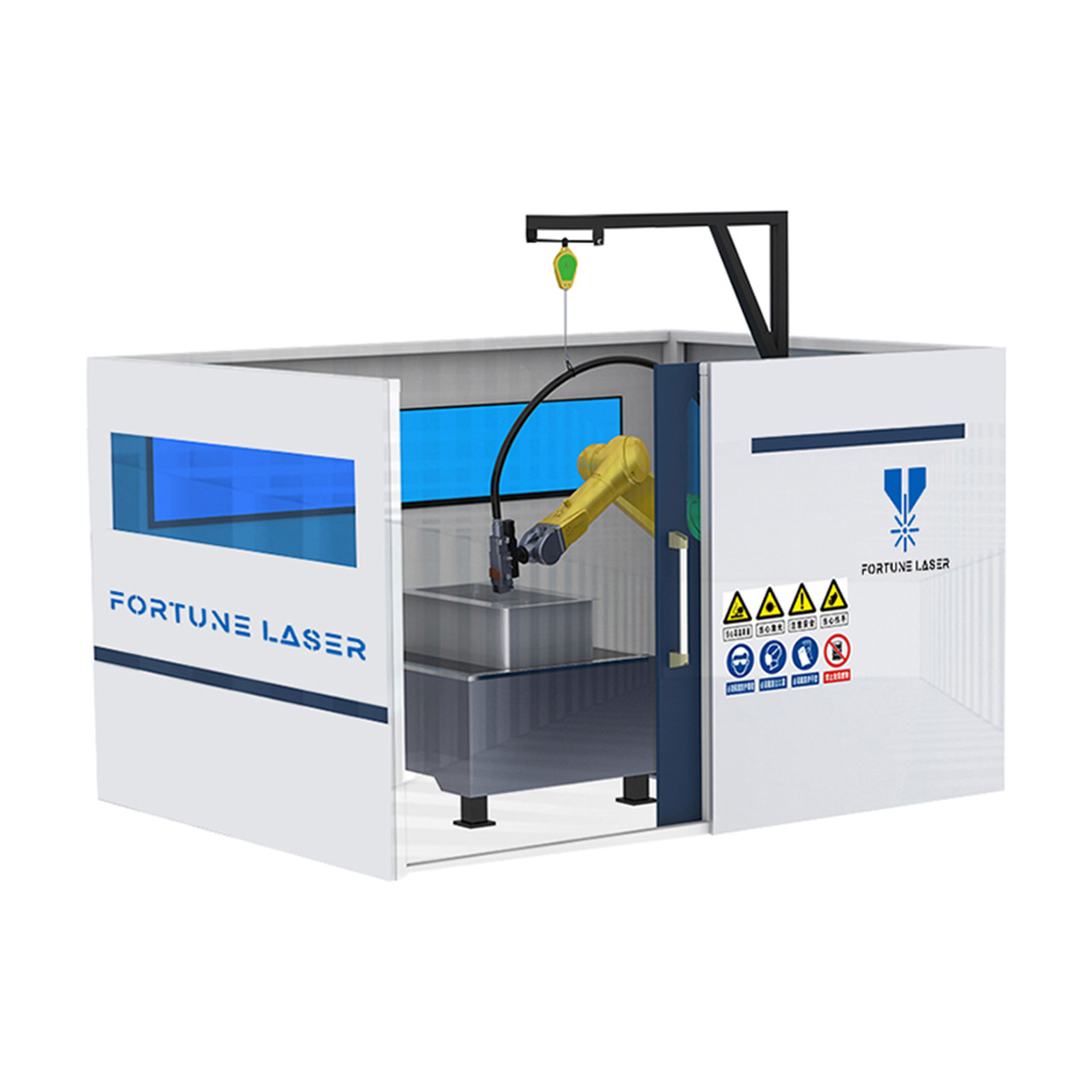

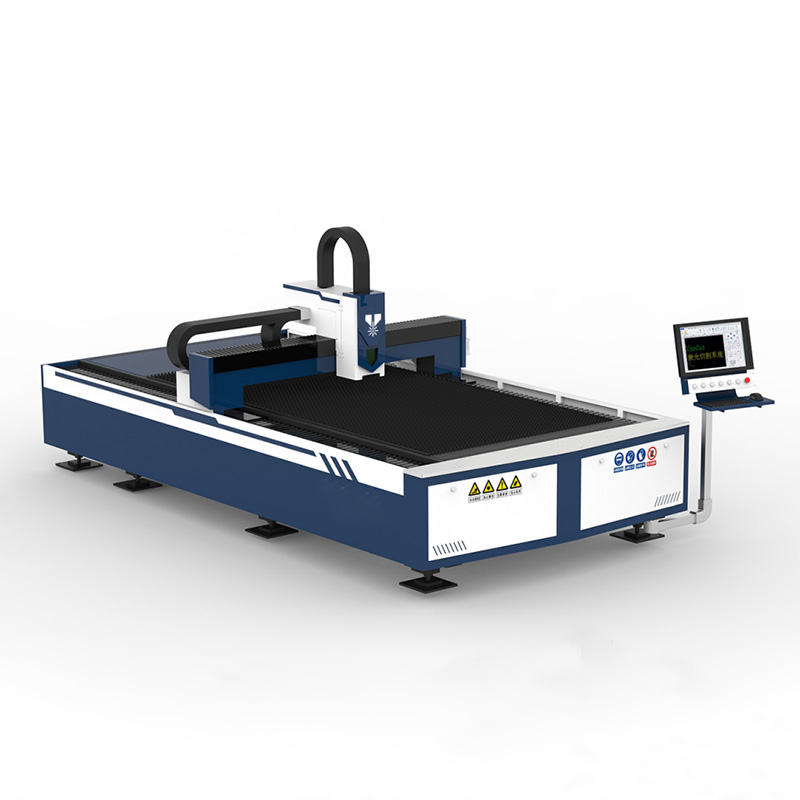

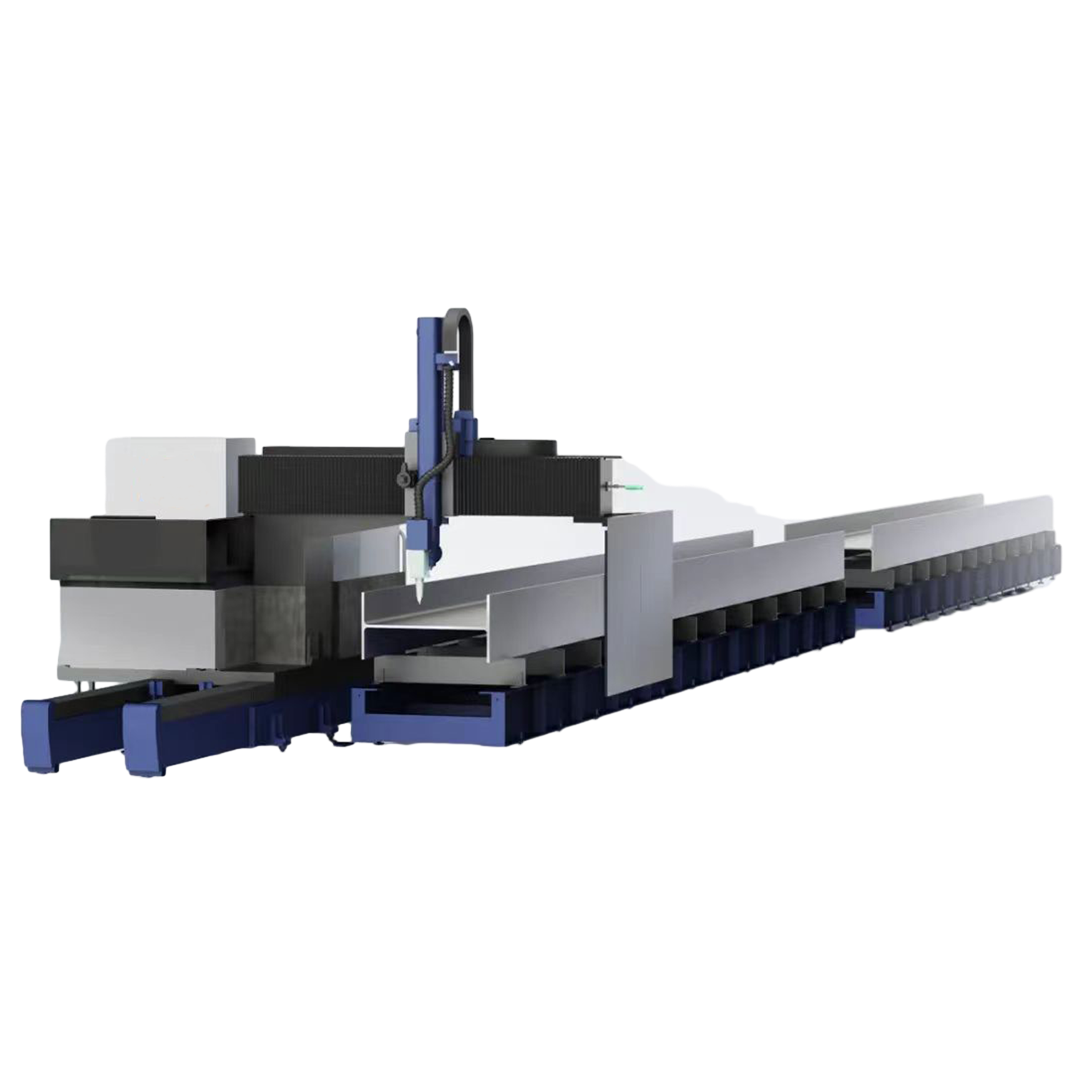

Chiller Application

Air Cooled Chiller RMFL-1000 For 1KW-1.5KW Handheld Fiber Laser Welding Machine

Air cooled chiller RMFL-1000 is developed by S&A Teyu based on the laser welding market demand and is applicable to cool 1000W-1500W handheld fiber laser welding machine. Water cooling chiller RMFL-1000 features ±0.5℃ temperature stability with dual temperature control system which is capable of cooling the fiber laser and the laser head at the same time. In addition, it is designed with intelligent and constant temperature modes which can meet different demands in different situations.

Product detail pictures:

Related Product Guide:

We emphasize progress and introduce new solutions into the market each year for New Arrival China Jpt Laser - Laser Cooling System for Laser Cutter Welder – Fortune , The product will supply to all over the world, such as: Saudi Arabia, Bolivia, Ecuador, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.